Preparation method and application of sulfur-doped graphene and derivatives thereof

A technology for sulfur-doped graphene and derivatives, applied in the field of graphene, can solve the problems of harsh chemical vapor deposition conditions, difficult to realize industrialization, complicated preparation methods, etc., and achieves convenient industrial production, simple and easy-to-operate preparation methods, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045]A preparation method of sulfur-doped graphene material, comprising the steps of:

[0046] (1) In the potassium sulfate solution 100mL containing 10g / L, add the graphene solution 1mL that concentration is 10g / L, and mix uniformly, obtain mixed suspension; The mass ratio of graphene and potassium sulfate in the suspension is 0.01:1 ;

[0047] (2) freeze-drying the suspension that step (1) obtains, obtains the solid mixture of graphene and potassium sulfate;

[0048] (3) in N 2 Under the protection of gas, the solid mixture of the obtained graphene and potassium sulfate was calcined at a high temperature of 300 ° C for 30 h to obtain a sulfur-doped graphene intermediate product;

[0049] (4) Cool the sulfur-doped graphene intermediate product to 20° C., wash with ultrapure water, and then dry to obtain the sulfur-doped graphene final product.

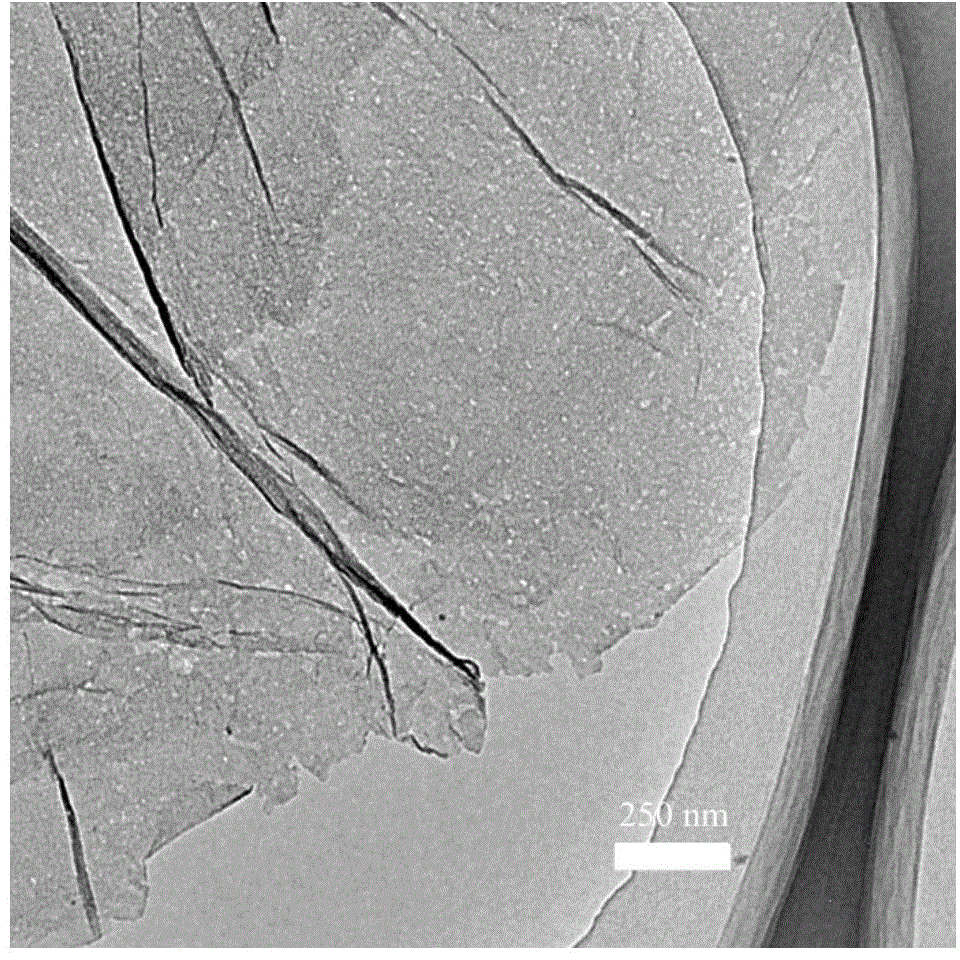

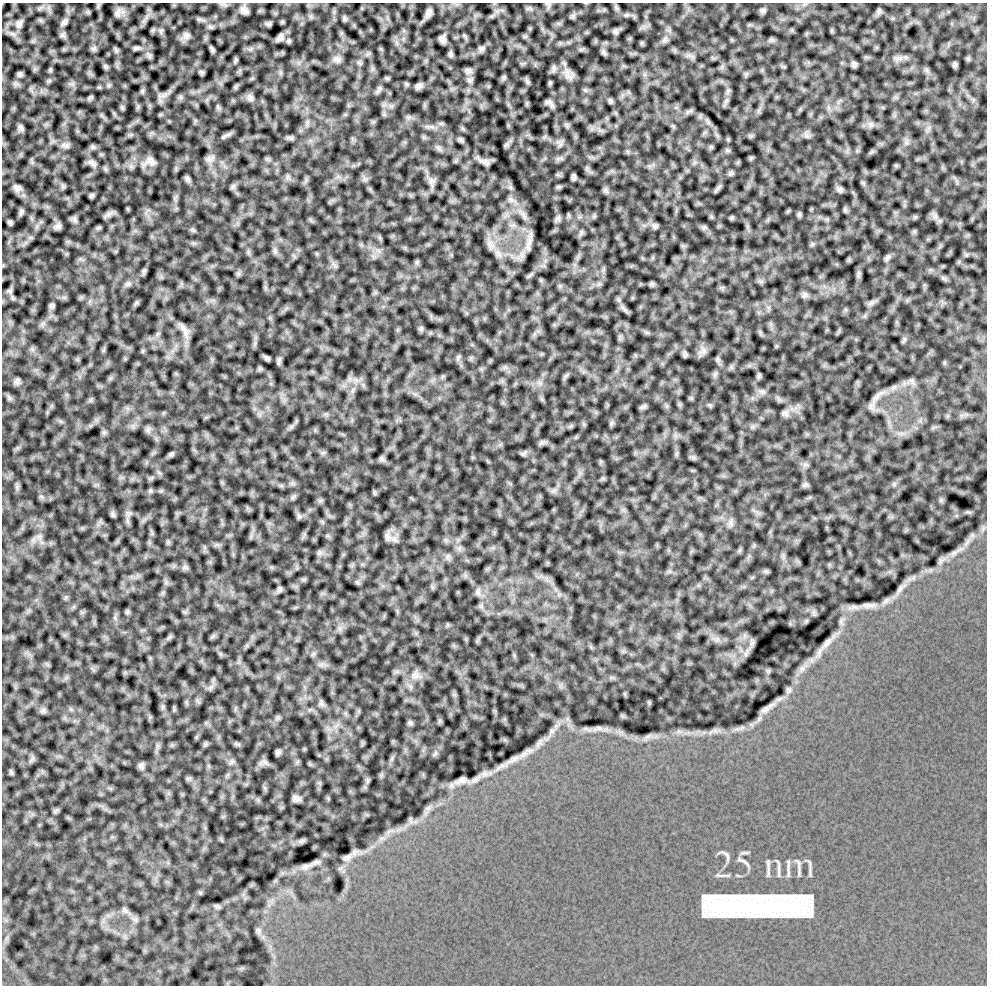

[0050] The sulfur-doped graphene that embodiment 1 obtains is carried out transmission electron microscope scanning on Hitachi J...

Embodiment 2

[0054] A preparation method of sulfur-doped graphene material, comprising the steps of:

[0055] (1) in the potassium sulfate solution 10mL that contains 0.1g / L, add the graphene solution 5mL that concentration is 10g / L, and mix uniformly, obtain mixed suspension, the mass ratio of graphene and potassium sulfate in the suspension is 5: 1;

[0056] (2) freeze-drying the suspension that step (1) obtains, obtains the solid mixture of graphene and potassium sulfate;

[0057] (3) in N 2 Under the protection of gas, the obtained graphene and potassium sulfate solid were calcined at a high temperature of 1200 ° C for 2 hours to obtain a sulfur-doped graphene intermediate product;

[0058] (4) Cool the obtained sulfur-doped graphene intermediate product to 30° C., wash with ultrapure water, and then dry to obtain the sulfur-doped graphene final product.

[0059] The sulfur-doped graphene that embodiment 2 obtains is carried out transmission electron microscope scanning, and scannin...

Embodiment 3

[0061] A preparation method of sulfur-doped graphene material, comprising the steps of:

[0062] (1) in the magnesium sulfate solution 100mL that contains 0.1g / L, add the graphene solution 1mL that concentration is 10g / L, and mix uniformly, obtain mixed suspension, the mass ratio of graphene and magnesium sulfate in the suspension is 1: 1;

[0063] (2) the suspension obtained in step (1) is freeze-dried to obtain a solid mixture of graphene oxide and magnesium sulfate;

[0064] (3) in N 2 Under the protection of gas, the solid mixture of the obtained graphene and magnesium sulfate was calcined at a high temperature of 800 ° C for 2 hours to obtain a sulfur-doped graphene intermediate product;

[0065] (4) After the obtained product is cooled to 30°C, it is washed with ultrapure water and dried.

[0066] The sulfur-doped graphene obtained in Example 3 is scanned by a transmission electron microscope, and the scanning conditions are the same as in Example 1; the test results ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com