Nano-diamond filled polyimide based compound aerogel material and preparation method thereof

A nano-diamond and composite airgel technology, which is applied in the field of nano-diamond-filled polyimide-based composite airgel materials and its preparation, can solve the problems of expensive cross-linking agents and limited use, and achieve design ideas Ingenious, low cost, strong water dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

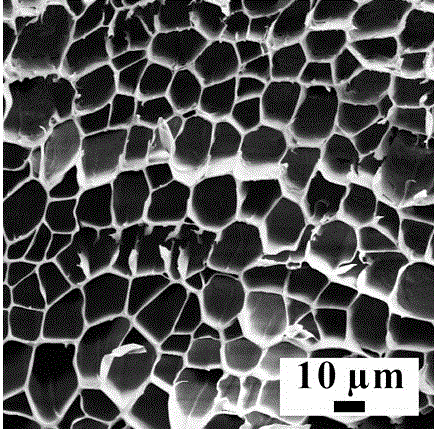

Embodiment 1

[0029] This embodiment includes the following steps:

[0030] by N,N -Dimethylacetamide is used as a solvent, and 4,4'-diaminodiphenyl ether and pyromellitic anhydride are used as monomers to carry out condensation polymerization in an ice-water bath to prepare polyamic acid filaments. The specific process is as follows: at room temperature, 8 g (0.04 mol) of 4,4′-diaminodiphenyl ether was fully dissolved in 95 g N,N -Dimethylacetamide, based on the clarity of the solution and the absence of particles. Then 8.85 g (0.046 mol) pyromellitic anhydride was added slowly, and then the reaction was moved to an ice-water bath and stirred for 2 h. Then add 0.04 mol triethylamine, continue to stir and react for about 2 h, and prepare a polyamic acid solution with a solid content of 15%. The prepared polyamic acid solution is sealed and stored, and after standing for two days, it is slowly poured into ice water, washed, frozen, and dried to obtain a water-soluble polyamic acid filam...

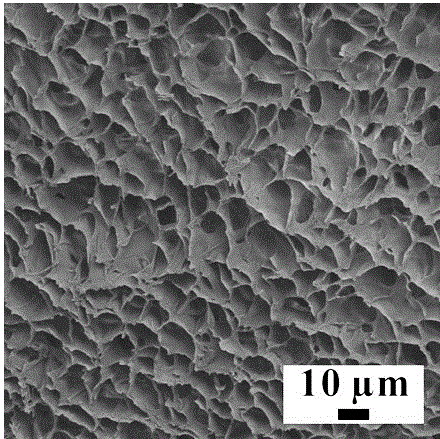

Embodiment 2

[0034] This embodiment includes the following steps:

[0035] The steps for preparing water-soluble polyamic acid are the same as in Example 1.

[0036] The steps of preparing polyimide-nanometer diamond composite airgel are as follows:

[0037] Take 40 mg of nano-diamonds and add them to 30 mL of deionized water, sonicate for 0.5 h to disperse the nano-diamonds evenly. Add 2 g of polyamic acid and 1 g of triethylamine into the obtained nanodiamond dispersion, sonicate for 1 h, and stir for 0.5 h to disperse the polyamic acid evenly, and obtain a polyamic acid-nanodiamond aqueous solution. All the other steps are the same as in Example 1. Obtain polyimide-nanometer diamond composite airgel, denoted as PI / ND 2% .

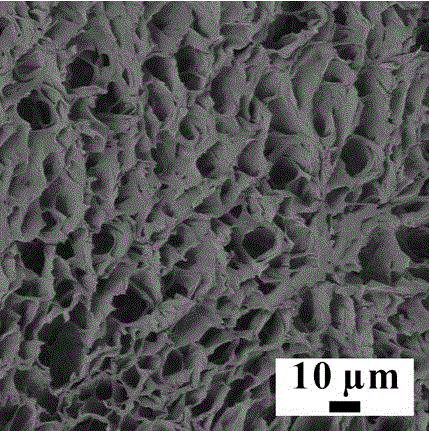

Embodiment 3

[0039] This embodiment includes the following steps:

[0040] The steps for preparing water-soluble polyamic acid are the same as in Example 1.

[0041] The steps of preparing polyimide-nanometer diamond composite airgel are as follows:

[0042] Take 80 mg of nano-diamonds and add them to 30 mL of deionized water, and sonicate for 0.5 h to disperse the nano-diamonds evenly. All the other are with embodiment 2. Obtain polyimide-nanometer diamond composite airgel, denoted as PI / ND 4% .

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com