Pure carbon fiber material adopting 'vesical string' structure and preparation method of pure carbon fiber material

A technology of carbon fiber materials and fiber materials, applied in the field of "vesicle string" structure carbon fiber materials and its preparation, can solve problems such as difficult to meet practical applications and single structure, and achieve ingenious design ideas, easy operation, and mild preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

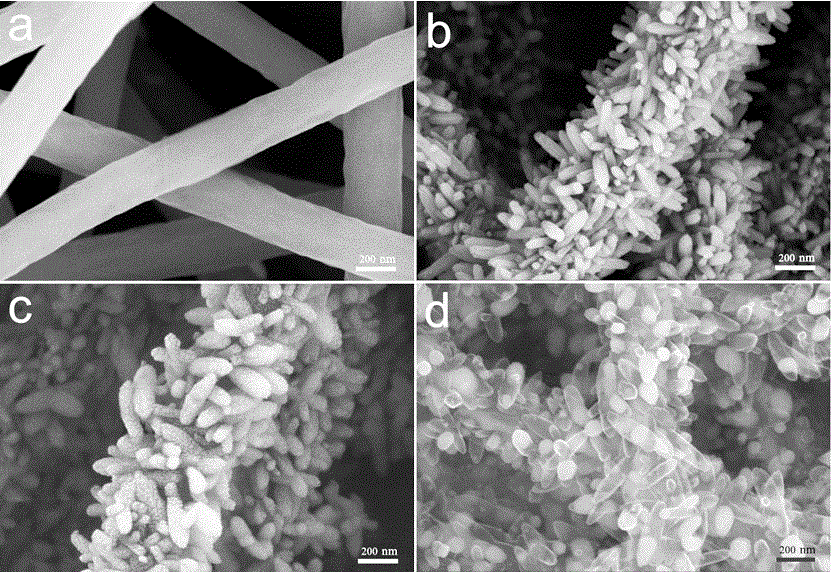

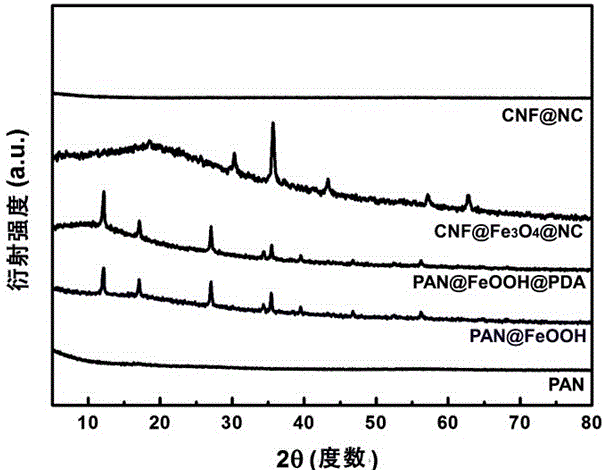

[0044] This embodiment includes the following steps:

[0045] (1) Dissolving polyacrylonitrile in dimethylformamide to prepare spinning solution, and preparing polyacrylonitrile nanofiber membrane through single-needle electrospinning technology;

[0046] (2) Place the polyacrylonitrile fiber membrane in a blast oven for pre-oxidation;

[0047] (3) Put the pre-oxidized polyacrylonitrile in 25mg / mLFeCl 3 ·6H 2 Obtain the polyacrylonitrile fiber that ferric oxyhydroxide is modified in O salt solution, be denoted as PANFeOOH;

[0048] (4) Put PANFeOOH in 1 mg / mL dopamine solution for 3 hours to obtain a coating layer of polydopamine, denoted as PANFeOOHPDA;

[0049] (5) Carry out high-temperature carbonization of PANFeOOHPDA to obtain "vesicle string" nanofibers containing ferric oxide in the vesicles, which are denoted as CNFFe 3 o 4 NC;

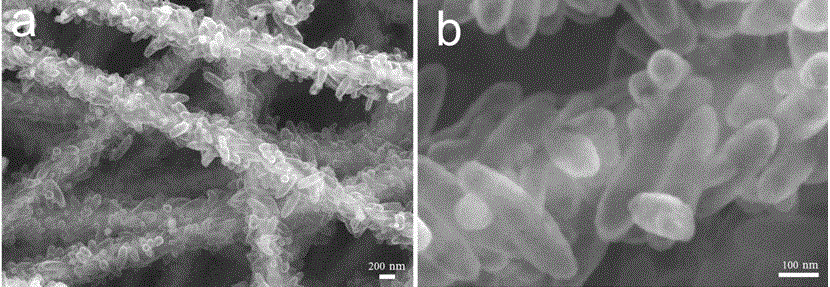

[0050] (6) will CNFFe 3 o 4 The NC is soaked in acid solution to remove iron oxides in the system to obtain pure carbon fibers with a...

Embodiment 2

[0052] The dopamine soaking time in Example 1 was changed to 6h, and the rest were the same as in Example 1. The hybrid material finally obtained was denoted as CNFNC-2. This material also showed good oxygen reduction catalytic activity, and its onset potential was low to 90mV(Vs.RHE), the steady state current density reaches 5.3mAcm -2 .

Embodiment 3

[0054] Change the solubility of the dopamine solution in Example 1 to 2mg / mL, and the rest are the same as in Example 1. The hybrid material obtained at last is denoted as CNFNC-3, and this material also shows a property slightly inferior to that of CNFNC and CNFNC-2. Oxygen reduction catalytic activity, its onset potential is as low as 90mV (Vs.RHE), and the steady-state current density is 4.2mAcm -2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com