Carbon nano fiber-graphene composite aerogel and cooperative assembly preparation method thereof

A graphene aerogel and graphene composite technology, which can be used in hybrid capacitor electrodes and other directions, can solve the problems of limited electrospinning technology collection methods and unsatisfactory results, and achieve rich pore structures, ingenious design ideas, and preparation processes. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

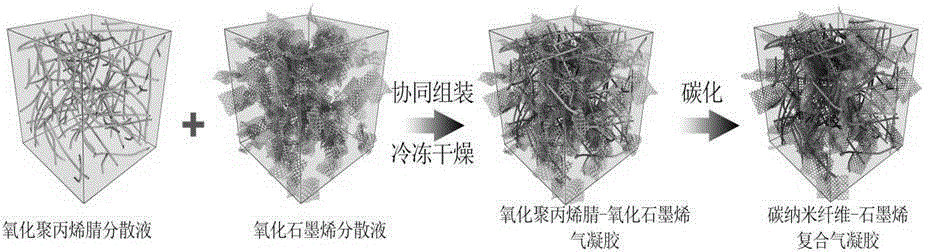

Method used

Image

Examples

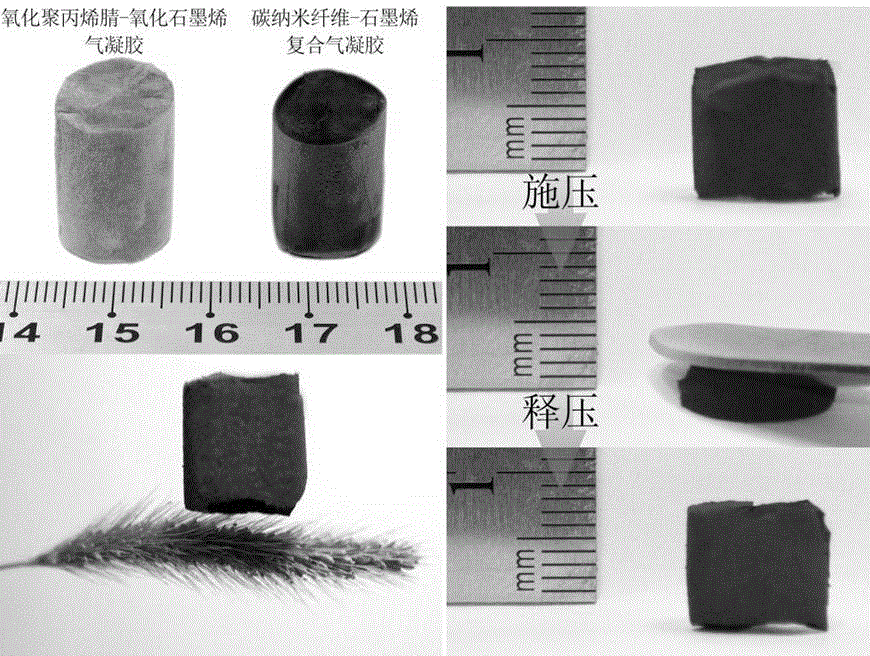

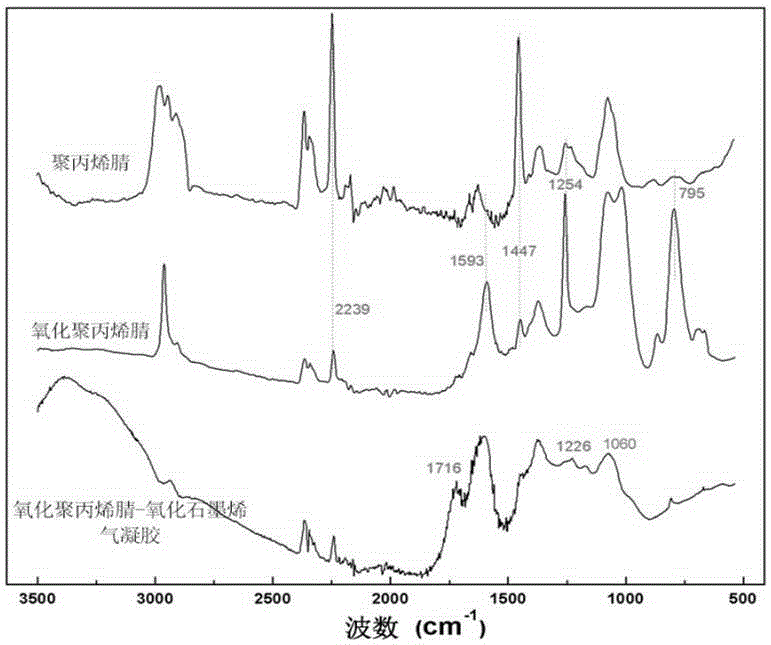

Embodiment 1

[0050] Weigh 1 g of polyacrylonitrile powder and add 10 mL of DMF, and stir at high speed for 5 h under heating in an oil bath at 80° C. to obtain a transparent polyacrylonitrile solution with a yellowish color. Electrospinning is carried out on the above polyacrylonitrile solution, and the spinning process conditions are set as follows: flow rate 0.3mm / min, voltage 20kV, receiving distance 15cm. The prepared polyacrylonitrile nanofibers were finally deposited on the drum receiver in the form of nanofiber films, and the fiber films were removed and dried in a vacuum oven for 24-28 hours to remove residual solvents. The prepared polyacrylonitrile fiber membrane was fixed on a flat plate and placed in a programmed temperature-controlled oven for pre-oxidation treatment. The temperature was raised from room temperature to 250 °C at a rate of 1 °C / min and kept for 2 hours, and then naturally lowered to room temperature. The color of the oxidized polyacrylonitrile fiber membrane be...

Embodiment 2

[0055] Weigh 1 g of polyacrylonitrile powder and add 10 mL of DMF, and stir at high speed for 5 h under heating in an oil bath at 80° C. to obtain a transparent polyacrylonitrile solution with a yellowish color. Electrospinning is carried out on the above polyacrylonitrile solution, and the spinning process conditions are set as follows: flow rate 0.3mm / min, voltage 20kV, receiving distance 15cm. The prepared polyacrylonitrile nanofibers were finally deposited on the drum receiver in the form of nanofiber films, and the fiber films were removed and dried in a vacuum oven for 24-28 hours to remove residual solvents. The prepared polyacrylonitrile fiber membrane was fixed on a flat plate and placed in a programmed temperature-controlled oven for pre-oxidation treatment. The temperature was raised from room temperature to 250 °C at a rate of 1 °C / min and kept for 2 hours, and then naturally lowered to room temperature. The color of the oxidized polyacrylonitrile fiber membrane be...

Embodiment 3

[0058] The graphene oxide prepared by the Hummers method was sonicated for 2 h to obtain a graphene oxide dispersion with a concentration of 4 mg / mL. The above-mentioned graphene oxide dispersion is divided into molds, placed in liquid nitrogen for 10 minutes to make it fully frozen, and then the frozen graphene oxide is transferred to a freeze dryer, and after drying for 48 hours, unformed flocculent graphite oxide is obtained ene instead of graphene oxide aerogels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com