Physical vapor deposition preparation method for high-entropy alloy film with uniform and controllable components

A physical vapor deposition, high-entropy alloy technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problem that high-entropy alloy target is difficult to control element content, difficult to obtain high-entropy coating with uniform composition, The problem of high production cost is to achieve the effect of controllable and uniform high-efficiency components, ingenious overall design ideas, and low production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] As an aspect of the technical solution of the present invention, it relates to a physical vapor deposition preparation method of a high-entropy alloy film with uniform and controllable composition, which includes:

[0033] Using magnetron sputtering technology, using a magnetron sputtering composite target as the target material, using one or more than two gases as the working gas, a negative bias is applied to the substrate, so that a uniform and controllable high-entropy composition can be deposited on the surface of the substrate. Alloy thin film, the working gas contains at least a protective gas;

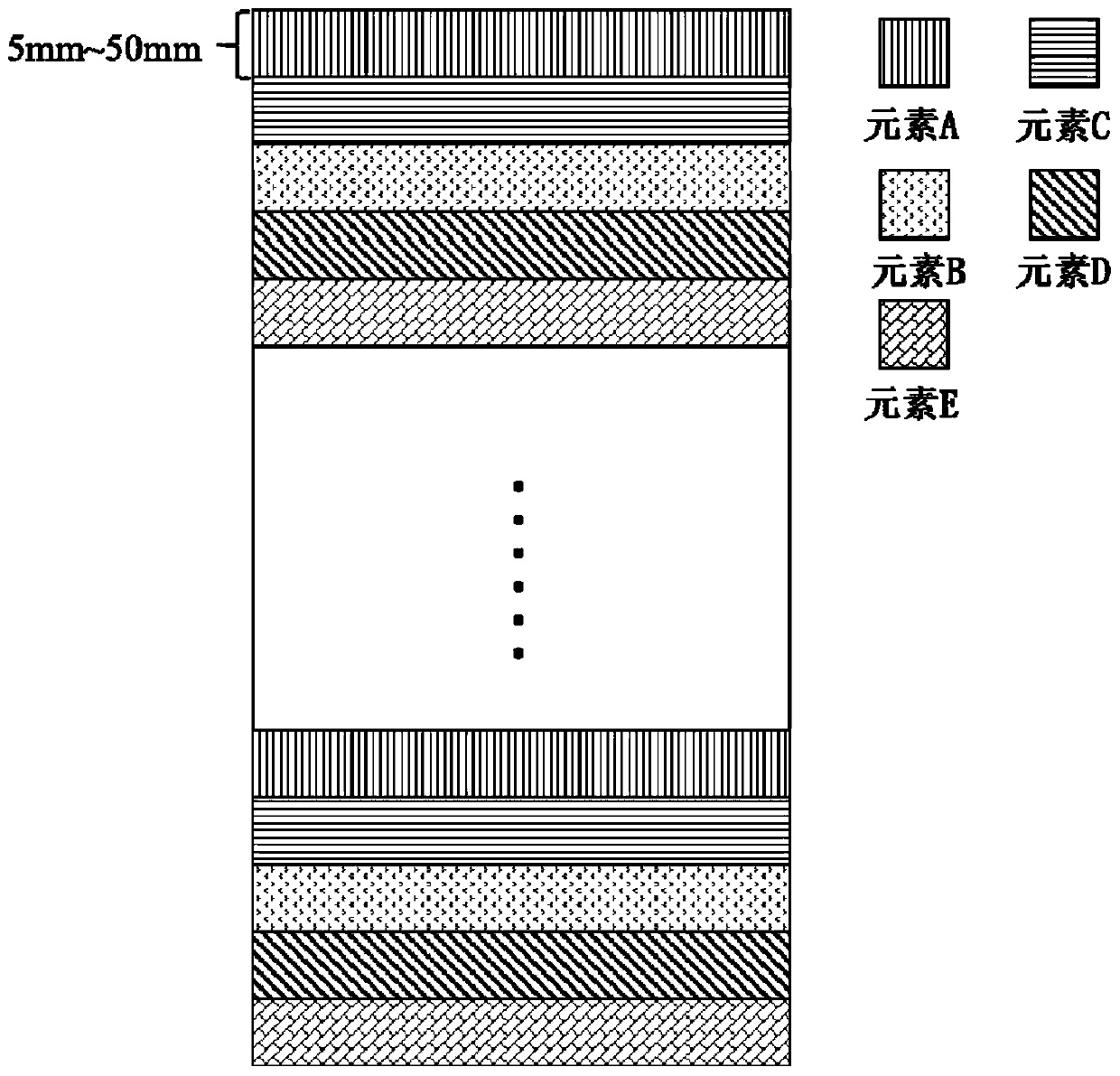

[0034] Wherein, the magnetron sputtering composite target includes at least one target period arranged periodically in the vertical direction, and each target period includes a plurality of single alloy targets stacked in sequence in the vertical direction.

[0035] Furthermore, in the present invention, the pure element targets are arranged and combined in a certain ord...

Embodiment 1

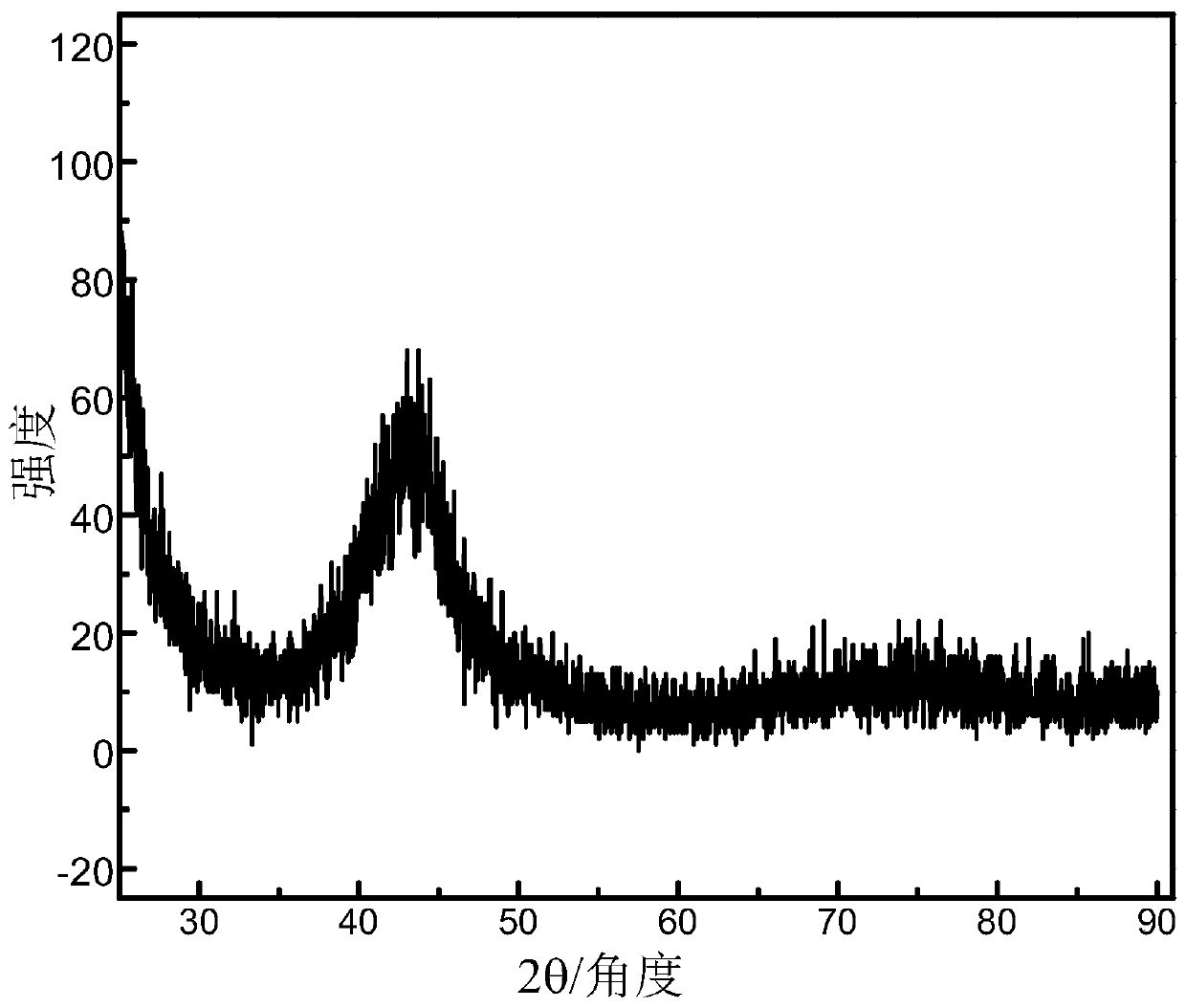

[0070] In this embodiment, the substrate material is 304 stainless steel, and the surface of the substrate is an amorphous VAlTiCrSi high-entropy alloy thin film.

[0071] The preparation method of this VAlTiCrSi high-entropy alloy thin film is as follows:

[0072] Using magnetron sputtering technology to prepare a VAlTiCrSi high-entropy alloy film on the surface of the substrate mainly includes the following steps:

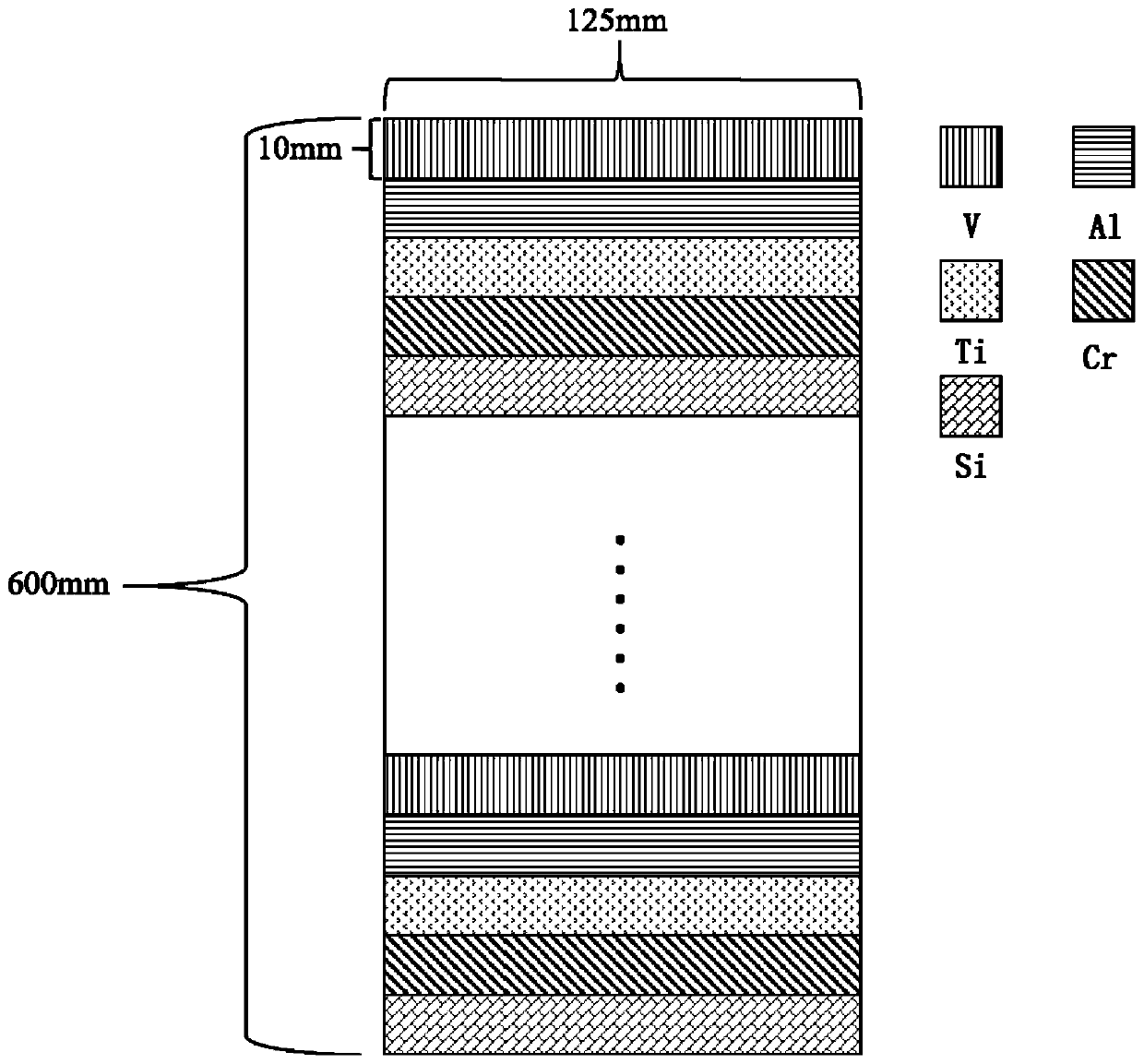

[0073] (1) if figure 2 As shown, select V target, Al target, Ti target, Cr target, and Si target, and stack and arrange each target with a thickness of 10 mm in the order of V-Al-Ti-Cr-Si in the vertical direction from top to bottom to form One target period; then, including 12 said target periods in the vertical direction, forming a composite target.

[0074] (2) Perform mechanical grinding and polishing on the surface of the substrate, ultrasonically clean it three times with petroleum ether, acetone and alcohol, and then dry it with flowing nitrogen; then, ...

Embodiment 2

[0083] In this embodiment, the substrate material is 304 stainless steel, and the surface of the substrate is a VAlTiCrCu high-entropy alloy thin film with a BCC structure.

[0084] The preparation method of this VAlTiCrCu high-entropy alloy thin film is as follows:

[0085] Using magnetron sputtering technology to prepare a VAlTiCrCu high-entropy alloy film on the surface of the substrate mainly includes the following steps:

[0086] (1) if Figure 4 As shown, select V target, Al target, Ti target, Cr target, and Cu target, and stack and arrange each target with a thickness of 10 mm in the order of V-Al-Ti-Cr-Cu in the vertical direction from top to bottom to form One target period; then, including 12 said target periods in the vertical direction, forming a composite target.

[0087] (2) Perform mechanical grinding and polishing on the surface of the substrate, ultrasonically clean it three times with petroleum ether, acetone and alcohol, and then dry it with flowing nitrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com