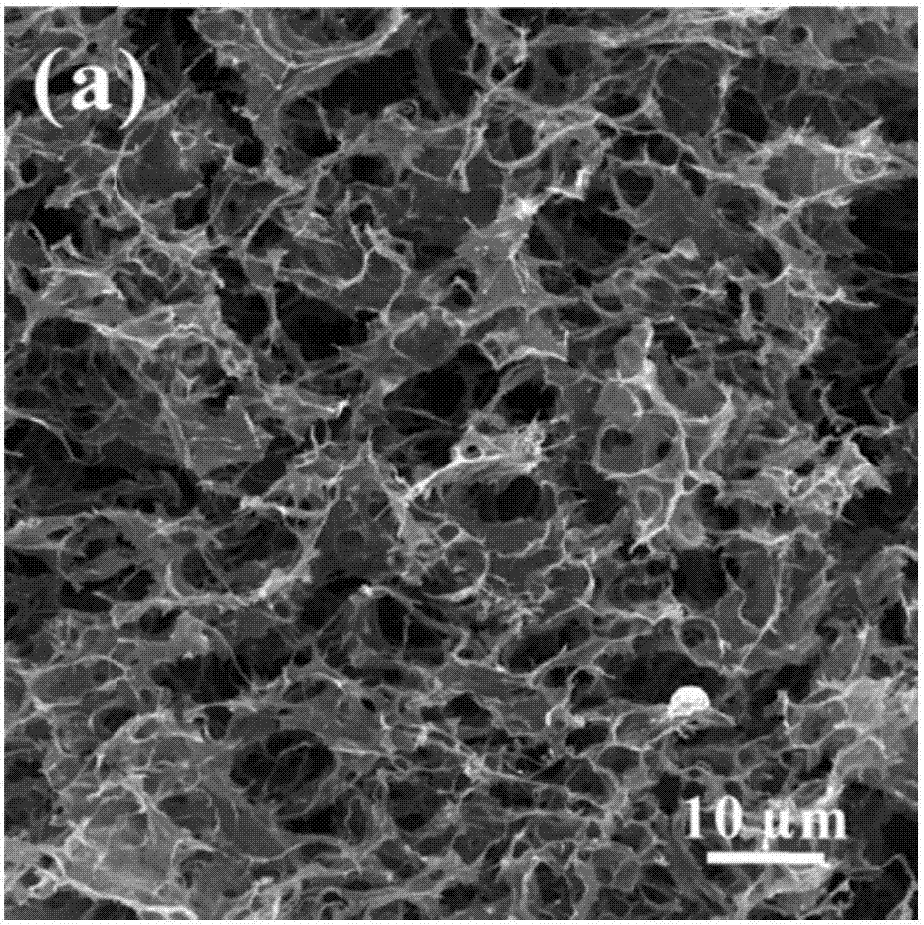

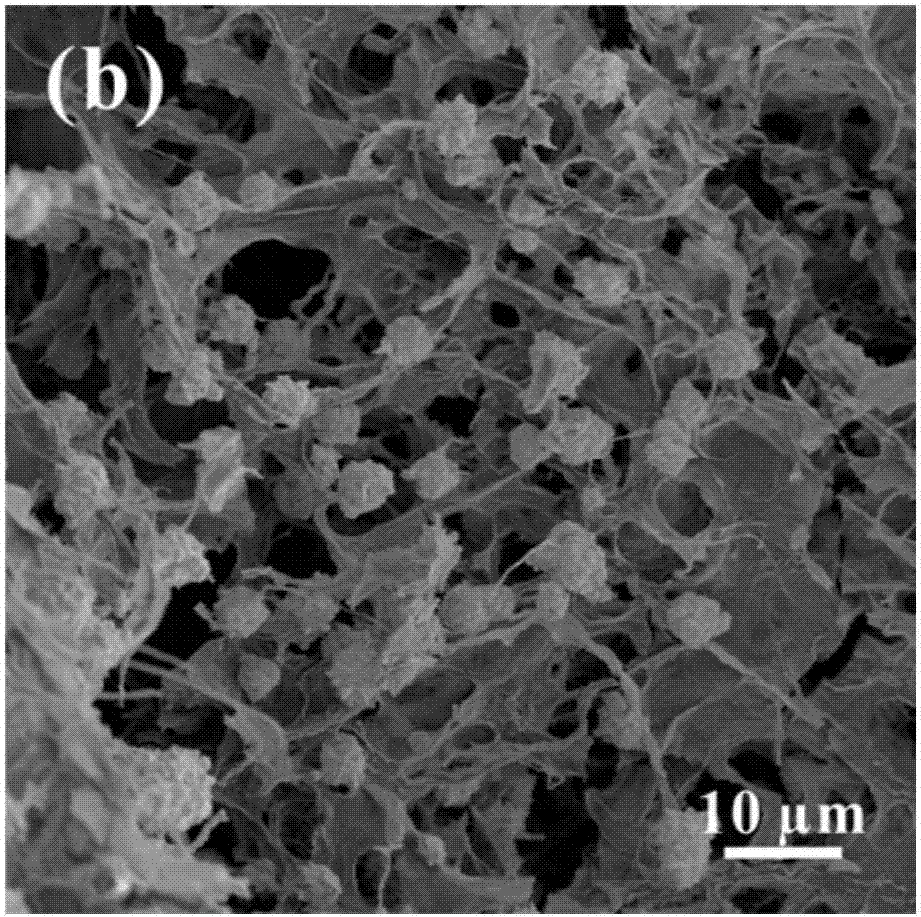

Preparation method of nickel sulfide particles/cellulose-based carbon aerogel materials

A cellulose hydrogel, cellulose-based technology, applied in the field of nickel sulfide particles/cellulose-based composite carbon airgel materials and its preparation, can solve the low specific capacity of carbon airgel, adverse effects on the environment and human health , carbon aerogel limitations, etc., to achieve the effect of optimizing electrochemical performance, ingenious design ideas, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Fully dissolve 20g of sodium hydroxide in 80g of deionized water to prepare a 20wt% sodium hydroxide solution; fully dissolve 30g of urea in 70g of deionized water to prepare a 30wt% urea solution. Among them, sodium hydroxide can also be replaced by other alkaline substances, such as potassium hydroxide and lithium hydroxide.

[0030] Get 19g of 20wt% sodium hydroxide mixed with 19g of 30wt% urea solution, add 2g of bacterial cellulose, and transfer it to a refrigerator to freeze, and the cooling temperature range is -18 to 10°C. Stir the frozen bacterial cellulose / sodium hydroxide / urea / water mixture rapidly to dissolve the cellulose to obtain a concentrated solution of bacterial cellulose.

[0031] The obtained concentrated cellulose solution is poured into a mold and heated in water for a period of time to obtain an alkaline cellulose hydrogel. Wherein the heating temperature is 50-120°C, preferably 60-90°C, and the heating time is 1-10 hours, preferably 2-6 hours. ...

Embodiment 2

[0037] Fully dissolve 10g of sodium hydroxide in 90g of deionized water to prepare a 10wt% sodium hydroxide solution; fully dissolve 20g of urea in 80g of deionized water to prepare a 20wt% urea solution. Get 99g of 10wt% sodium hydroxide mixed with 99g of 20wt% urea solution, add 2g of plant cellulose, and transfer it to a refrigerator to freeze, and the cooling temperature range is -18~10°C. Other processes of the preparation of the nickel sulfide / cellulose-based composite carbon aerogel are the same as in Example 1.

Embodiment 3

[0039] Fully dissolve 15g of sodium hydroxide in 85g of deionized water to prepare a 15wt% sodium hydroxide solution; fully dissolve 25g of urea in 75g of deionized water to prepare a 25wt% urea solution. Get 49g of 15wt% sodium hydroxide mixed with 49g of 25wt% urea solution, add 2g of bacterial cellulose, and transfer it to a refrigerator to freeze, and the cooling temperature range is -18 to 10°C. Other processes of the preparation of the nickel sulfide / cellulose-based composite carbon aerogel are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com