Boron-nitrogen co-doped carbon/manganese oxide composite nanosheet material, preparation method and application

A technology of manganese oxide and carbon nanosheets, which is applied in the field of composite materials, can solve the problems of poor conductivity of manganese oxide, and achieve the effects of easy operation, high specific surface area, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of boron-nitrogen co-doped carbon nanosheet material:

[0038] (1) Add 2g of chitosan and 5mL of acetic acid into 150mL of deionized water to fully dissolve, and fully stir to form a chitosan hydrogel.

[0039] (2) Add 0.5 g of boric acid to the chitosan hydrogel obtained in step (1), stir evenly, and fully freeze-dry to obtain a solid mixture of boric acid and chitosan hydrogel.

[0040] (3) Transfer the sample obtained in step (2) to a tube furnace, raise the temperature to 800°C at a rate of 2°C / min in a nitrogen atmosphere, keep it for 2h, and carry out carbonization to obtain boron-nitrogen co-doped carbon Nanosheet, denoted as BNC.

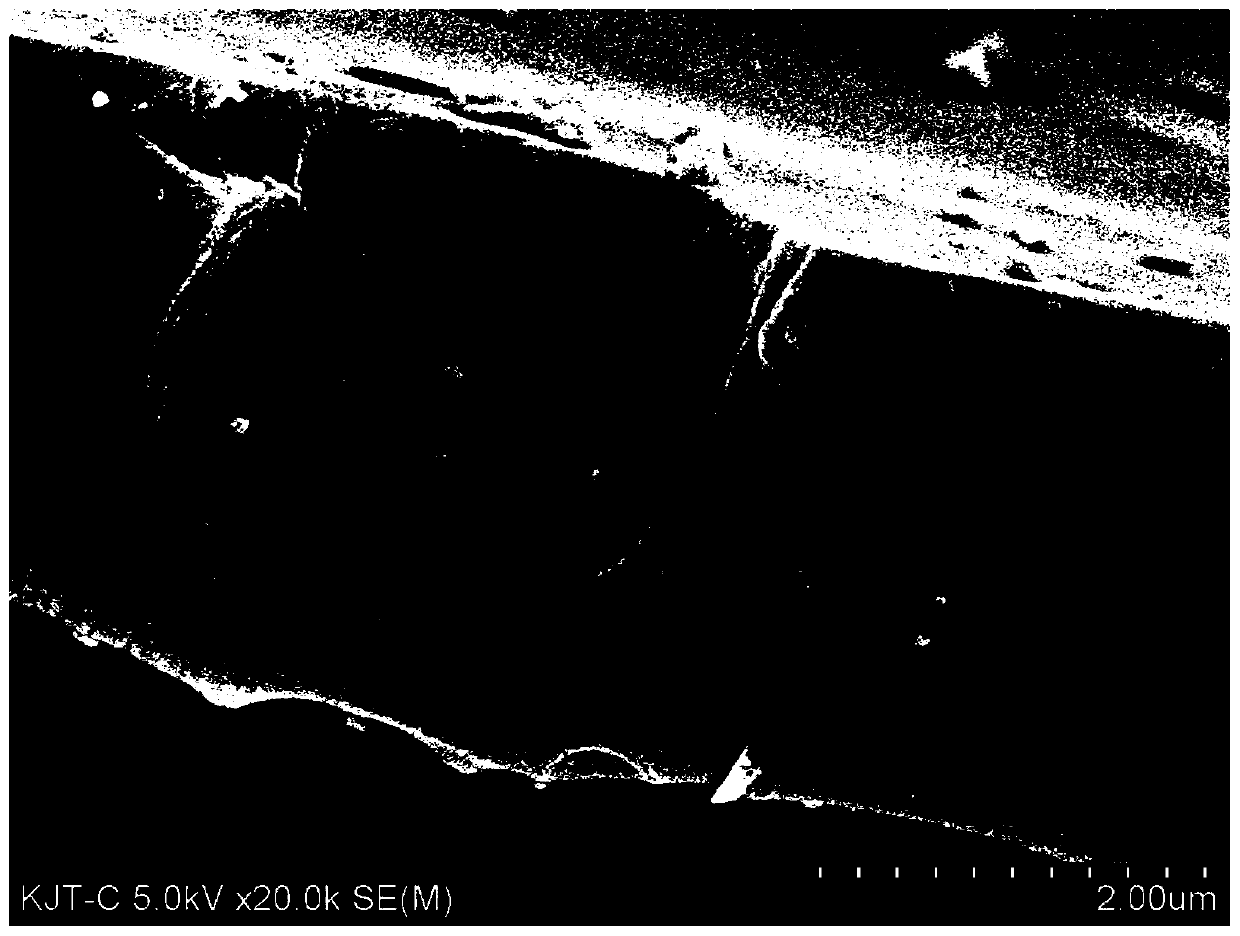

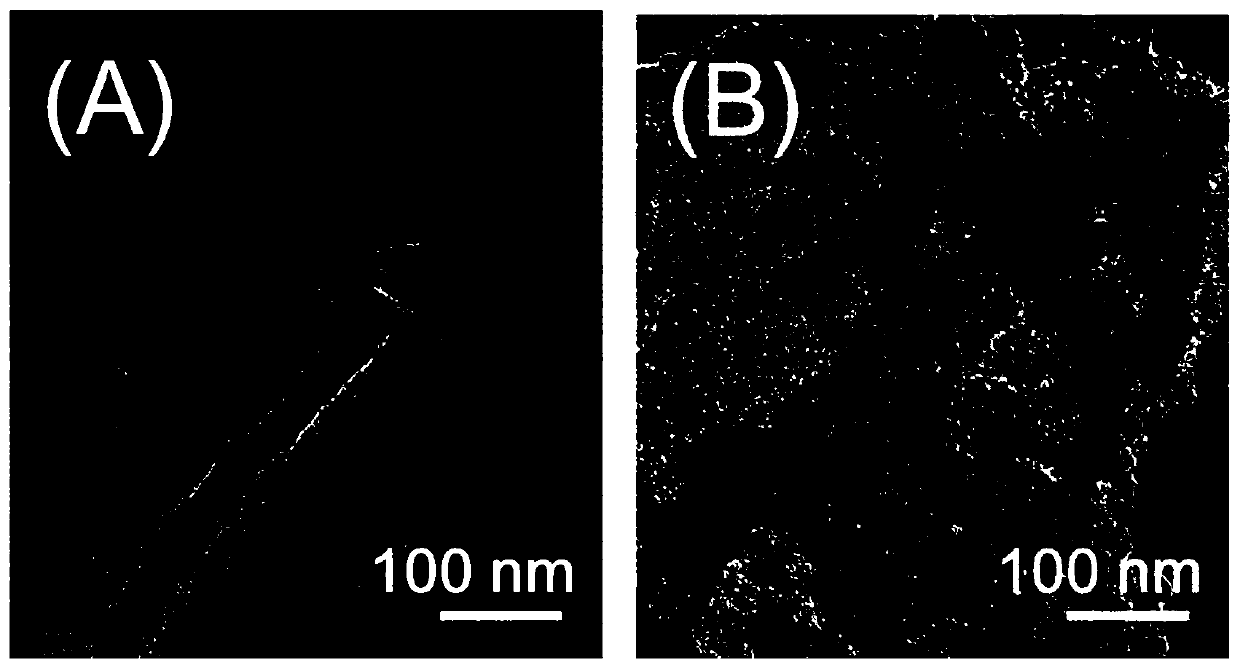

[0041] The scanning electron microscope picture and the transmission electron microscope picture of boron nitrogen co-doped carbon nanosheet BNC in the present embodiment are respectively as follows figure 1 Middle (A) and image 3 As shown in (A), it can be seen that the thickness of the boron-nitrogen co-dope...

Embodiment 2

[0046] A preparation method of boron and nitrogen co-doped carbon / manganese oxide composite nanosheet material:

[0047] (1) Add 2g of chitosan and 5mL of acetic acid into 150mL of deionized water to fully dissolve, and fully stir to form a chitosan hydrogel.

[0048] (2) Add 0.5 g of boric acid to the chitosan hydrogel obtained in step (1), stir evenly, and fully freeze-dry to obtain a solid mixture of boric acid and chitosan hydrogel.

[0049] (3) Transfer the sample obtained in step (2) to a tube furnace, raise the temperature to 800°C at a rate of 2°C / min in a nitrogen atmosphere, keep it for 2h, and carry out carbonization to obtain boron-nitrogen co-doped carbon Nanosheet, denoted as BNC.

[0050] (4) react the sample obtained in step (3) with 100mL 10mM potassium permanganate solution, the reaction time is 2h, and the reaction temperature is 50°C to obtain the boron-nitrogen co-doped carbon / manganese oxide composite nanosheet material, denoted as MnO-2@BNC.

[0051] ...

Embodiment 3

[0056] A preparation method of boron and nitrogen co-doped carbon / manganese oxide composite nanosheet material:

[0057] (1) Add 2g of chitosan and 5mL of acetic acid into 150mL of deionized water to fully dissolve, and fully stir to form a chitosan hydrogel.

[0058] (2) Add 0.5 g of boric acid to the chitosan hydrogel obtained in step (1), stir evenly, and fully freeze-dry to obtain a solid mixture of boric acid and chitosan hydrogel.

[0059] (3) Transfer the sample obtained in step (2) to a tube furnace, raise the temperature to 800°C at a rate of 2°C / min in a nitrogen atmosphere, keep it for 2h, and carry out carbonization to obtain boron-nitrogen co-doped carbon Nanosheet, denoted as BNC.

[0060] (4) react the sample obtained in step (3) with 100mL 10mM potassium permanganate solution, the reaction time is 4h, and the reaction temperature is 50°C to obtain the boron-nitrogen co-doped carbon / manganese oxide composite nanosheet material, denoted as MnO-4@BNC.

[0061] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com