Preparation method of hydrophilic and antistatic polyester fiber

A polyester fiber and antistatic technology, applied in the field of synthetic fibers, can solve the problems of limited antistatic performance of polyester fiber, achieve good hydrophilicity and antistatic performance, ingenious design ideas, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

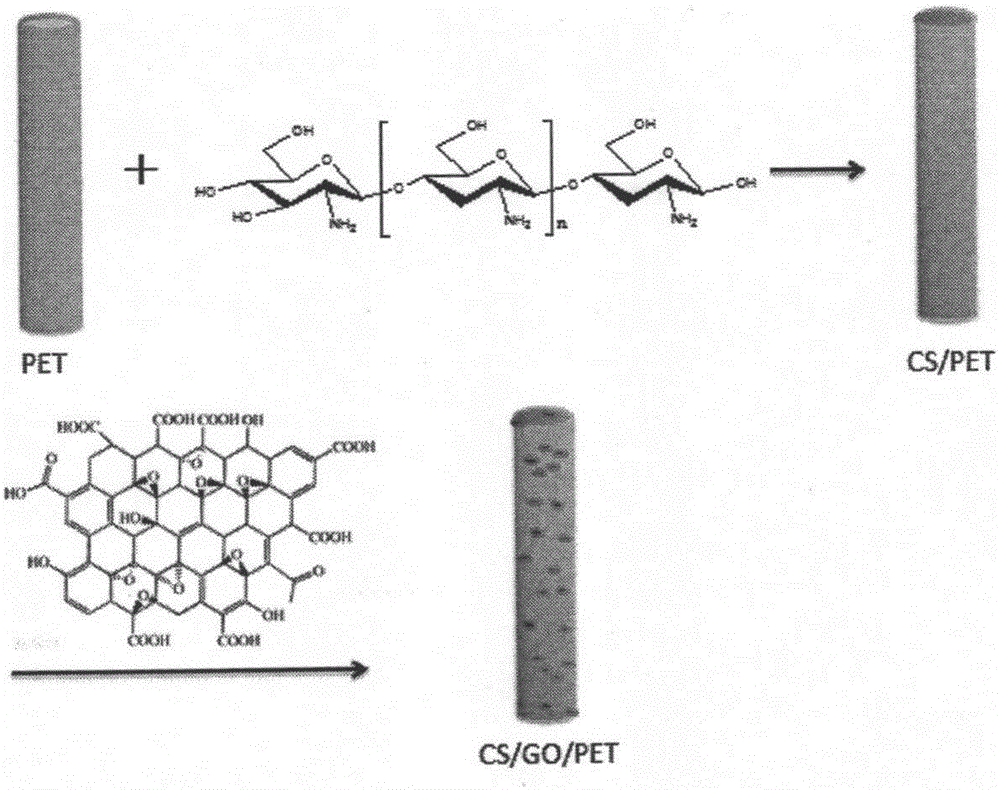

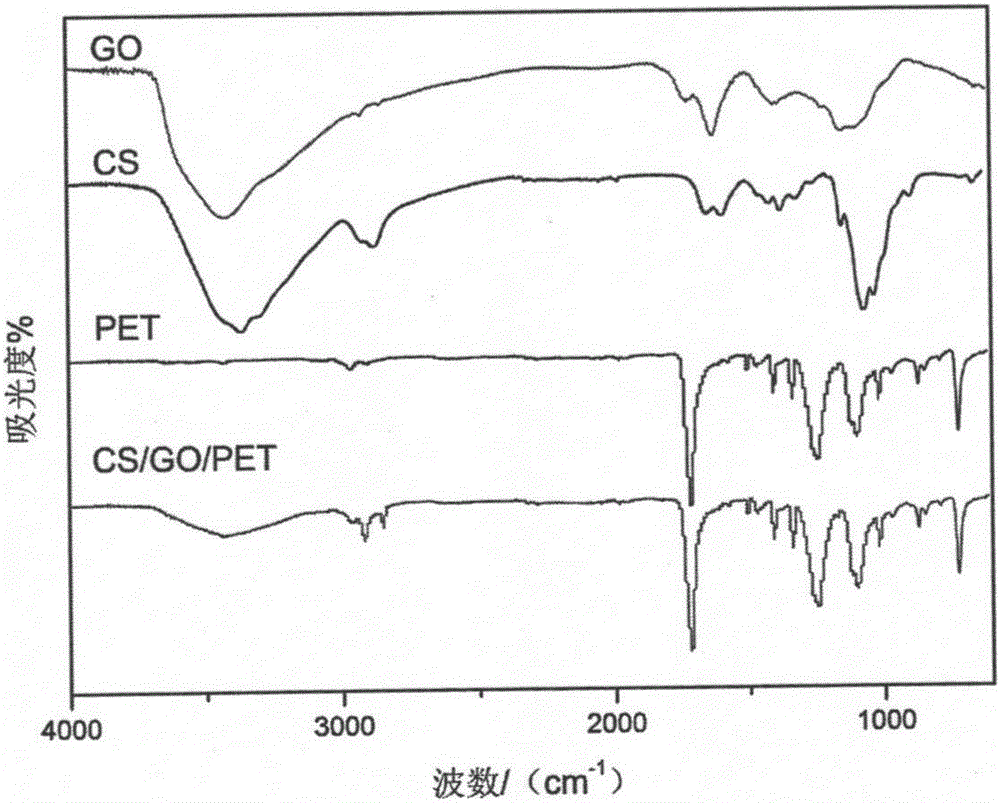

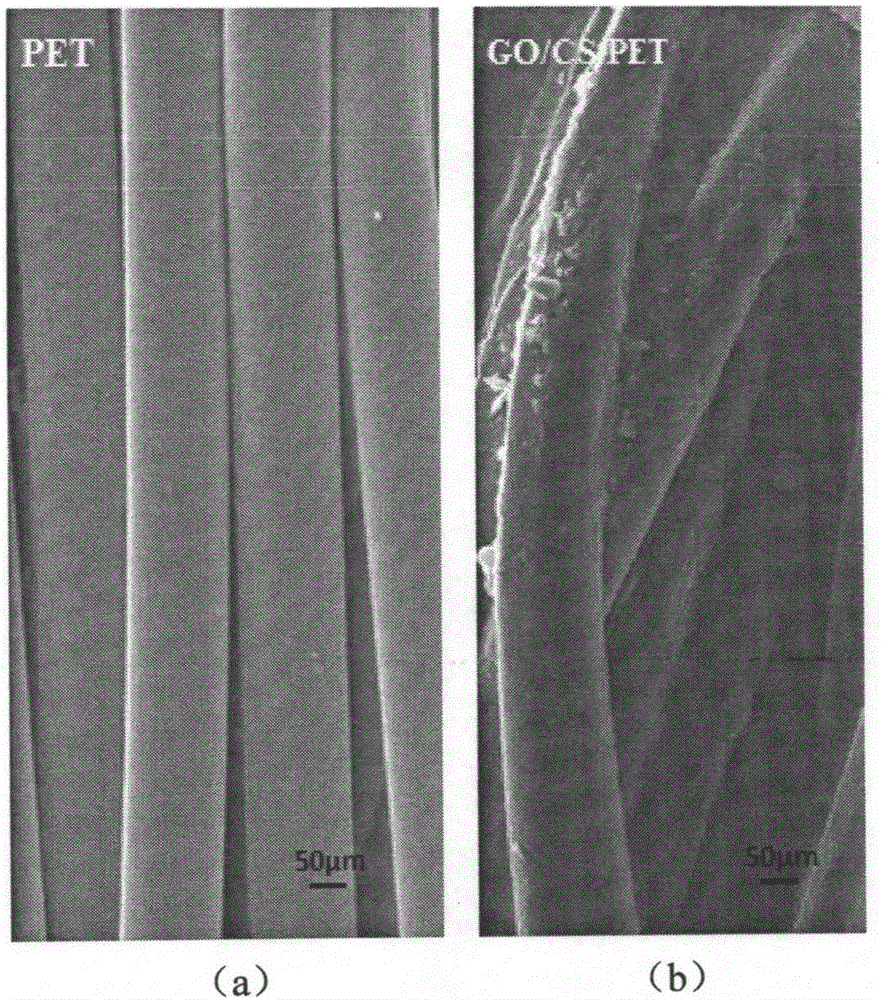

[0037] figure 1 For the preparation process schematic diagram of hydrophilic antistatic polyester fiber, 1g chitosan is dissolved in the 0.5% concentration hydrochloric acid solution of 100ml, stirs 12h, obtains the chitosan solution of clarification, and the concentration of chitosan is 1%; Slowly add 0.5 mol / L NaOH solution dropwise to chitosan solution to form chitosan gel; filter to obtain chitosan gel, wash with water until neutral, 100ml constant volume, pass through CO at room temperature 2 Gas until the solution is clear and transparent to obtain chitosan carbonated solution; 3g polyester fibers with a weight reduction rate of 11% are immersed in the chitosan carbonated solution, and after 6h, take out and place in an oven to dry to obtain chitosan / polyester fiber, record It is CS / PET; disperse graphene oxide in deionized water, and ultrasonically obtain a stable dispersed graphene aqueous solution; the mass concentration of graphene oxide aqueous solution is 0.1mg / ml;...

Embodiment 2

[0045] 2g chitosan is dissolved in the 0.5% concentration hydrochloric acid solution of 100ml, stirs 12h, obtains the chitosan solution of clarification, and the concentration of chitosan is 2%; In chitosan solution, slowly add 0.5mol / L NaOH solution forms chitosan gel; filter to obtain chitosan gel, wash with water until neutral, and after 100ml constant volume, pass through CO at room temperature 2 Gas until the solution is clear and transparent to obtain chitosan carbonated solution; 3g polyester fibers with a weight reduction rate of 11% are immersed in the chitosan carbonated solution, and after 6h, take out and place in an oven to dry to obtain chitosan / polyester fiber, record It is CS / PET; disperse graphene oxide in deionized water, and ultrasonically obtain a stable dispersed graphene aqueous solution; the mass concentration of graphene oxide aqueous solution is 0.1mg / ml; immerse the polyester fiber treated with chitosan into the prepared In the graphene oxide solution...

Embodiment 3

[0047] Dissolve 1g chitosan in 100ml of 2% concentration acetic acid solution, stir for 12h to obtain a clear chitosan solution, the concentration of chitosan is 1%; slowly add 0.5mol / L of NaOH solution forms chitosan gel; filter to obtain chitosan gel, wash with water until neutral, and after 100ml constant volume, pass through CO at room temperature 2 Gas until the solution is clear and transparent to obtain chitosan carbonated solution; 3g polyester fibers with a weight reduction rate of 11% are immersed in the chitosan carbonated solution, and after 6h, take out and place in an oven to dry to obtain chitosan / polyester fiber, record It is CS / PET; disperse graphene oxide in deionized water, and ultrasonically obtain a stable dispersed graphene aqueous solution; the mass concentration of graphene oxide aqueous solution is 0.5mg / ml; immerse the polyester fiber treated with chitosan into the prepared In the graphene oxide solution, take it out after 3 hours, wash with water, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com