Integrated automobile tail gas purification three-way catalyst and preparation method thereof

A three-way catalyst and automobile exhaust technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of affecting catalytic activity and catalytic life, the selection of noble metal catalysts Poor performance, easy loss of catalyst active components, etc., to overcome uneven coating, improve catalytic effect, and wide active temperature window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Put the first carrier cordierite honeycomb ceramics into 20% glacial acetic acid solution, boil in a water bath at 80°C for 2 hours, wash the surface layer and residual acid in the pores with water after cooling to neutral, and dry in an oven at 120°C for 2 hours h and above are reserved.

[0031] (2) Mix 2.7 g aluminum powder with 300 mL, 1 mol / L nitric acid solution, heat in a water bath at 100°C for 1 h, cool and filter, concentrate the filtrate to 100 mL, and add dropwise to 1 mol / L at a rate of 10 mL / min Add 10 mL of 1 mol / L nitric acid solution to ammonia water, then stir in a water bath at 85°C for 6 h to make a sol.

[0032] (3) Impregnate the first carrier cordierite honeycomb ceramics treated in step (1) into the sol in step (2), and use a box-type microwave oven reactor to heat and impregnate for 10 minutes at 40°C and 200W power. After heating, take it out, blow off the remaining sol in the channel, dry at 120°C for 2 hours, and bake at 550°C for 4 hour...

Embodiment 2

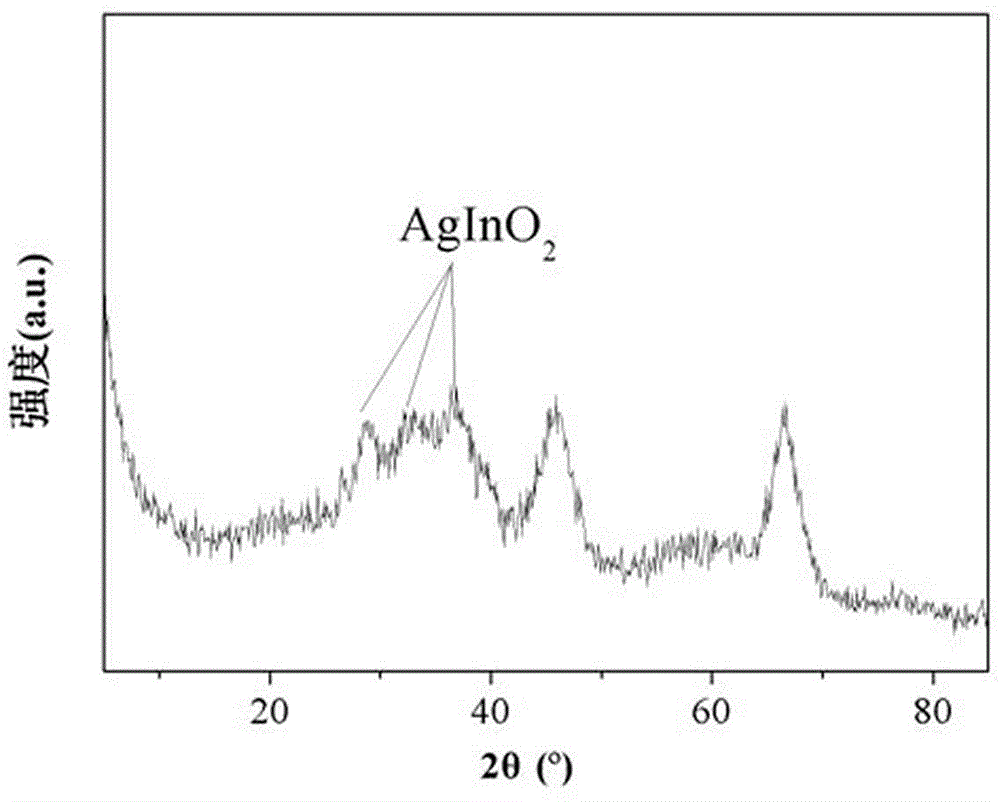

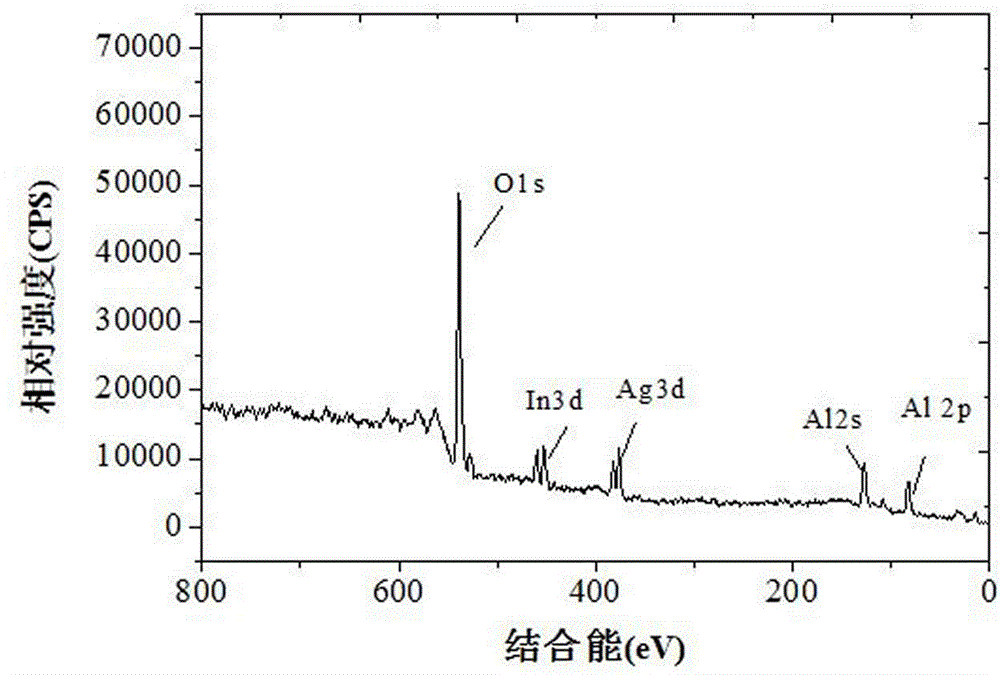

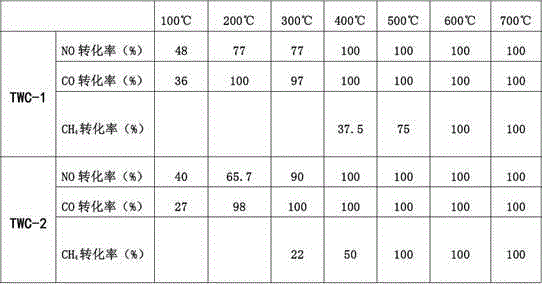

[0044] An integral three-way catalyst for automobile exhaust purification TWC-1, with cordierite honeycomb ceramics as the first carrier, γ-Al 2 o 3 is the second carrier, indium, silver, nickel, cerium composite metal oxide is the active component, and the second carrier and the active component constitute the coating of the catalyst; the mass percentage of cordierite honeycomb ceramics is 81.2%, and the coating mass The percentage content is 18.8%, and the mass percentage content of active components in the total coating amount is 4% indium, 4% silver, 2% nickel, and 1% cerium.

[0045] The catalyst is prepared according to the following steps: Put the pre-cut cube-shaped first carrier cordierite honeycomb ceramics into 20% oxalic acid solution, boil in a water bath at 80°C for 2 hours, wash the surface layer and the residual acid solution in the pores with water after cooling To neutrality, dry in an oven at 120°C for more than 2 h for later use; (2) Mix 2.7 g of aluminum ...

Embodiment 3

[0047] An integral three-way catalyst for automobile exhaust purification TWC-2, with cordierite honeycomb ceramics as the first carrier, γ-Al 2 o 3 is the second carrier, indium, silver, nickel, cerium composite metal oxide is the active component, and the second carrier and the active component constitute the coating of the catalyst; the mass percentage of cordierite honeycomb ceramics is 82.1%, and the coating mass The percentage content is 17.9%, and the mass percentage content of active components in the total coating is 5% indium, 2% silver, 2% nickel, and 1% cerium.

[0048] The catalyst is prepared according to the following steps: put the pre-cut cube-shaped first carrier cordierite honeycomb ceramic into 15% nitric acid solution, boil in a water bath at 100°C for 5 hours, and wash the surface layer and residual acid in the pores with water after cooling To neutrality, dry in an oven at 100°C for more than 4 h for later use; (2) Mix 2.7 g of aluminum powder with 300 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com