Preparation method and application of magnetic nanometer catalyst loading nanogold

A magnetic nanometer and magnetic nanoparticle technology, applied in the field of preparation of magnetic nanocatalysts, can solve the problems affecting the stability of nano-gold loading, reusability, weak force, etc., and achieve convenient and fast recovery, mild reaction conditions and high performance. The effect of catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

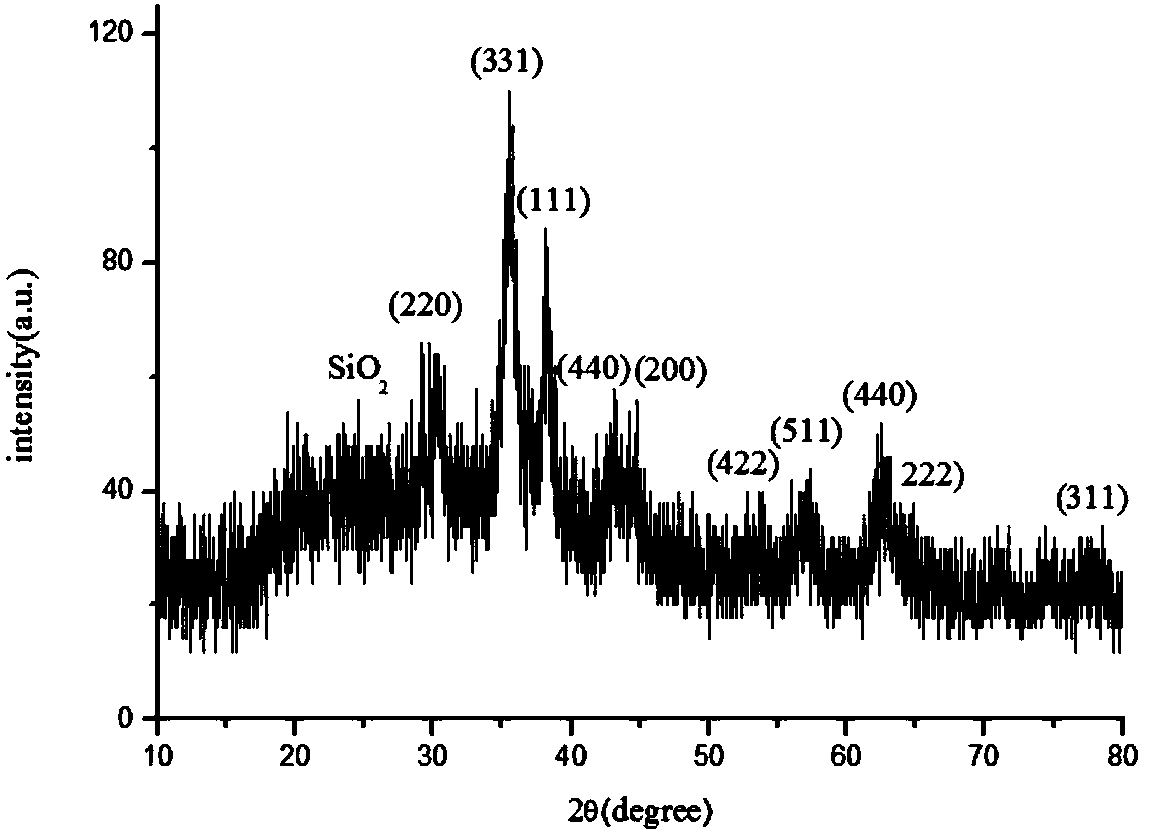

[0029] (1) The magnetic nanoparticles are prepared by a hydrothermal method, and then coated with a silicon dioxide layer. Disperse the magnetic nanoparticles in absolute ethanol to obtain a magnetic nanoparticle ethanol dispersion, add ammonia and tetraethyl orthosilicate in turn, wherein the volume ratio of the magnetic nanoparticles ethanol dispersion, ammonia and tetraethyl orthosilicate is 50: 1:0.5, stirred at room temperature for 12 hours to obtain silicon-coated magnetic nanoparticles.

[0030] (2) Disperse the silicon-coated magnetic nanoparticles in ethanol to obtain a silicon-coated magnetic nanoparticle dispersion (0.2 mg / mL). Ammonia water was added thereto and stirred for 15 min, and then 3-mercaptopropyltrimethoxysilane solution was added dropwise to the solution, wherein the volume ratio of the silicon-coated magnetic nanoparticle dispersion, ammonia water, and 3-mercaptopropyltrimethoxysilane was It is 50:0.5:0.25. After stirring at room temperature for 24 h...

Embodiment 2

[0034] (1) The magnetic nanoparticles are prepared by a hydrothermal method, and then coated with a silicon dioxide layer. Disperse the magnetic nanoparticles in absolute ethanol to obtain a magnetic nanoparticle ethanol dispersion, add ammonia and tetraethyl orthosilicate in turn, wherein the volume ratio of the magnetic nanoparticles ethanol dispersion, ammonia and tetraethyl orthosilicate is 50: 1:0.5, stirred at room temperature for 12 hours to obtain silicon-coated magnetic nanoparticles.

[0035](2) Disperse the silicon-coated magnetic nanoparticles in ethanol to obtain a silicon-coated magnetic nanoparticle dispersion (2.5 mg / mL). Ammonia water was added thereto and stirred for 15 min, and then 3-mercaptopropyltriethoxysilane solution was added dropwise to the solution, wherein silicon magnetic nanoparticle dispersion liquid, ammonia water, and 3-mercaptopropyltriethoxysilane were included. The volume ratio is 50:2.5:1.25. After stirring at room temperature for 24 hou...

Embodiment 3

[0039] (1) The magnetic nanoparticles are prepared by a hydrothermal method, and then coated with a silicon dioxide layer. Disperse the magnetic nanoparticles in absolute ethanol to obtain a magnetic nanoparticle ethanol dispersion, add ammonia and tetraethyl orthosilicate in turn, wherein the volume ratio of the magnetic nanoparticles ethanol dispersion, ammonia and tetraethyl orthosilicate is 50: 1:0.5. Stir at room temperature for 12 hours to obtain silicon-coated magnetic nanoparticles.

[0040] (2) Disperse the silicon-coated magnetic nanoparticles in ethanol to obtain a silicon-coated magnetic nanoparticle dispersion (5 mg / mL). Ammonia water was added thereto and stirred for 15 min, and then 3-mercaptopropyltrimethoxysilane solution was added dropwise to the solution, wherein the volume ratio of the silicon-coated magnetic nanoparticle dispersion, ammonia water, and 3-mercaptopropyltrimethoxysilane was It is 50:5:2.5. After stirring at room temperature for 24 hours, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com