Patents

Literature

262 results about "Nanoparticle dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

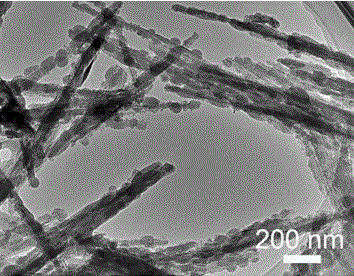

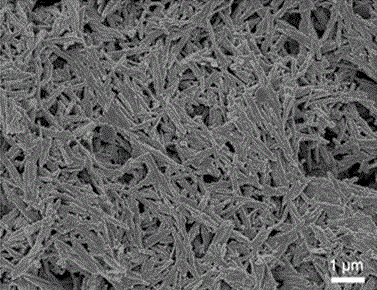

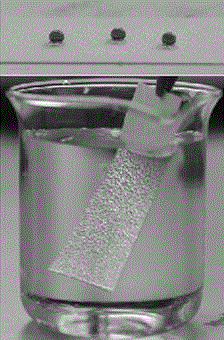

Nanoparticle Dispersion. High shear forces created by ultrasonic cavitation have the ability to break up particle agglomerates and result in smaller and more uniform particles sizes. The stable and homogenous suspensions produced by ultrasonics are widely used in many industries today.

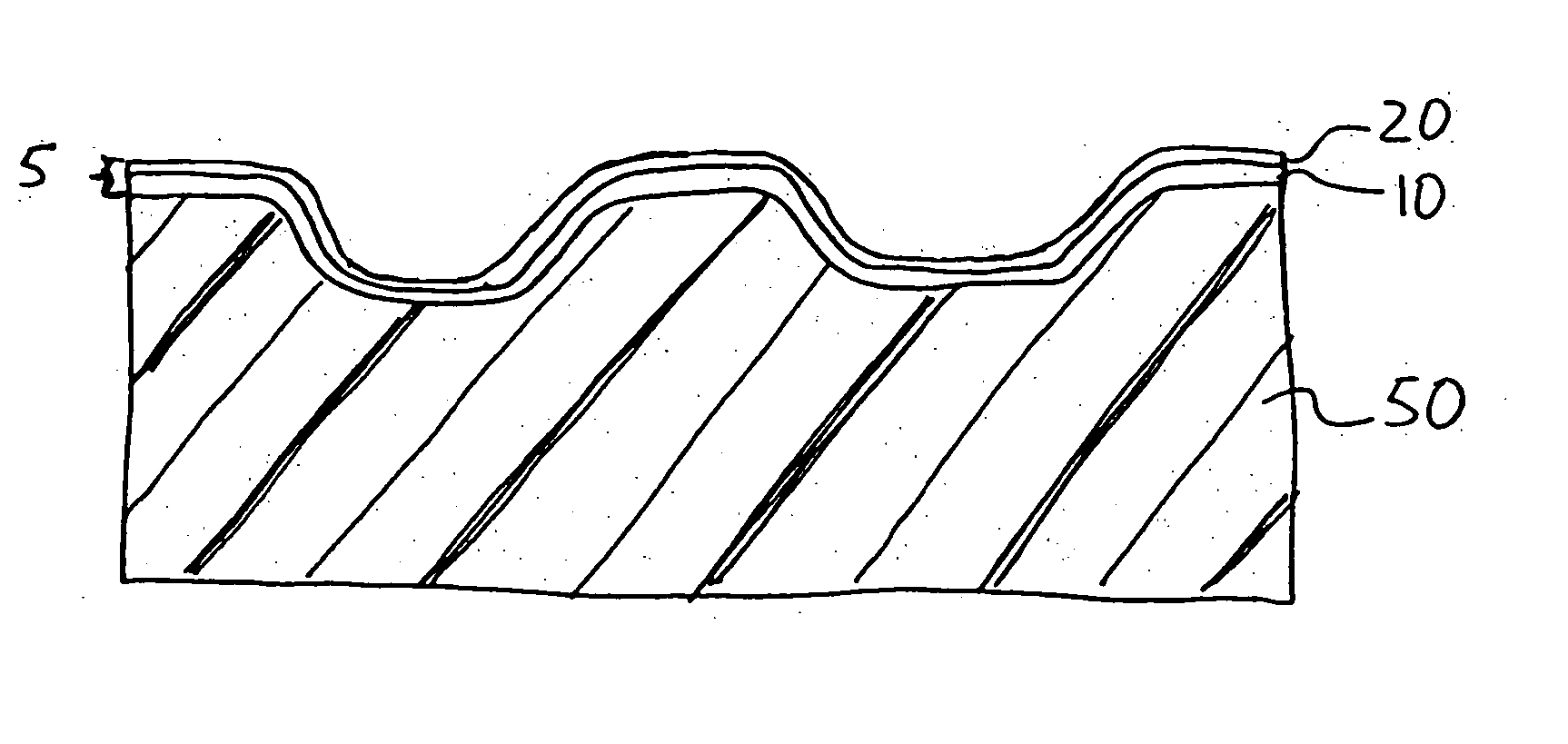

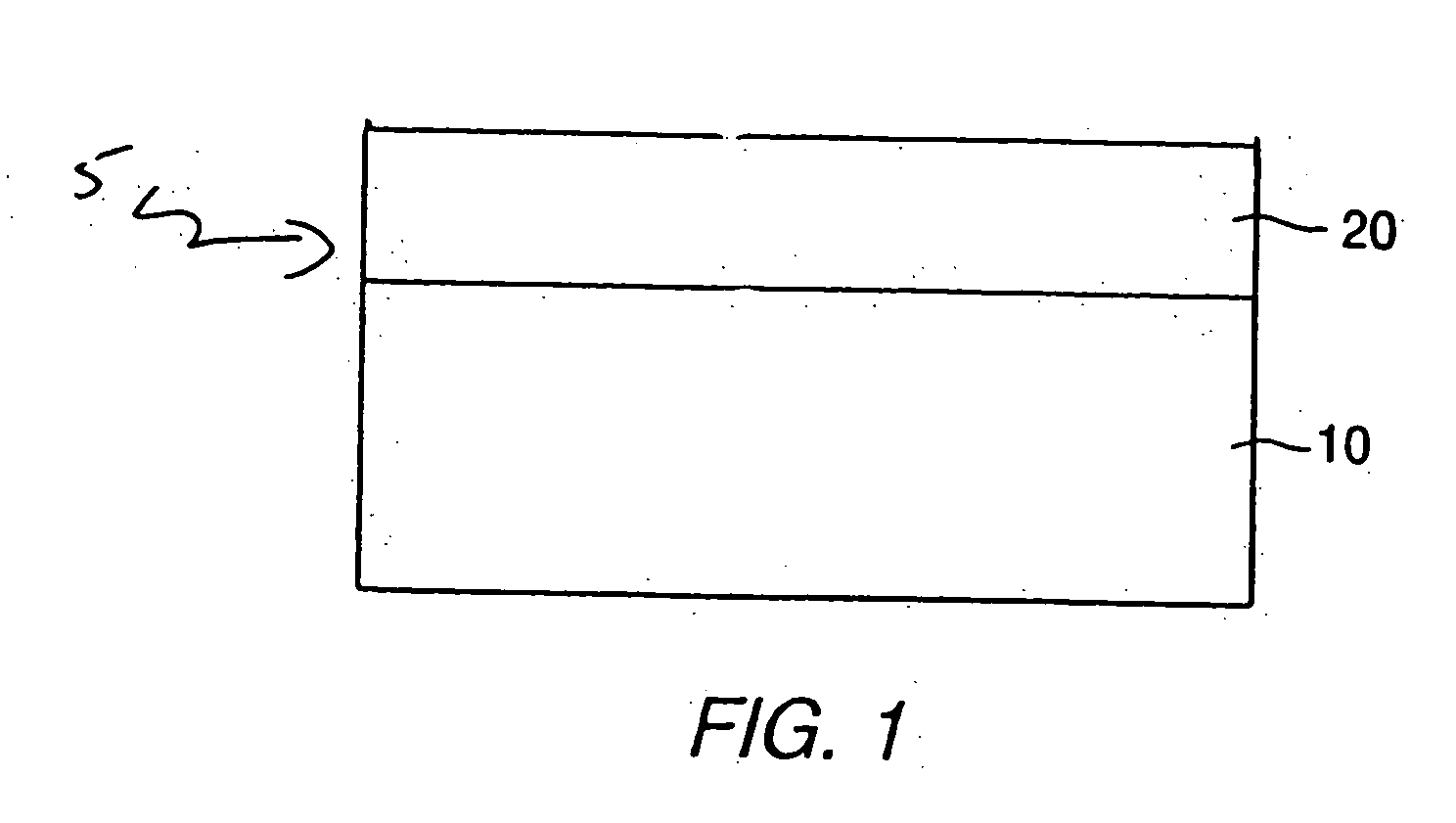

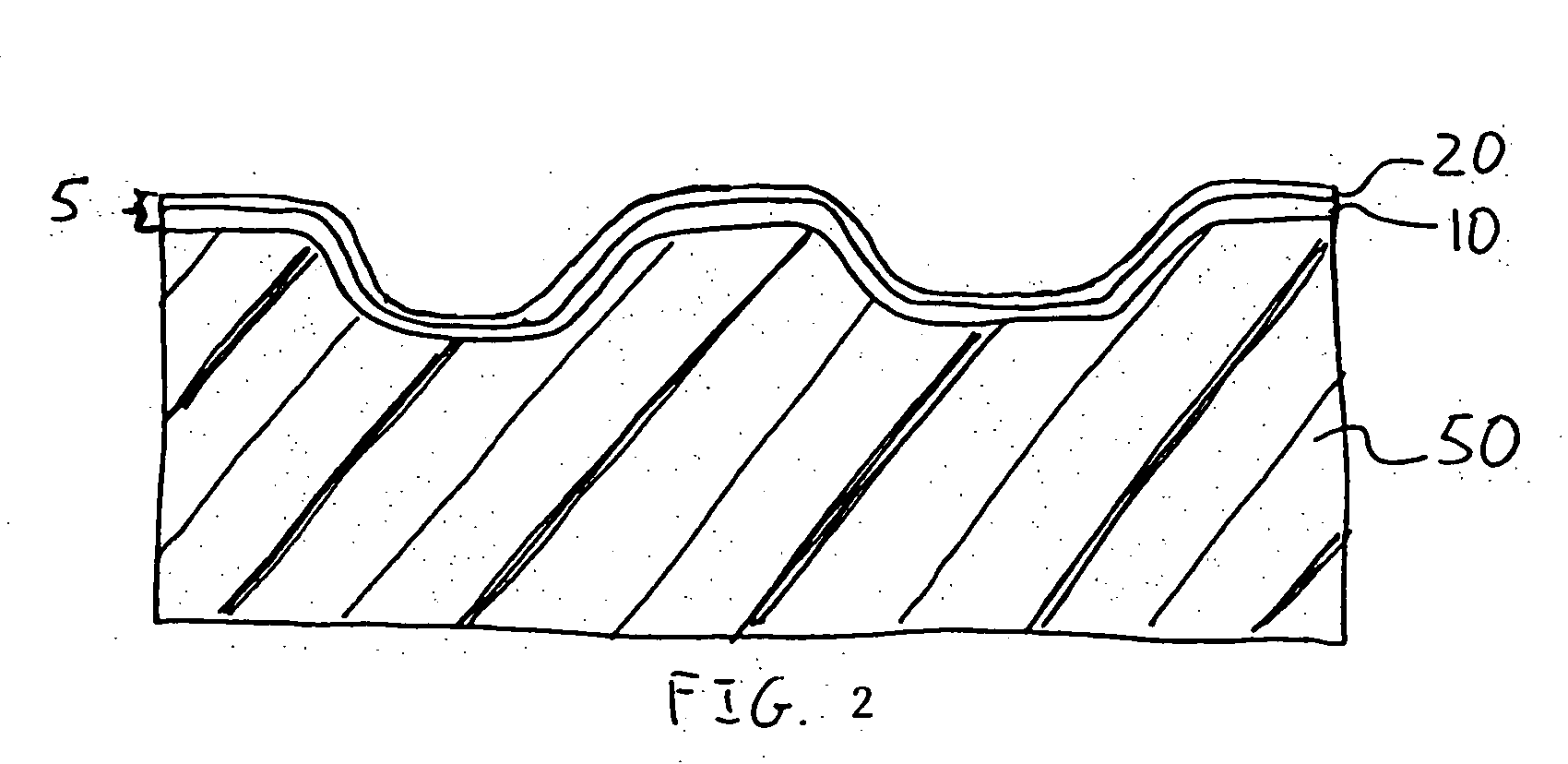

Nanoparticle coatings for flexible and/or drawable substrates

ActiveUS20050287348A1Better able to withstandHigh glossPretreated surfacesRecord information storageNanometreMaterials science

Owner:PPG IND OHIO INC

Carbon nanoparticle-containing lubricant and grease

InactiveUS20070158609A1Modulate viscosityImprove thermal conductivityMaterial nanotechnologyHeat-exchange elementsCarbon nanotubeMaterials science

The present invention relates to processes for preparing a stable suspension of carbon nanoparticles in a thermal transfer fluid to enhance thermal conductive properties, viscosity, and lubricity. One process is to disperse carbon nanoparticles directly into a thermal transfer fluid and other additives in the present of surfactants with intermittent ultrasonication. The second process is carried out in three stages. First, carbon nanoparticles are dispersed into a volatile solvent. Then, a thermal transfer fluid, surfactants, and other additives are added into this intermediate dispersion and mixed thoroughly. At last, the volatile solvent is removed to produce a uniformly dispersed nanofluid. The third process is to disperse carbon nanoparticles at an elevated temperature into a homogeneous mixture of surfactants and other additives in a thermal transfer fluid with help of a physical agitation. The present invention also relates to compositions of carbon nanoparticle nanofluids, such as nanolubricants and nanogreases. The nanofluid of the present invention is a dispersion of carbon nanoparticles, particularly carbon nanotubes, in a thermal transfer fluid in the present of surfactants. Addition of surfactants significantly increases the stability of nanoparticle dispersion. For nanogreases, carbon nanoparticles function both as a thickener to modulate viscosity and as a solid heat transfer medium to enhance thermal conductivity and high temperature resistance.

Owner:SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY

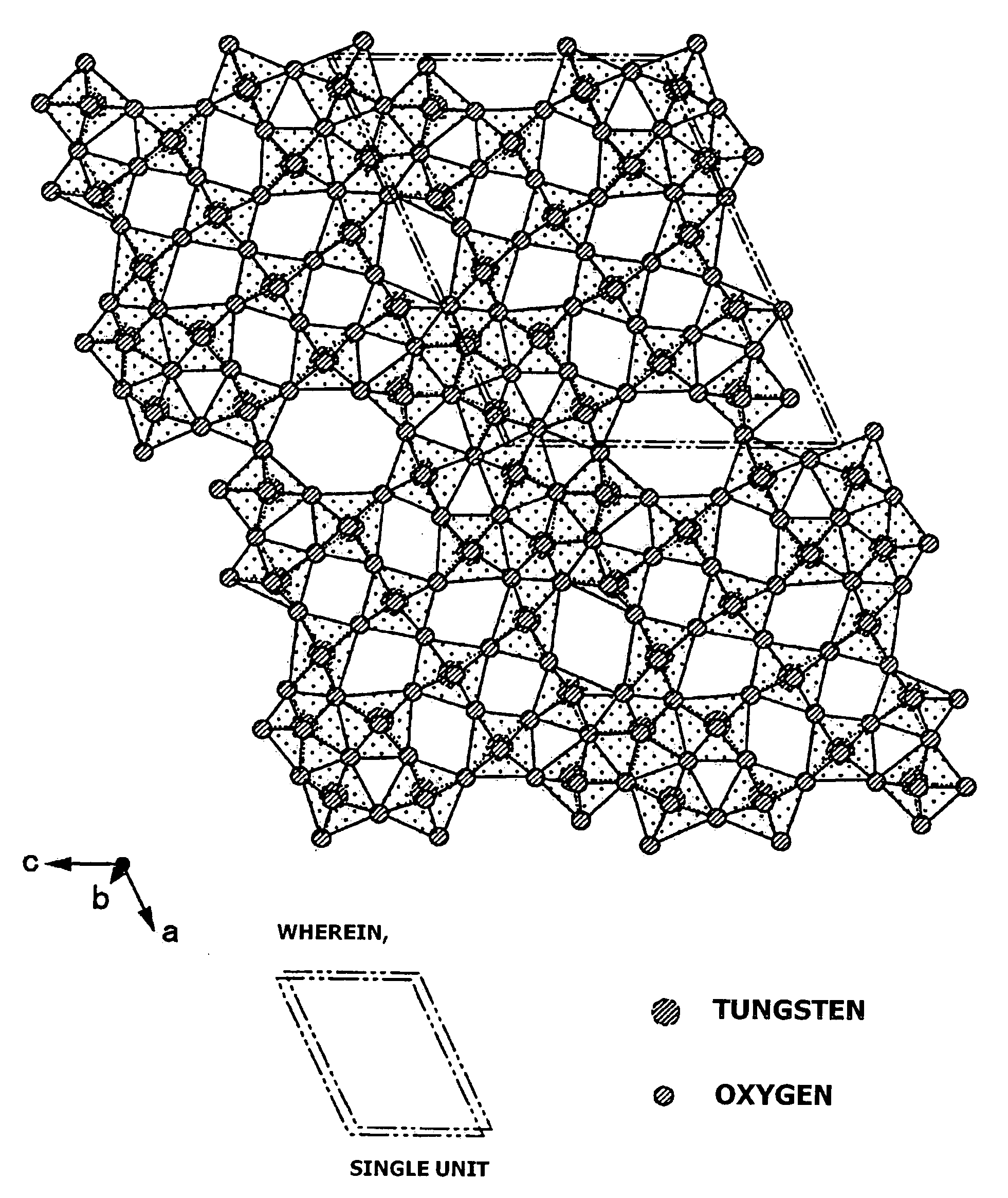

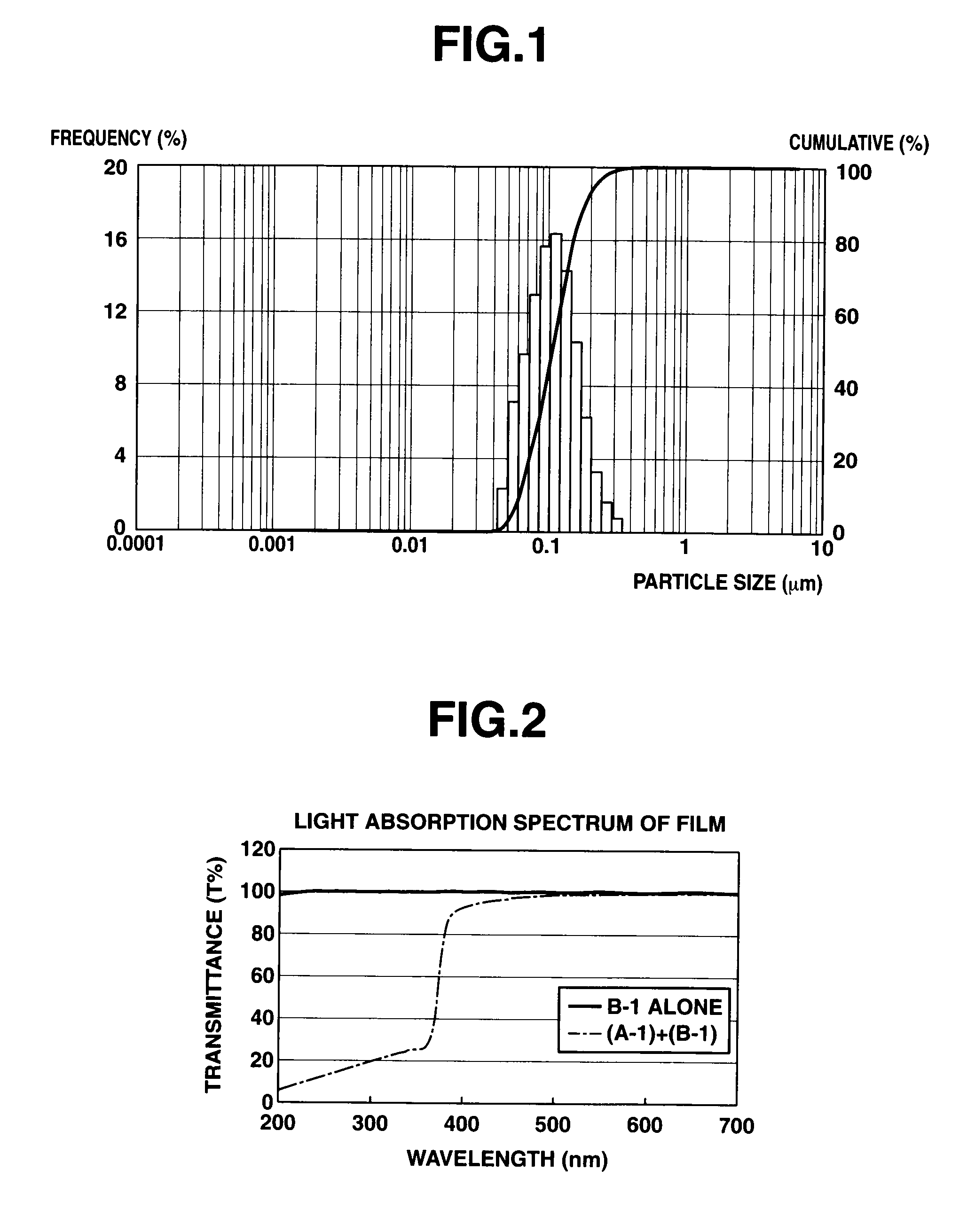

Conductive particle, visible light transmissive particle dispersed conductor, method for producing same, transparent conductive thin film, method for producing same, transparent conductive article using same, and infrared shielding article

ActiveUS20070187653A1Improve conductivityGood visible light transmittanceMaterial nanotechnologyConductive materialInfraredRare-earth element

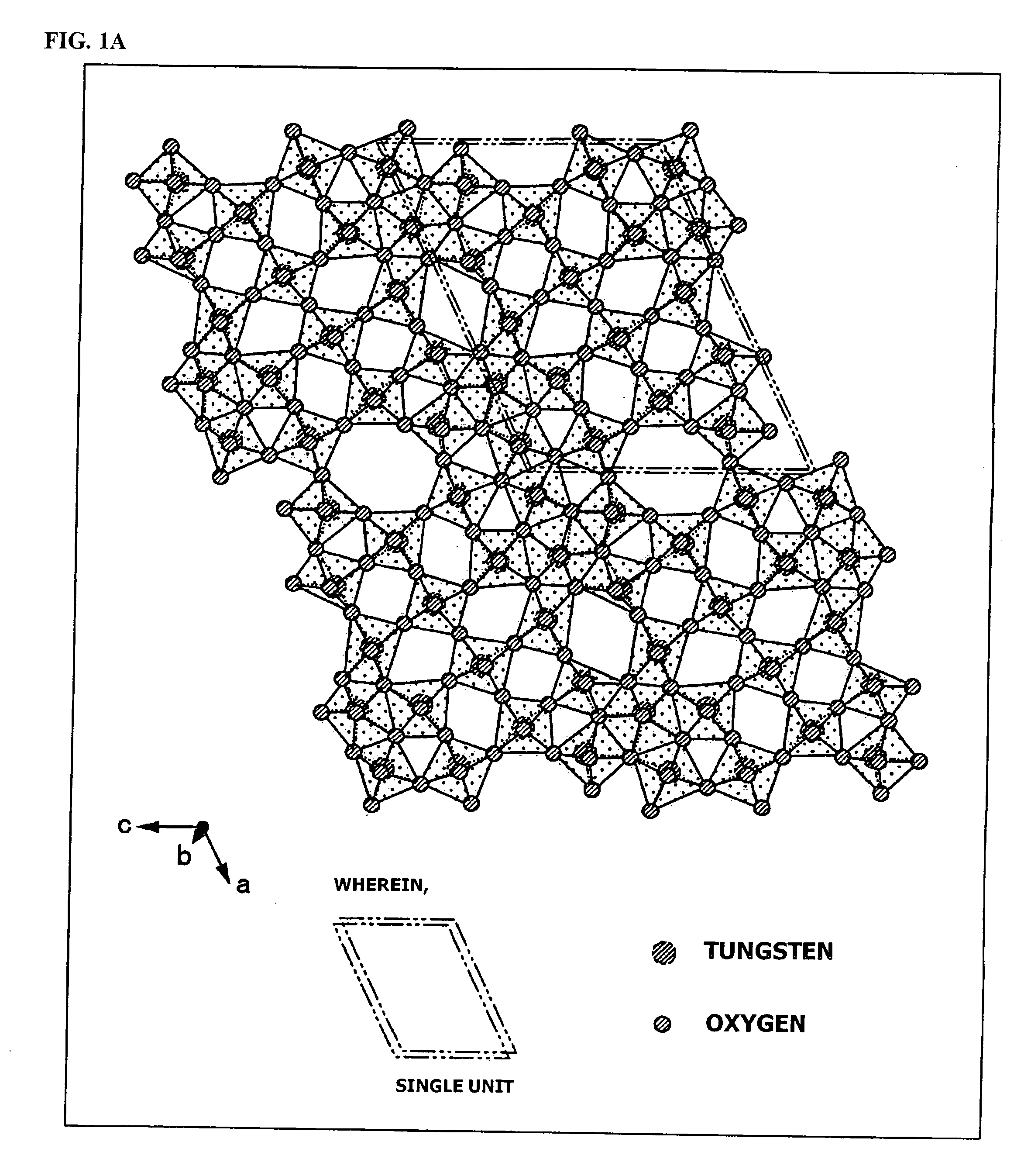

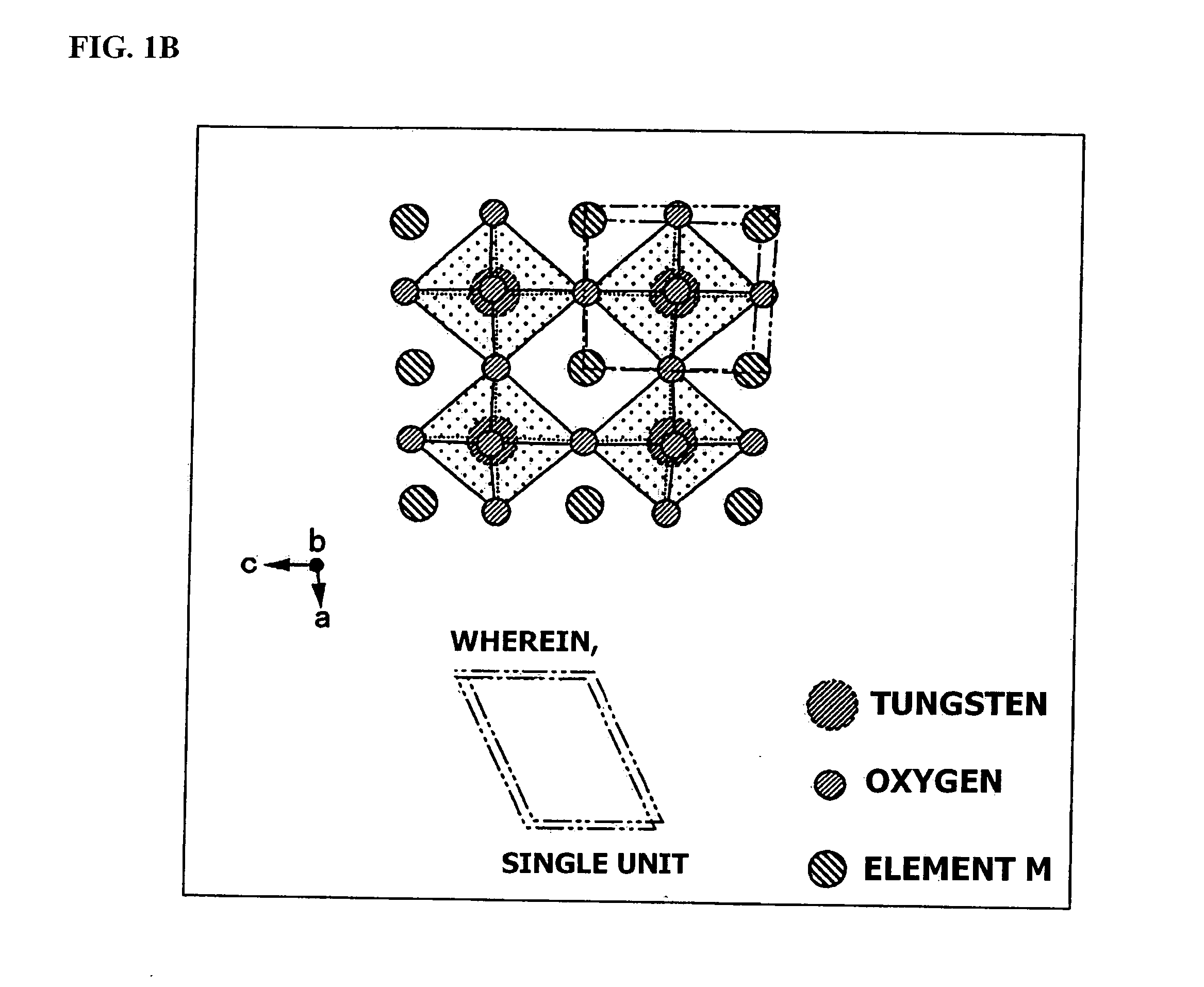

An object of the present invention is to provide an infrared-shielding nanoparticle dispersion that has a property whereby visible light is adequately transmitted, and light in the near-infrared region is adequately shielded; an infrared-shielding body manufactured using the infrared-shielding nanoparticle dispersion; a method for manufacturing infrared-shielding nanoparticles that are used in the infrared-shielding nanoparticle dispersion; and infrared-shielding nanoparticles manufactured using the method for manufacturing infrared-shielding nanoparticles. The present invention is a method for manufacturing infrared-shielding nanoparticle dispersion obtained by dispersing infrared-shielding nanoparticles in a medium, an infrared-shielding body manufactured by using the infrared-shielding nanoparticle dispersion, and infrared-shielding nanoparticles used in the infrared-shielding nanoparticle dispersion, wherein the infrared-shielding nanoparticles include a substance expressed by the general formula MXAYW(1-Y)O3 (where M is one or more elements selected from H, He, alkali metals, alkaline-earth metals, rare earth elements, Mg, Zr, Cr, Mn, Fe, Ru, Co, Rh, Ir, Ni, Pd, Pt, Cu, Ag, Au, Zn, Cd, Al, Ga, In, Tl, Si, Ge, Sn, Pb, Sb, B, F, P, S, Se, Br, Te, Ti, Nb, V, Mo, Ta, Re, Be, Hf, Os, Bi, and I; A is one or more elements selected from Mo, Nb, Ta, Mn, V, Re, Pt, Pd, and Ti; W is tungsten; O is oxygen; 0<X≦1.2; 0<Y≦1).

Owner:SUMITOMO METAL MINING CO LTD

Metal salt reduction to form alloy nanoparticles

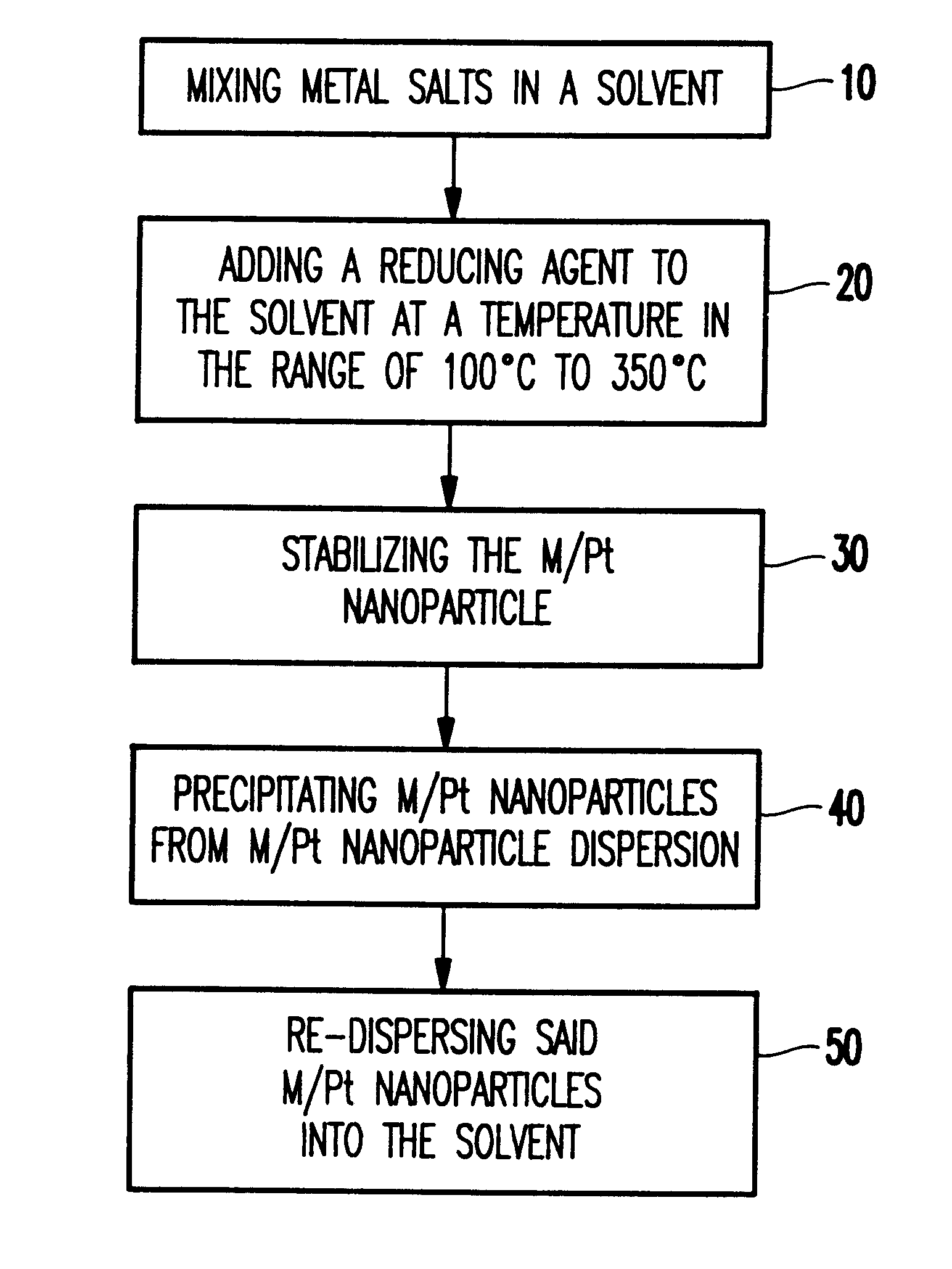

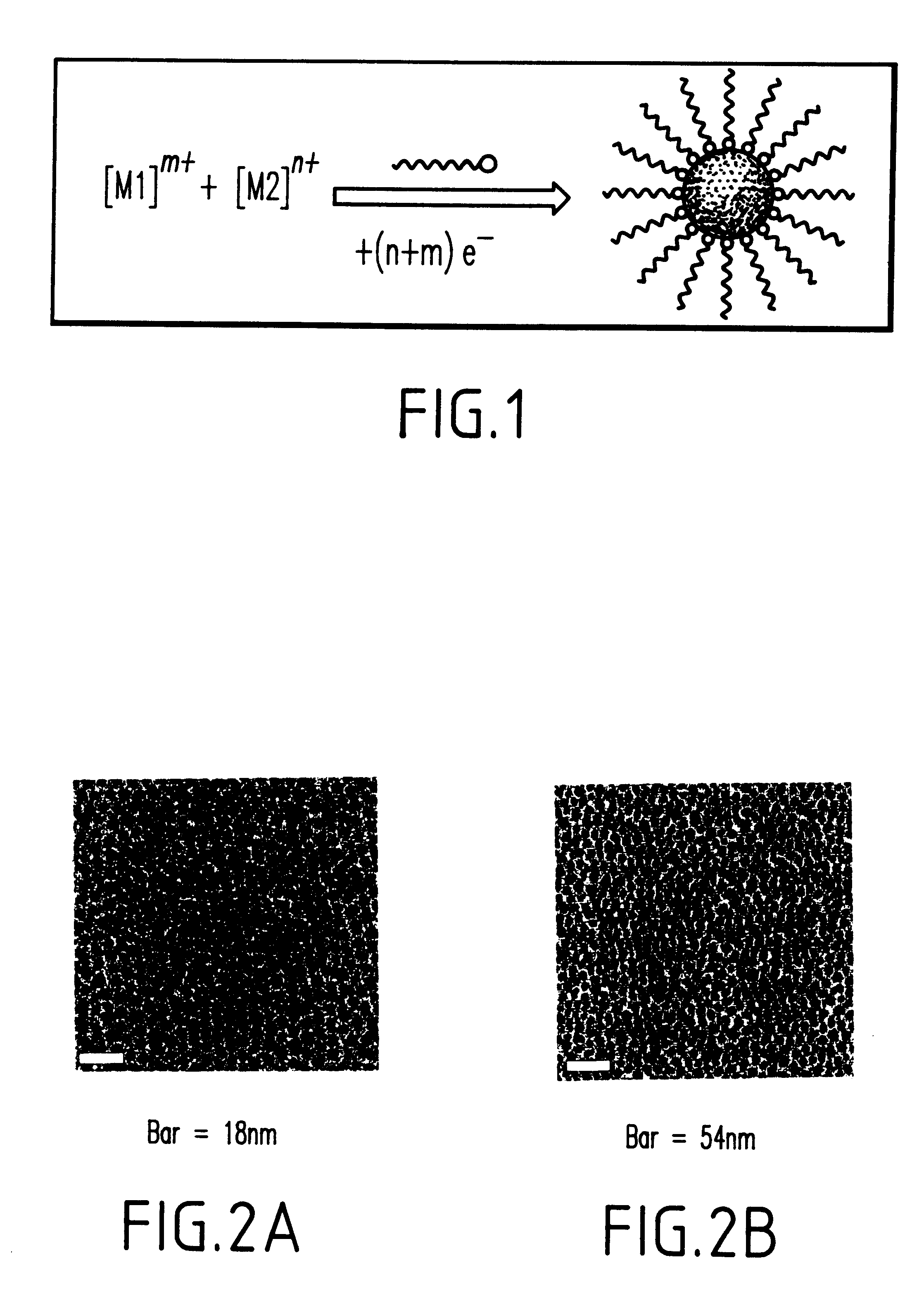

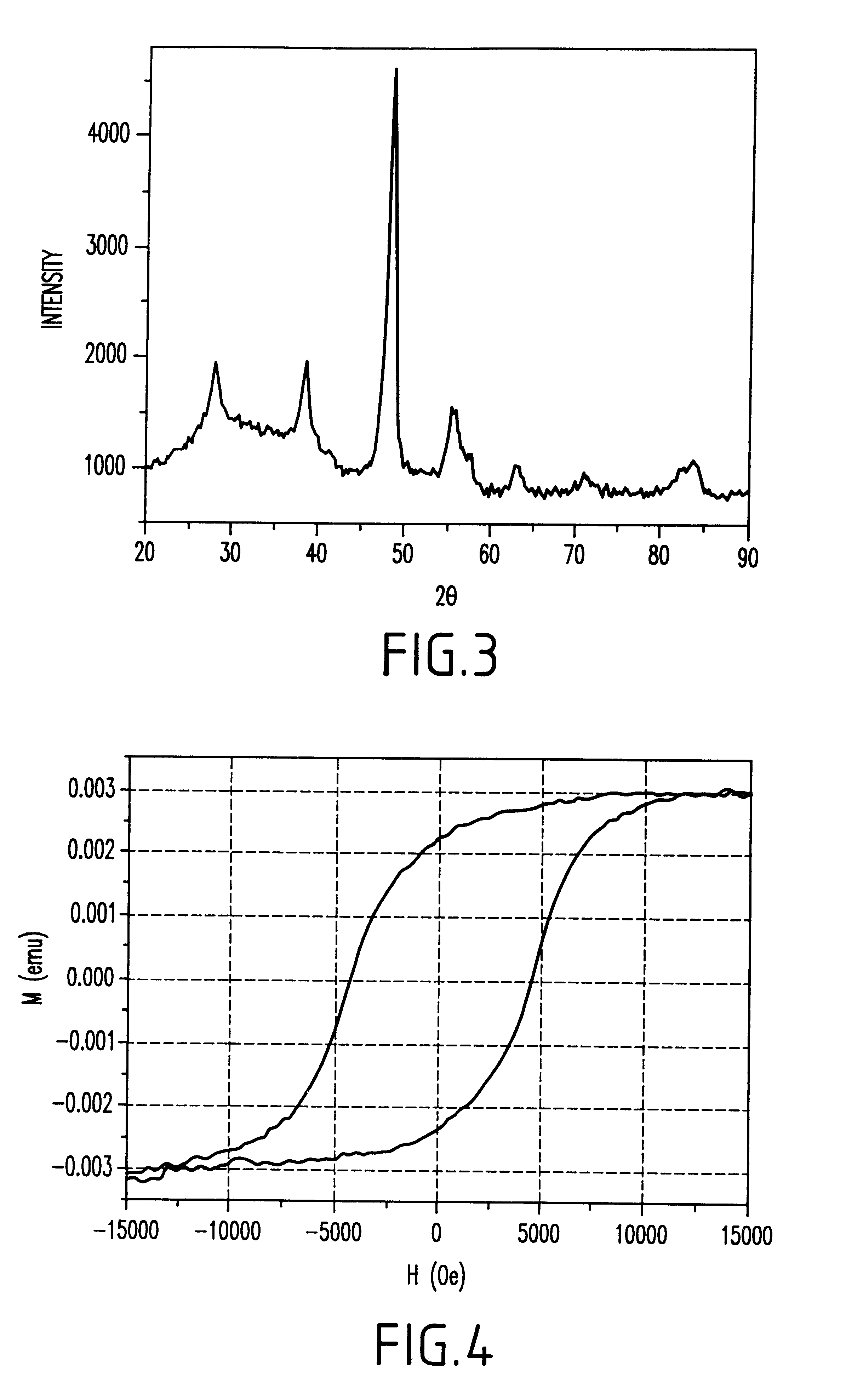

A method for making nanoparticles via metal salt reduction comprises, first, mixing metal salts in a solvent. Second, a reducing agent is added to the solvent at a temperature in the range of 100° C. to 350° C. Third, the nanoparticles dispersion is stabilized. Fourth, the nanoparticles are precipitated from the nanoparticle dispersion. Finally, the nanoparticles are re-dispersed into the solvent. The metal salt comprises a combination of FeCl2, FeCl3, Fe(OOCR)2, Fe(RCOCHCOR)3, CoCl2, Co(OOCR)2, Co(RCOCHCOR)2, and one of Pt(RCOCHCOR)2, PtCl2. The reducing agent comprises one of MBR3H, MH, M naphthalides, and polyalcohol; wherein R comprises one of H and an alkyl group, wherein M comprises one of Li, Na, and K. Long chain alkyl diols, and alkyl alcohol, can be used as a co-surfactant or a co-reducing agent to facilitate nanoparticle growth and separation.

Owner:GOOGLE LLC

Synthesis of Metallic Nanoparticle Dispersions

InactiveUS20070144305A1Material nanotechnologyTransportation and packagingMaterials scienceMetal nanoparticles

Owner:PCHEM ASSOC

Carbon naoparticle-containing hydrophilic nanofluid

InactiveUS20070158610A1Stabilize nanoparticle dispersionImprove thermal conductivityHeat-exchange elementsCarbon nanotubeHydrophile

The present invention relates to a process for preparing a stable suspension of carbon nanoparticles in a hydrophilic thermal transfer fluid to enhance thermal conductive properties and other characteristics such as freezing point of an antifreeze coolant. The process involves the step of dispersing carbon nanoparticles directly into a mixture of a thermal transfer fluid and other additives in the present of surfactants with intermittent ultrasonication. The present invention also relates to the composition of a hydrophilic nanofluid, which comprises carbon nanoparticles, particularly carbon nanotubes, a hydrophilic thermal transfer fluid, and at least one surfactant. Addition of surfactants significantly increases the stability of nanoparticle dispersion.

Owner:SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY

Preparation method of aqueous super-hydrophobic/super-hydrophobic and oileophobic coating

InactiveCN106811114AExcellent superhydrophobicityExcellent super amphiphobic propertiesAntifouling/underwater paintsPaints with biocidesNanoparticles dispersionSolvent

The invention discloses a preparation method of a water-based super-hydrophobic or super-amphiphobic coating. Nano-particles are ultrasonically dispersed into water, the pH of the solution is adjusted to obtain a nano-particle dispersion; The silane coupling agent is hydrolyzed under stirring to obtain an organosilane polymer / nanoparticle composite suspension; and then applied to the surface of the base material by spraying or dipping to obtain a water-based superhydrophobic / superamphiphobic coating. The present invention successfully prepares a water-based super-hydrophobic or super-amphiphobic coating with excellent performance without using any additives (organic solvent, surfactant and water-based solvent), and has many advantages such as water-based environmental protection, low price and excellent performance. , It has broader application prospects in the fields of self-cleaning surface, anti-corrosion coating, oil pollution prevention and oil transportation.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

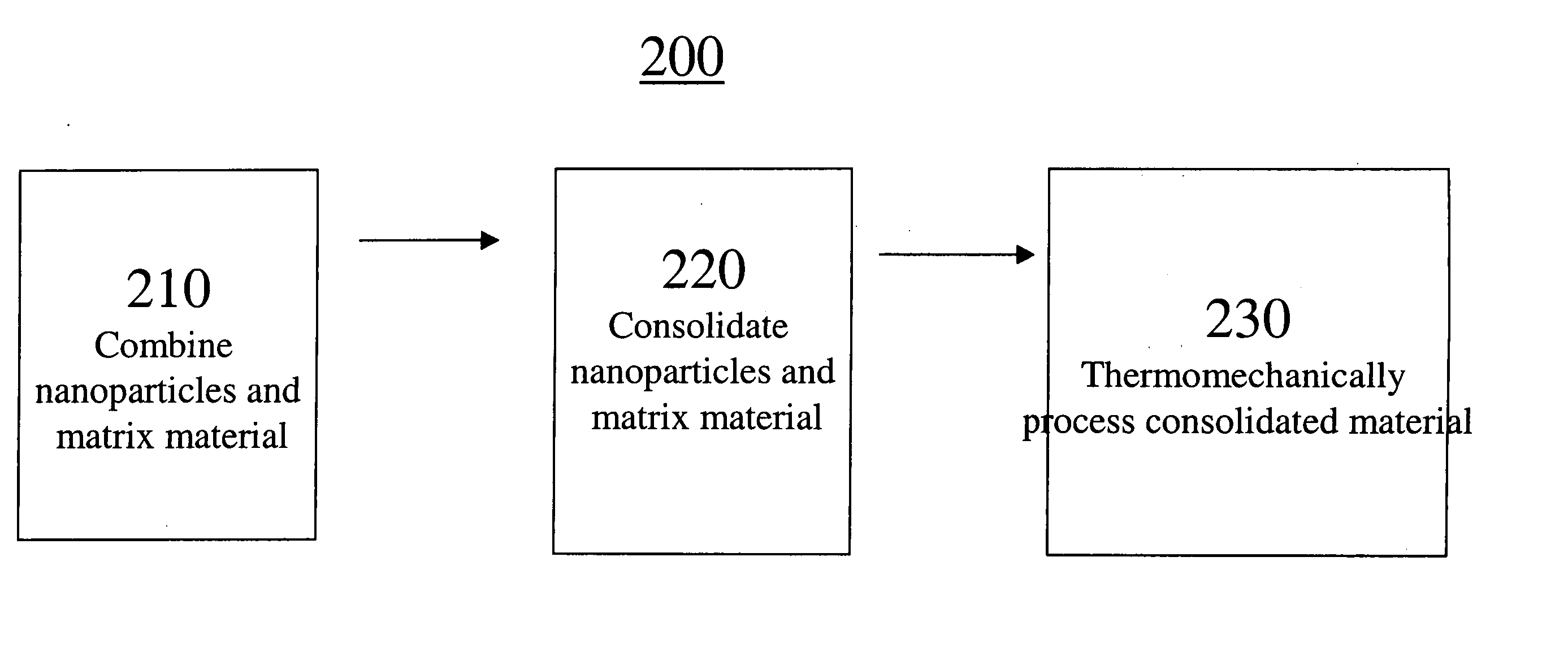

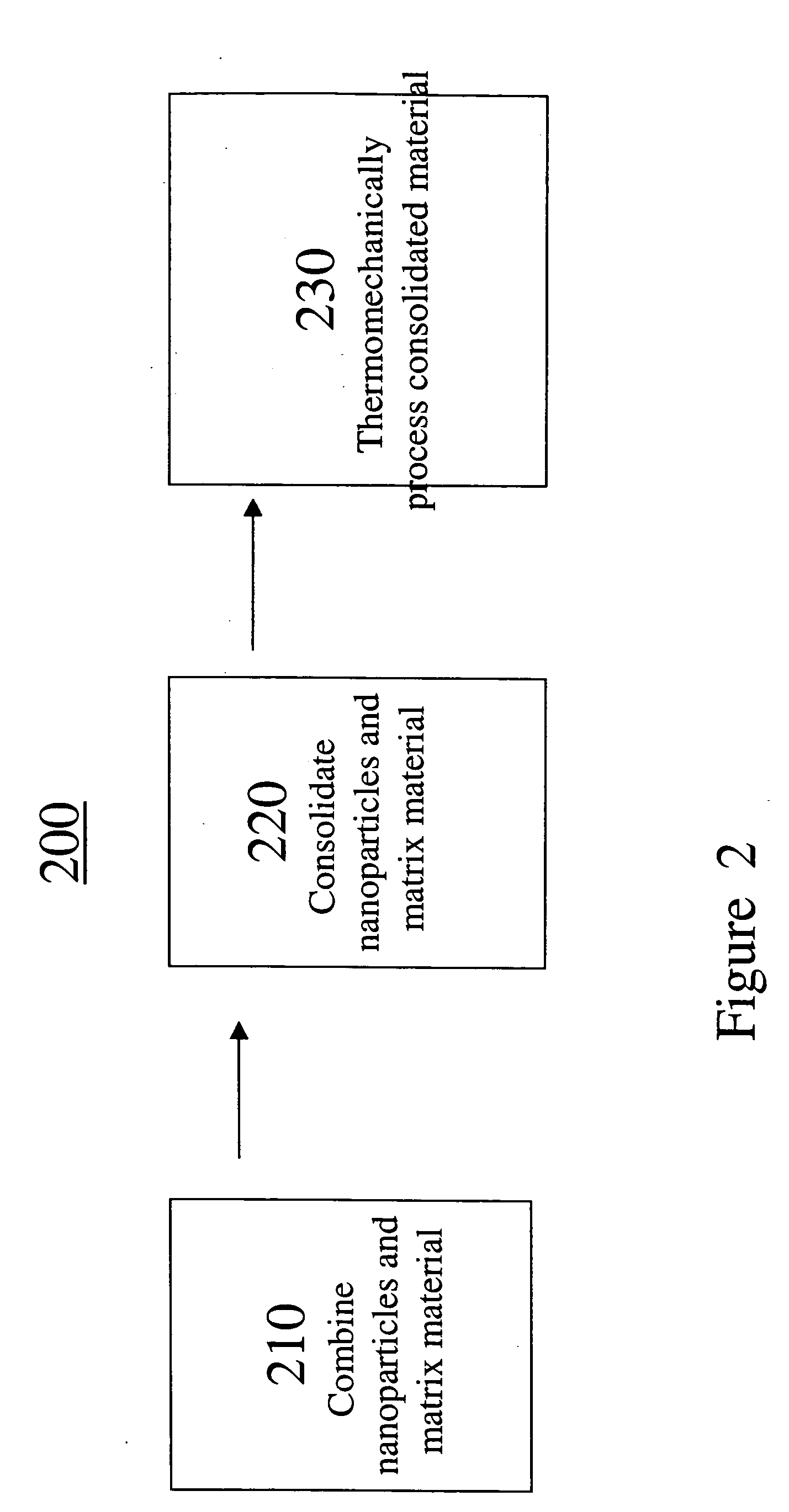

Metallic alloy nanocomposite for high-temperature structural components and methods of making

InactiveUS20050133121A1Increase volume fractionTransportation and packagingMetal-working apparatusNanocompositeAirplane

A nanocomposite comprising a plurality of nanoparticles dispersed in a metallic alloy matrix, and a structural component formed from such a nanocomposite. The metallic matrix comprises at least one of a nickel-based alloy and an iron-based alloy. The nanocomposite contains a higher volume fraction of nanoparticle dispersoids than those presently available. The structural component include those used in hot gas path assemblies, such as steam turbines, gas turbines, and aircraft turbine. A method of making such nanocomposites is also disclosed.

Owner:GENERAL ELECTRIC CO

Process for Solvent Shifting a Nanoparticle Dispersion

ActiveUS20100152077A1Less polar phaseEfficient and economical processSolvent extractionTransportation and packagingSolventNanometre

A process for replacing the continuous phase of a nanoparticle dispersion with a less polar phase, includes filtering the dispersion through a semi-permeable membrane filter to remove the continuous phase, and introducing a less polar phase.

Owner:CERION

Non ionic/electrolyte, liquid/gaseous, mechanically refined/nanoparticle dispersion Building Materials/High Wear-Heat Resistant Part Brushes, Windings, Battery Cells, Brake Pads, Die Cast Molding, Refrigeration, Polarized/Integrated Optical, Spectrometric Processors, Central Processor Unit Processors, Electronic Storage Media, Analogous Series/Parallel Circuit Generators/Transceivers, Particulate Matter PM Carbonaceous-Polyamide, Crystalline Silica, and Cellulosic Filament Extraction/Miners Suit

InactiveUS20140178513A1High wear-heat resistant partAuxillary shaping apparatusShaping pressTransceiverTransformer

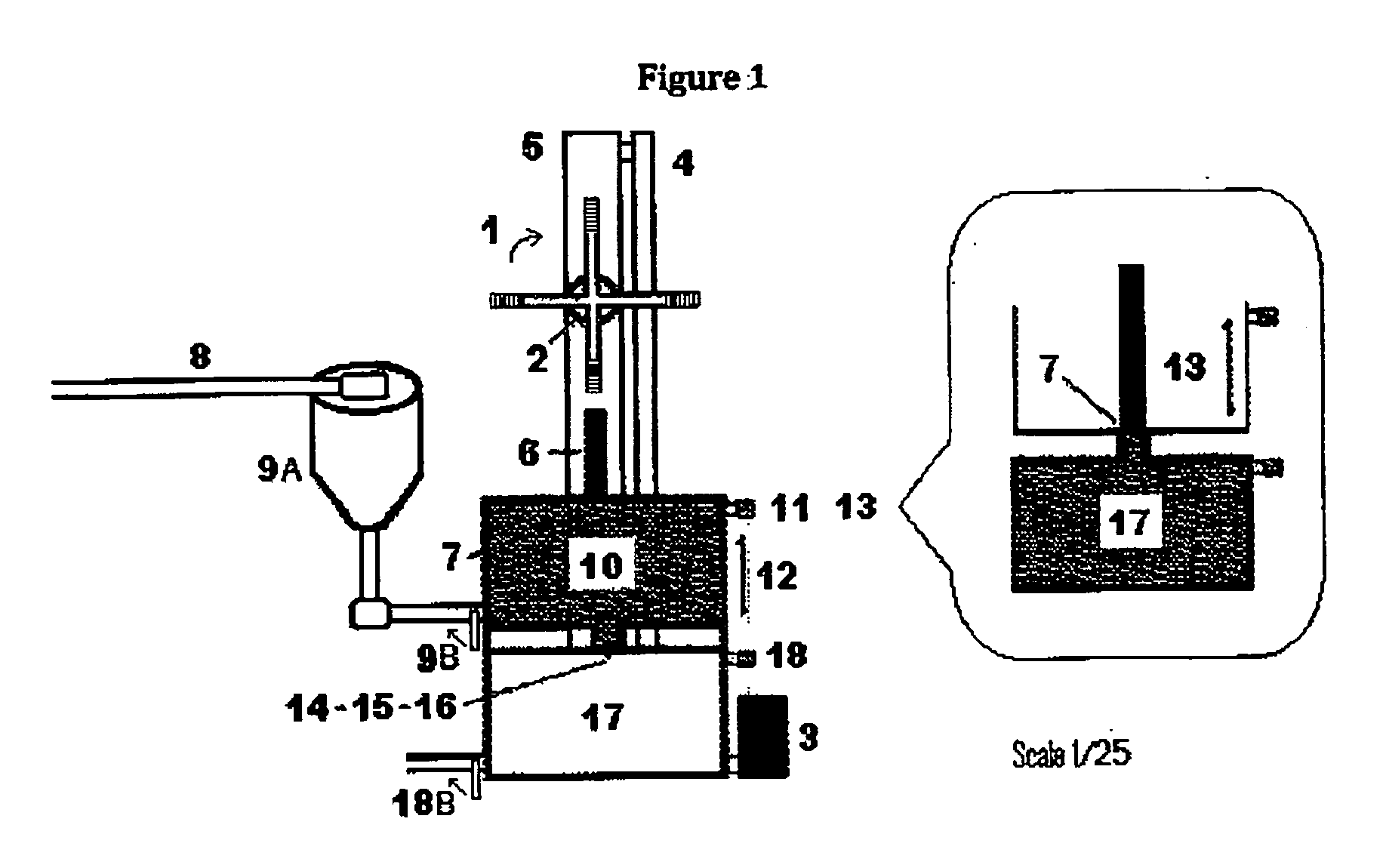

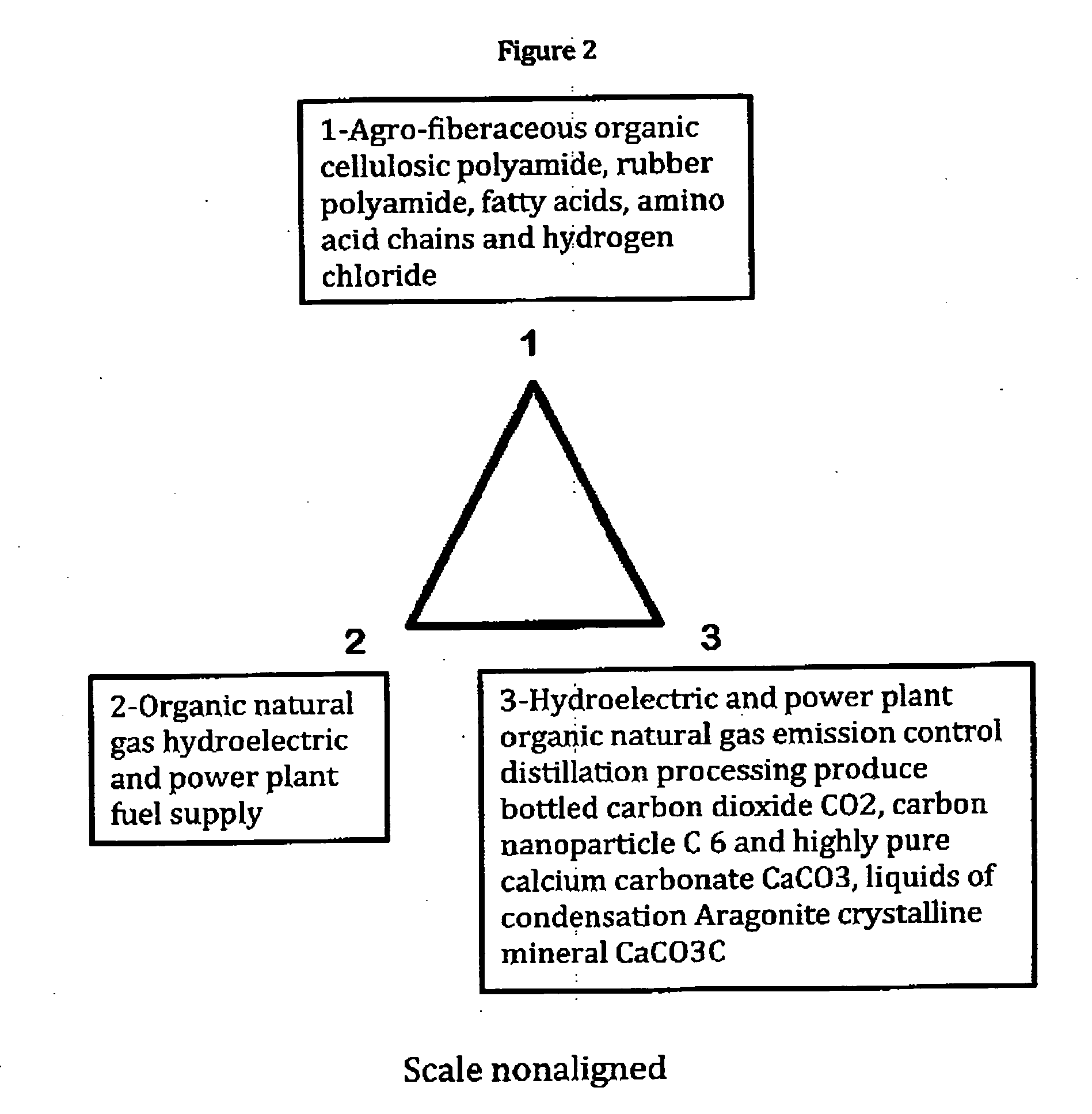

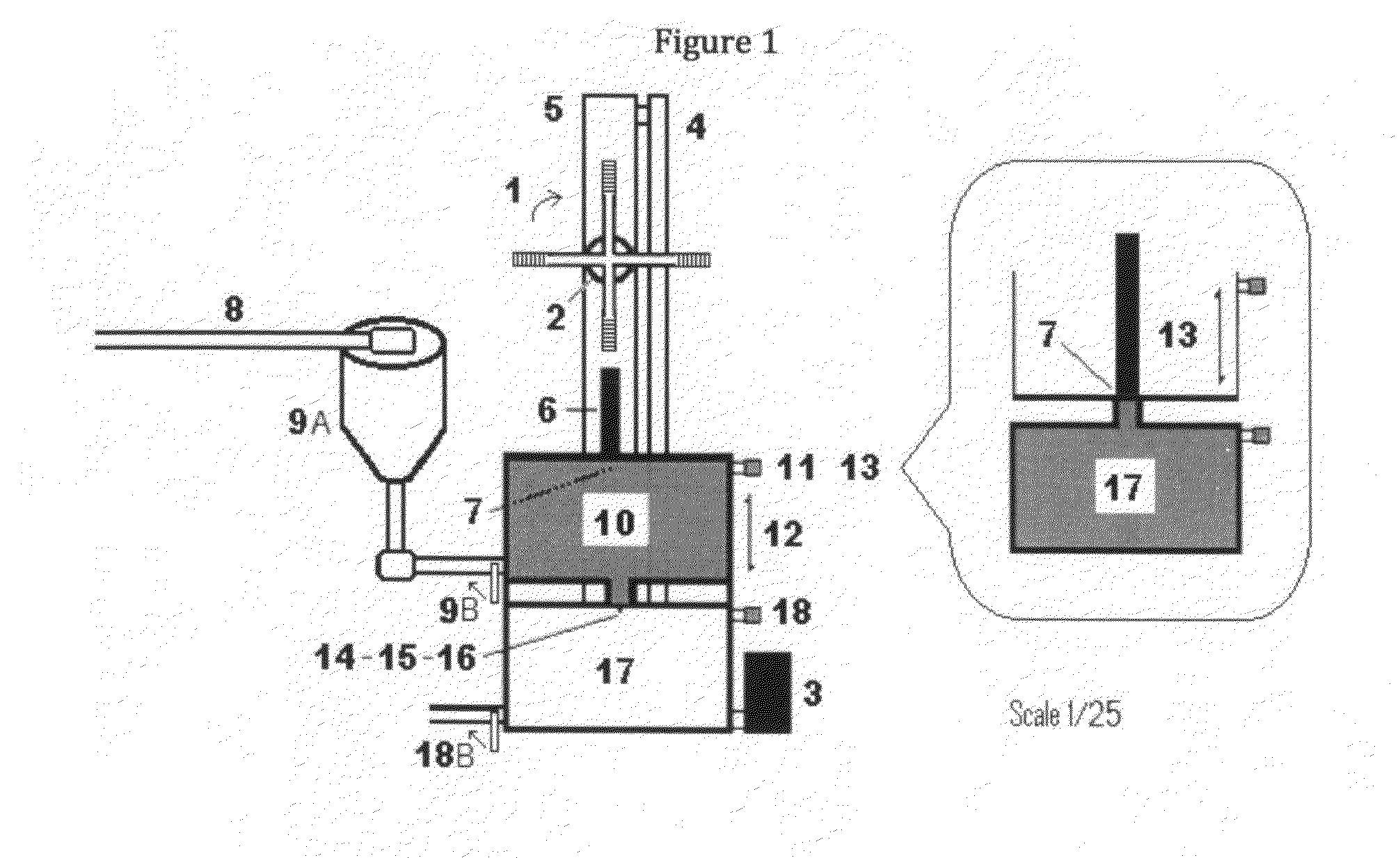

The variable hydraulic press and distillation reservoir process scientific formula non ionic or electrolyte mechanically refined and nanoparticle dispersion preform slurry extrusion with or without ionic suspension Preform slurry high wear-heat resistant parts electronic composite coils, windings, annealing, drawn, spun, coils, windings, wire, woven textile mesh, shielding, parts brushes, inductors, antinode couplers, electric rheostats, starters, motors, alternators, generators, ionic suspension enhanced composite coils, composite windings, spun wound coils and windings beryllium Be4, magnesium Mg12, copper Cu29 and carbon nanofoam C6, electronic parts capacitors, ionic suspension circuit battery cells, electronic parts rheostats, resistors, transformers, transducers, rectifiers, power supplies, or heat sinks Preform slurry high wear-heat resistant parts aerospace, automotive, and transportation brake calipers, rotors, pads, and bushings Preform slurry non ionic or electrolyte mechanically refined and nanoparticle high wear-heat resistant parts precision casting molds 2.5 phase die cast molding Building Materials fine concrete, mortar, brick, and tiles.

Owner:MATTHEWS ROBERT RICHARD

Anode, cathode, grid and current collector material for reduced weight battery and process for production thereof

InactiveUS20090317710A1Improve adhesionEconomy in coatingActive material electrodesJackets/cases materialsPolymer substrateMaterials science

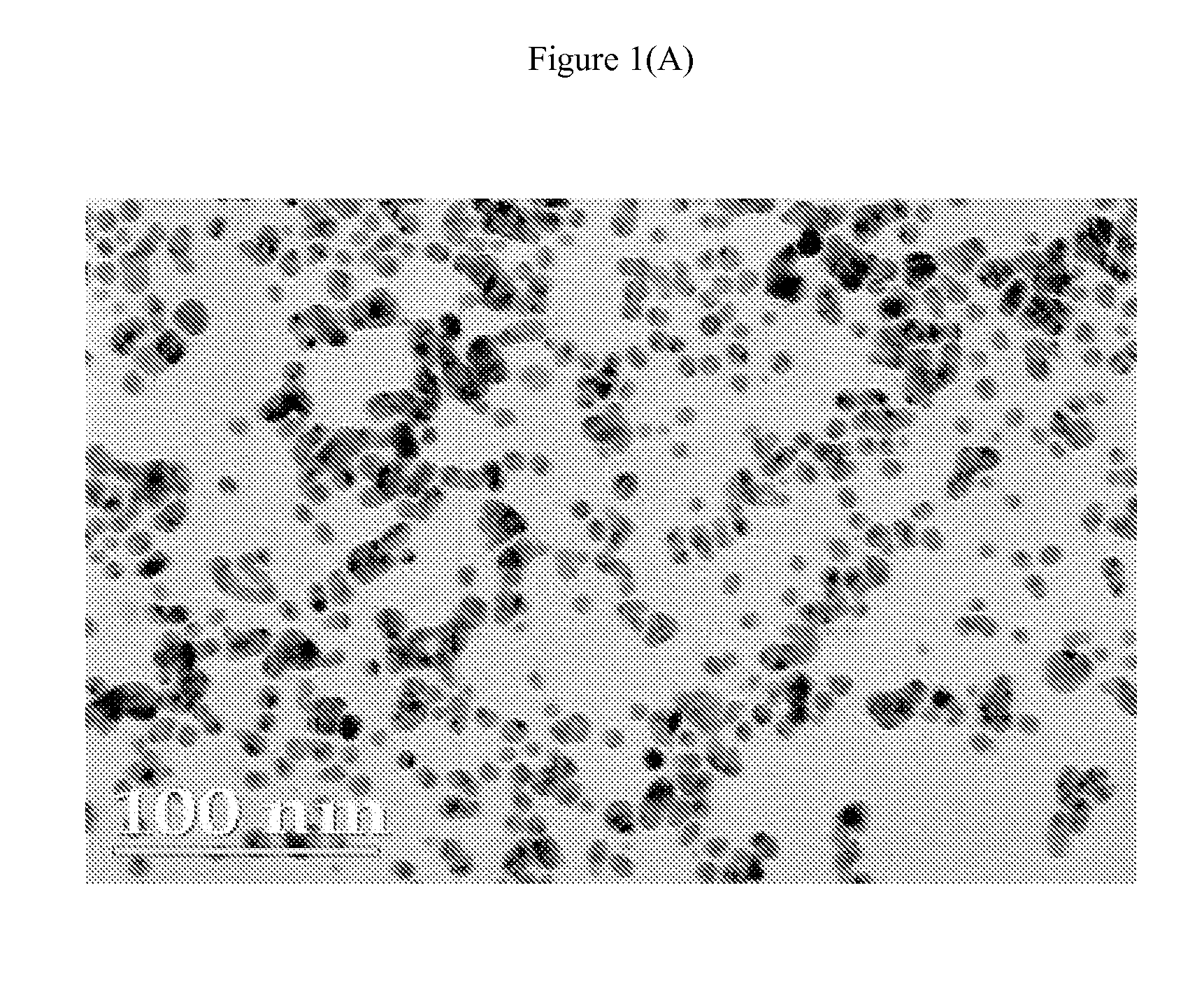

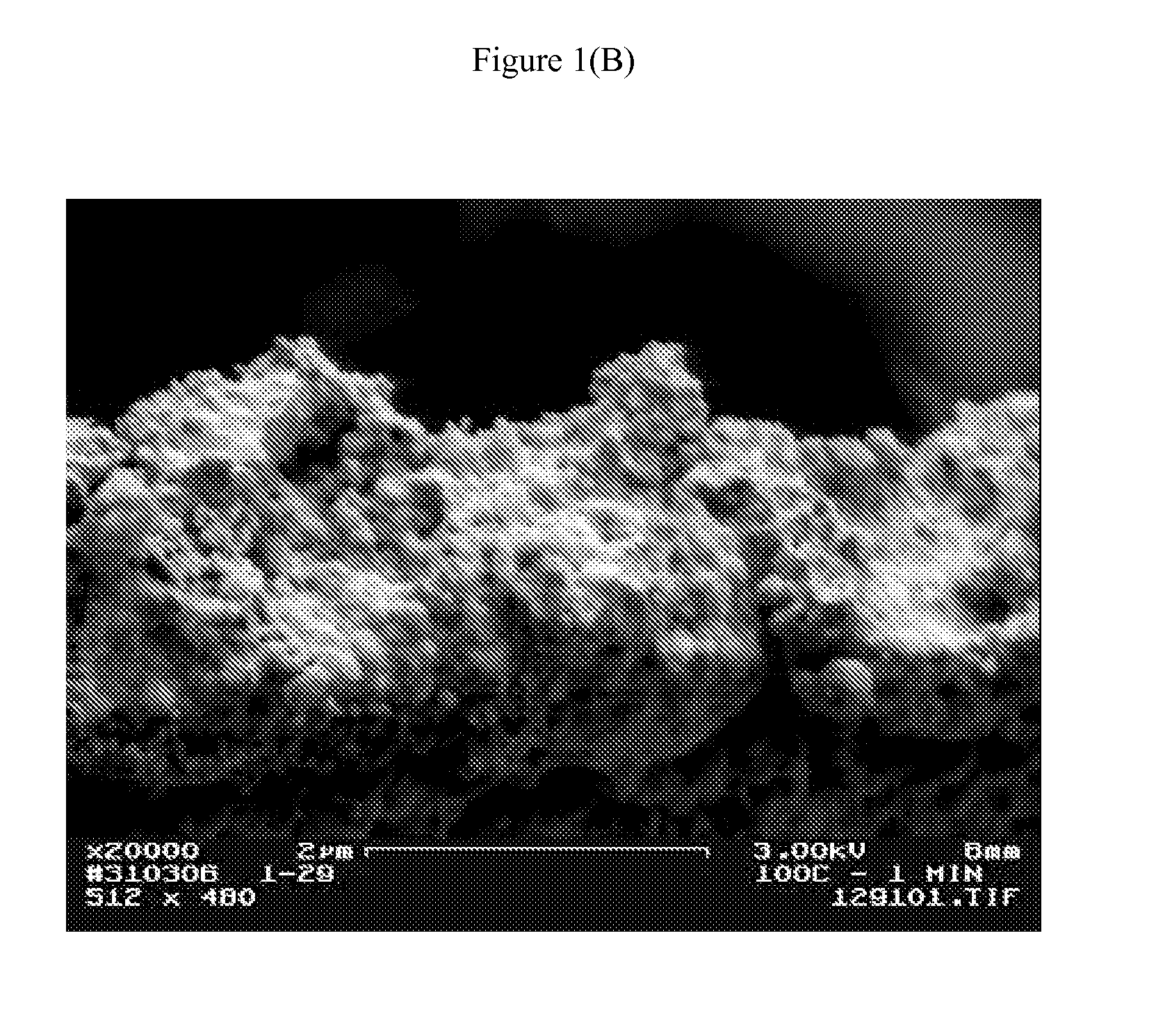

A process for producing lightweight materials for a battery comprises lightweight polymer substrate coated with dispersions of nano particles, conductive matrixes and active material.

Owner:MYSTICMD

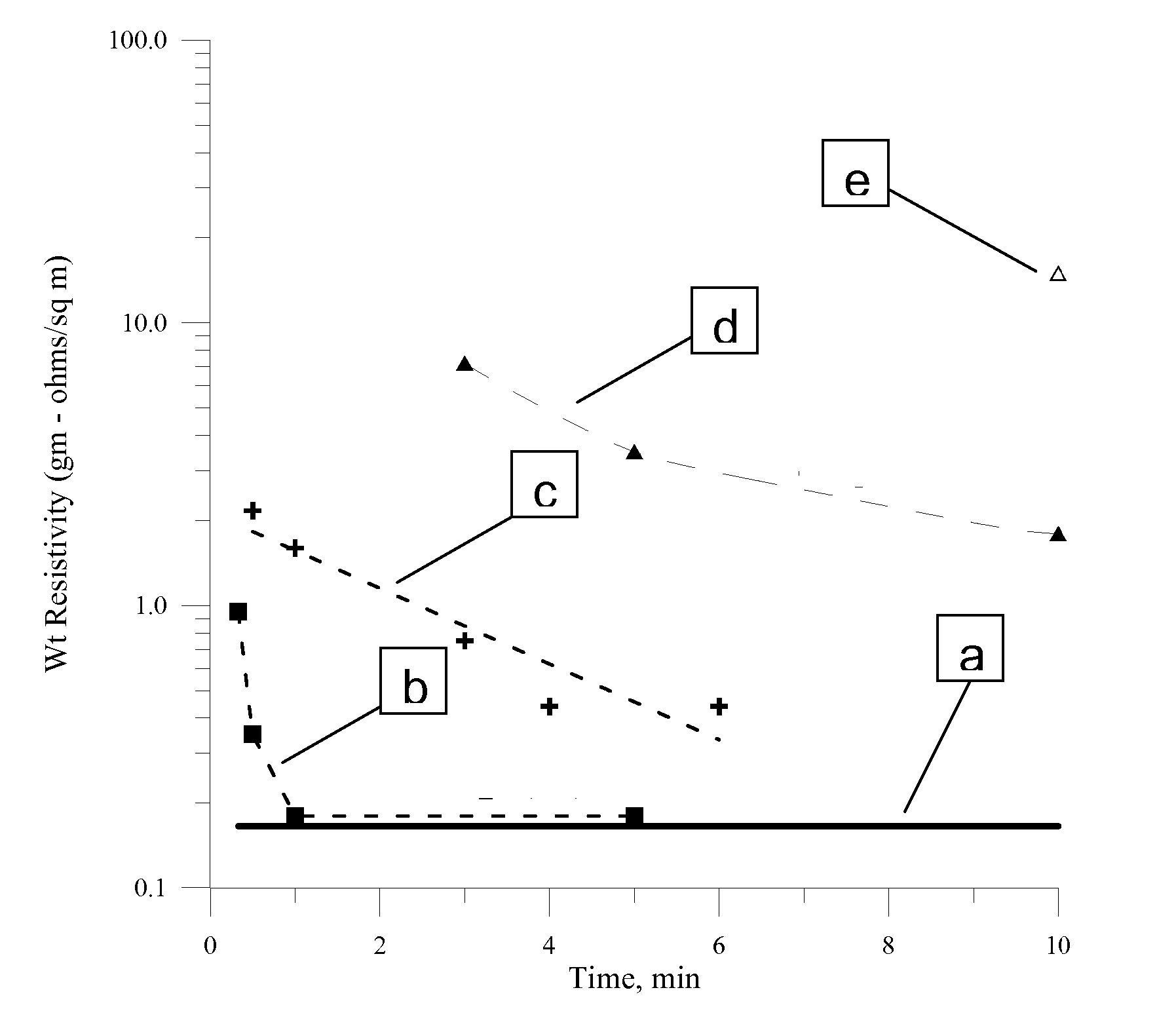

Synthesis of metallic nanoparticle dispersions capable of sintering at low temperatures

A process is described for the synthesis of metallic nanoparticles by chemical reduction of metal salts in the presence of organic ligands capable of binding to the metal particle surfaces and stabilizing them against agglomeration. The resultant nanoparticles or dispersions of the particles can be sintered into highly conductive films or traces at temperatures as low as 80° C. in 10 minutes or less.

Owner:NCC NANO LLC

Pigment dispersant

A pigment dispersant is disclosed comprising a tri-block copolymer having a first block comprising a glycidyl (meth)acrylate reacted with a napthoic acid, a second block comprising (meth)acrylic acid alkyl esters, and a third block comprising (meth)acrylic acid alkyl esters, wherein said third block is different from said second block. The dispersant is suited for use in a nanoparticulate dispersion comprising pigment particles having an average primary particle size of less than 100 nm.

Owner:PPG IND OHIO INC

Uv-shielding silicone coating composition and coated article

ActiveUS20100221557A1Solve the lack of durabilitySolve the lack of resistanceLayered productsCoatingsUltravioletSolvent

A UV-shielding silicone coating composition comprises (A) a dispersion in a dispersing medium of composite zinc oxide nanoparticles which are obtained by coating zinc oxide nanoparticles with an oxide or hydroxide of Al, Si, Zr or Sn, the dispersion having a photocatalytic degradability of up to 25%, (B) a silicone resin, (C) a curing catalyst, and (D) a solvent, the solids content of composite zinc oxide nanoparticle dispersion (A) being 1 to 50% by weight based on silicone resin (B). The composition is transparent to visible light, mar resistant, UV-shielding, weatherable, and durable.

Owner:SHIN ETSU CHEM IND CO LTD

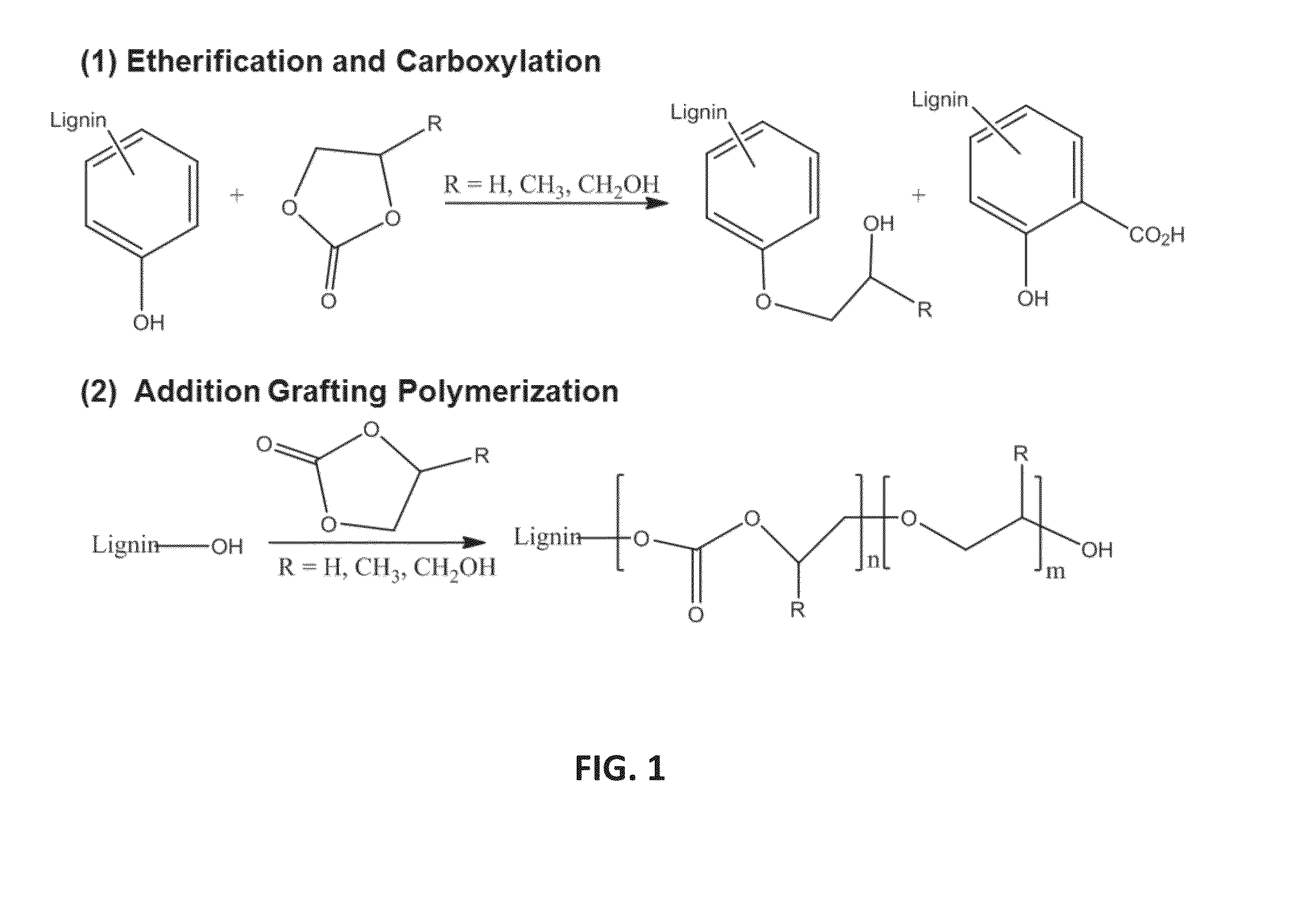

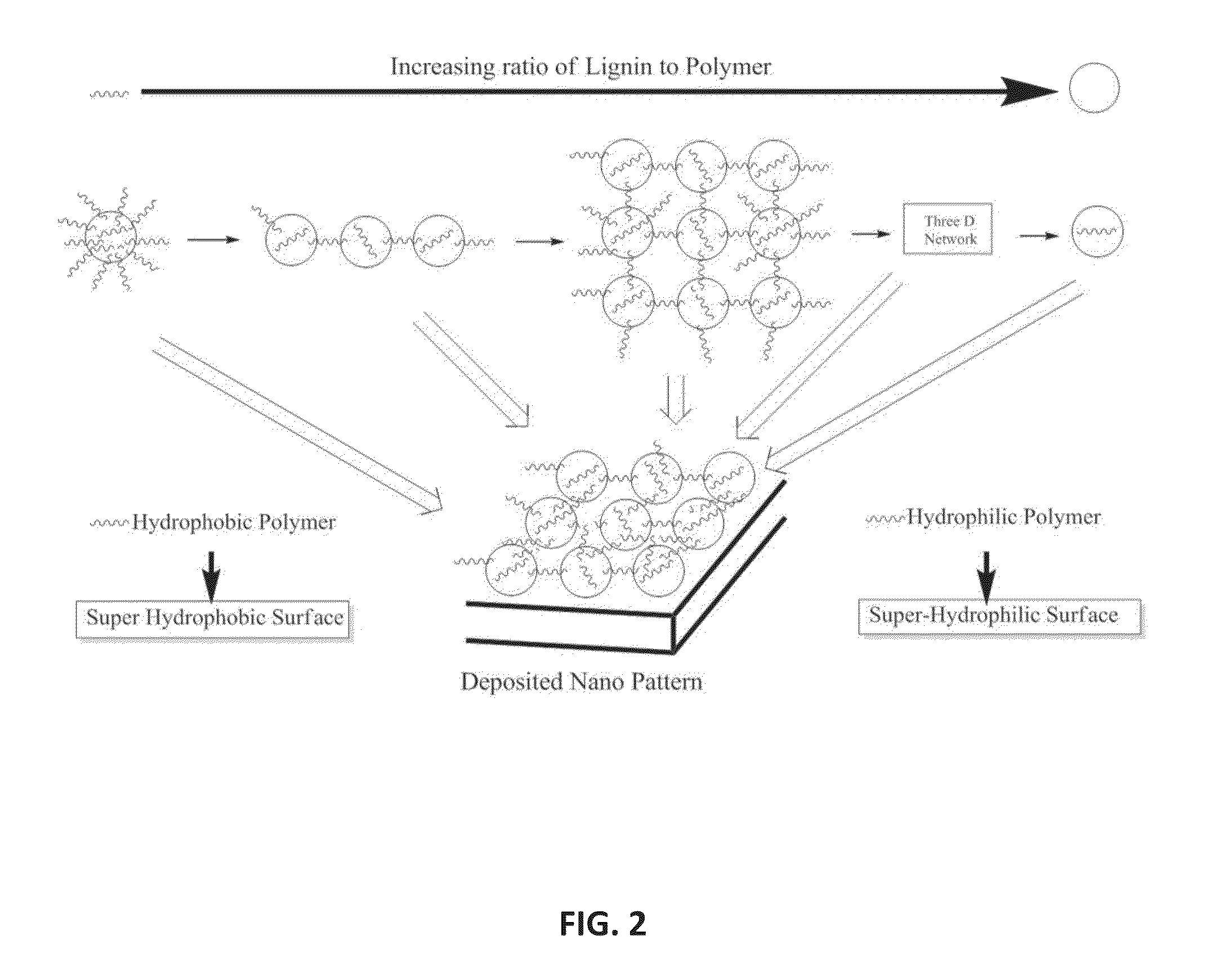

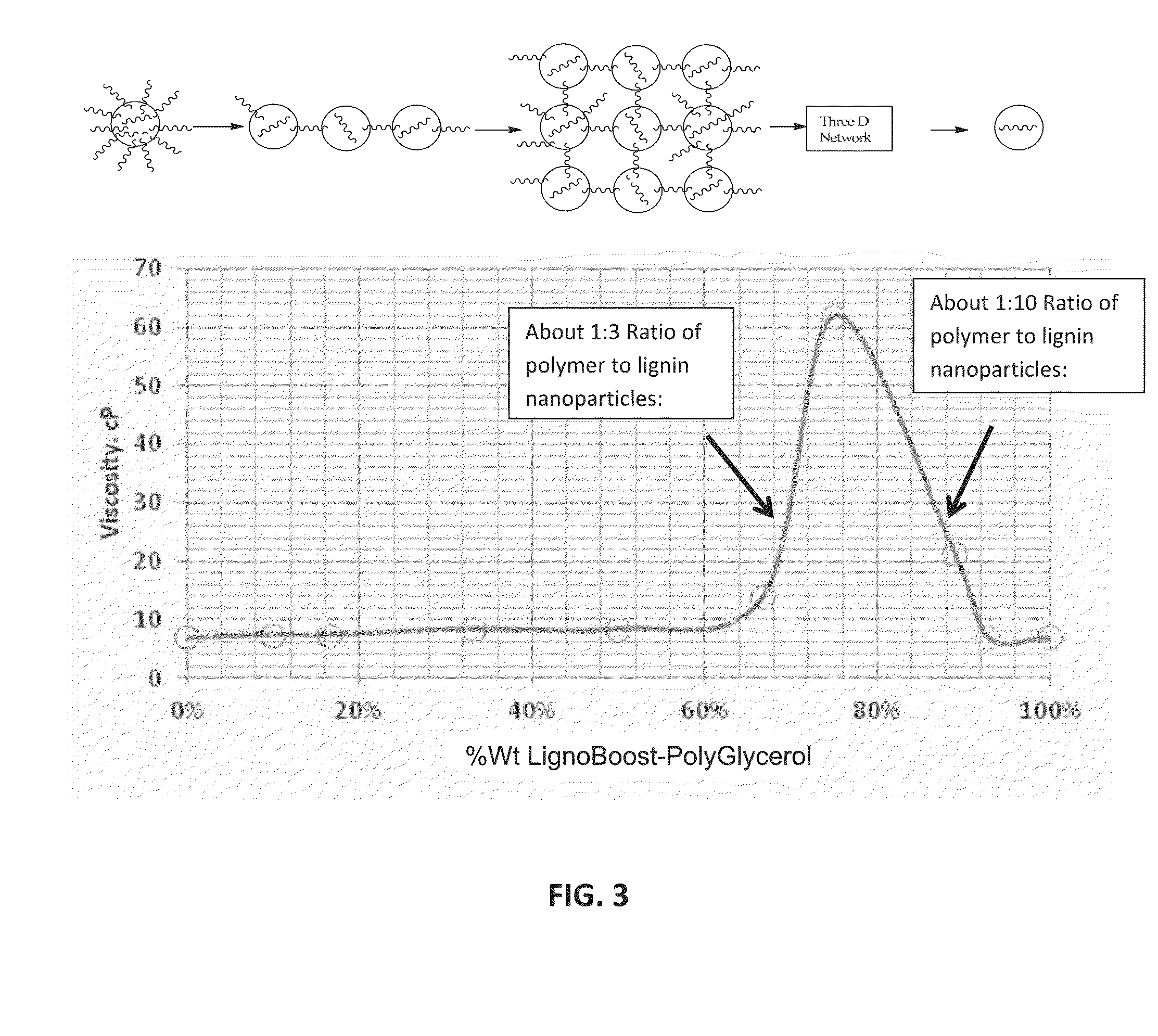

Lignin nanoparticle dispersions and methods for producing and using the same

A mild, simple process of preparing lignin nanoparticle dispersions is disclosed. Additionally, compositions and methods of making lignin nanoparticle-polymer complexes comprising derivatized and / or non-derivatized lignin nanoparticle dispersions and water soluble and / or water dispersible polymers are disclosed. Further, methods of using at least one of the lignin nanoparticle dispersions, derivatized lignin nanoparticle dispersions, and / or the lignin nanoparticle-polymer complex to impart rinse-resistant properties, such as hydrophilic properties, to substrates, or function as tunable nanoparticle surfactants are disclosed.

Owner:SOLENIS TECH CAYMAN

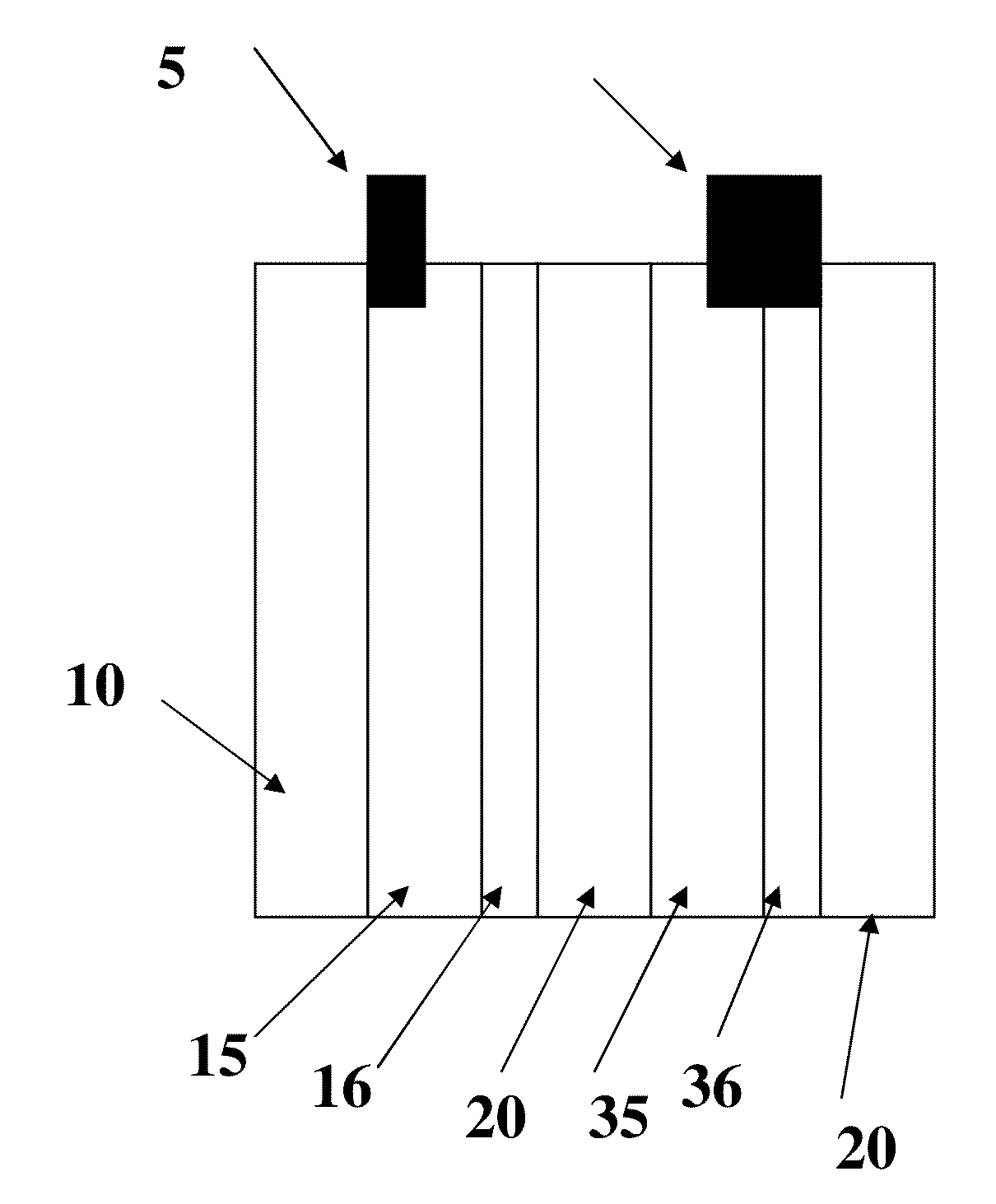

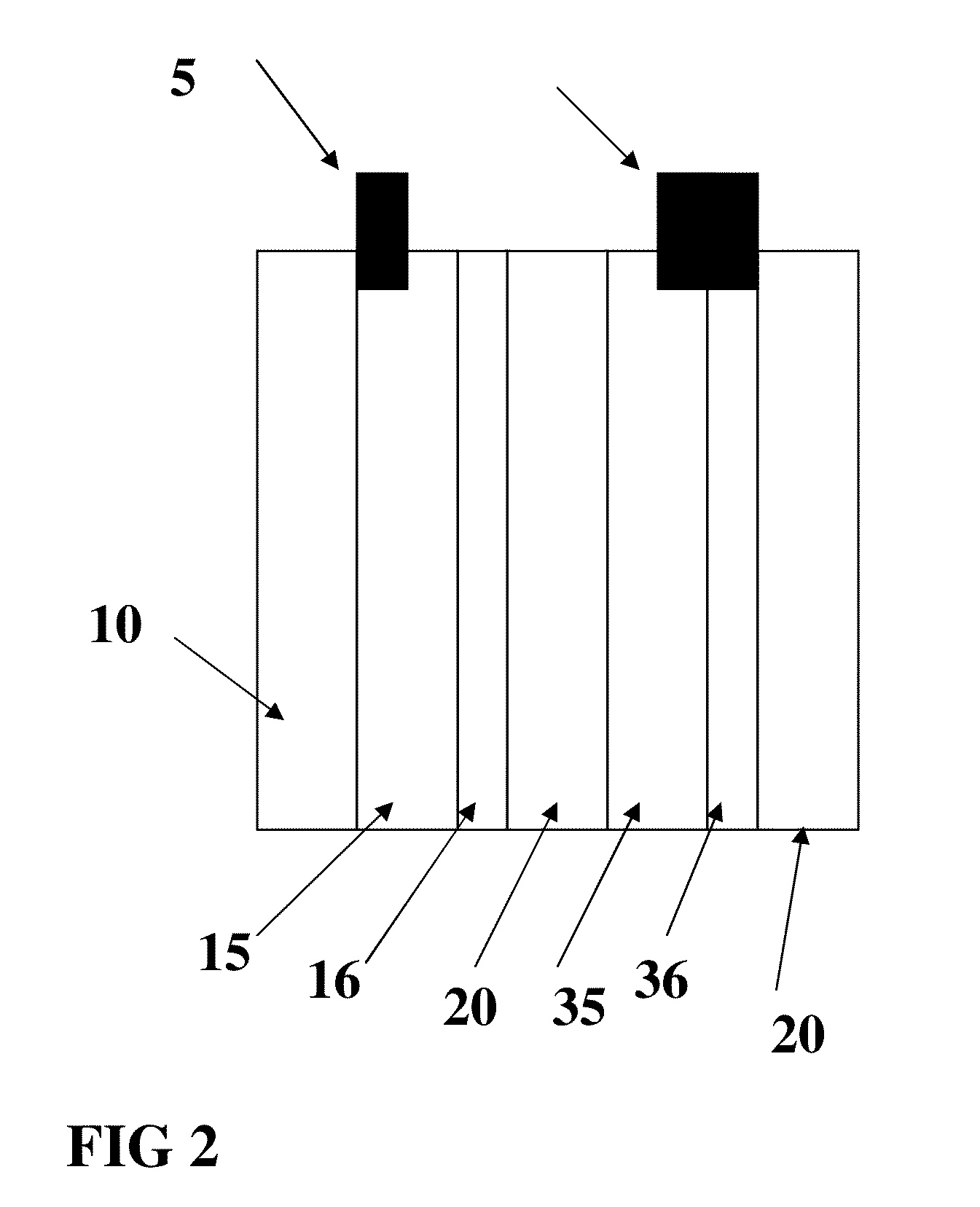

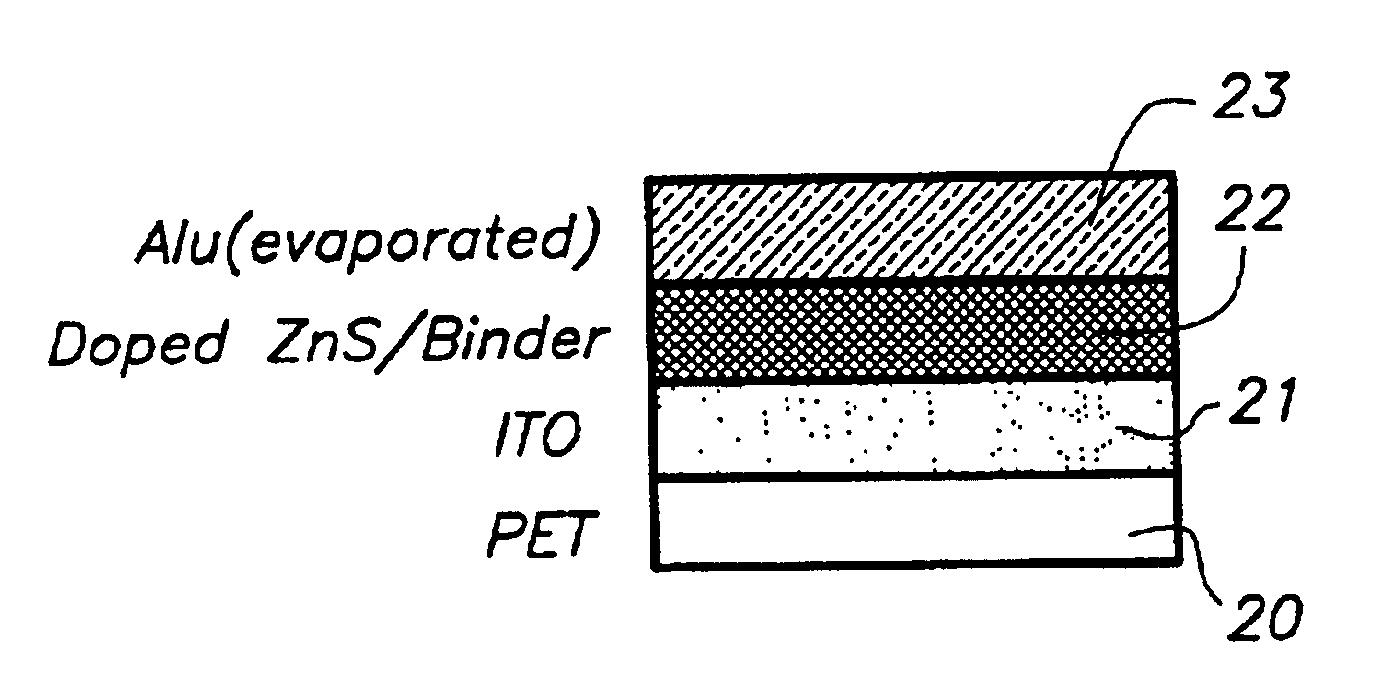

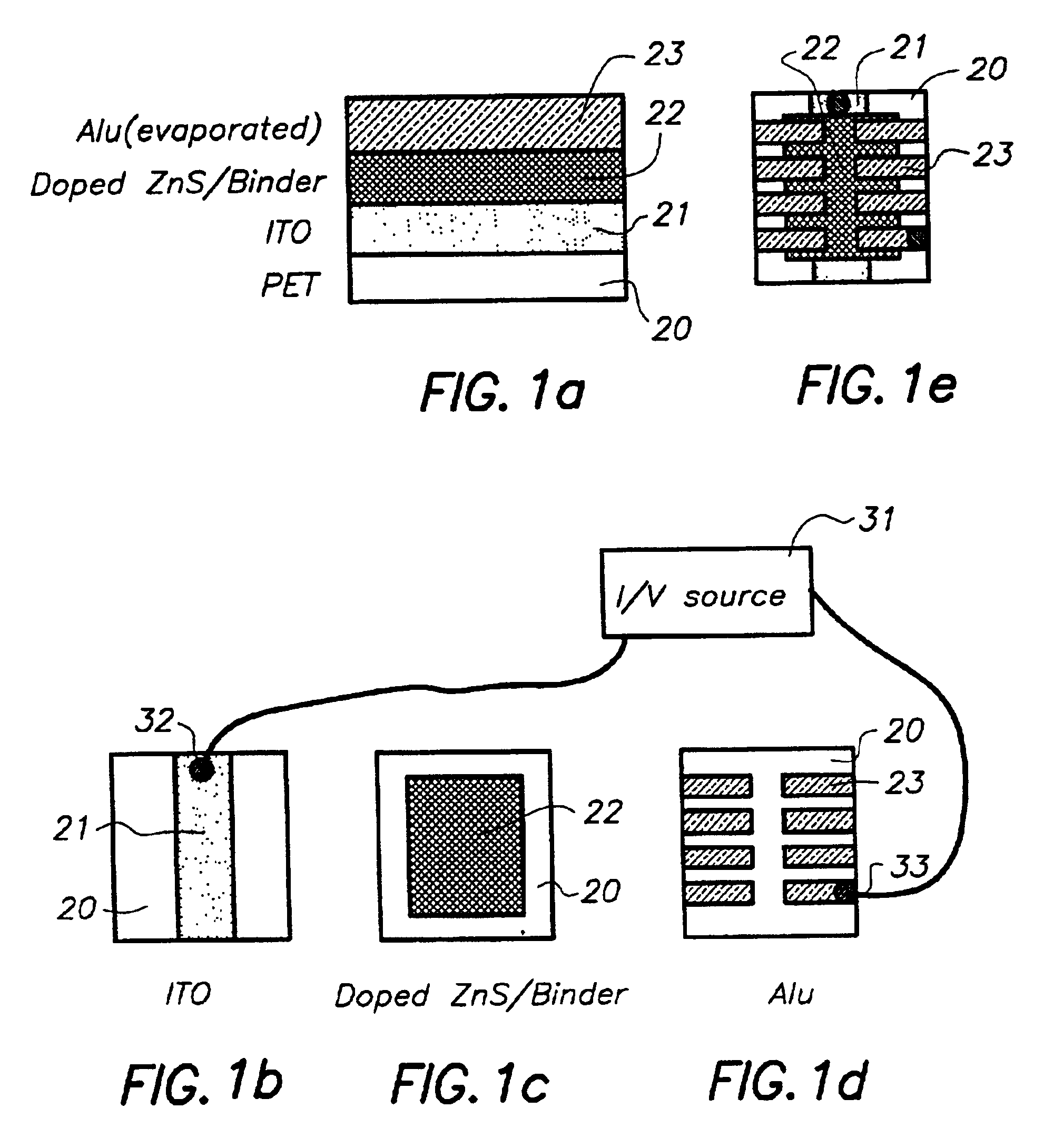

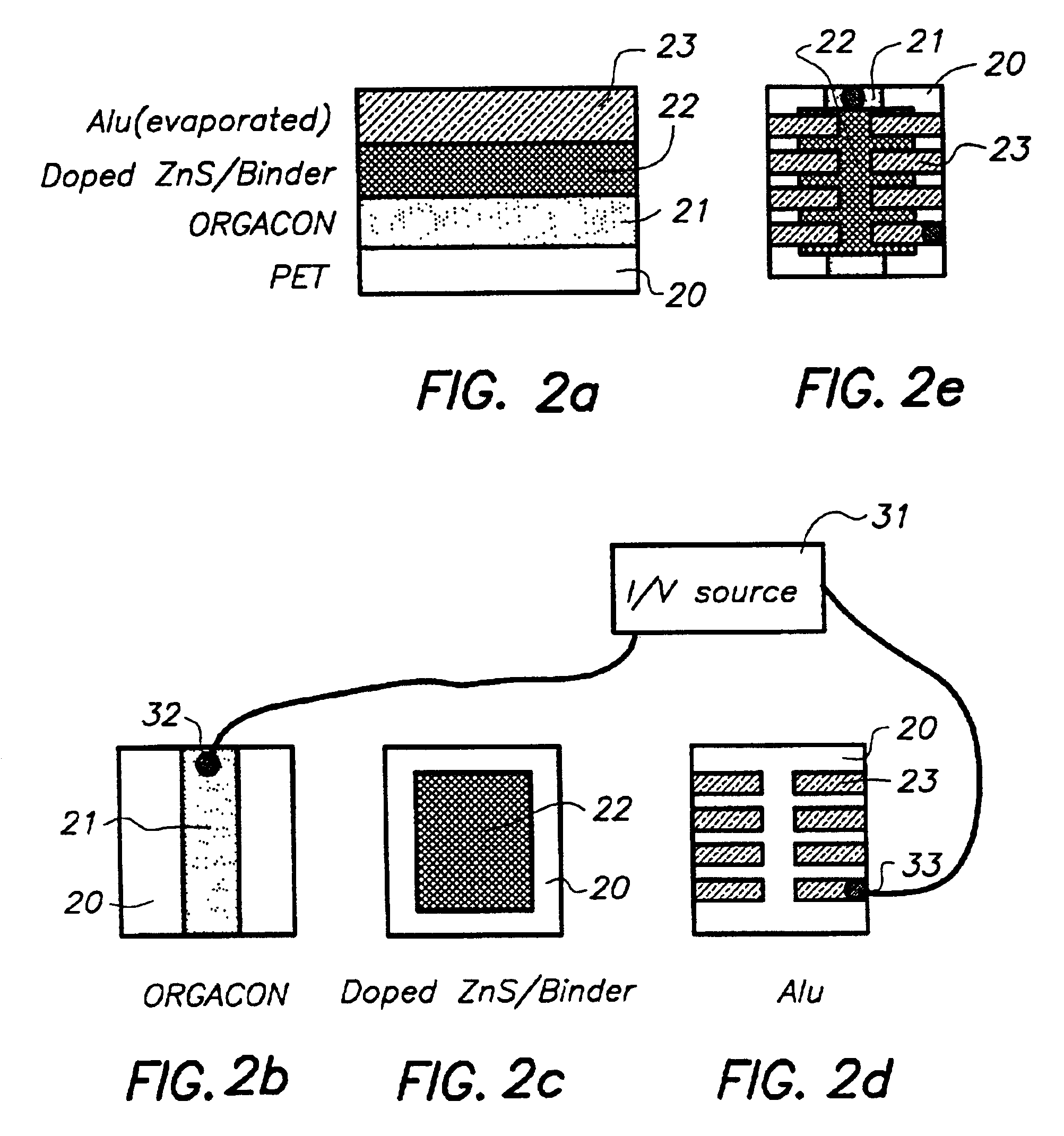

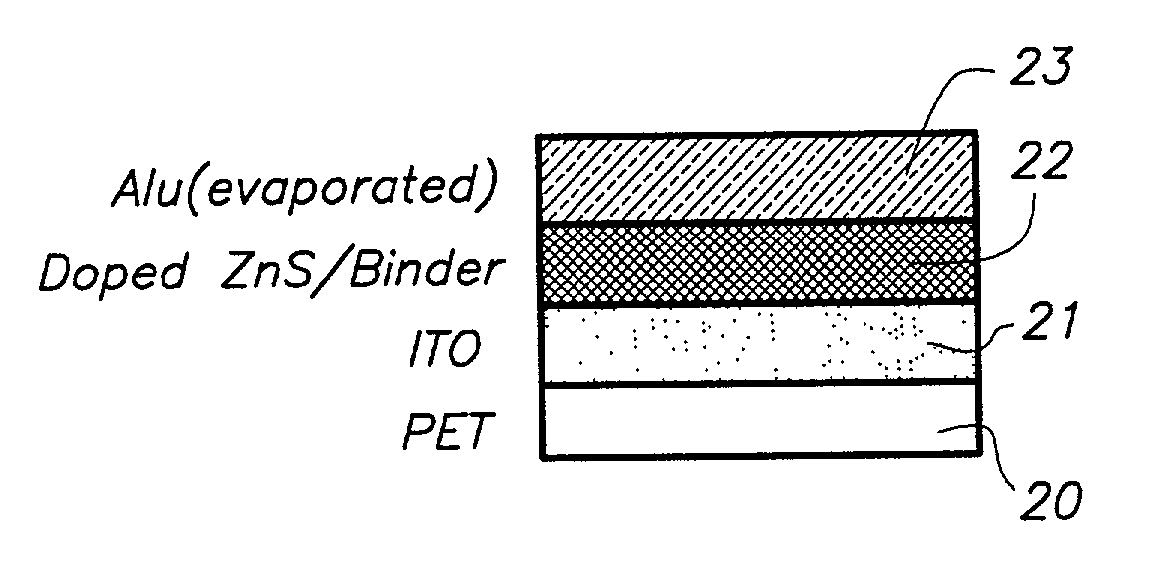

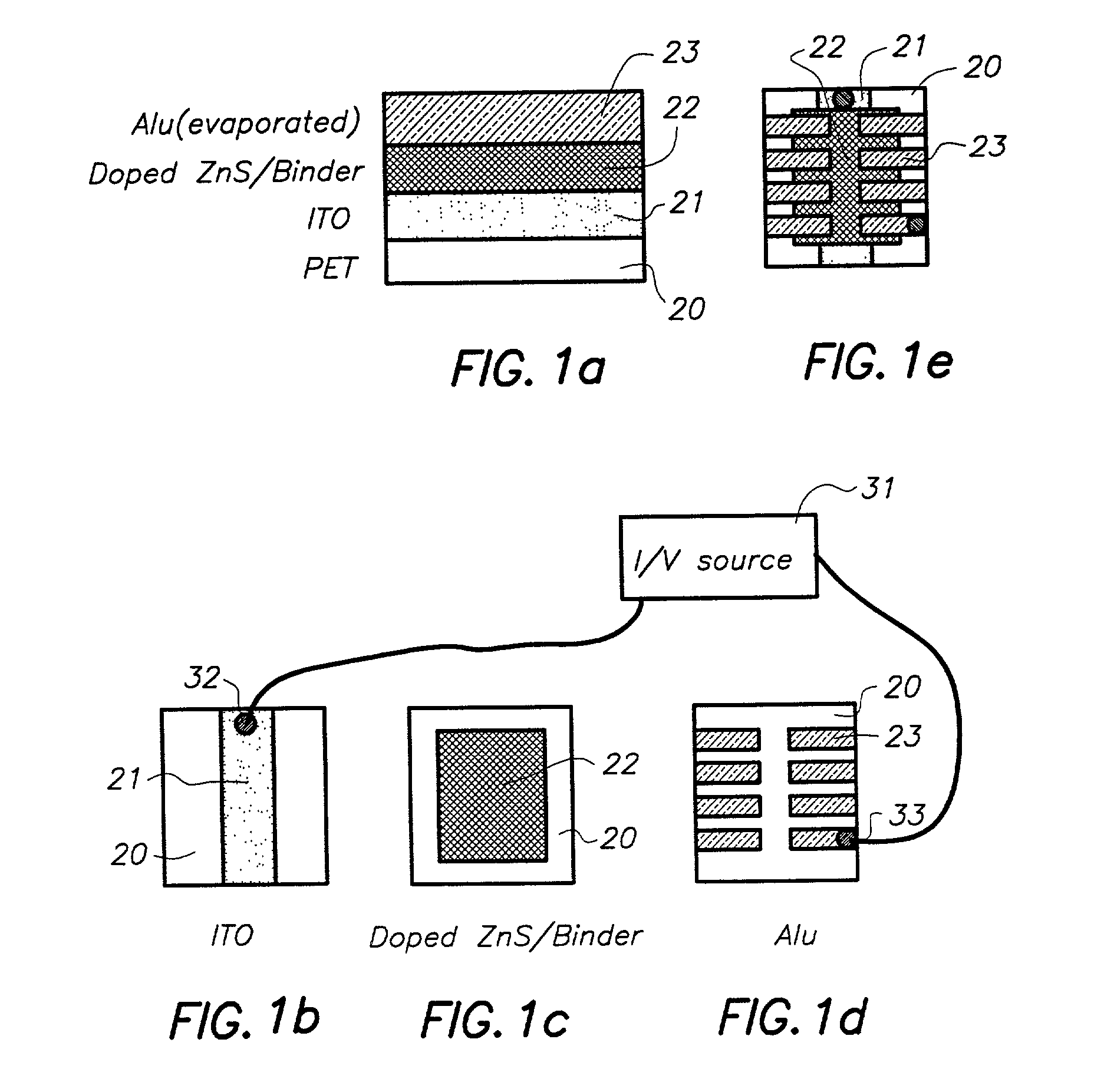

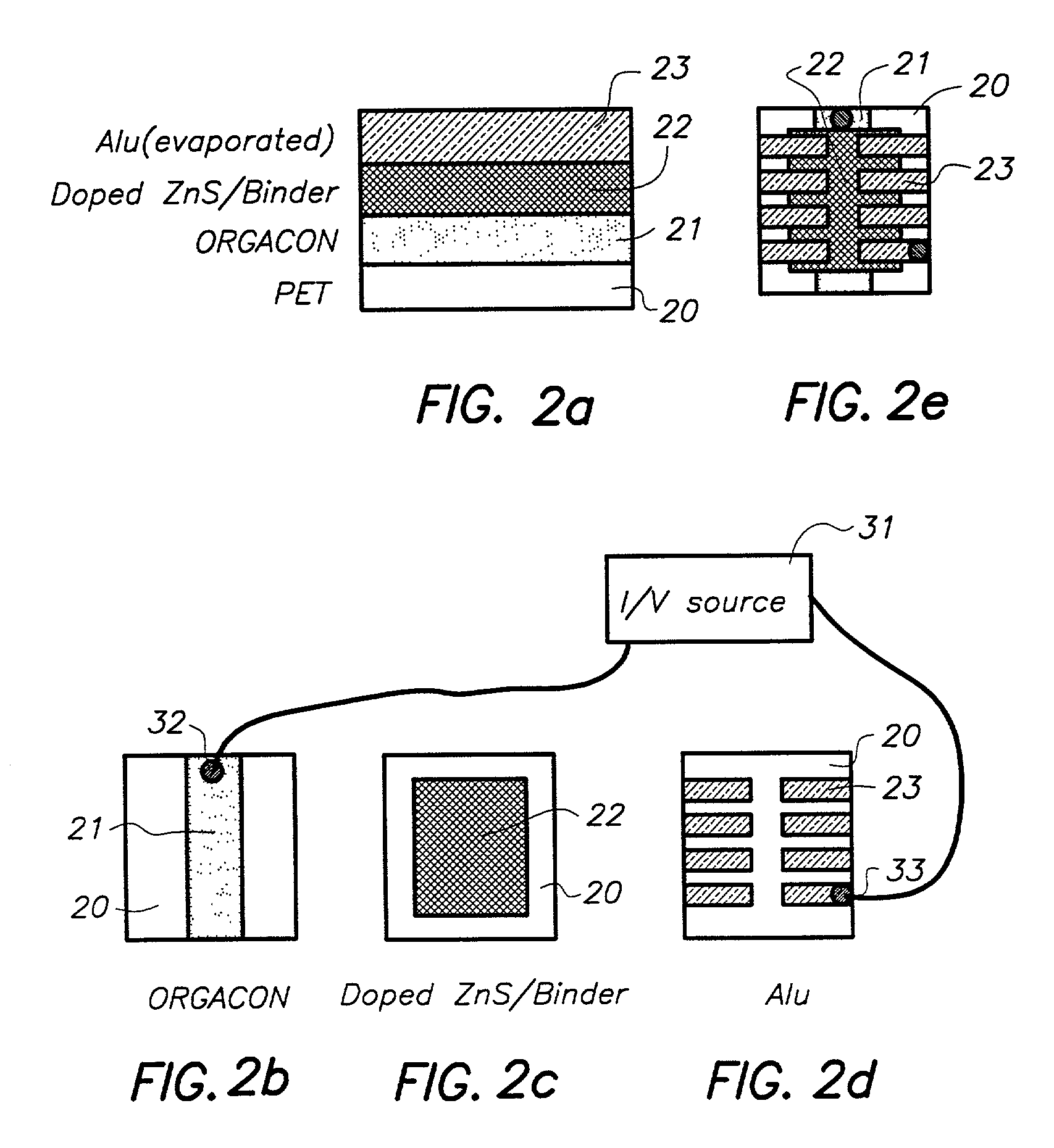

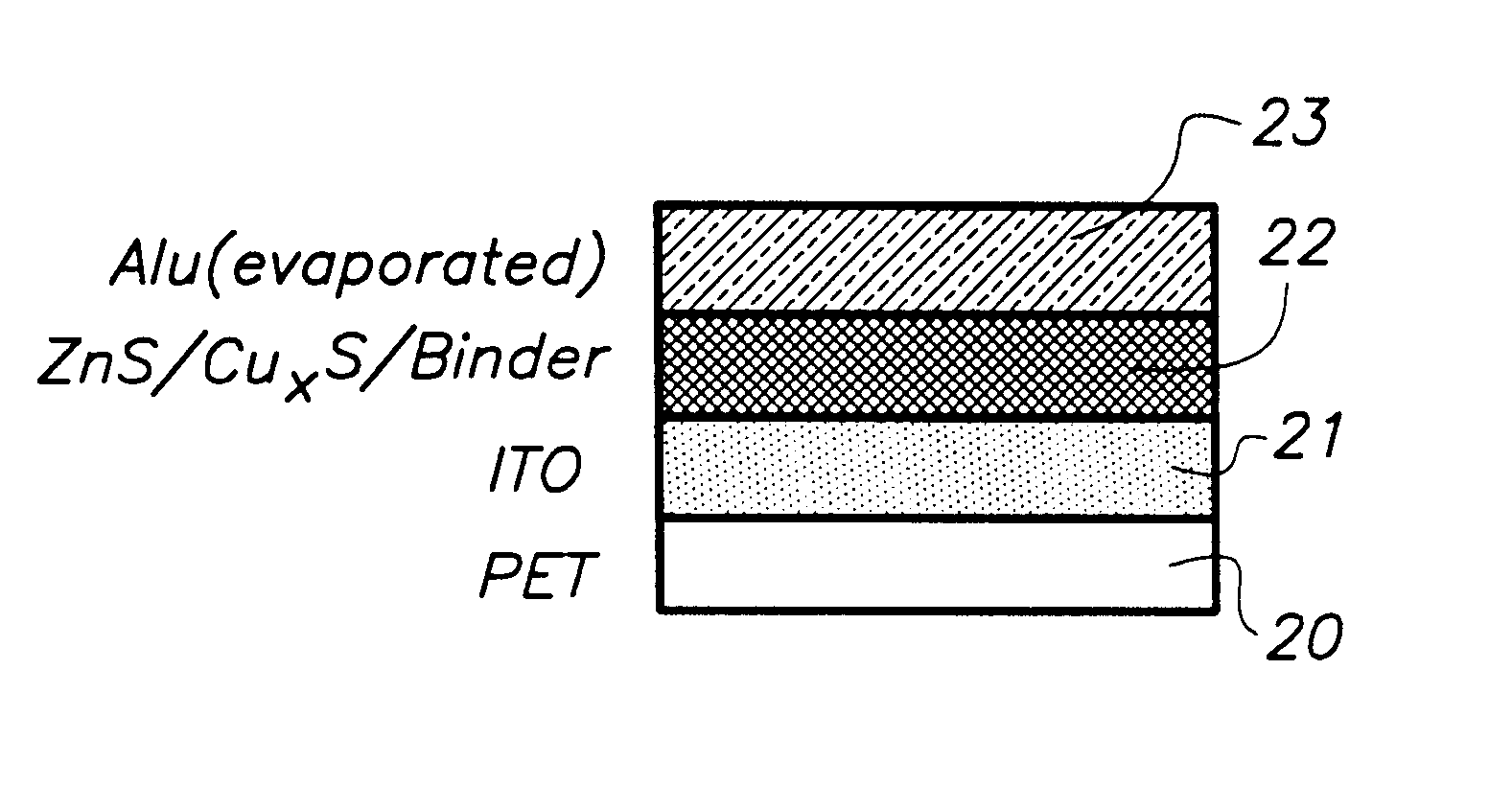

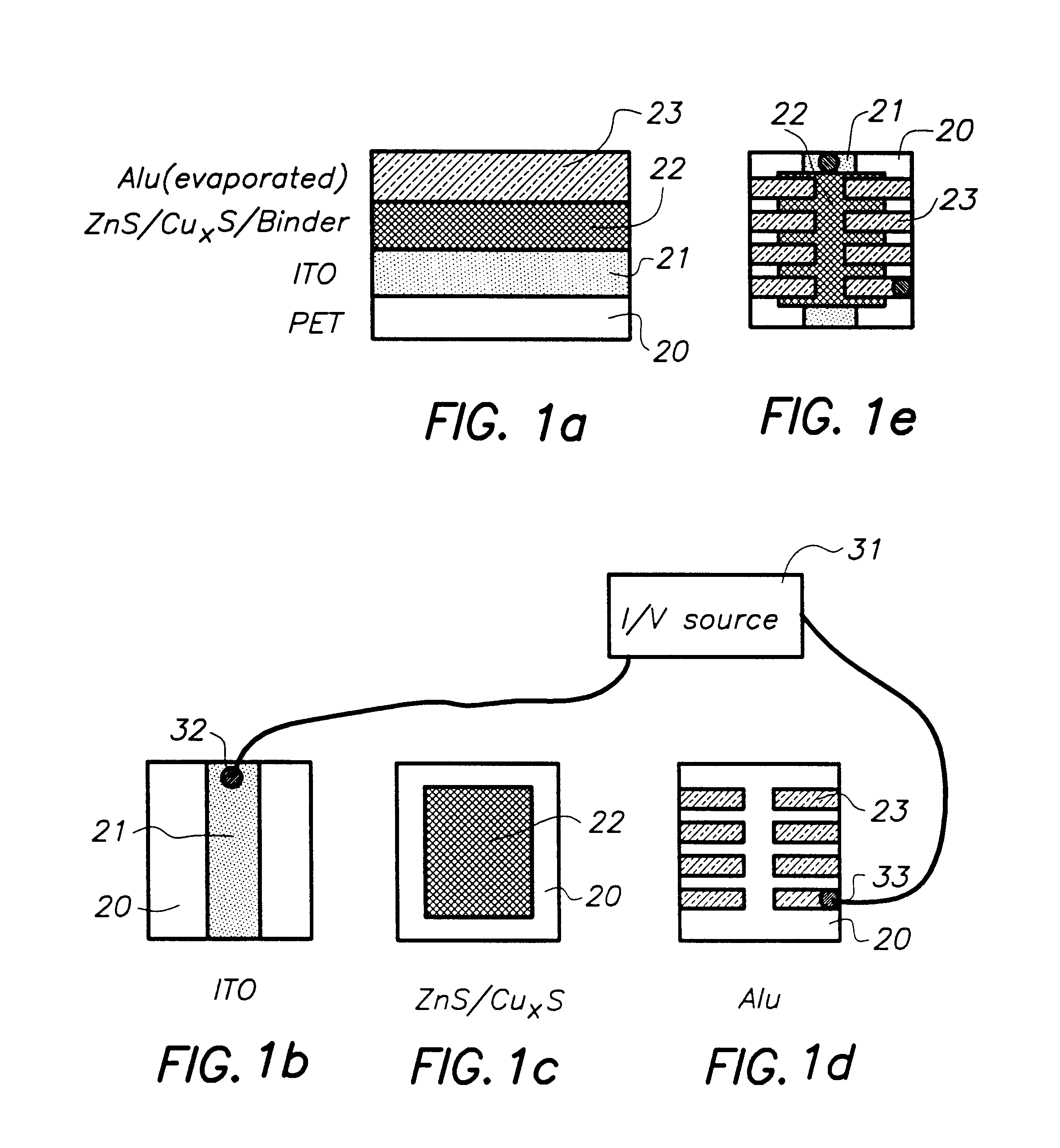

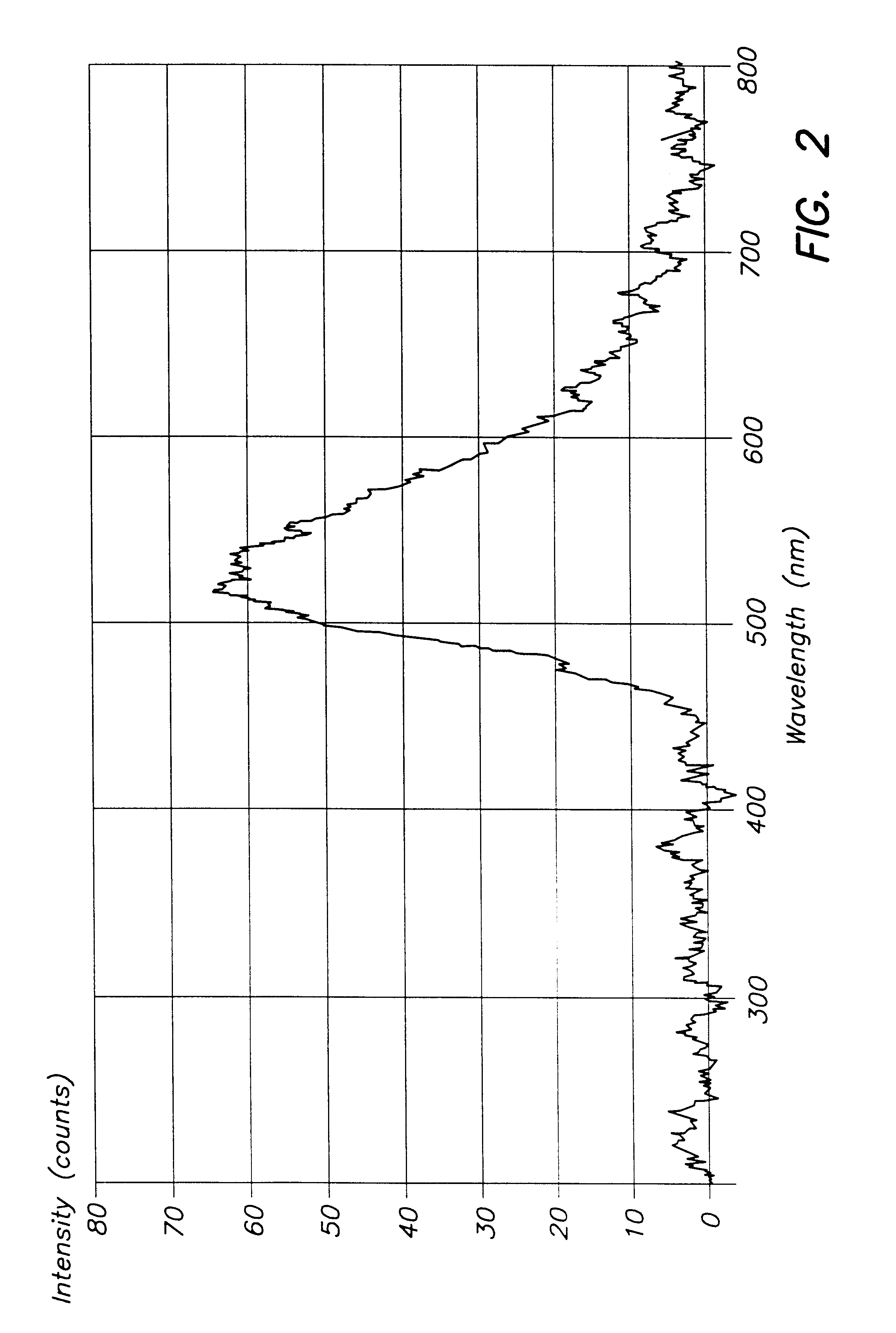

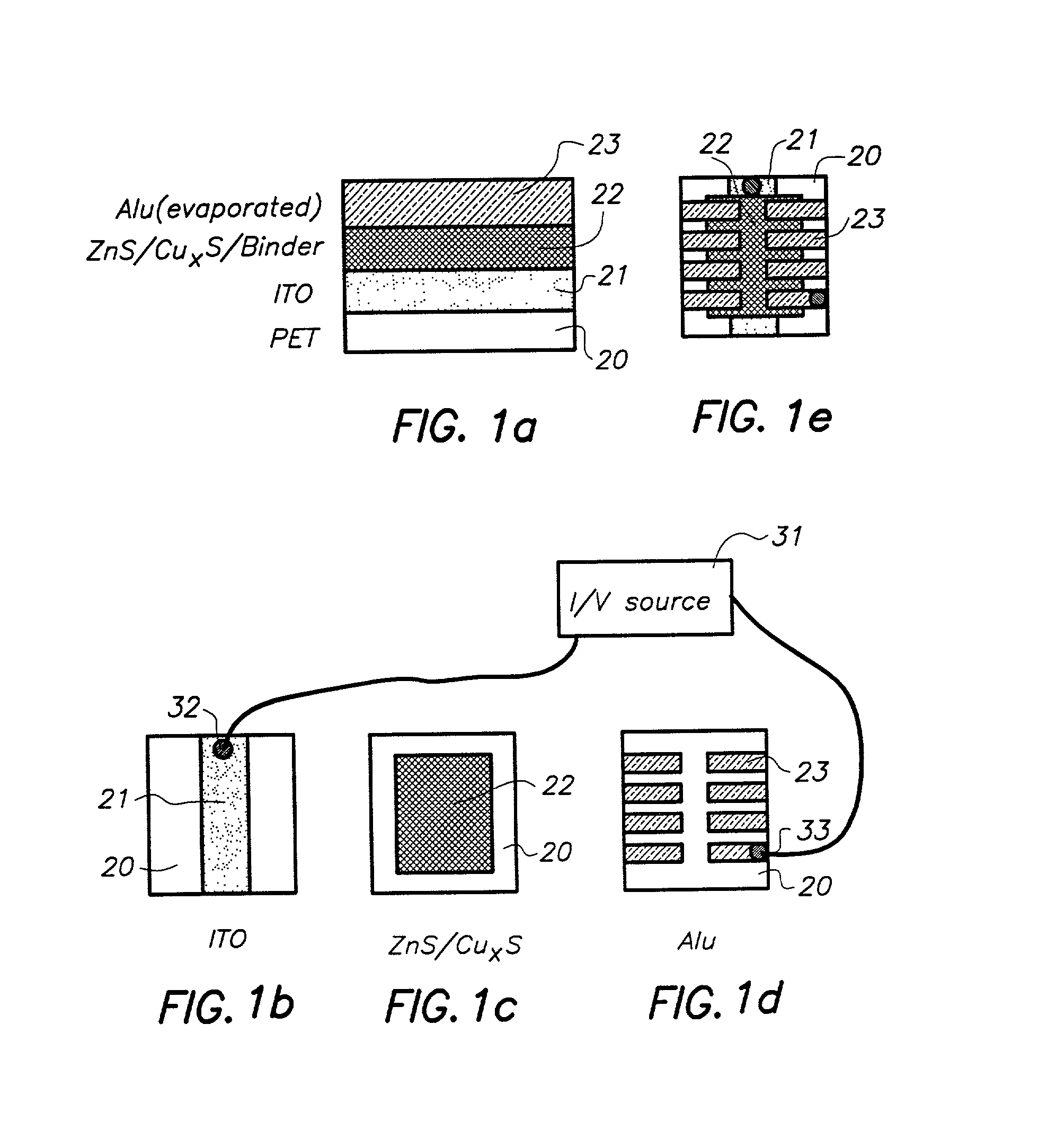

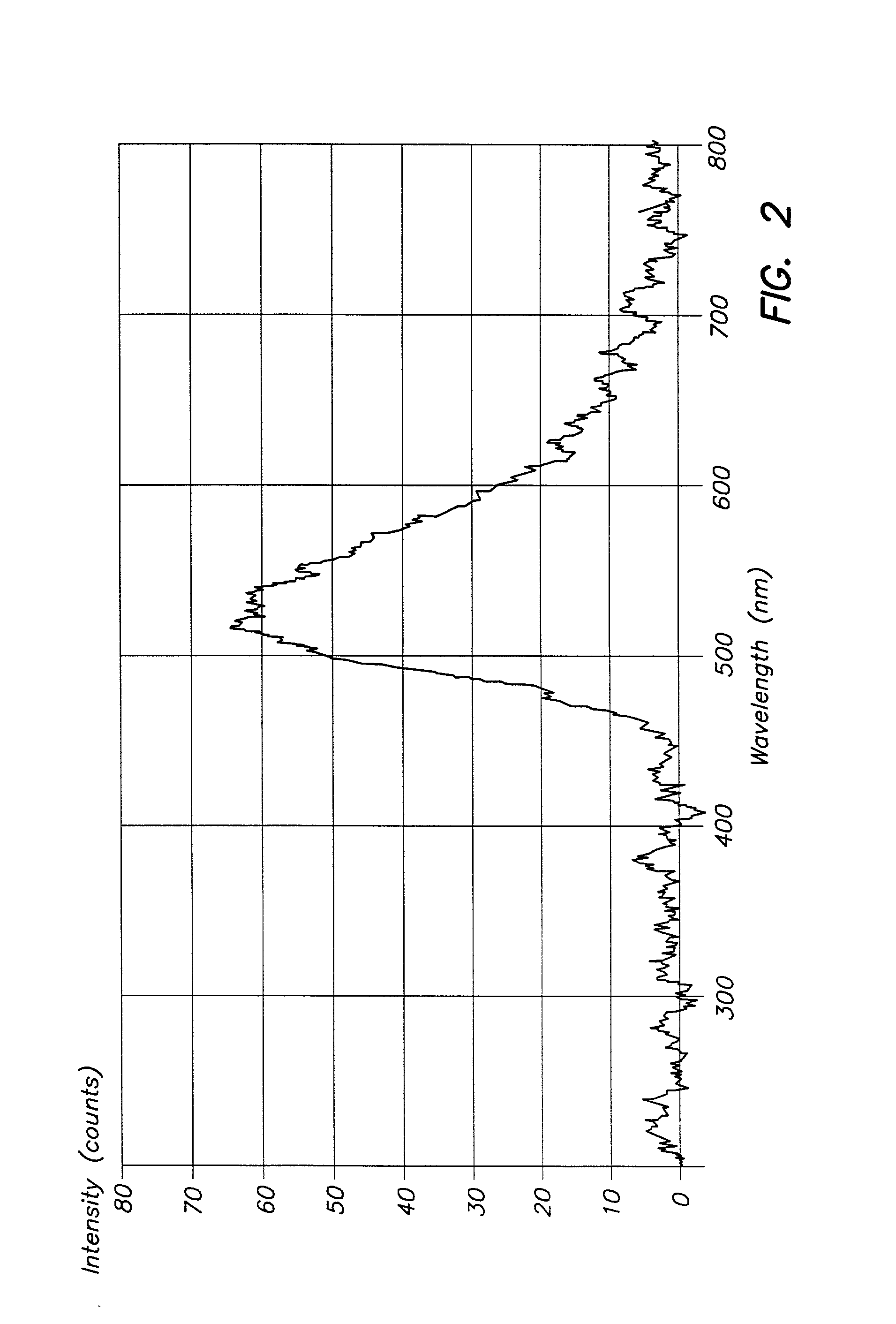

Manufacturing of a thin film inorganic light emitting diode

InactiveUS6737293B2Economical and simpleEasy and economical to manufactureSolid-state devicesSemiconductor/solid-state device manufacturingAqueous solutionNanometre

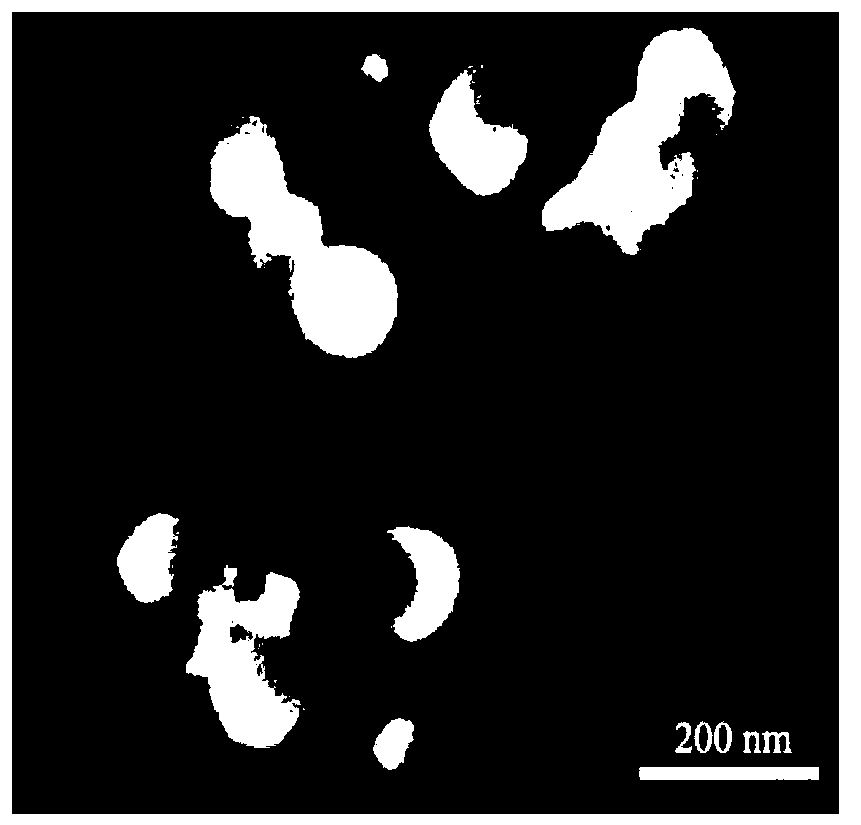

Nanoparticle dispersions of ZnS doped with a luminescent center are prepared by precipitation from aqueous solutions. When such dispersions are coated between conductive electrodes a Thin Film Inorganic Light Emitting Diode device is obtained.

Owner:AGFA GEVAERT AG

Non ionic groups of amphoteric polysaccharide linear or branched alkyl or acid and base distillation reservoir liquid or gas mechanically refined and Nano particle dispersion and recovery basin in vacuum processing for Building Materials and High Wear-Heat Resistant Parts Brushes; Windings; Coils; Battery Cells; Brake Pads; Bushings; 2.5 Phase Extrusions Die Cast Molding; Refrigeration; Polarized Glass; and Central Processing Unit Processors.

Manufacture process scientific formula mechanically refined and nanoparticle dispersion preform slurry non ionic or electrolyte carbon nanofoam CNFs with or without ionic suspension elements manufactured, Preform slurry high wear-heat resistant parts electronic component composite coils, composite windings, drawn, annealing, spun, coils, windings, wire, woven textile mesh, shielding, brushes, inductors, antinode couplers, electric rheostats, starters, motors, alternators, generators, ionic suspension element enhanced composite coils, composite windings, drawn, annealing, spun, coils, windings, wire, woven textile mesh, shielding, brushes, capacitors, battery cells, rheostats, electronic resistors, transformers, transducers, rectifiers, power supplies, or heat sinks, Preform slurry carbon nanofoam CNFs extrusion high wear-heat resistant parts aerospace, automotive, and transportation brake calipers, rotors, pads, washers, spacers, and bushings, Preform slurry carbon nanofoam CNFs extrusion high wear-heat resistant parts precision casting molds manufacturing highly pure metal, Super Alloy, acid-solid, alkaline, glass, acrylic, halide, alkalide, or ceramics specializing in 2.5 phase die cast molding.

Owner:MATTHEWS ROBERT RICHARD

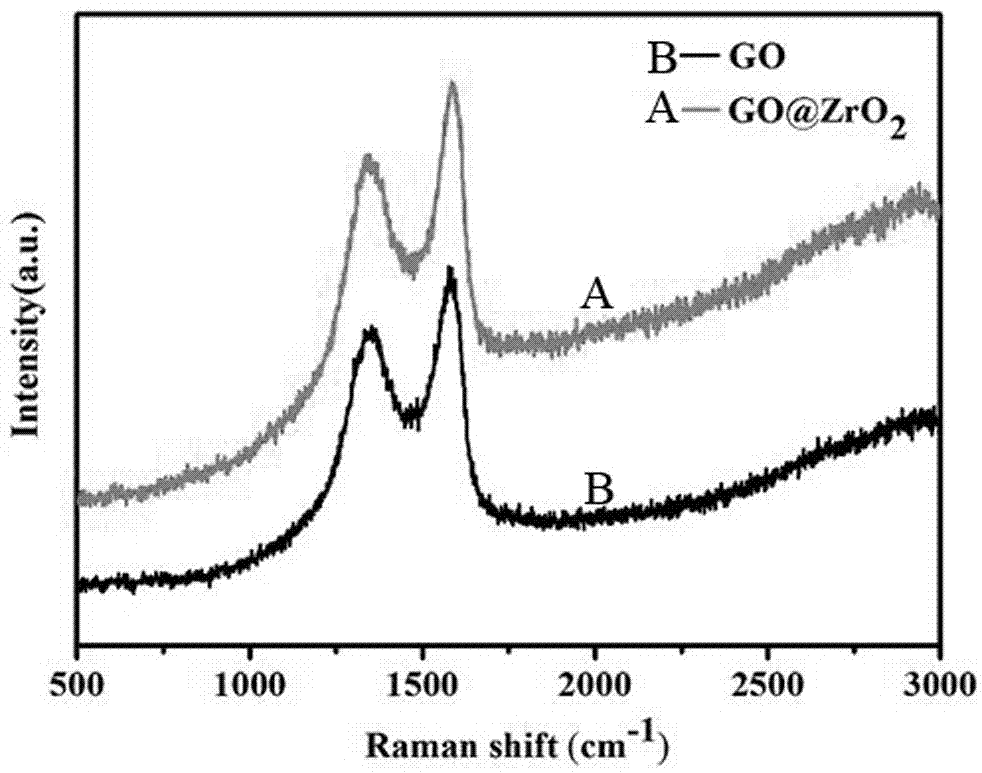

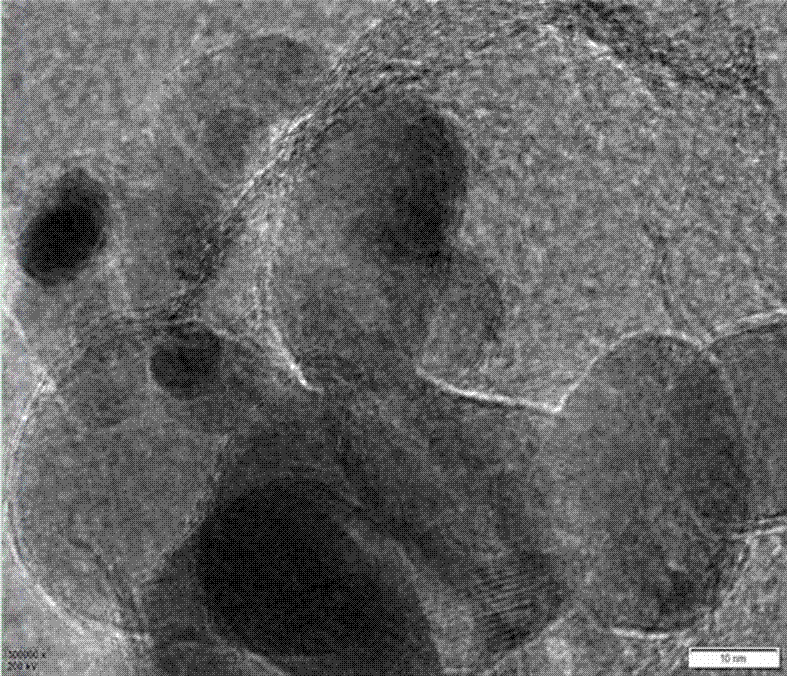

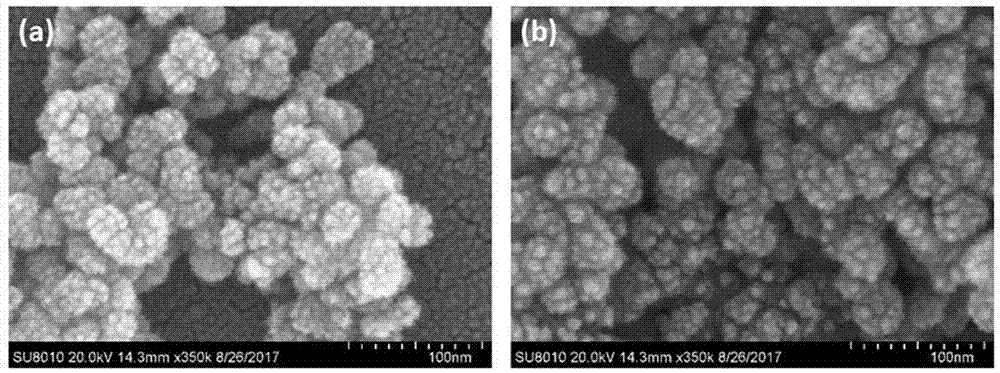

Nanoparticle/graphene oxide composite modified high polymer material and preparation thereof

ActiveCN107880484AImprove mechanical propertiesImprove tribological propertiesPolymer scienceOxide composite

The invention belongs to the field of high polymer composites and particularly relates to a nanoparticle / graphene oxide composite modified high polymer material and a preparation method thereof. The composite is prepared from nanoparticle / graphene oxide composite particles and a macromolecular polymer matrix, wherein the nanoparticle / graphene oxide composite particles are synthesized with an electrostatic self-assembly method, that is, an amino modified nanoparticle dispersion liquid is ionized to have positive charges while graphene oxide contains a large quantity of carboxyls and hydroxyls and is ionized to have negative charges, particles with positive and negative charges are sufficiently contacted, and electrostatically self-assembled nanoparticle and graphene oxide composite particles are obtained. The prepared nanoparticle / graphene oxide composite modified high polymer material has excellent mechanical and tribological performance, is simple and efficient to prepare and has goodapplication prospects in automobiles, aerospace, electronic and electrical engineering, machinery, weapons and other fields.

Owner:ZHONGBEI UNIV

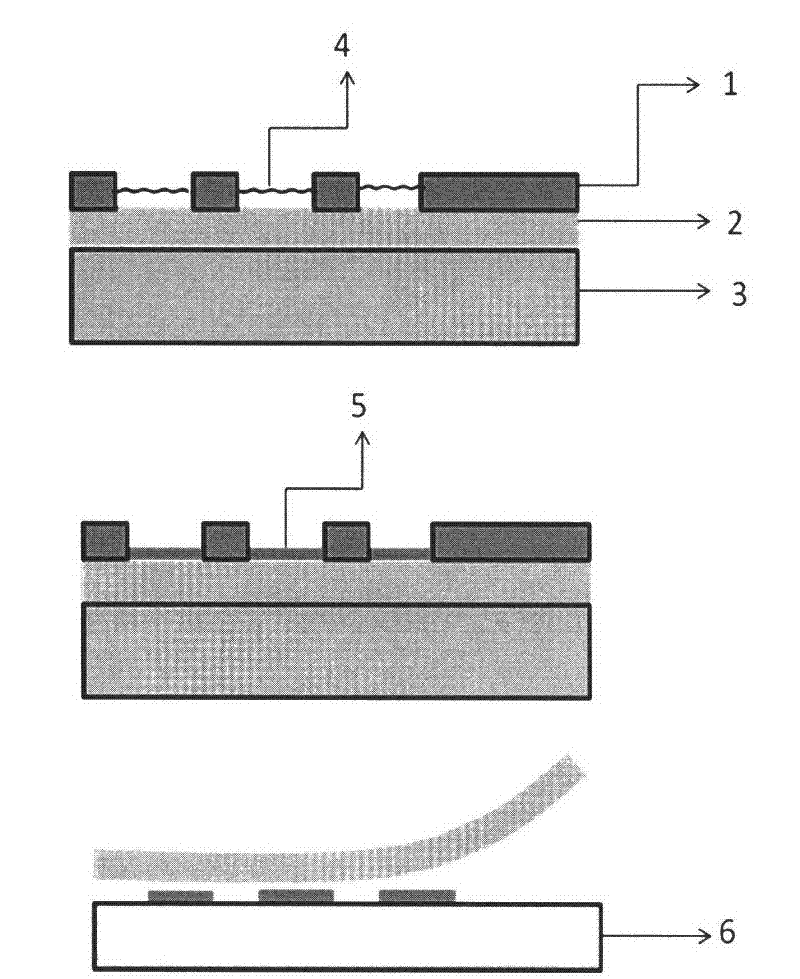

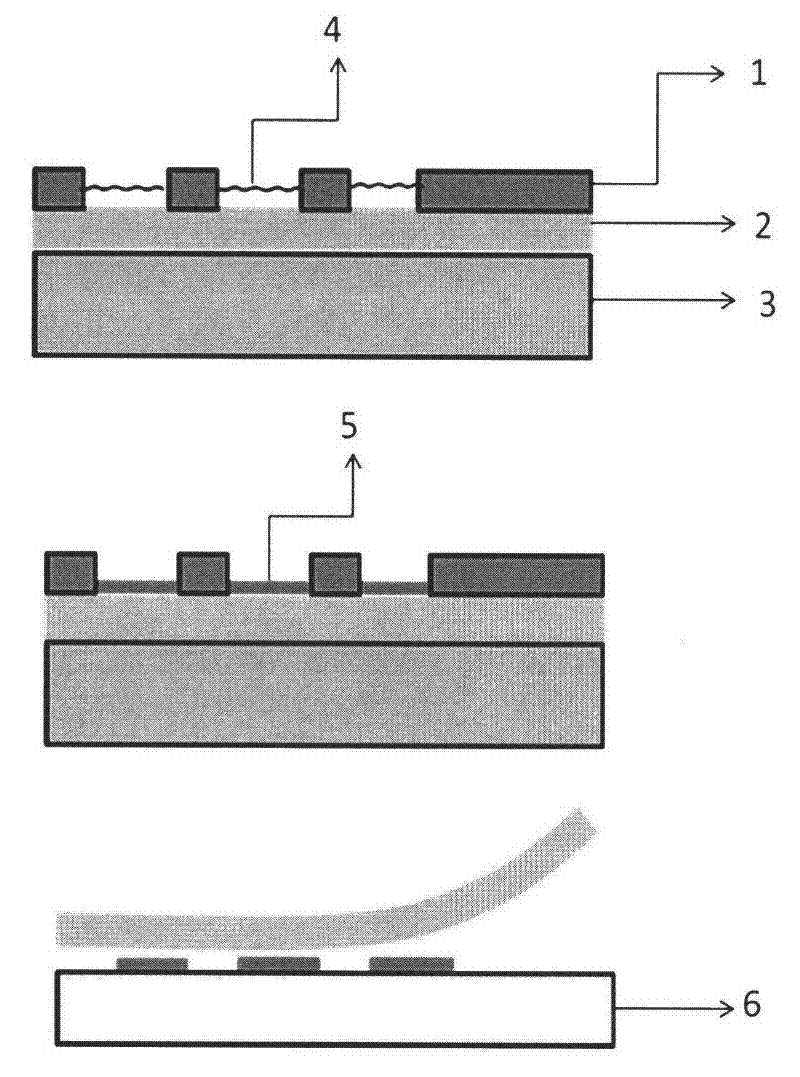

Patterned transparent electrode fabrication method

ActiveCN102543303AEnsure controllabilityEfficient removalConductive layers on insulating-supportsCable/conductor manufactureMaterials scienceNanomaterials

The invention discloses a patterned transparent electrode fabrication method. The method comprises the steps of (1) depositing a conductive nanoparticle dispersion solution on a porous filter membrane with a negative pattern mask to obtain a patterned transparent conductive film adhered on the porous filter membrane; and (2) removing the mask, transferring the patterned transparent conductive film on the porous filter membrane onto a transparent substrate, and removing the porous filter membrane to obtain the patterned transparent electrode; wherein the dispersion solution contains conductive nanoparticles 0.015wt% to 5wt%, dispersing agent 0.15wt% to 20wt%, and water in balance; and the dispersing agent is selected from arbitrary one or the combination of a surfactant, organic acid, high-molecular polysaccharide and DNA macromolecules. The method has the advantages of simple process, low cost and large material selection range, and can accurately design and control the formed pattern according to requirement.

Owner:浙江暖科能源技术有限公司

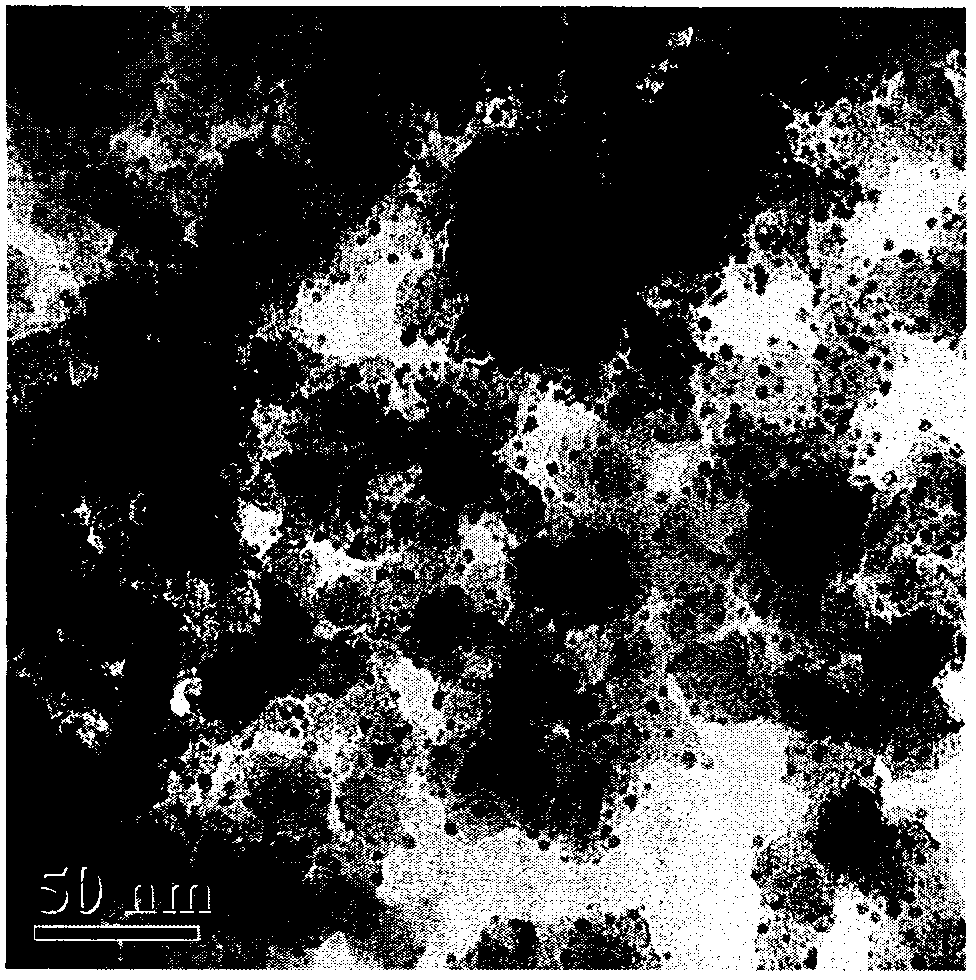

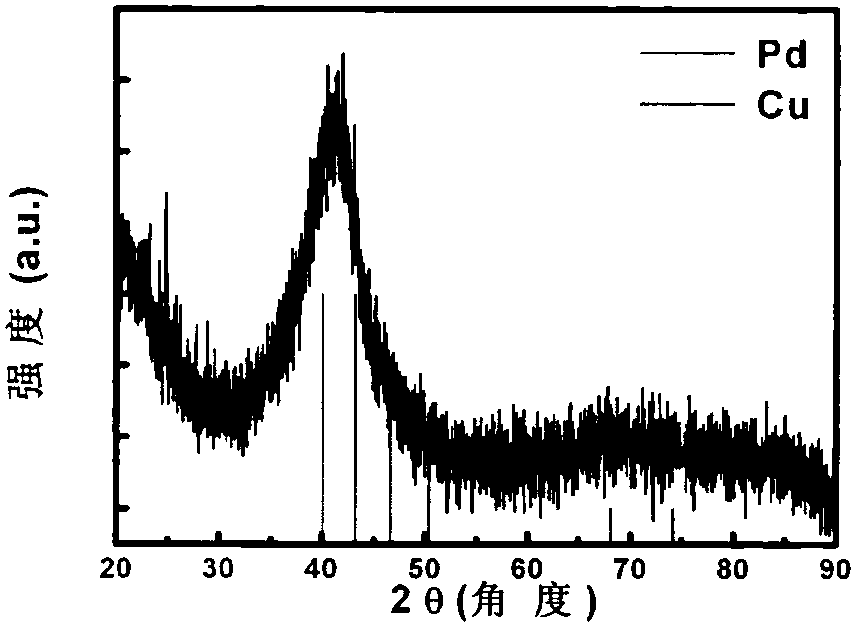

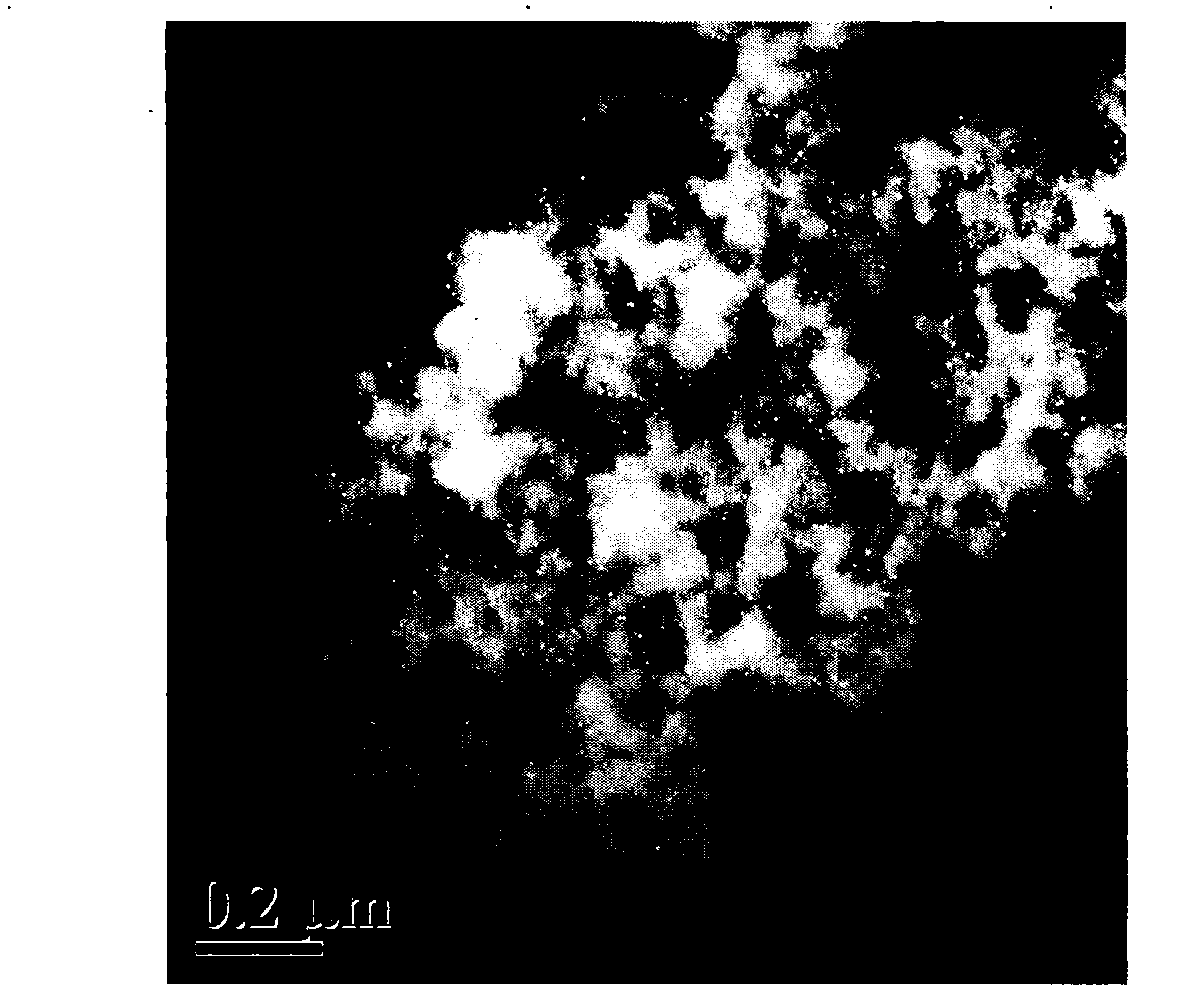

Method for preparing load type high-dispersion multi-component precious metal nanoparticle catalyst

InactiveCN102974365AGood dispersionUniform particle size distributionMetal/metal-oxides/metal-hydroxide catalystsRoom temperatureSurface-active agents

The invention relates to a method for preparing a load type high-dispersion multi-component precious metal nanoparticle catalyst. The method comprises the steps of 1) under inert atmosphere, uniformly stirring a solvent and a surface active agent, then adding a precious metal precursor solution, rising the temperature, reacting for a certain period of time, cooling to the room temperature, adding normal hexane, and performing extraction layering; 2) uniformly mixing the obtained upper layer nanoparticle solution with a carrier, and stirring or performing ultrasonic treatment; and 3) centrifugating, washing and drying or baking the mixed solution to obtain the catalyst. For the precious metal catalyst, even under a relatively high carrying amount, relatively good precious metal nanoparticle dispersion degree can be still guaranteed; the particle sizes of the particles are uniformly distributed; the precious metal carrying amount is controlled easily and accurately; the particle sizes and the components of multi-component particles can be controlled; and the catalysis application range is wide. The process is simple; the preparation cost is low; the applicability is high; and load-type high-dispersion precious metal and the multi-component precious metal nanoparticle catalyst can be prepared in a large scale.

Owner:TIANJIN POLYTECHNIC UNIV

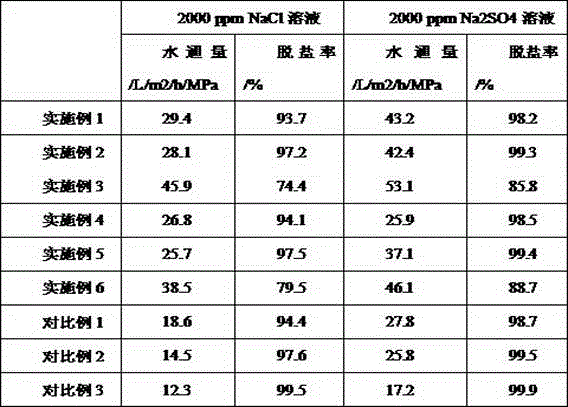

Grapheme oxide quantum dot function sphere nanoparticle, polyamide reverse osmosis membrane/nanofiltration membrane modified by nanoparticle and preparation method

ActiveCN105771696AHigh desalination rateIncrease water fluxGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisReverse osmosisPolyamide

The invention discloses a grapheme oxide quantum dot function sphere nanoparticle, a polyamide reverse osmosis membrane / nanofiltration membrane modified by the nanoparticle and a preparation method. The grapheme oxide quantum dot function sphere nanoparticle comprises a sphere kernel taking positive charge nanoparticles as supports and grapheme oxide quantum dots wrapping the sphere kernel layer by layer, and is prepared by slowly adding grapheme oxide quantum dot dispersion liquid into positive charge nanoparticle dispersion liquid prior to centrifugal precipitation, separation and purification. The function sphere nanoparticle based modified polyamide reverse osmosis membrane / nanofiltration membrane is prepared by inlaying the grapheme oxide quantum dot function sphere nanoparticle in a reverse osmosis membrane / nanofiltration membrane polyamide separation layer, and can be applied to the fields of seawater and brackish water desalination, seawater and brackish water softening, drinking water treatment, advanced wastewater treatment and the like. The spherical shell type special-shaped nanochannel is provided with multiple inlets and outlets, and water flux of the membrane can be increased.

Owner:OCEAN UNIV OF CHINA

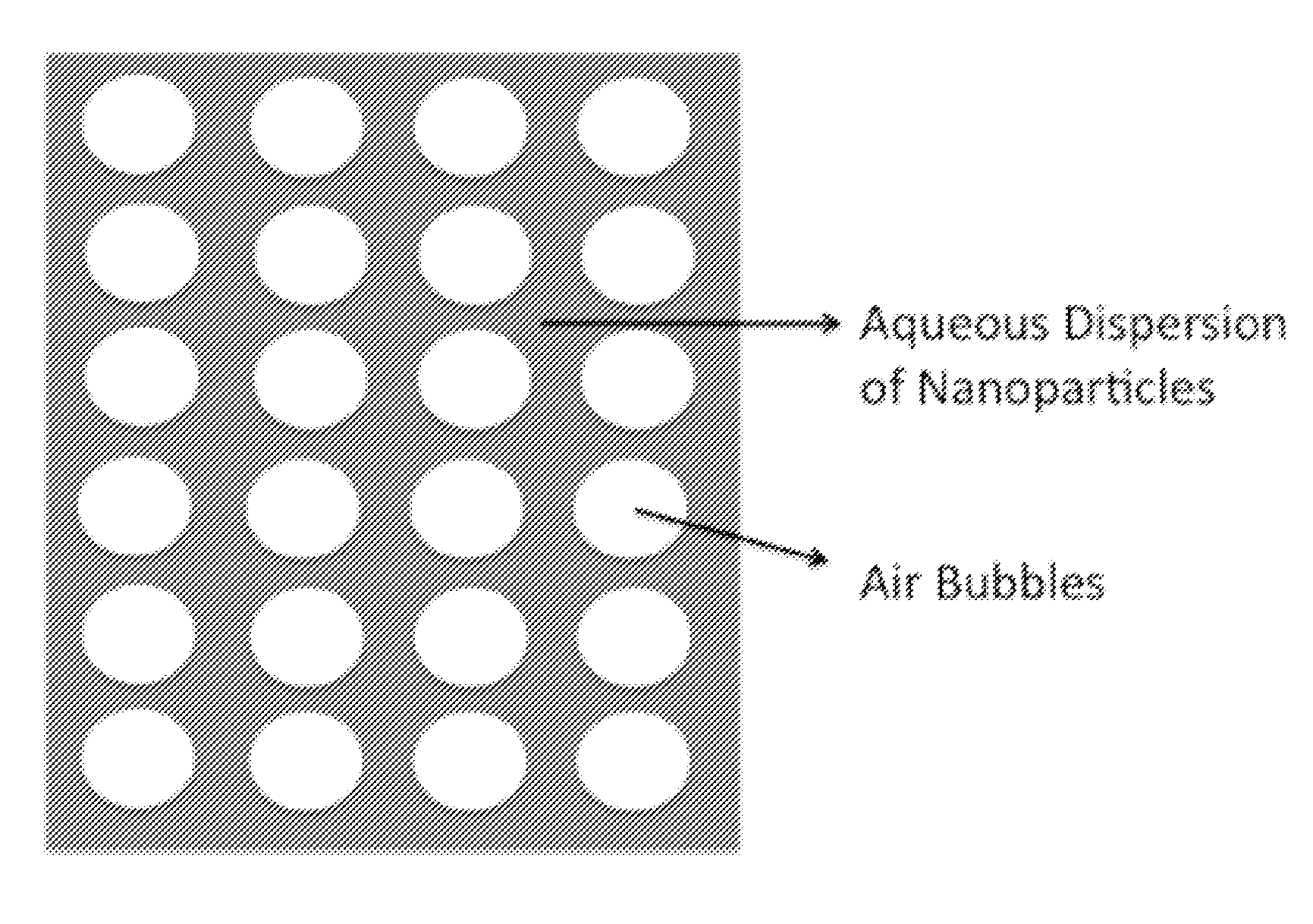

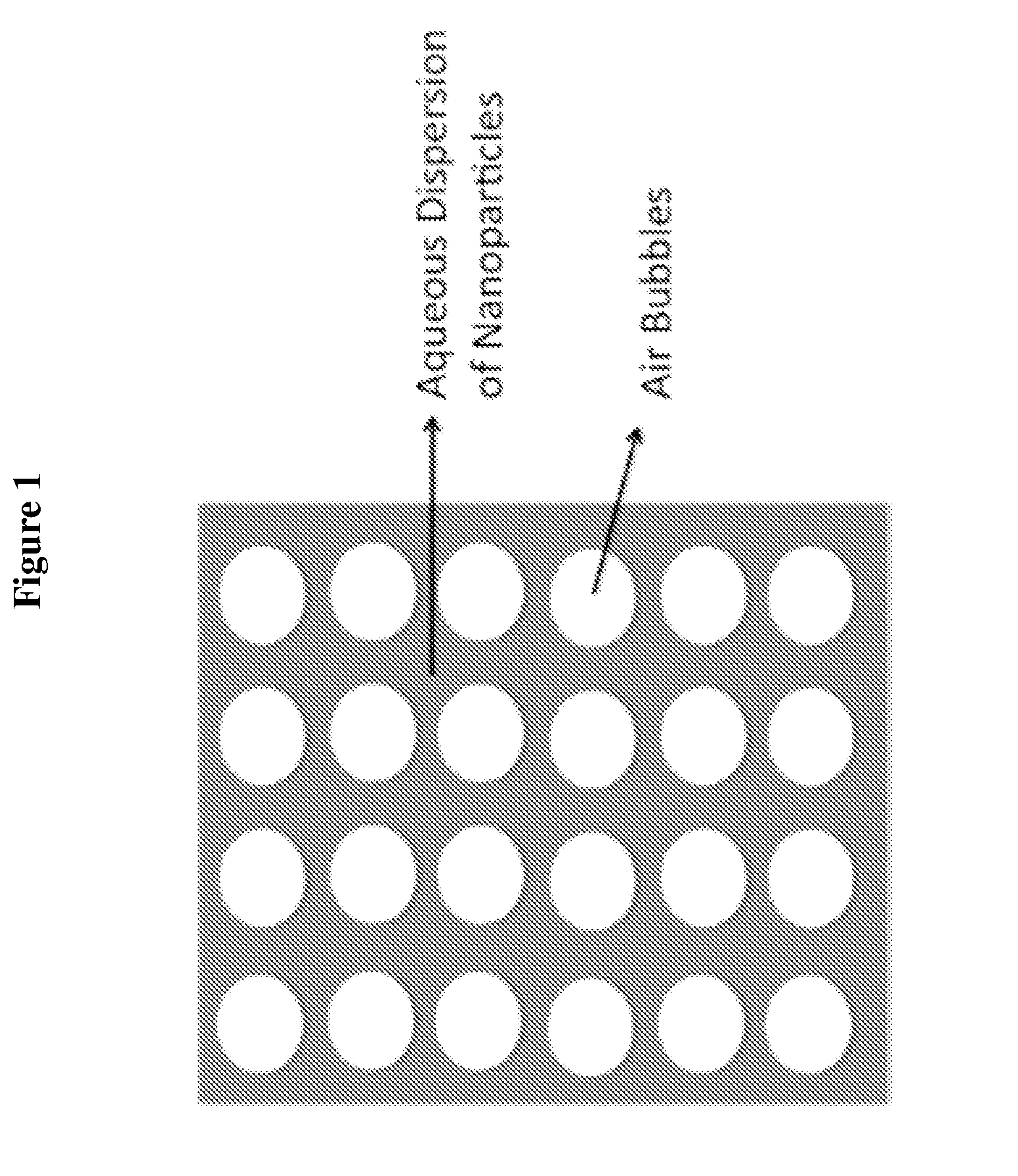

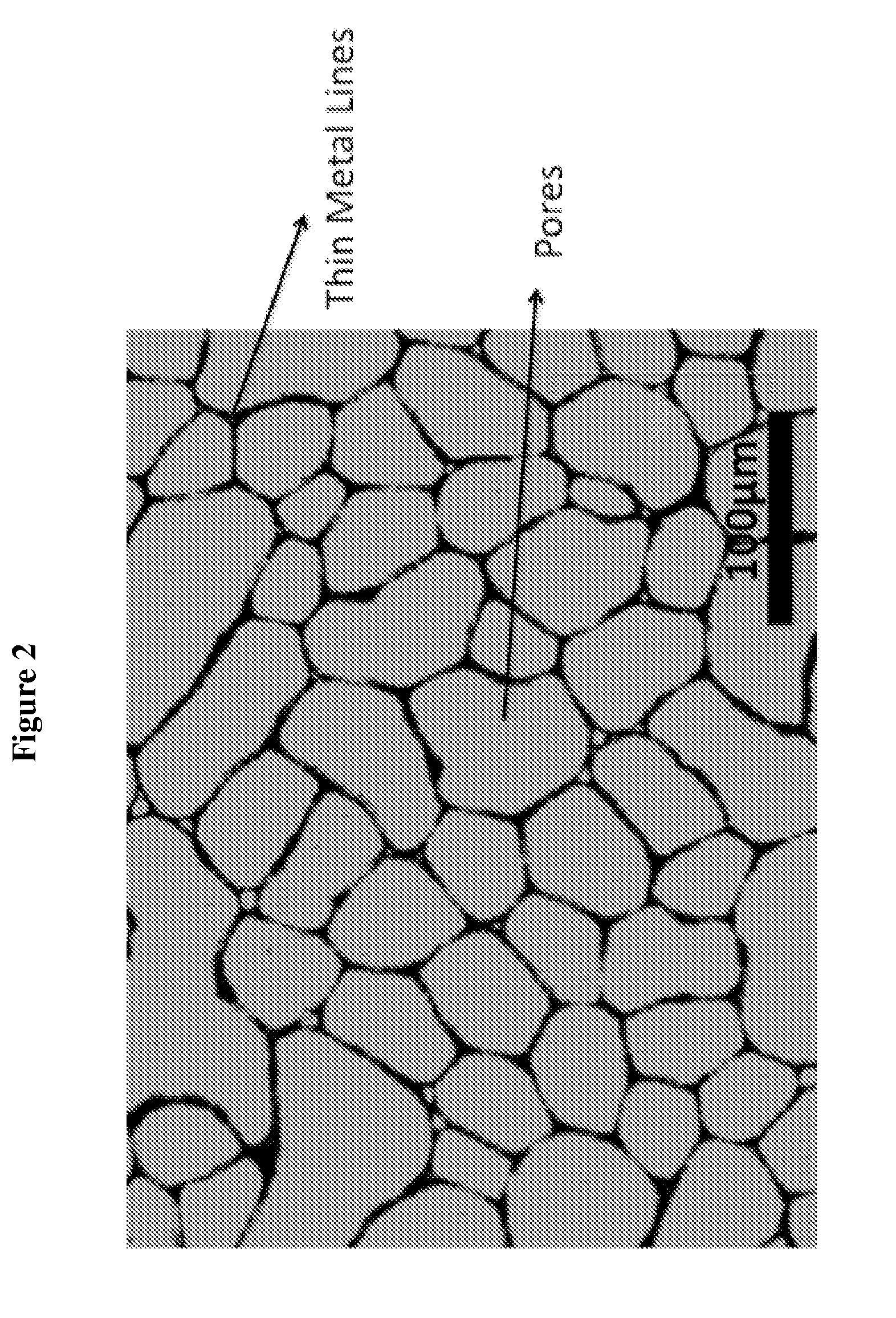

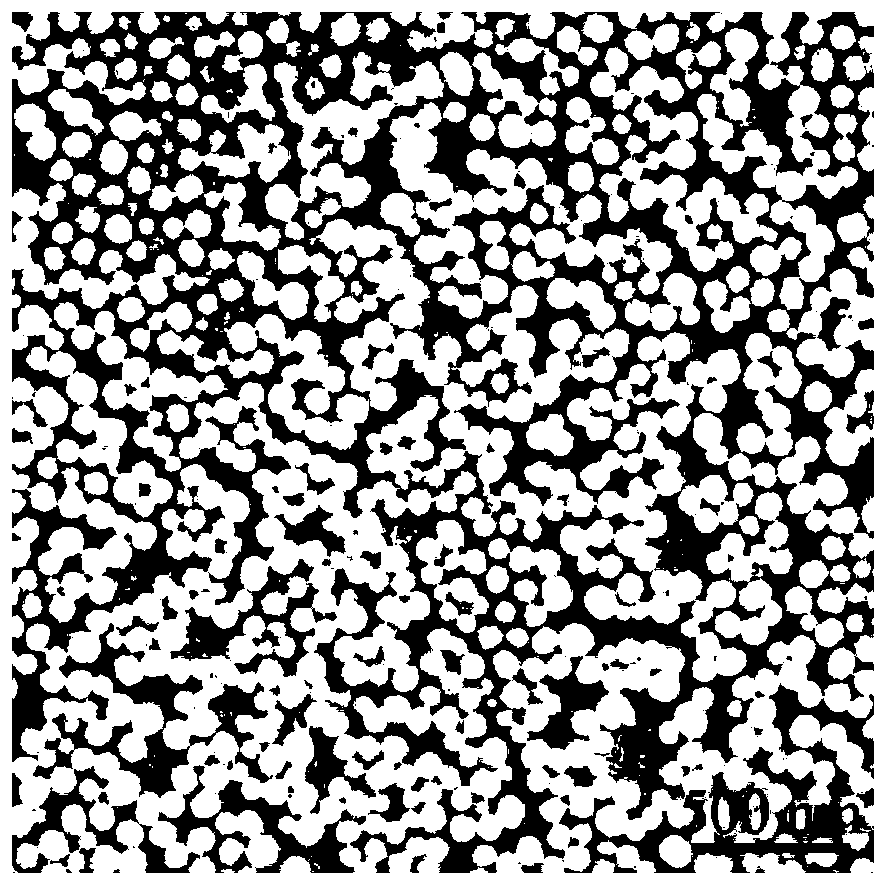

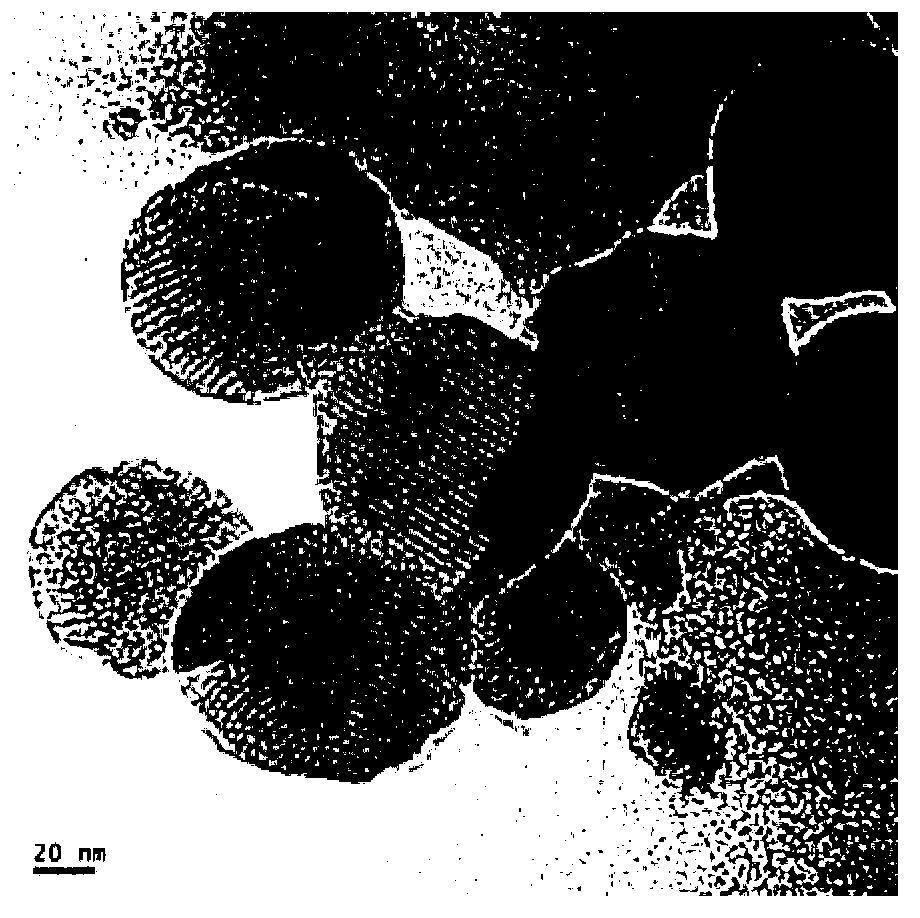

Composition for making transparent conductive coating based on nanoparticle dispersion

InactiveUS20110193032A1Conductive materialNon-conductive material with dispersed conductive materialOrganic solventConductive coating

The present invention is directed to a composition for preparing transparent conductive coating on transparent substrate by an environment friendly method. An aqueous foam dispersion containing metal nanoparticles can form a transparent film by spontaneous self-assembly, which becomes conductive after sintering. The foam formulation contains mainly water without any toxic organic solvent.

Owner:TECONA TECH

Mesoporous silica nanomotor, and preparation method and application thereof

InactiveCN103011067ASolve technical problems with large dimensionsObvious yin and yang characteristicsIndividual molecule manipulationNanosensorsNanomotorMesoporous silica

The invention discloses a mesoporous silica nanomotor, and a preparation method and the application thereof, relates to a motor, a preparation method and the application thereof, and aims at solving the technical problem of large size of the existing motor. The mesoporous silica nanomotor adopts mesoporous silica particles with the particle sizes of 50 to 90 nm, and a platinum layer is sputtered on the partial surface of the nanomotor. The preparation method comprises the following steps: firstly, synthesizing mesoporous silica nanoparticles, secondly, performing hydrophilic treatment to silicon chips, thirdly, dripping silicon dioxide nanoparticle dispersion liquid onto the hydrophilic silicon chips, drying, and sputtering platinum onto the silicon chips, on which a single-particle layer is arranged, obtained in step III, and fourthly, drying after ultrasonic vibration for shaking off, so as to obtain the mesoporous silica nanomotor. The application is to put the mesoporous silica nanomotor into hydrogen peroxide solution to be used. The nanomotor has Yin and Yang structural characteristics and a carrying function, the preparation method is simple to operate, and the primary synthetic amount is large. The mesoporous silica nanomotor can be applied to fields of biomedical, chemical and environment detection.

Owner:HARBIN INST OF TECH

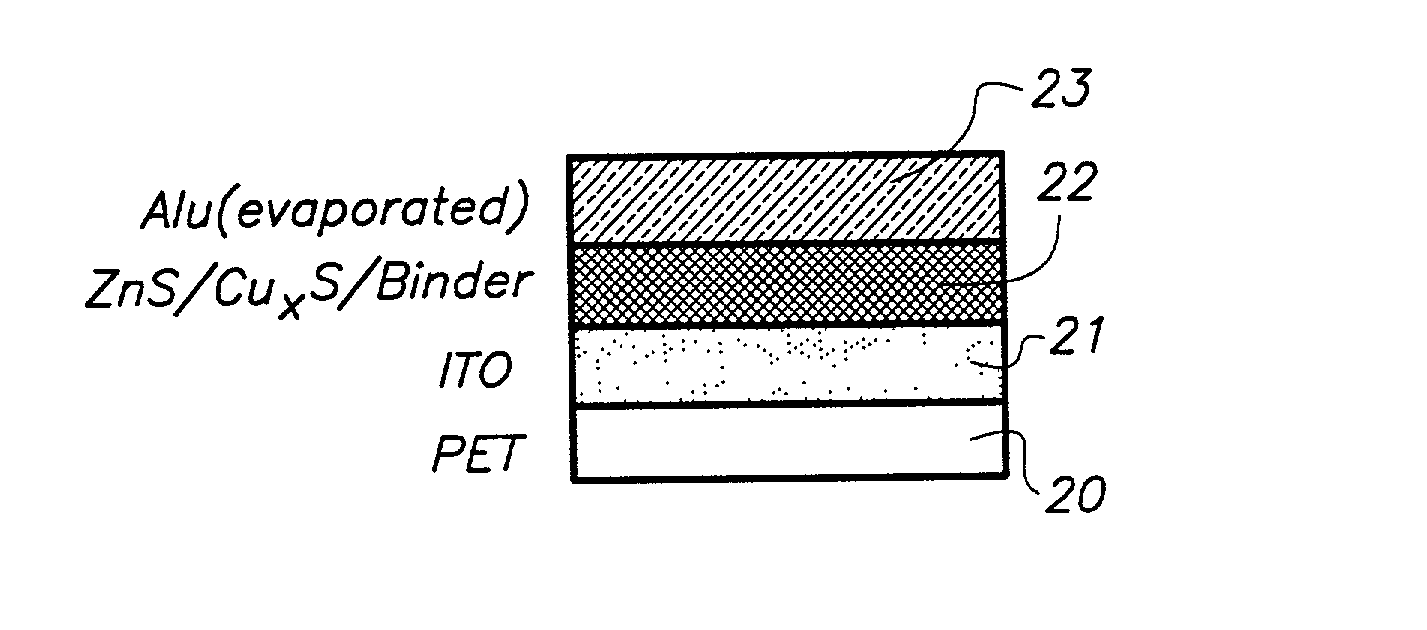

Manufacturing of a thin film inorganic light emitting diode

InactiveUS20020153830A1Economical and simpleEasy and economical to manufactureSolid-state devicesSemiconductor/solid-state device manufacturingAqueous solutionLight-emitting diode

Nanoparticle dispersions of ZnS doped with a luminescent center are prepared by precipitation from aqueous solutions. When such dispersions are coated between conductive electrodes a Thin Film Inorganic Light Emitting Diode device is obtained.

Owner:AGFA GEVAERT AG

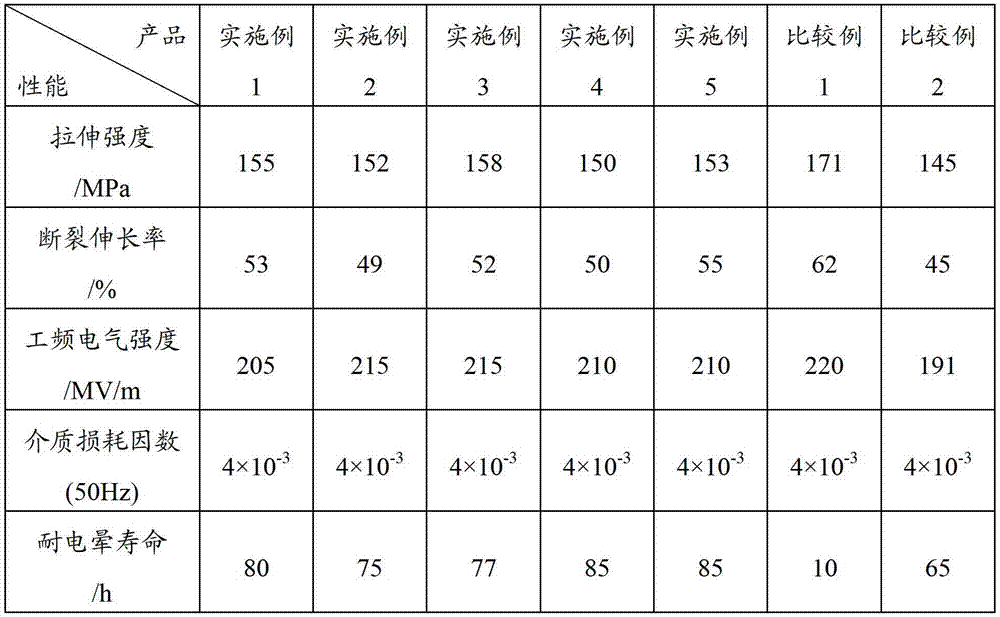

Polyamide acid dispersion liquid and preparation method thereof as well as polyimide film

ActiveCN103172859AImproved corona resistance lifeHigh tensile strengthMetal oxide nanoparticlesOrganic solvent

The invention provides a preparation method of a polyamide acid dispersion liquid. The preparation method comprises the following steps: dispersing metal oxide nanoparticles with the surfaces modified by a coupling agent into an organic solvent, thereby obtaining a nanoparticle dispersion liquid; and mixing the obtained nanoparticle dispersion liquid with dianhydride and diamine and reacting, thereby obtaining the polyamide acid dispersion liquid. According to the preparation method, the surfaces of the metal oxide nanoparticles are modified firstly; and then the nanoparticles are dispersed into the organic solvent with the low viscosity, so that the nanoparticles are dispersed evenly and stably, and therefore, the defect that the nanoparticles are not dispersed evenly because the polyamide acid solution is high in viscosity is overcome. Finally, the polyamide acid dispersion liquid is obtained by performing a polymerization reaction. A polyimide film prepared by the polyamide acid dispersion liquid is good in corona-resistant performance and mechanical performance.

Owner:株洲时代华鑫新材料技术有限公司

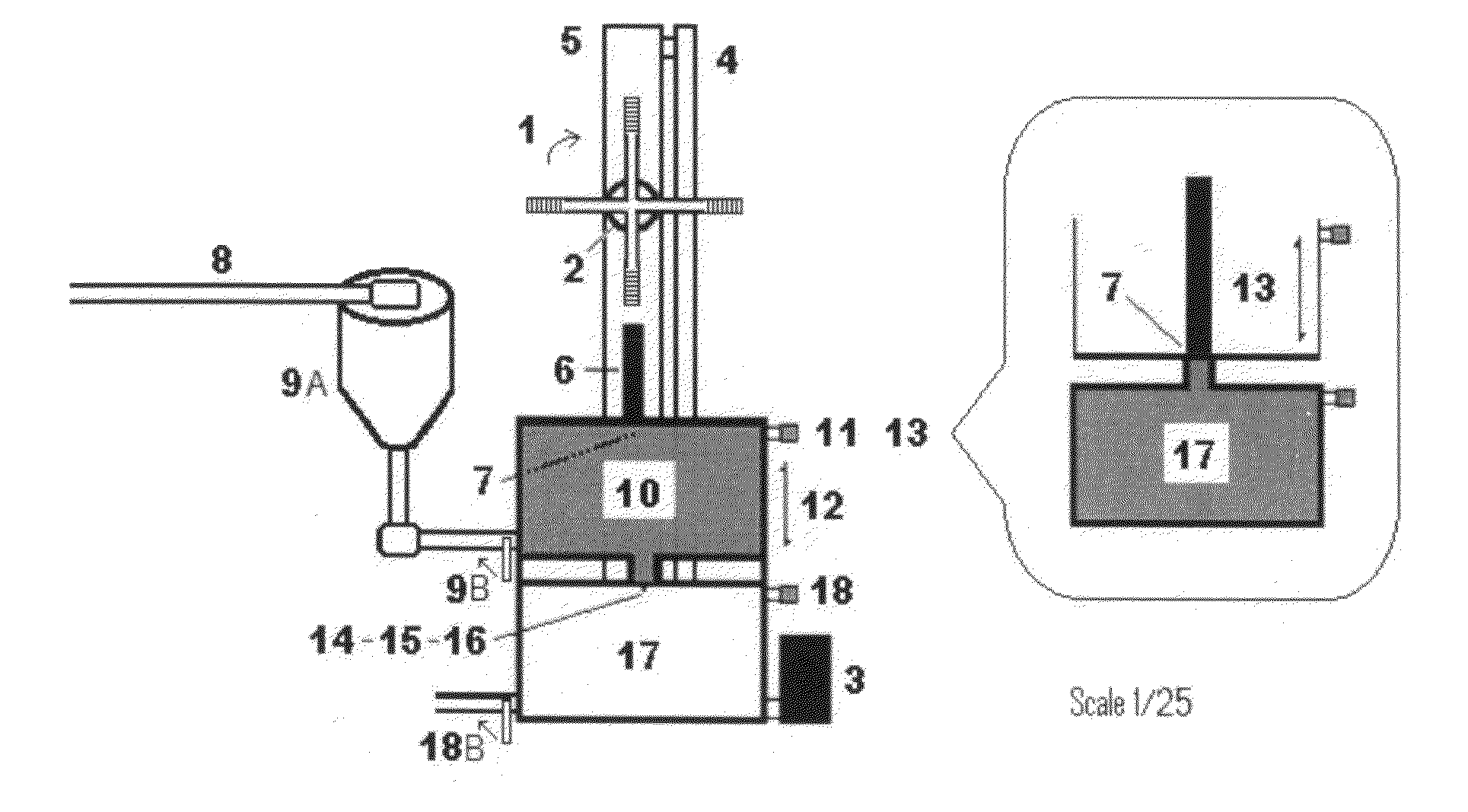

Manufacturing of a thin inorganic light emitting diode

InactiveUS6602731B2Economical and simpleEasy and economical to manufactureMaterial nanotechnologyPigmenting treatmentAqueous solutionNanometre

Owner:AGFA GEVAERT AG

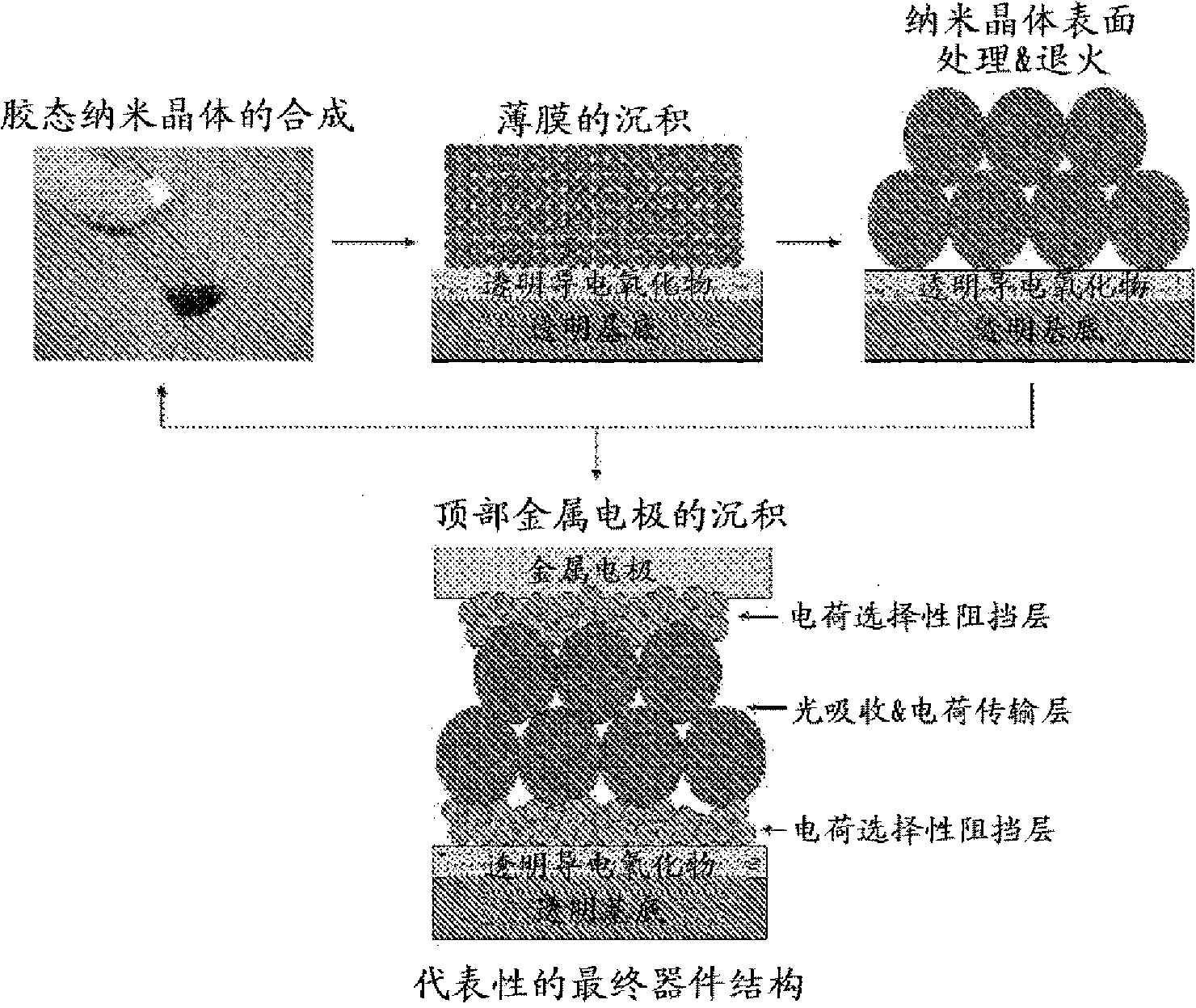

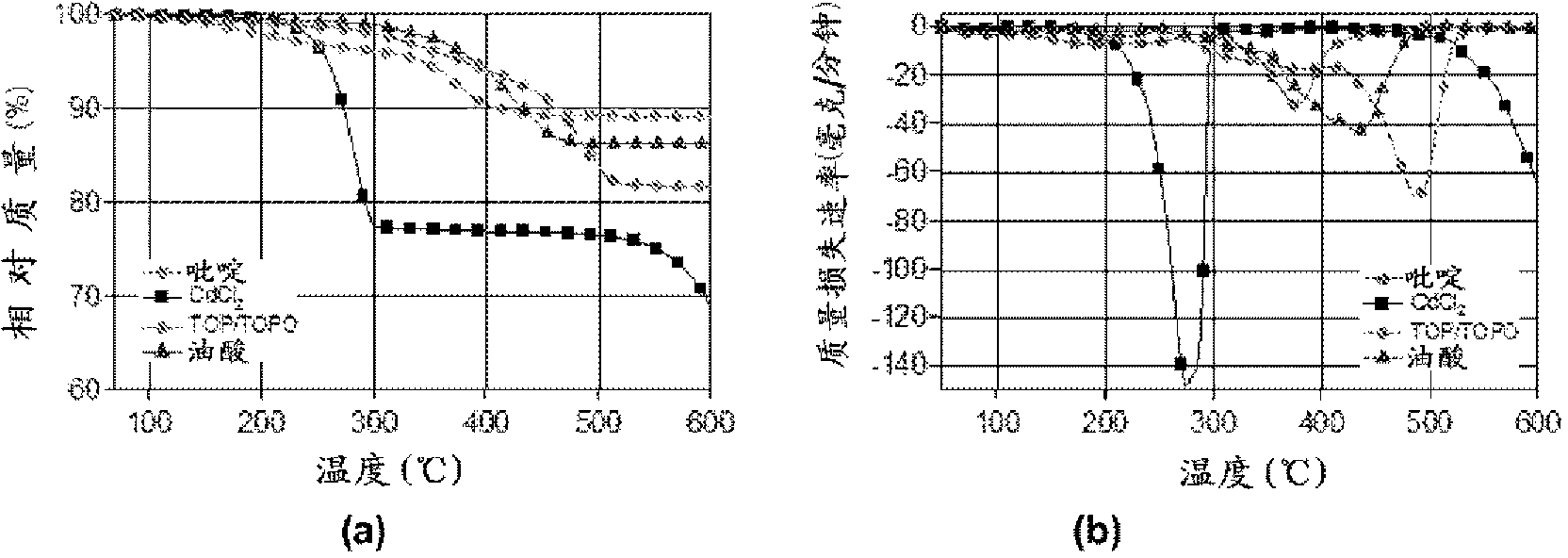

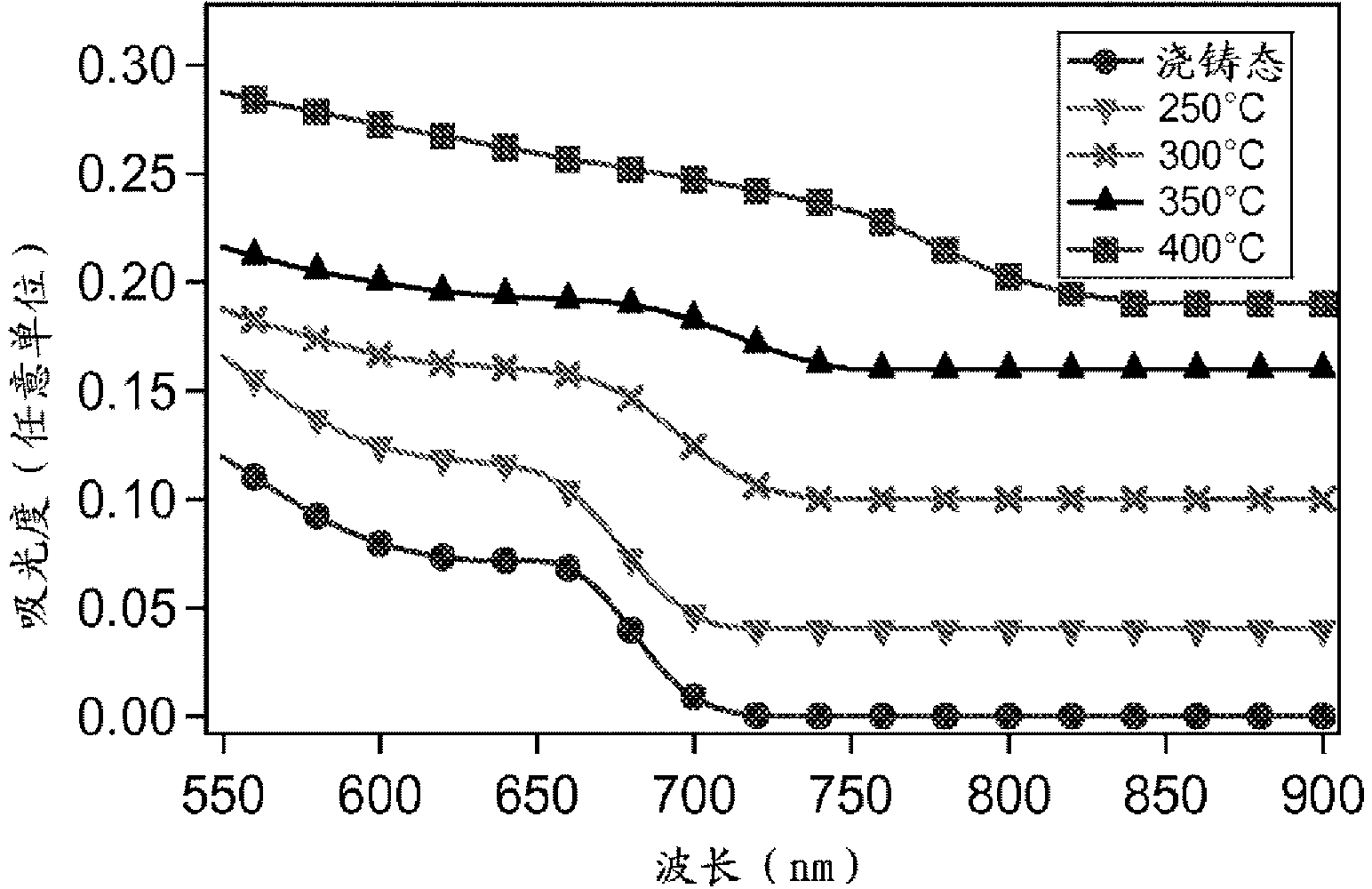

Sintered device

InactiveCN103222032AImprove power conversion efficiencyMaterial nanotechnologyFinal product manufactureRepeated treatmentMaterials science

Owner:COMMONWEALTH SCI & IND RES ORG +1

Manufacturing of a thin film inorganic light emitting diode

InactiveUS20030003614A1Economical and simpleEasy and economical to manufactureMaterial nanotechnologyPigmenting treatmentAqueous solutionNanometre

Nanoparticle dispersions of ZnS doped with a luminescent center and of CuxS are prepared together or separately by precipitation from aqueous solutions. When such dispersions are coated between conductive electrodes a Thin Film Inorganic Light Emitting Diode device is obtained.

Owner:AGFA GEVAERT AG

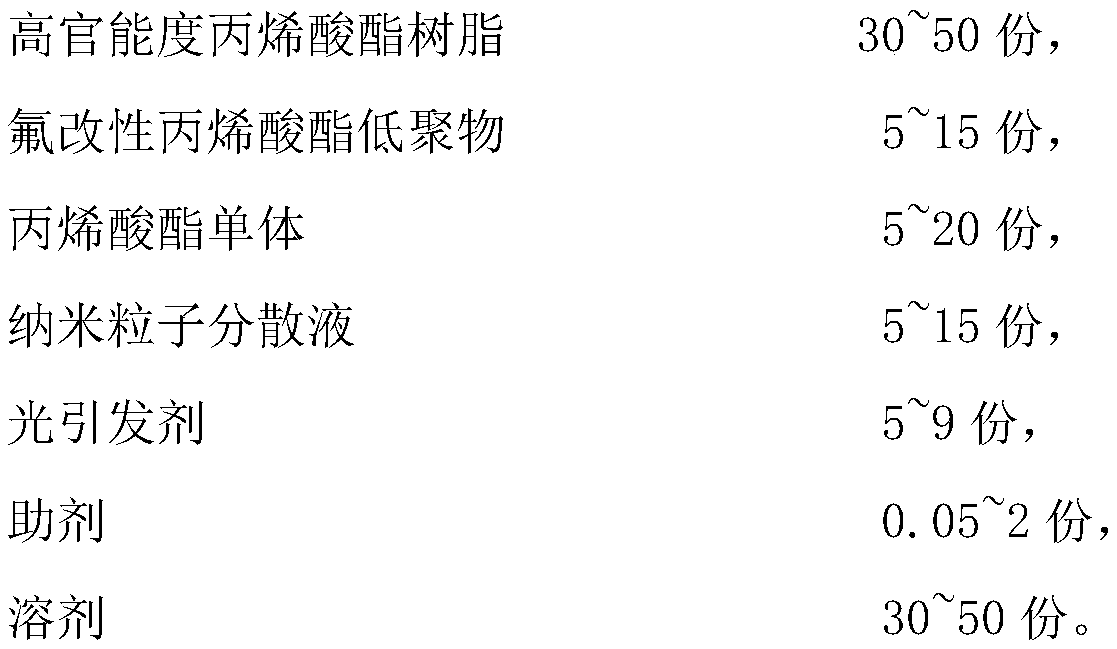

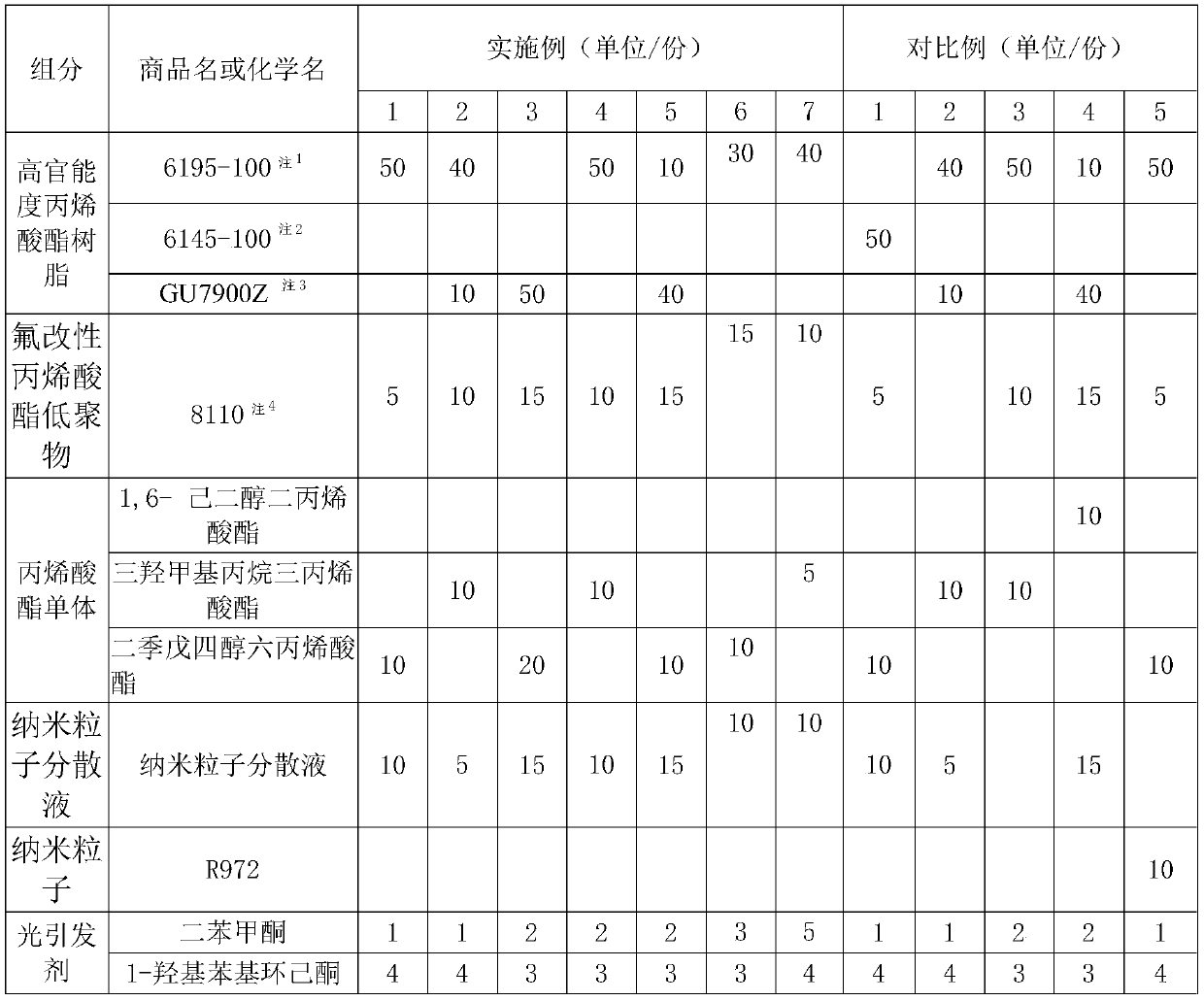

Ultraviolet curing coating composition with high wear resistance and fingerprint resistance and preparation method thereof

InactiveCN111100545AHigh steel wool wear-resistantImprove anti-fingerprintPolyurea/polyurethane coatingsPolyester coatingsPolymer scienceOligomer

The invention provides an ultraviolet curing coating composition with high wear resistance and fingerprint resistance and a preparation method thereof. The composition is prepared from the following components in parts by weight: 30-50 parts of high-functionality acrylate resin, 5-15 parts of fluorine-modified acrylate oligomer, 5-20 parts of an acrylate monomer, 5-15 parts of nanoparticle dispersion liquid, 5-9 parts of a photoinitiator, 0.05-2 parts of an auxiliary agent and 30-50 parts of a solvent. Compared with the prior art, the steel wool of the prepared ultraviolet curing coating composition is excellent in wear resistance and has fingerprint resistance and hand sweat resistance; and the coating has high hardness, is suitable for surface protection of plastic base materials, has excellent comprehensive performance, and can be applied to the related fields of mobile phone plastic rear covers, mobile phone films and the like.

Owner:SHANGHAI WEIKAI CHEM +2

Organic pigment nano particle dispersion and preparation method, photo-sensitive resin combination, trans-printing material, filter, liquid display device and ccd device

InactiveCN101081942ALittle change over timeIncreased durabilityAzo dyesInksAlkaline earth metalOligomer

An organic pigment nanoparticle dispersion, its preparation method, a colored photosensitive resin composition containing the dispersion, a photosensitive resin transfer material using the composition, a color filter using the transfer material, and an LCD device using the color filter are provided to improve contrast, display characteristics and display durability. An organic pigment nanoparticle dispersion comprises an organic pigment nanoparticle, and contains 0.001-500 ppm of an alkali metal or an alkaline earth metal. Preferably the organic pigment nanoparticle dispersion comprises a polymer having a weight average molecular weight of 1,000 or more. A colored photosensitive resin composition comprises the organic pigment nanoparticle dispersion; a binder; a monomer or an oligomer; and a photopolymerization initiator. Preferably the pigment of the dispersion is a pyrrolopyrrole-based pigment.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com