Preparation method of aqueous super-hydrophobic/super-hydrophobic and oileophobic coating

A super-hydrophobic and super-amphiphobic technology, used in coatings, antifouling/underwater coatings, anti-corrosion coatings, etc., can solve the problems of difficult dispersion and low surface energy of active components, and achieve excellent mechanical stability, Good environmental stability and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

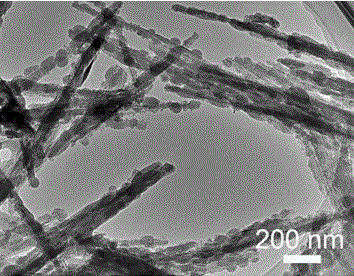

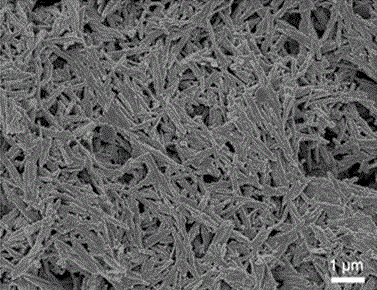

[0034] Weigh 0.8g attapulgite, add it into a 100mL Erlenmeyer flask, then measure 80mL water respectively, adjust the pH to 5, stir magnetically for 10min, and sonicate for 30min. After that, 0.5 mL of methyltrimethoxysilane was measured and added into the Erlenmeyer flask, and stirred and reacted at room temperature for 24 hours to obtain a uniform organosilane polymer / attapulgite composite suspension. Measure 4mL of the organosilane polymer / attapulgite composite suspension, spray on the glass surface at a spraying pressure of 0.2MPa, a spraying distance of 15cm, and a substrate heating temperature of 50°C to obtain a water-based superhydrophobic coating. Depend on figure 1 The transmission electron microscope photos show that the smooth surface of the attapulgite is covered with a large number of organosilane polymer nanoparticles. figure 2 It can be seen from the scanning electron microscope photos that the coating is composed of attapulgite modified by organosilane poly...

Embodiment 2

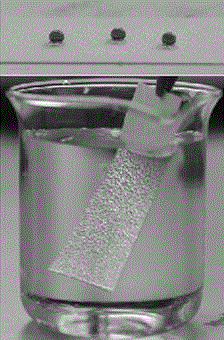

[0036] Weigh 0.2g of SiO with a diameter of 100nm 2Add nanoparticles into a 50mL Erlenmeyer flask, then measure 40mL water to adjust the pH to 3, stir magnetically for 10min, and sonicate for 30min. Then measure 0.1mL of hexadecyltrimethoxysilane, 0.2mL of ethyl orthosilicate and 0.1mL of aminopropyltrimethoxysilane, add them into the Erlenmeyer flask, stir and react at room temperature for 24h to obtain a homogeneous organosilane polymerization Matter / SiO 2 Complex suspension. Measure 4mL organosilane polymer / SiO 2 The composite suspension is sprayed on the surface of the aluminum sheet under the control of the spraying pressure of 0.2MPa, the spraying distance of 20cm, and the substrate heating temperature of 100°C to obtain a superhydrophobic coating. Depend on image 3 It can be seen that the coating exhibits good repellency to water, and the surface does not wet after soaking in water for 24 h. The contact angle and rolling angle were measured with 5 μL water droplet...

Embodiment 3

[0038] Weigh 10g of titanium dioxide with a diameter of 30nm and add it into a 200mL Erlenmeyer flask, then measure 160mL of water respectively, adjust the pH to 2, stir mechanically for 10min, and sonicate for 30min. Then measure 0.3mL tetraethoxysilane, 1.2mL perfluorodecyltriethoxysilane and 0.05mL phenyltriethoxysilane, add them into the Erlenmeyer flask, stir and react at room temperature for 12h to obtain a uniform organosilane Polymer / titanium dioxide composite suspension. Measure 2mL of organosilane polymer / titanium dioxide composite, control spraying pressure 0.3MPa, spraying distance 10 cm, substrate heating temperature 50 ℃ to spray on the glass surface to obtain water-based superamphiphobic coating. The contact angle and rolling angle were measured with 5 μL water droplet and n-decane droplet. The results showed that: the contact angle of the layer to water was >159°, and the rolling angle was 150°, and the rolling angle was <16°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com