Fumed silica modified acrylate waterproof paint, and preparation method thereof

A technology of fumed silica and waterproof coating, which is applied in the direction of coating, etc., can solve the problems that low temperature flexibility and tensile strength cannot be improved at the same time, the tensile strength of acrylate waterproof coating is low, and waterproof coating does not have superhydrophobicity, etc. Achieve the effects of improving tensile strength and scrub resistance, high elongation at break, and strong resistance to deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

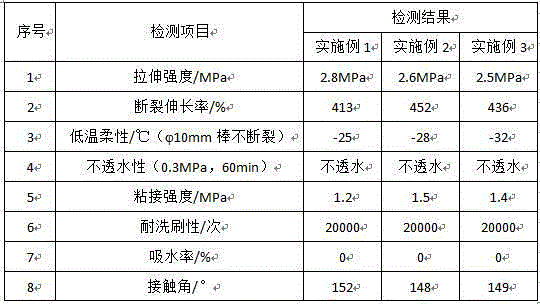

Examples

Embodiment 1

[0049] Embodiment 1 A kind of fumed silica modified acrylate waterproof coating

[0050] Described waterproof paint, by weight, comprises following raw material:

[0051] 40 parts of polymer emulsion, 30 parts of modified fumed silica, 0.6 parts of wetting and dispersing agent, 0.5 parts of defoamer, 0.2 parts of preservative, 0.2 parts of thickener, 5 parts of kaolin, 20 parts of heavy calcium powder, titanium 5 parts white powder, 1 part water;

[0052] Wherein, the modified fumed silica includes, in parts by weight, 15 parts of fumed silica, 10 parts of water, 6 parts of ethanol, 6 parts of acetone, and 1.5 parts of silane coupling agent.

[0053] The polymer emulsion is a styrene-acrylic emulsion with a glass transition temperature of -20°C, purchased from Dongying Jinyoulai Industry and Trade Co., Ltd., and the model is GT-167;

Embodiment 2

[0054] Embodiment 2 A kind of fumed silica modified acrylate waterproof coating

[0055] Described waterproof paint, by weight, comprises following raw material:

[0056] 45 parts of polymer emulsion, 25 parts of modified fumed silica, 0.4 part of wetting and dispersing agent, 0.4 part of defoamer, 0.1 part of preservative, 0.3 part of thickener, 8 parts of kaolin, 25 parts of heavy calcium powder, titanium 5 parts white powder, 3 parts water;

[0057] Wherein, the modified fumed silica includes, in parts by weight, 12 parts of fumed silica, 8 parts of water, 5 parts of ethanol, 4 parts of acetone, and 1.2 parts of silane coupling agent.

[0058] The polymer emulsion described is a styrene-acrylic emulsion with a glass transition temperature of -6°C, from Shanghai Badefu Industrial Co., Ltd., and the model is 300s;

Embodiment 3

[0059] Embodiment 3 A kind of fumed silica modified acrylate waterproof coating

[0060] Described waterproof paint, by weight, comprises following raw material:

[0061] 50 parts of polymer emulsion, 20 parts of modified fumed silica, 0.2 parts of wetting and dispersing agent, 0.2 parts of defoamer, 0.2 parts of preservative, 0.5 parts of thickener, 10 parts of kaolin, 20 parts of heavy calcium powder, titanium 5 parts white powder, 5 parts water;

[0062] Wherein, the modified fumed silica includes, in parts by weight, 10 parts of fumed silica, 5 parts of water, 4 parts of ethanol, 4 parts of acetone, and 1 part of silane coupling agent.

[0063] The polymer emulsion is a pure acrylic emulsion with a glass transition temperature of -23°C, from Dongying Jinyoulai Industry and Trade Co., Ltd., and the model is TX-2068;

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com