Nano SiO2 composite polysiloxane modified water-based terpenyl EP/PU (Epoxy Resin/Polyurethane) superhydrophobic self-cleaning polymer and preparation method thereof

A polysiloxane and superhydrophobic technology, which is applied in antifouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor water resistance and pollution resistance of film-forming materials, and achieve good hydrophobicity , excellent superhydrophobic, small particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] use nano-SiO 2 and hydrophobic nano-SiO 2 .

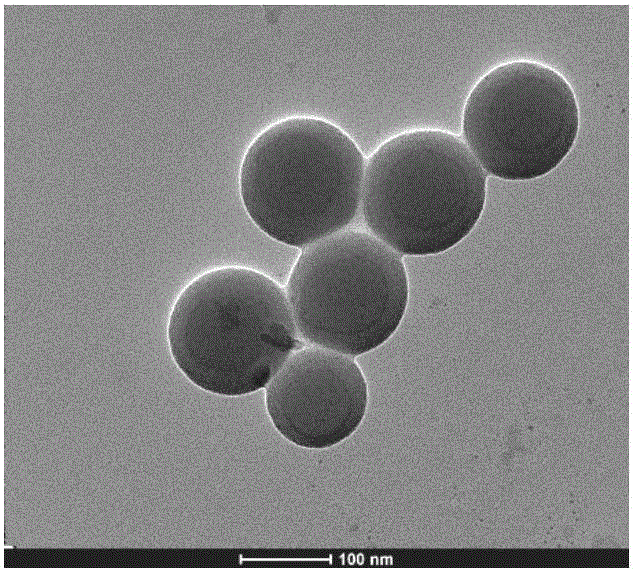

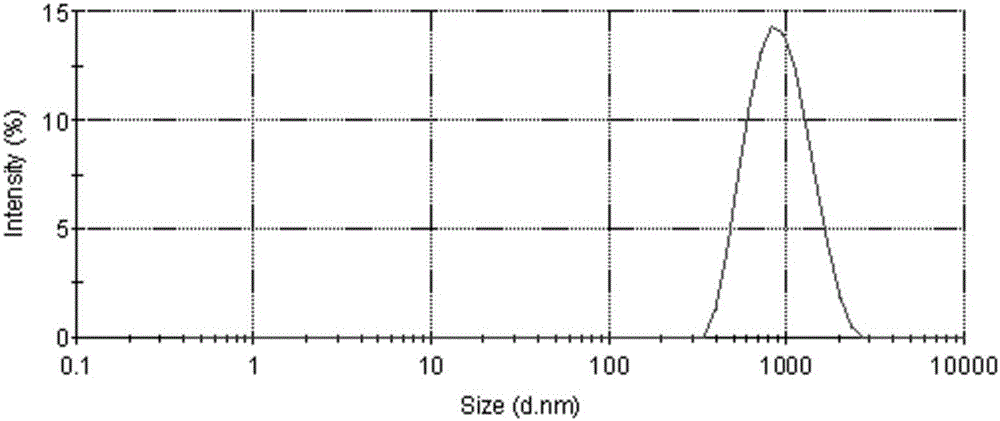

[0033] Add a certain proportion of ethanol, ammonia water and distilled water into a 250mL round bottom flask, stir and heat to 60°C, quickly add the mixed solution of TEOS and ethanol into the reaction flask, and react at 60°C for 1h to obtain nano-SiO 2 ; Add the mixture of trimethylethoxysilane and ethanol dropwise into the reaction flask, stir at 60°C for 2 hours at high speed, and obtain SiO by high-speed centrifugation 2 , repeatedly centrifuged and washed with absolute ethanol until the solution was neutral, and dried to obtain hydrophobic nano-SiO 2 powder. Hydrophobic nano-SiO 2 The average particle size is 100nm (such as figure 2 ).

Embodiment 2

[0035] Hydrophobic nano-SiO 2 The addition amount is 5% of the solid resin mass in the polysiloxane-modified waterborne terpene-based EP / PU composite system.

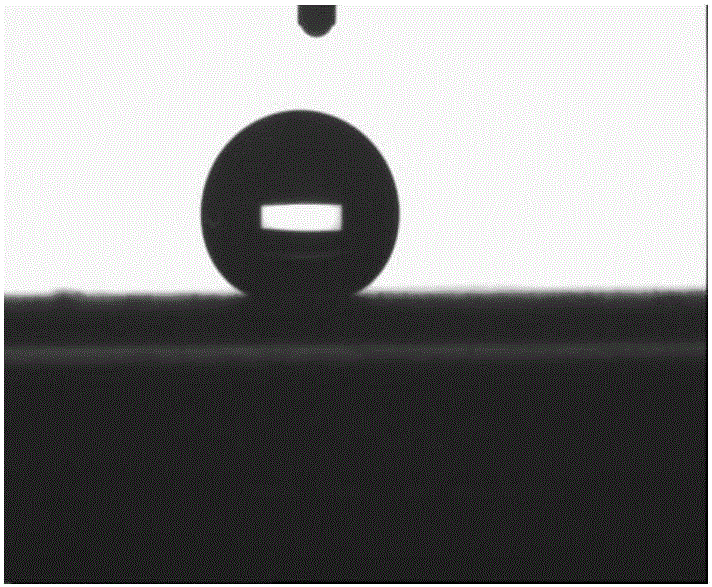

[0036] 0.37g hydrophobic nano-SiO 2 Add to the composite system of 10.00g polysiloxane-modified terpene-based epoxy resin polyol aqueous dispersion (solid content 35%) and 4.86g hydrophilic modified isocyanate, stir and ultrasonic treatment 5min, mix well, add 4. Dilute with 50g of distilled water, spray to form a film, place at room temperature for 24 hours, and then bake in an oven at 120°C for 5 hours. After standing at room temperature for 24 hours, the surface static water contact angle of the coating measured by a contact angle measuring instrument according to the national standard GB / T 30447-2013 is 104°.

Embodiment 3

[0038] Hydrophobic nano-SiO 2 The addition amount is 10% of the solid resin mass in the polysiloxane-modified waterborne terpene-based EP / PU composite system.

[0039] 0.59g hydrophobic nano-SiO 2 Add to the composite system of 8.00g polysiloxane-modified terpene-based epoxy resin polyol aqueous dispersion (solid content 35%) and 3.87g hydrophilic modified isocyanate, ultrasonic 8min, mix well, add 5.81g distilled water Diluted, sprayed to form a film, placed at room temperature for 24 hours, and then baked in an oven at 120°C for 5 hours. After standing at room temperature for 24 hours, the surface static water contact angle of the coating measured by a contact angle measuring instrument according to the national standard GB / T30447-2013 is 132°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Static water contact angle | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com