Preparation method of bionic no-modification super-hydrophobic Cu-Zn-CeO2 layer and application thereof

A cu-zn-ceo2, super-hydrophobic technology, applied in coatings, electrolytic coatings, etc., can solve problems such as reducing the stability of super-hydrophobic surfaces, and achieve the effect of excellent hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

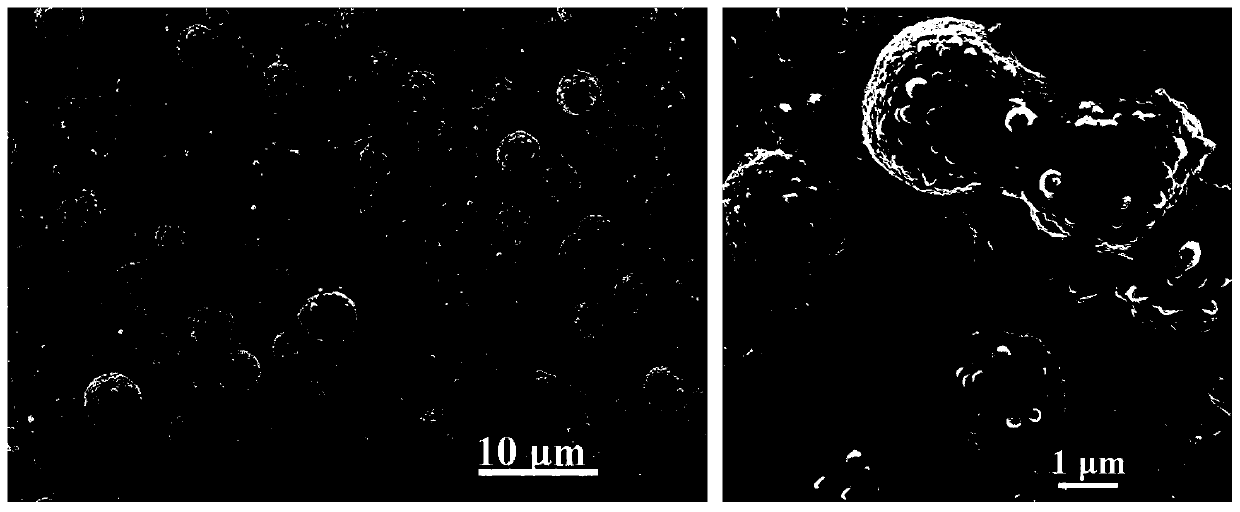

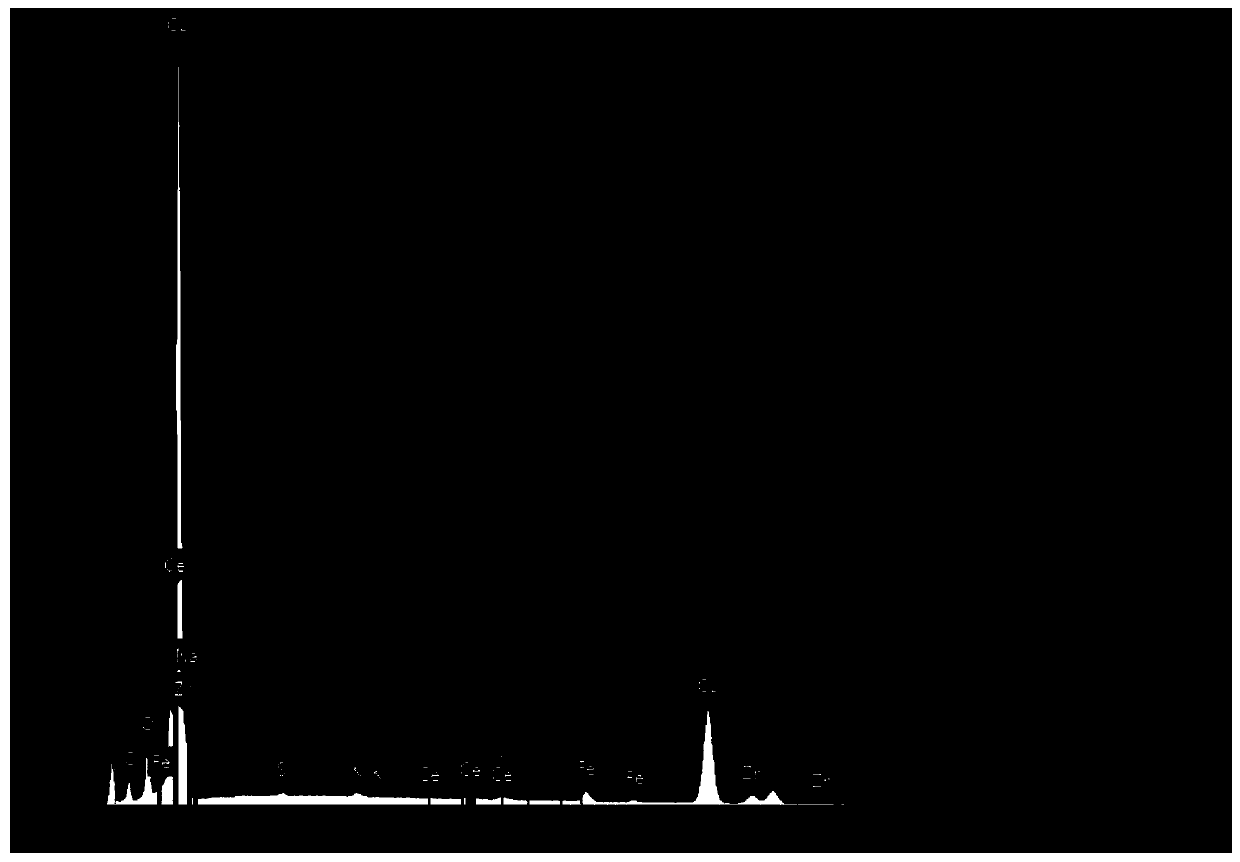

[0038] first embodiment , a biomimetic modification-free superhydrophobic Cu-Zn-CeO 2 The preparation method of layer, the steps are:

[0039] (1) Pretreatment of samples: Cut X90 pipeline steel and brass into 20mm×50mm×3mm and 20mm×50mm×5mm samples respectively, and use 400#, 1000#, 1500#, 2000# water mills in sequence Grind with sandpaper, then ultrasonically clean with anhydrous ethanol solution for 10 minutes, and dry with a hair dryer.

[0040] (2) Configure the electrodeposition solution:

[0041] Dissolve copper sulfate pentahydrate in 50 mL of deionized water, then add potassium sodium tartrate to obtain solution A, wherein the concentrations of copper sulfate and potassium sodium tartrate are 20 g / L and 100 g / L respectively;

[0042] Dissolve zinc sulfate heptahydrate in 50mL deionized water, then add potassium sodium tartrate to obtain solution B, wherein the concentrations of zinc sulfate and potassium sodium tartrate are 30g / L and 100g / L respectively;

[0043]...

no. 2 example

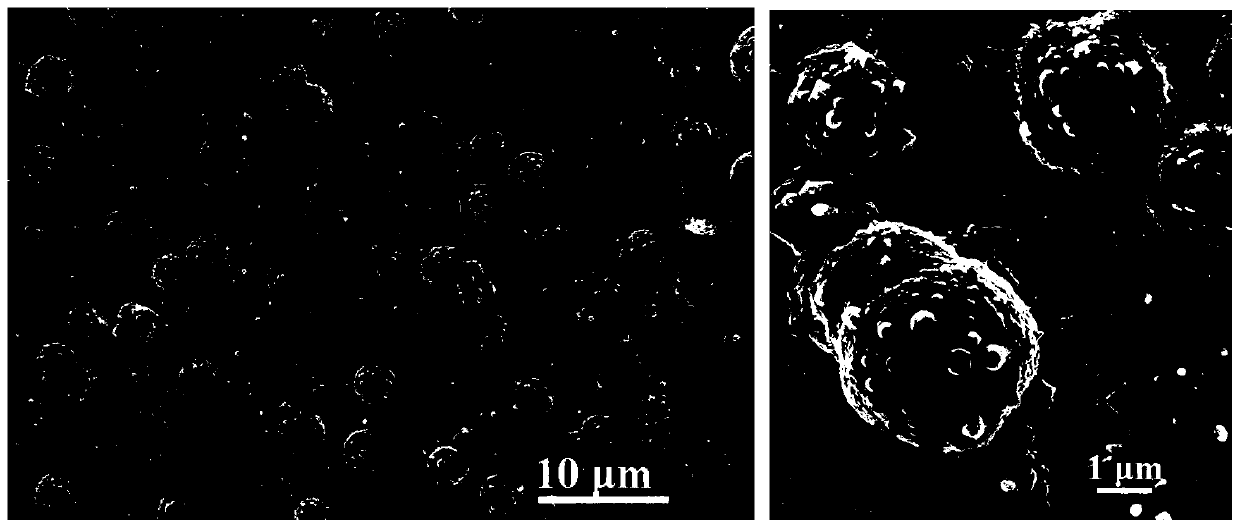

[0046] second embodiment , a biomimetic modification-free superhydrophobic Cu-Zn-CeO 2 The preparation method of layer, the steps are:

[0047] (1) Pretreatment of the sample: same as in Example 1.

[0048] (2) Configure the electrodeposition solution:

[0049] Dissolve copper chloride dihydrate in 50mL deionized water, then add potassium sodium tartrate to obtain solution A, wherein the concentrations of copper chloride and potassium sodium tartrate are respectively 10g / L and 100g / L;

[0050] Dissolve zinc chloride dihydrate in 50mL deionized water, then add potassium sodium tartrate to obtain solution B, wherein the concentrations of zinc chloride and potassium sodium tartrate are respectively 10g / L and 100g / L;

[0051] Mix solution A with solution B, then add 4g (40g / L) sodium hydroxide to the mixed solution, and finally add 0.4g (4g / L) nano CeO 2 (particle size 20-50nm), stir with a magnetic stirrer for 10min to obtain an electrodeposition solution.

[0052] (3) Pret...

no. 3 example

[0054] third embodiment , a biomimetic modification-free superhydrophobic Cu-Zn-CeO 2 The preparation method of layer, the steps are:

[0055] (1) Pretreatment of the sample: same as in Example 1.

[0056] (2) Configure the electrodeposition solution:

[0057] Copper nitrate pentahydrate was dissolved in 50 mL of deionized water, and potassium sodium tartrate was added to obtain solution A, wherein the concentrations of copper nitrate and potassium sodium tartrate were 30 g / L and 100 g / L respectively;

[0058] Dissolve zinc nitrate pentahydrate in 50 mL of deionized water, then add potassium sodium tartrate to obtain solution B, wherein the concentrations of zinc nitrate and potassium sodium tartrate are respectively 35 g / L and 100 g / L;

[0059] Mix solution A with solution B, then add 6g (60g / L) sodium hydroxide to the mixed solution, and finally add 1.2g (12g / L) nano-CeO 2 (particle size 20-50nm), stir with a magnetic stirrer for 20min to obtain an electrodeposition sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com