Patents

Literature

114 results about "Micro nanostructure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-durability super-hydrophobic self-cleaning coating material and preparation method thereof

InactiveCN101962514AHas the following advantages: (1) cleanlinessHas the following advantages: (1) has the functionAntifouling/underwater paintsPaints with biocidesDouble bondDimethyl siloxane

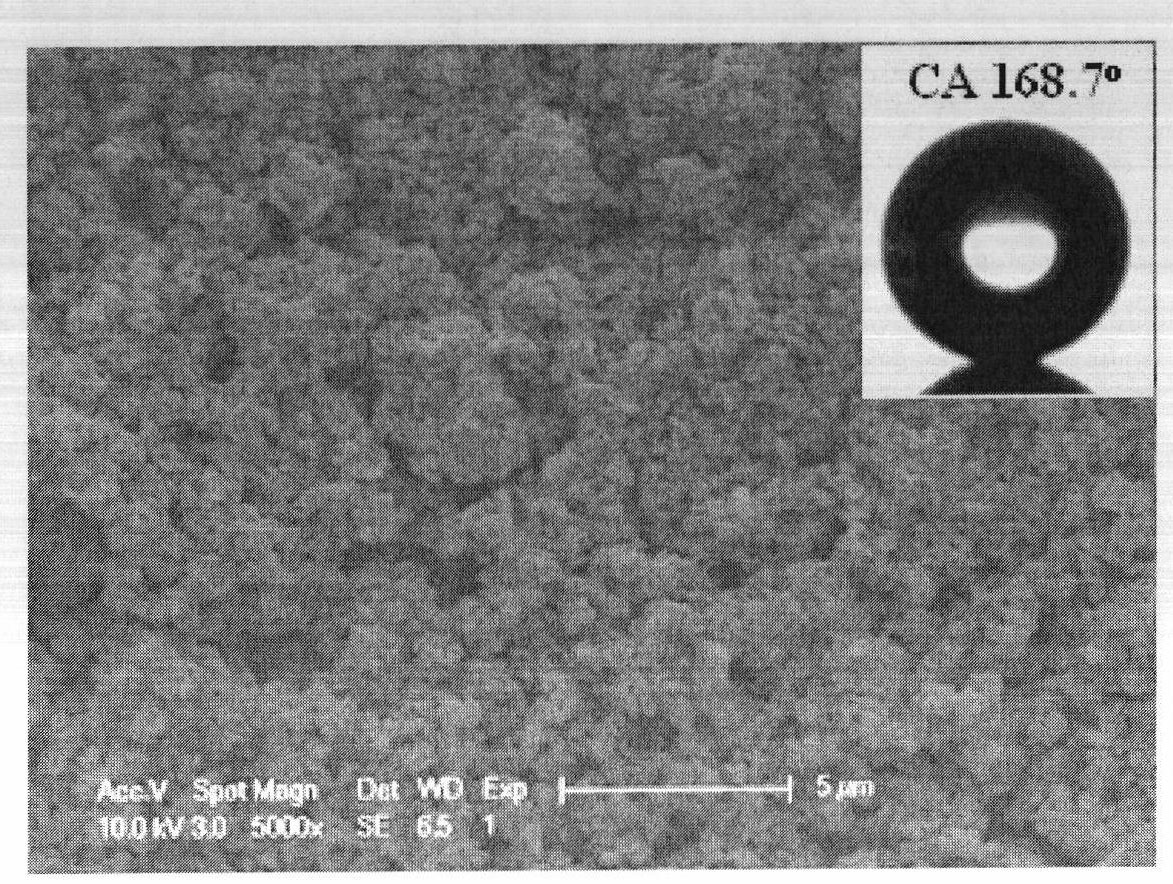

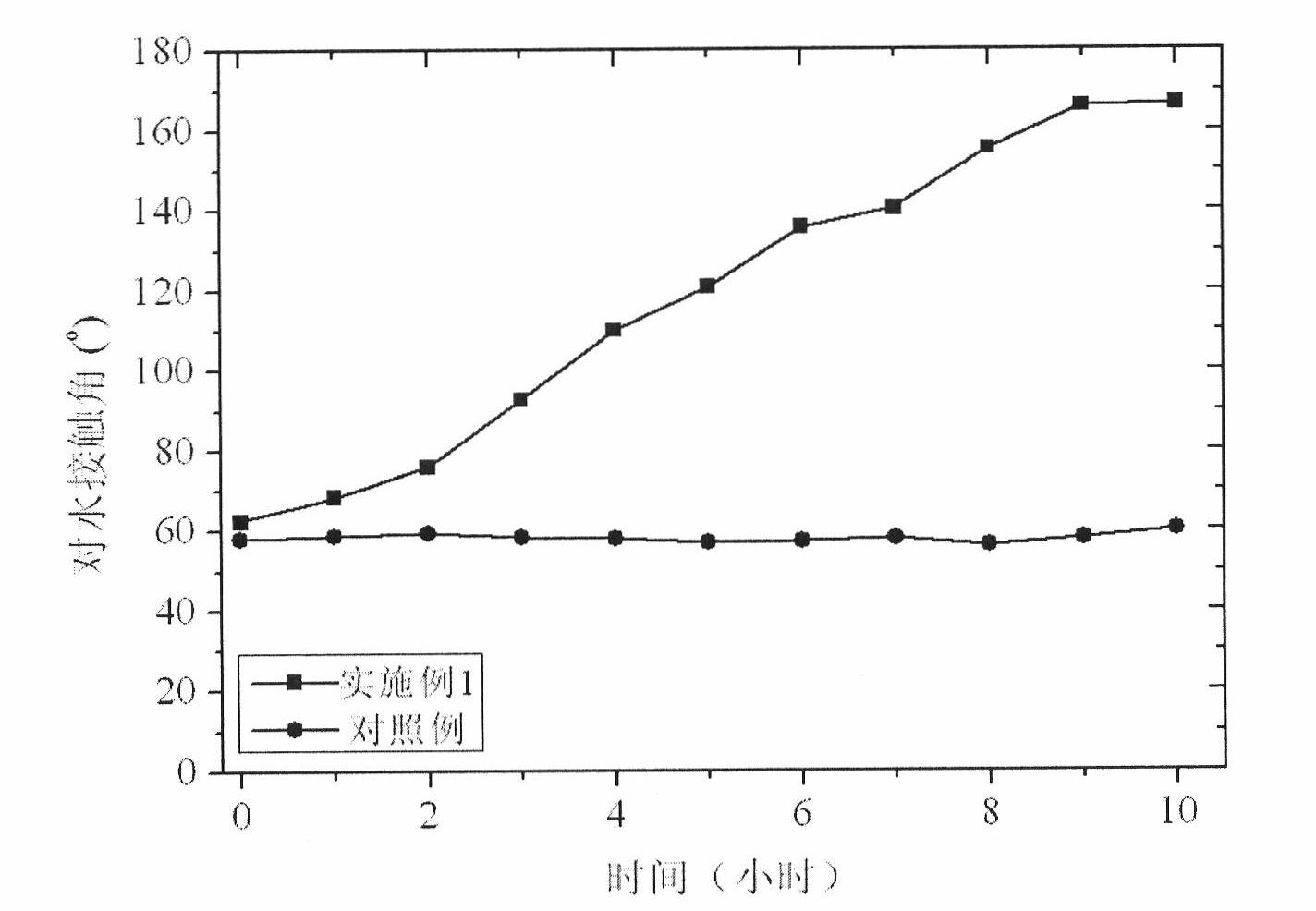

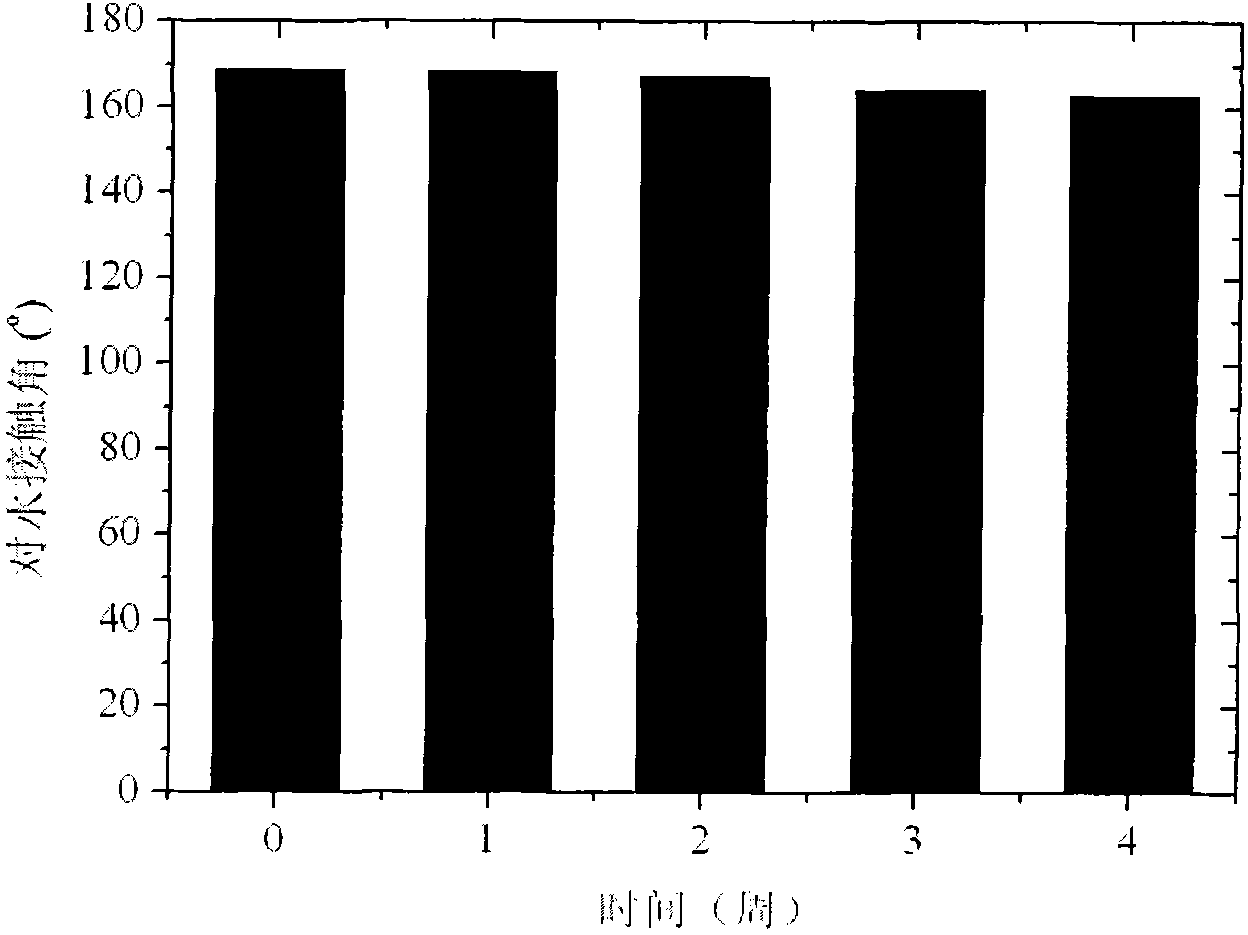

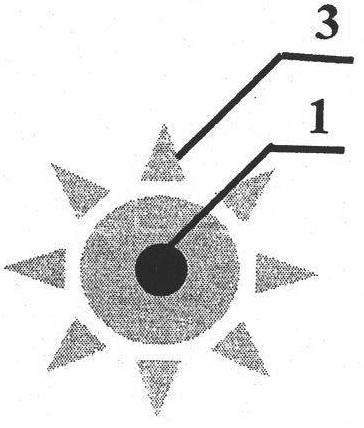

The invention belongs to the technical field of a new chemical material, and in particular relates to a high-durability super-hydrophobic self-cleaning coating material and a preparation method thereof. The coating material of the invention is prepared by curing and drying nanoparticles with photo-catalytic activity, a low-surface-free-energy polymer and a cross-linking agent at the room temperature, wherein the low-surface-free-energy polymer consists of one or more of polysiloxane fluoride, dimethyl silicone polymer and polyphenylene methyl siloxane, which contain active groups, such as hydroxyl alkoxy group, carbon-carbon double bond, silanol group, siloxy group, and the like; the cross-linking agent is hydrogen-containing silicone oil or aminosilane; and the mass content of the photo-catalytic nanoparticles in the coating ranges from 10 to 60 percent. The coating is formed into a micro-nanostructure by nanoparticle self-organization; a super-hydrophobic self-cleaning coating with lotus effect is prepared from the coating and a cross-linked filming matrix with low surface energy; the persistence of a lotus-shaped super-hydrophobic characteristic of the coating is realized by using the photo-catalytic decomposition characteristic of an organic pollutant for the nanoparticles; and thus the material is suitable for large-area construction and has high weathering resistance andprominent self-cleaning characteristic.

Owner:FUDAN UNIV

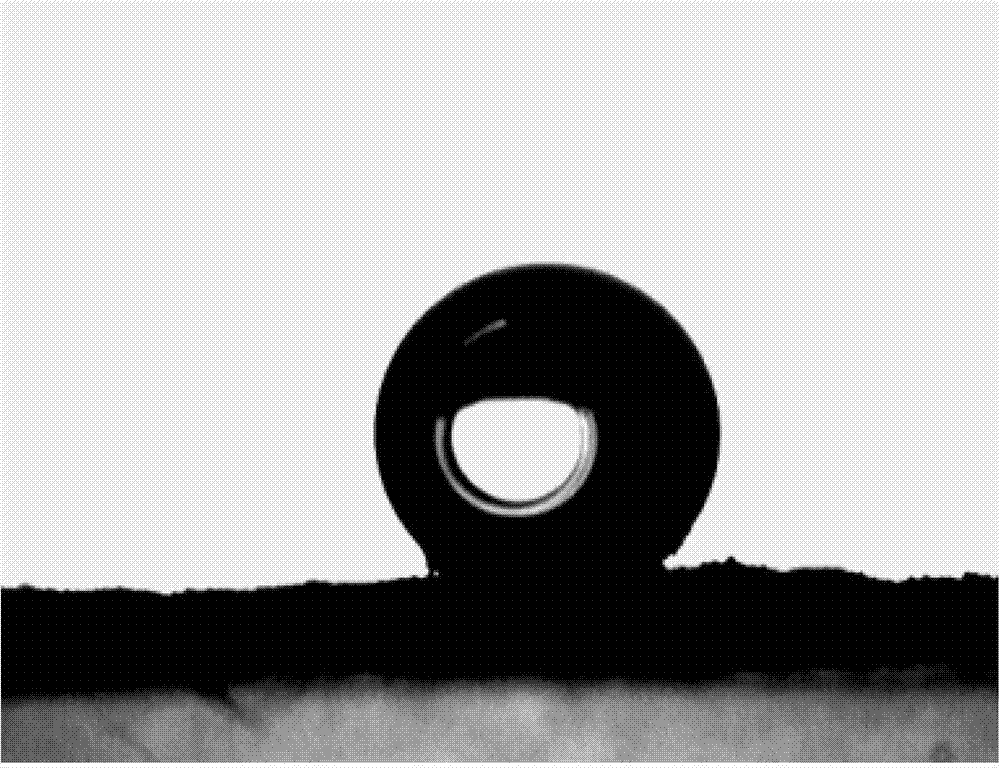

Method for preparing metal titanium or titanium alloy super-oleophobic surface

InactiveCN102021628AImprove stabilityReduce resistanceSurface reaction electrolytic coatingSpecial surfacesFine structureTitanium alloy

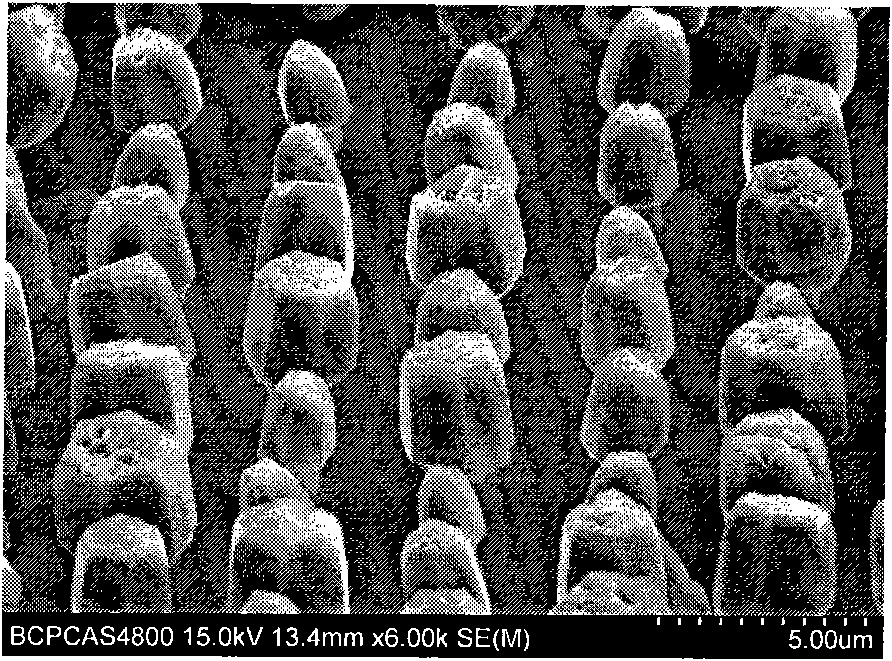

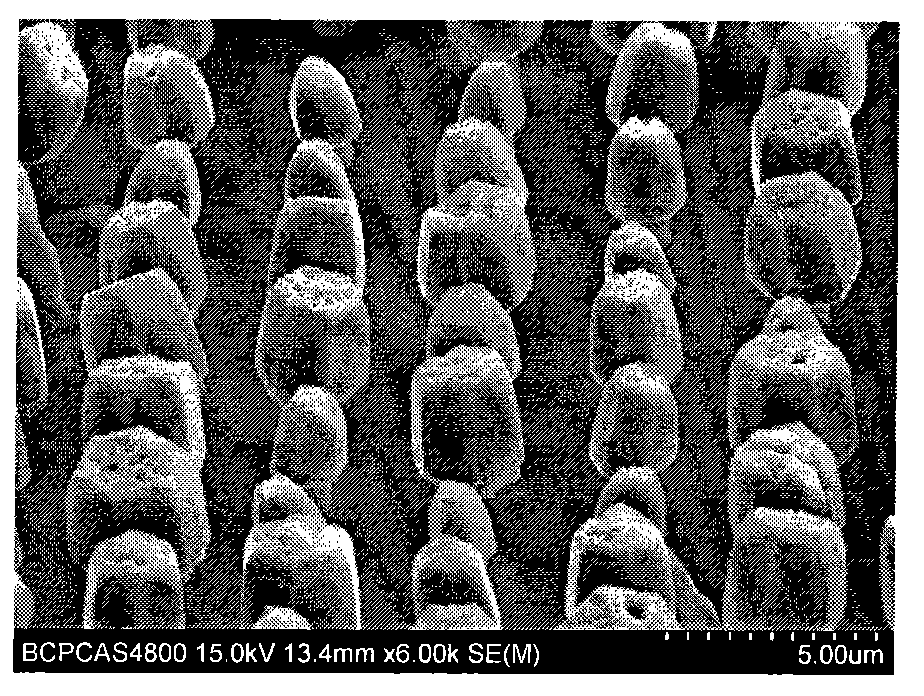

The invention discloses a method for preparing a metal titanium or titanium alloy super-oleophobic surface. The method comprises the following steps of: performing primary anodic oxidation treatment on metal titanium or titanium alloy to obtain a roughened surface with a microstructure; forming a titanium dioxide nanotube array film on the surface with microstructure through secondary anodic oxidation so as to obtain a composite fine structured micro-nanostructure; and modifying with a low-surface-energy substance to obtain the super-oleophobic surface and the super-hydrophobic and super-oleophobic surface. The metal titanium or titanium alloy surface has super-oleophobic and super-hydrophobic characteristics for multiple kinds of organic liquid, the static contact angle is greater than 155 degrees; the rolling angle is less than 10 degrees; meanwhile, the surface also shows superior super-oleophobic and super-hydrophobic characteristics for pure water and aqueous solution of acid, alkali and salt.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

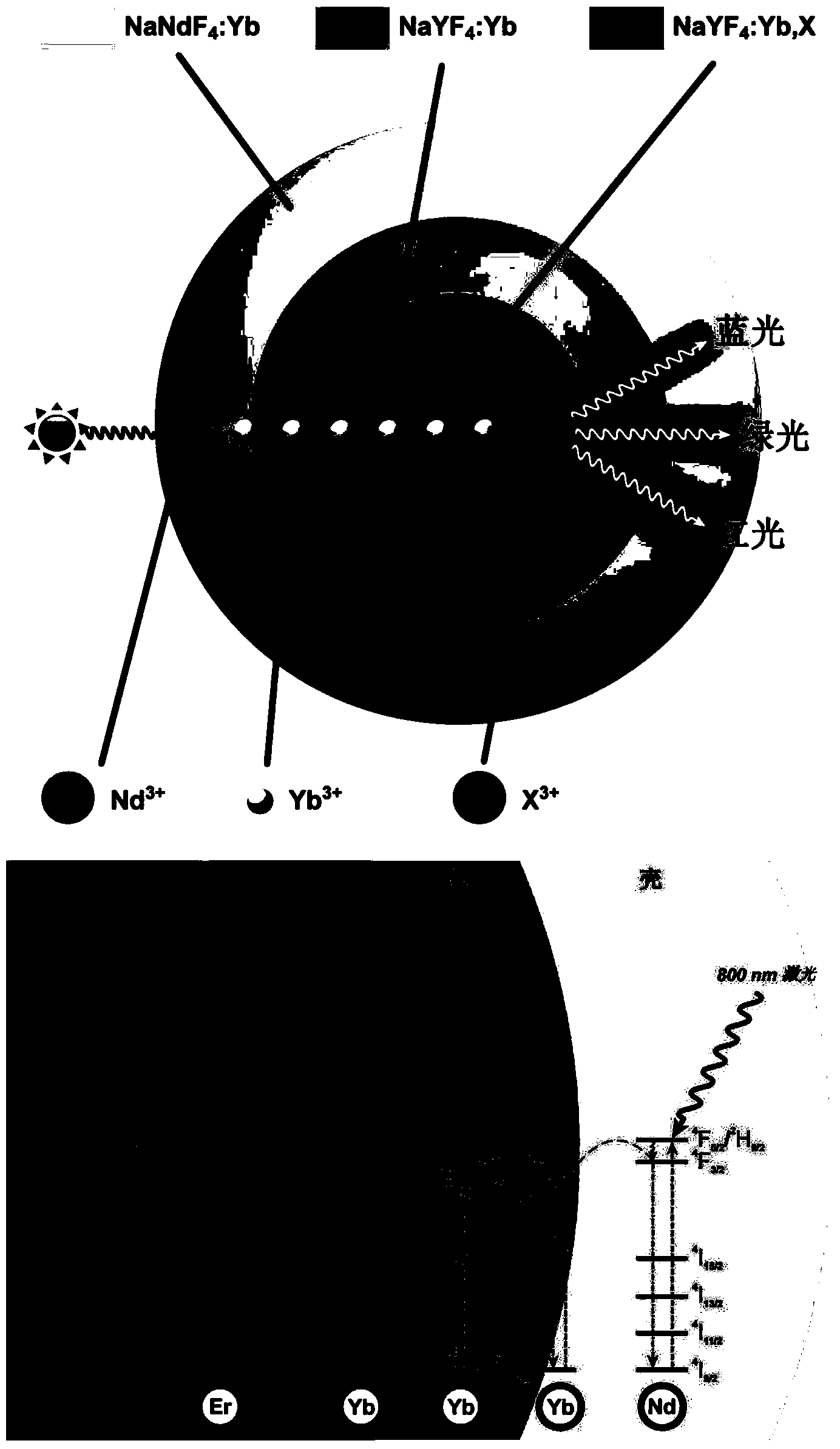

800-nanometer continuous laser excited rare earth upconversion nanoparticles (UCNPs), and preparation method and application thereof

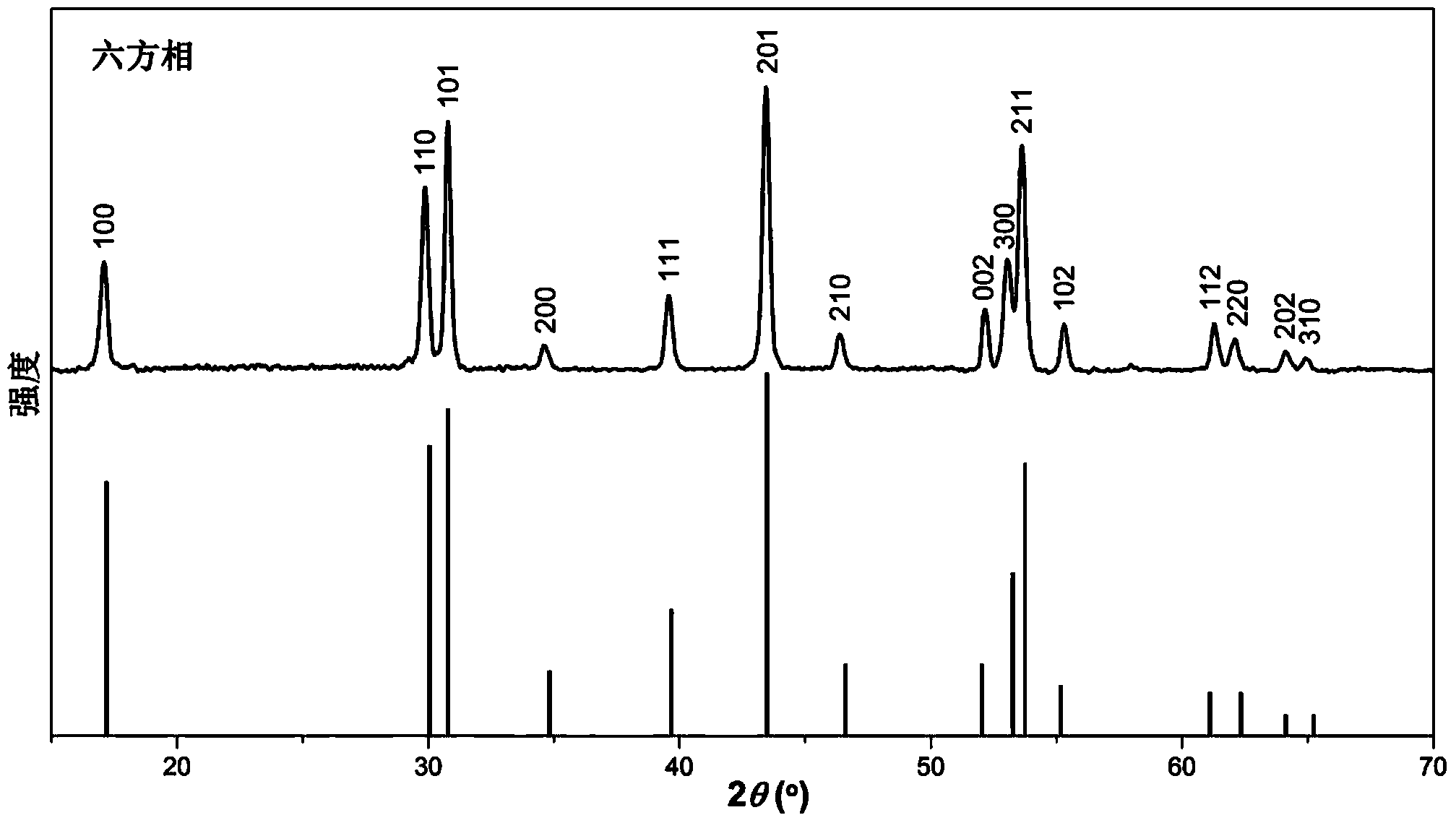

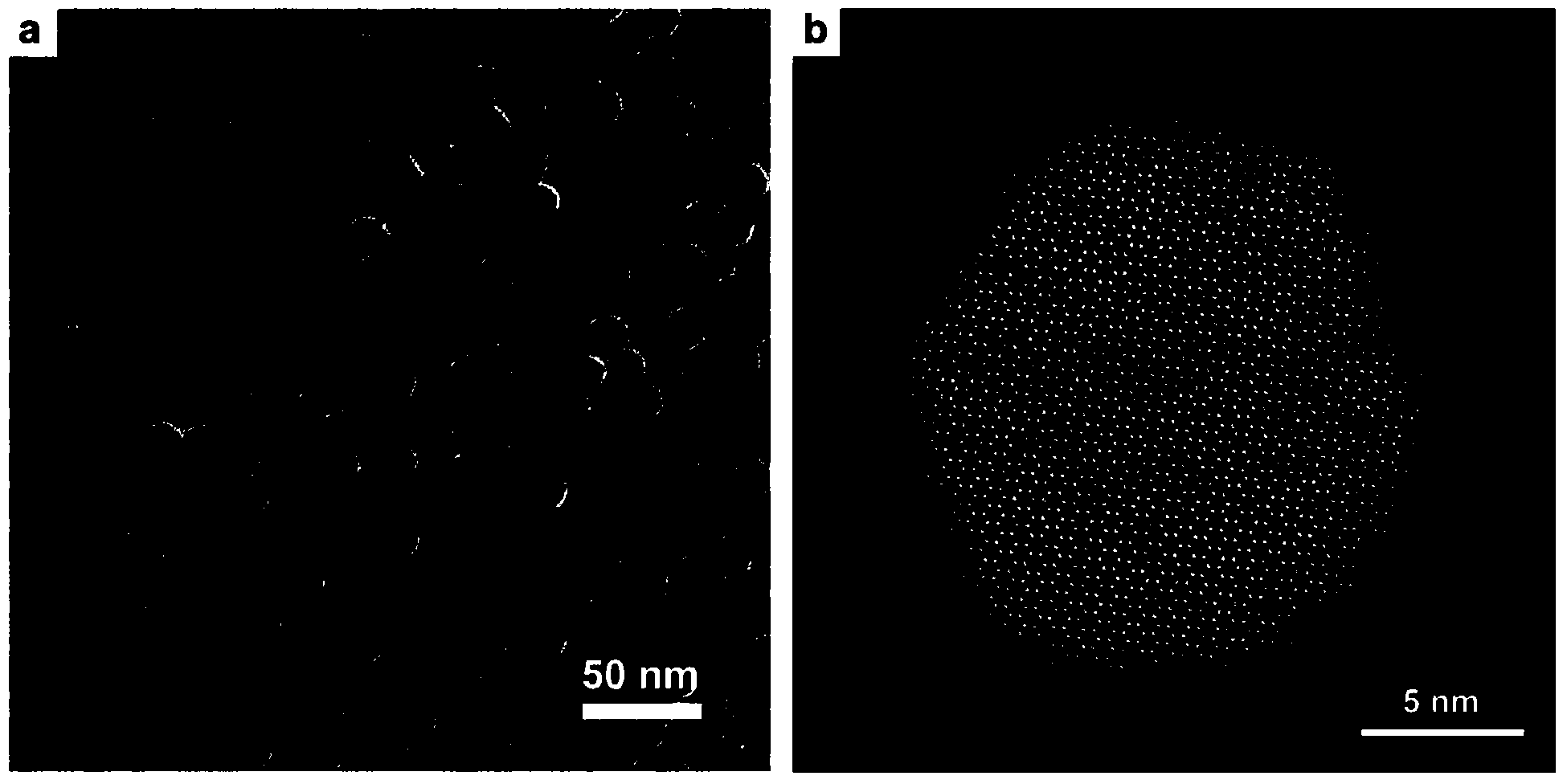

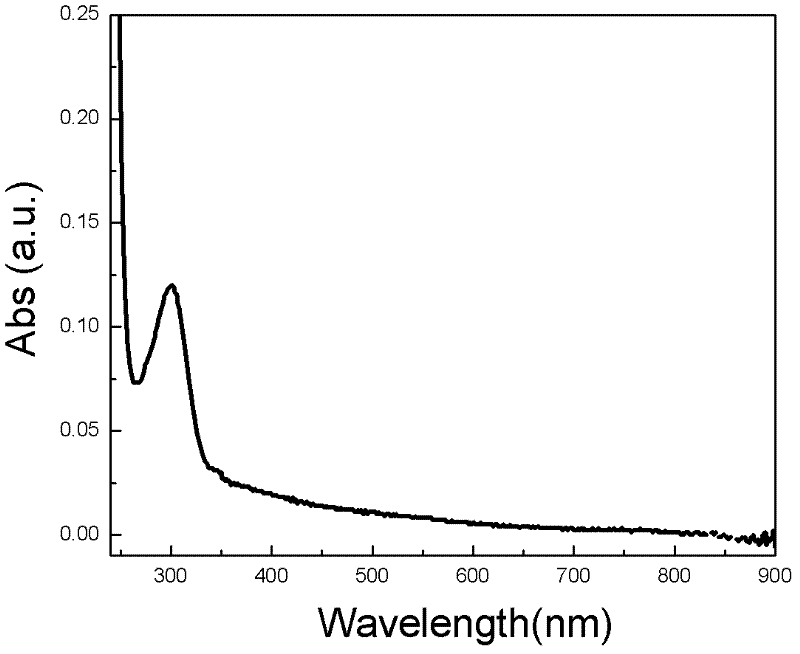

ActiveCN103450875AEffective absorptionAvoid quenchingLuminescent compositionsFluorescenceNanoparticle

The invention provides 'core-shell-shell' rare earth upconversion nanoparticles (UCNPs) using Nd as a sensitizing agent. The rare earth UCNPs are characterized in that the shell layer of the rare earth UCNPs contains Nd<3+> and each layer contains Yb<3+>. The special microscopic nanostructure solves the problem about the quenching effect on upconversion fluorescence in an Nd doping process, so bright upconversion fluorescence can be obtained. Compared with the traditional Yb-sensitized UCNPs, the Nd-sensitized UCNPs have higher infrared absorption intensity so as to greatly improve upconversion efficiency and fluorescence. The Nd-sensitized UCNPs adopt 800-nanometer instead of 980-nanometer laser as an exciting light source, so the Nd-sensitized UCNPs have smaller overheating effect and stronger biological tissue penetrating power. Therefore, the novel rare earth upconversion material is expected to be widely applied in the field of biomedicines.

Owner:INST OF CHEM CHINESE ACAD OF SCI

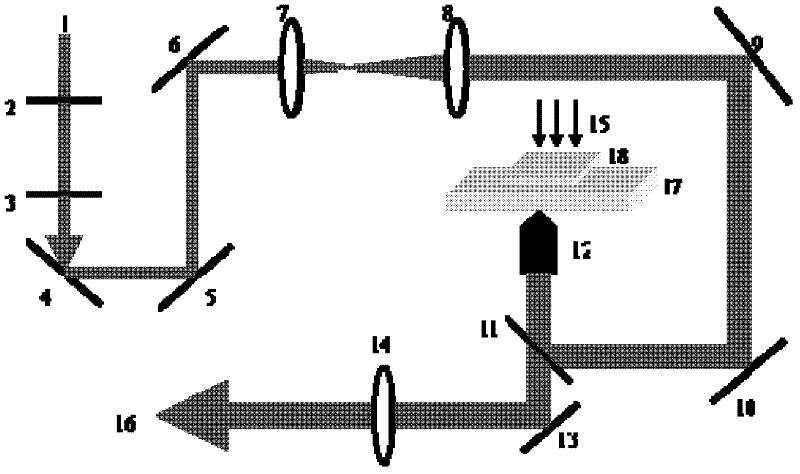

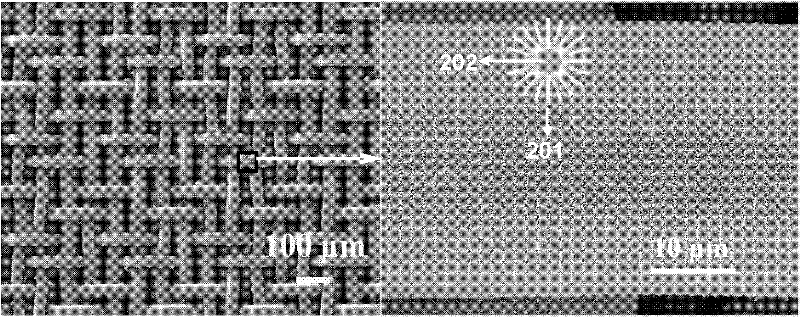

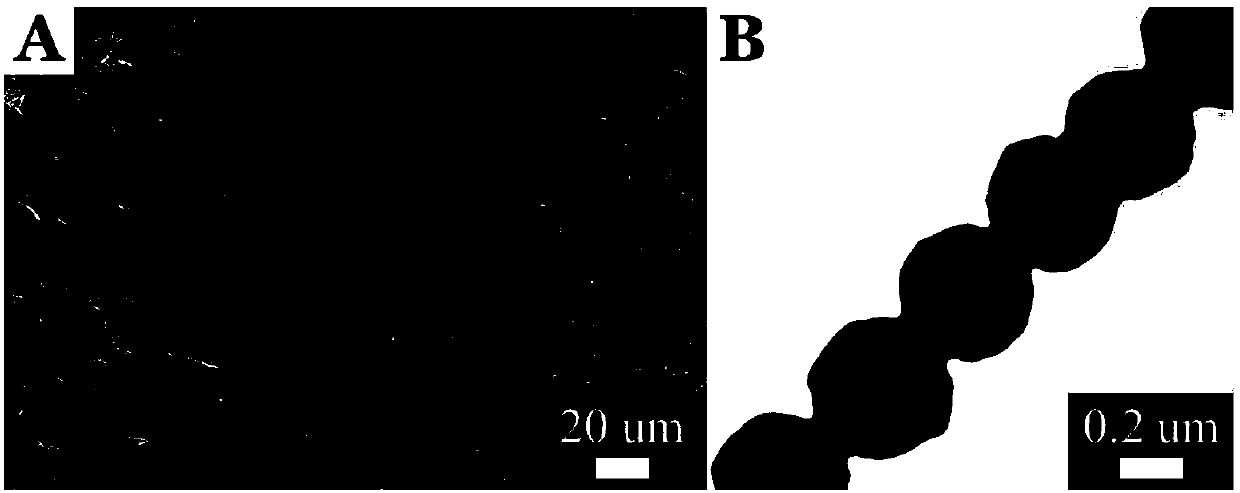

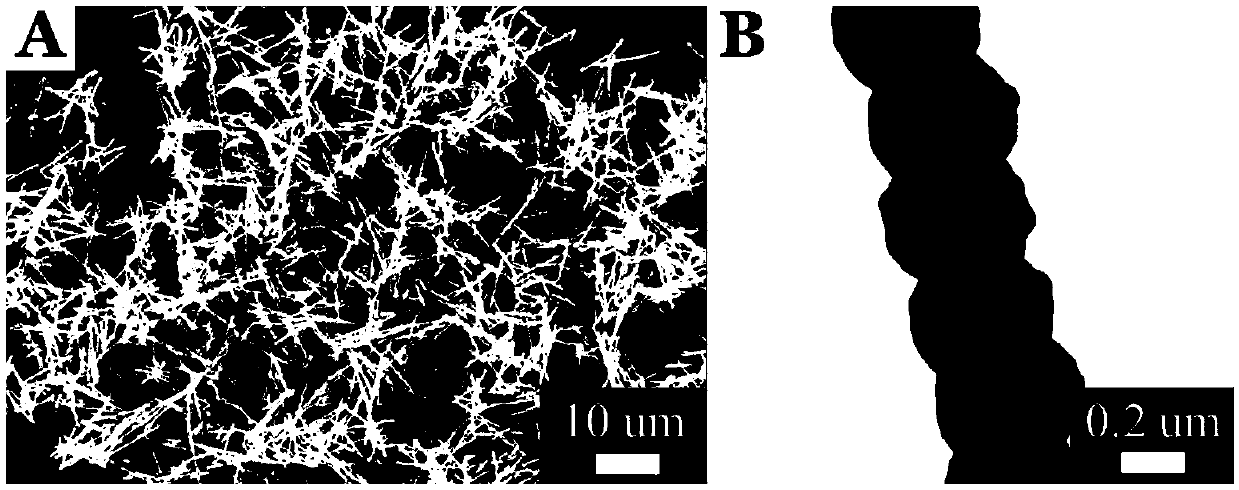

Method for preparing multistage metal micro-nanostructures inside micro fluidic chip

InactiveCN102311095ADecorative surface effectsChemical vapor deposition coatingMicro nanoSurface-enhanced Raman spectroscopy

The invention relates to a method for selectively preparing or integrating multistage silver micro-nanostructures inside various plane substrates and micro fluidic chip channels by the utilization of the femtosecond laser inducing metallic silver reduction technology. In addition, the silver multistage micro-nanostructure substrate prepared by the method is used as a reinforced substrate for surface-enhanced raman spectroscopy SERS. The method provided by the invention comprises the following steps of: preparing a silver plating solution for femtosecond laser micro-nano machining, establishing a femtosecond laser micro-nano machining system for realizing multi-point scan in the silver plating solution, placing the silver plating solution and the substrate into the femtosecond laser micro-nano machining system and preparing the multistage silver micro-nanostructures on the substrate. According to the invention, a laser beam scans in the silver plating solution along a track designed in advance by a program. The preparation method is independent of the smoothness of the substrate. In particular, the preparation of silver multistage structure SERS substrate can be accomplished on the bottom of the micro fluidic chip channels, thus realizing catalysis and surface-enhanced raman test application.

Owner:JILIN UNIV

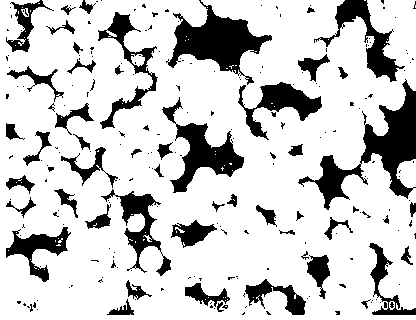

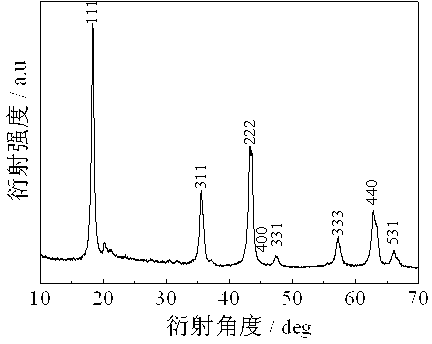

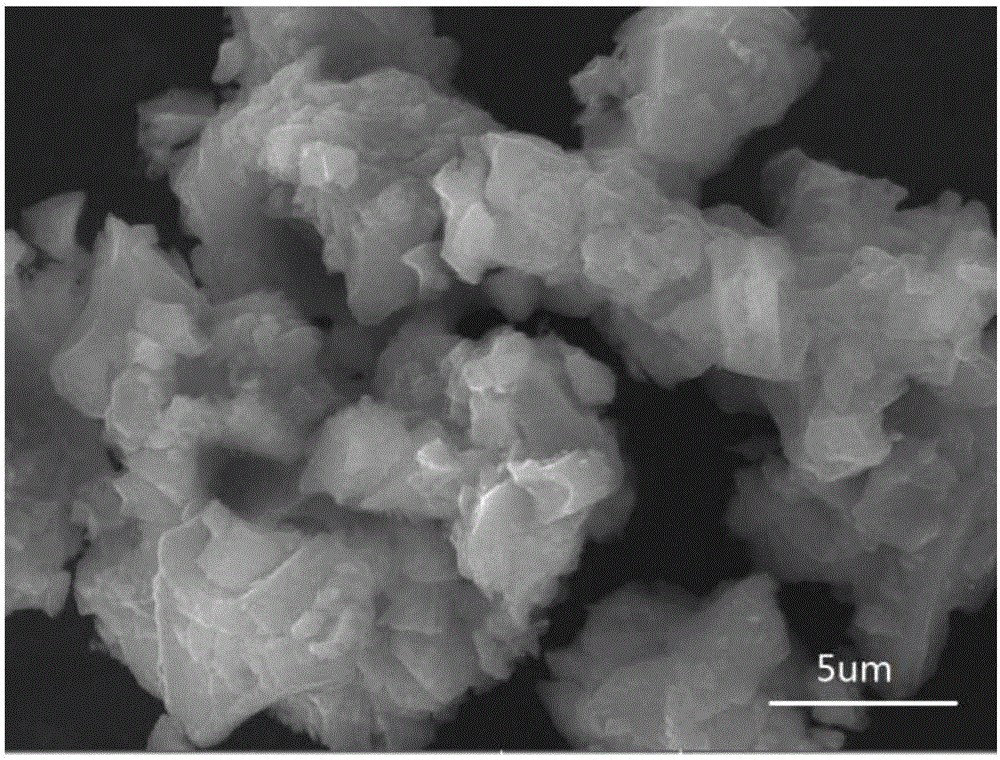

Preparation method of lithium titanate negative electrode material with micro-nanostructure

InactiveCN103107321AGood dispersionNarrow size distributionCell electrodesHigh rateLithium hydroxide

The invention provides a preparation method of a lithium titanate negative electrode material with a micro-nanostructure. The method is characterized by comprising the steps of: a. preparing a titanium dioxide precursor; b. under a stirring state, adding the titanium dioxide precursor into water, or a mixed solution of water and ethanol, further adding lithium hydroxide under a stirring state, then transferring the solution into a hydrothermal reaction kettle to undergo a hydrothermal reaction, leaving the solution to natural cooling to room temperature, then carrying out filtering, washing, drying and calcination, thus obtaining the lithium titanate negative electrode material end product. The method adopts spherical titanium dioxide as an initial raw material, and takes water or ethanol as a reaction solvent to prepare plush-like hollow microspheres with an average diameter of 1.5-3 micrometers through a hydrothermal reaction and a calcination treatment. The microspheres are composed of nanosheets. The material also shows certain mesoporous characteristic, the inner micropores of the material have an average diameter of 5-15nm. The lithium titanate negative electrode material with a micro-nanostructure involved in the invention has the characteristic of excellent high-rate discharge, and is suitable for use by power batteries.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

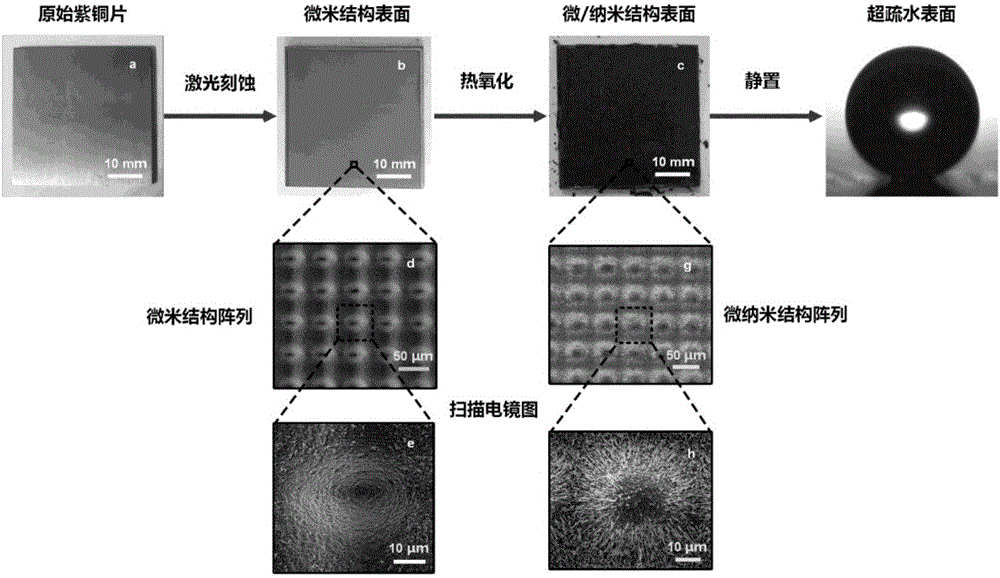

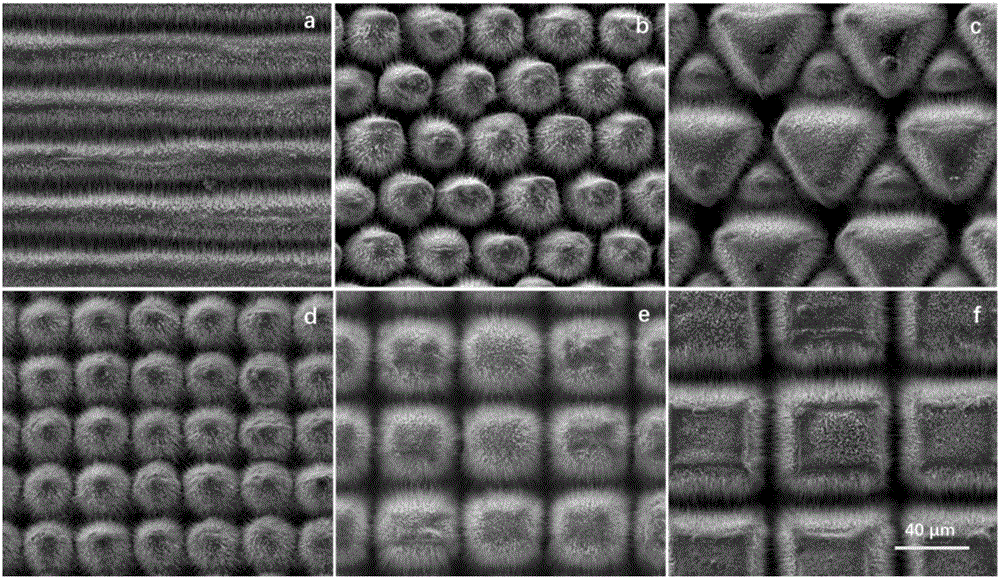

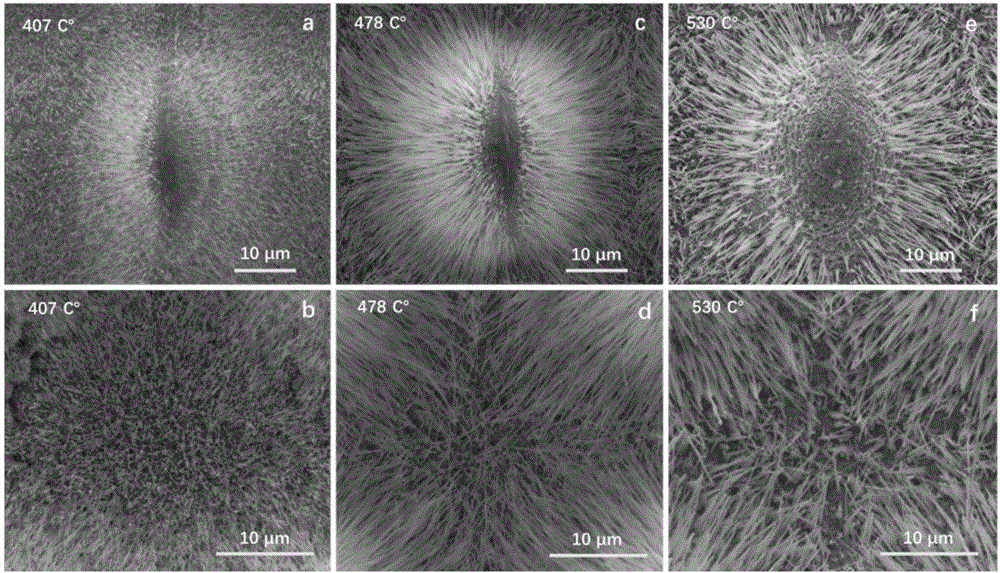

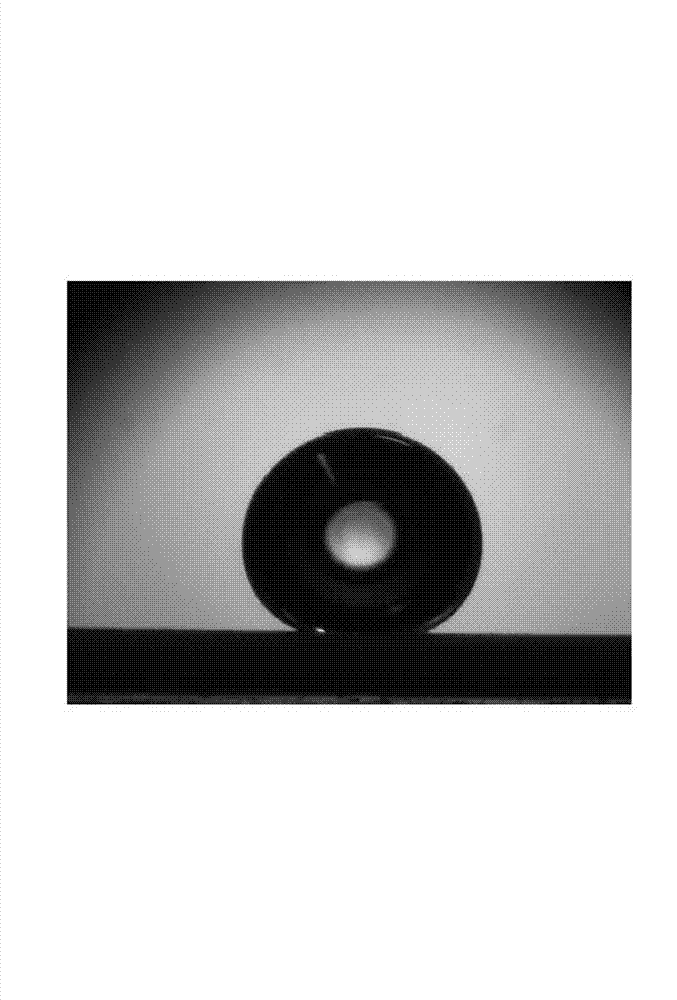

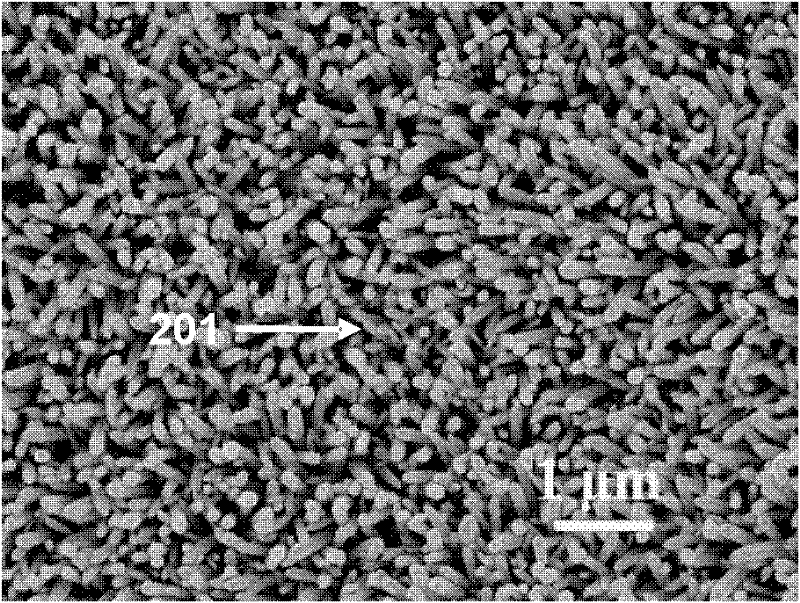

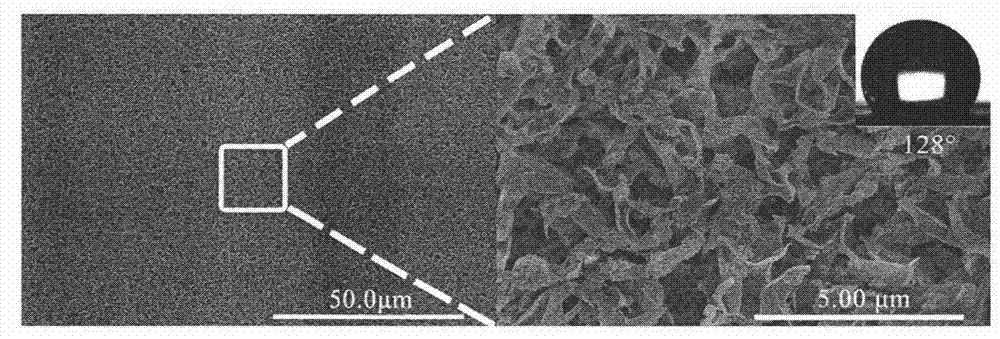

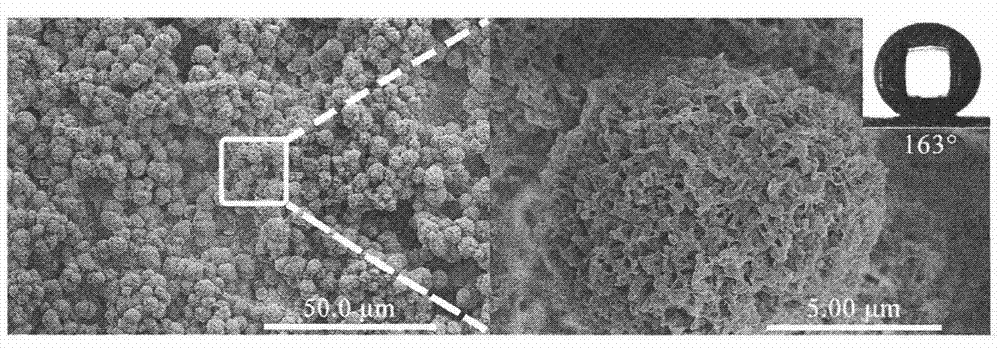

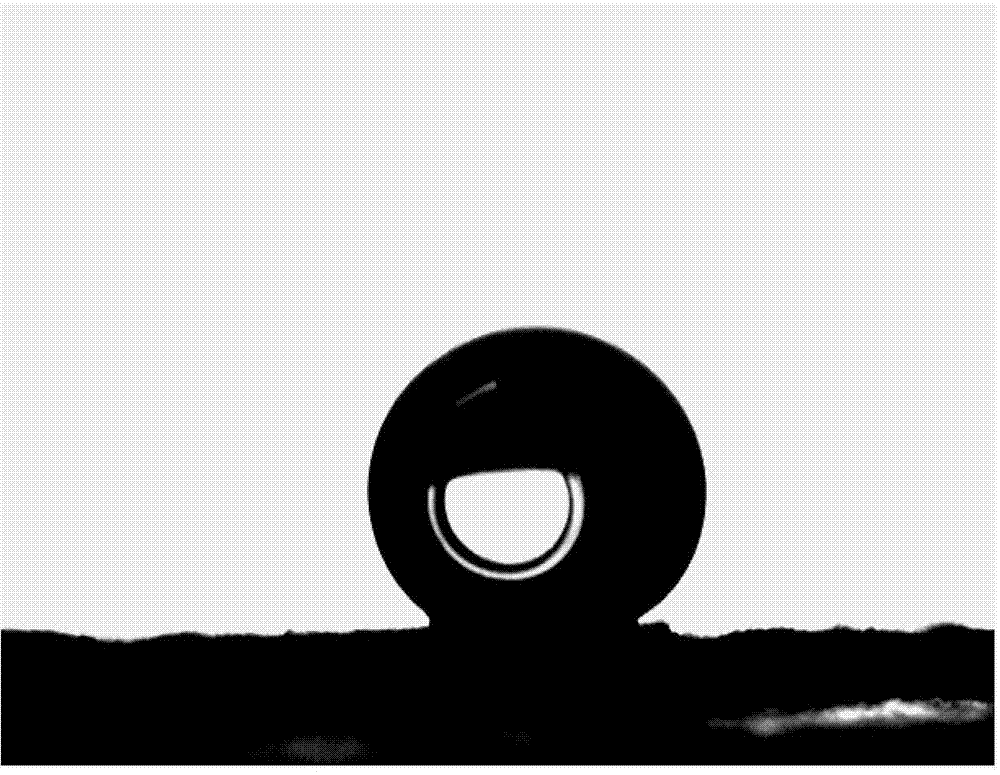

Micro-nanostructure controlled copper-based superhydrophobic surface and preparation method and application thereof

InactiveCN107522161AReduce pollutionEasy to mass manufactureSemi-permeable membranesVolume/mass flow by thermal effectsMicro structureNanowire

The invention discloses a micro-nanostructure controlled copper-based superhydrophobic surface and a preparation method and application thereof. The copper-based superhydrophobic surface comprises micro structure arrays and nanowires, wherein center spacing of the micro structure arrays is 10 to 500[mu]m, the height of each micro structure array is 5 to 500[mu]m; the nanowires have the diameter of 40 to 200nm, the length of 2 to 50[mu]m and average spacing of 0.1 to 3[mu]m; and the nanowires grow in parallel to the direction of a local normal of the copper-based superhydrophobic surface and has the ingredient being copper oxide. The copper-based superhydrophobic surface can implement liquid droplet bouncing heat exchange of water vapor condensation and can also promote classical droplet condensation so as to reinforce heat exchange. Moreover, the micro-nanostructure controlled copper-based superhydrophobic surface can also be used for the fields of self-cleaning, corrosion resistance, ice prevention, frosting resistance and the like.

Owner:TSINGHUA UNIV

Method for preparing steel surface super-hydrophobic film

InactiveCN102776548AGuaranteed wear resistanceImprove bindingElectrolytic coatingsSpecial surfacesMicro nanostructureHeat treated

The invention relates to a method for preparing a steel surface super-hydrophobic film, which comprises the following steps: providing a first steel, and carrying out treatment on the steel surface; providing a composite plating solution which comprises a nickel and phosphorus plating solution and nano polytetrafluoroethylene particles; providing two battery lead plates, putting the steel which is subjected to surface treatment and the two battery lead plates into the composite plating solution to be plated, positioning the steel between the two battery lead plates, and forming a layer of micro nanostructure on the surface of the steel; and putting the steel which has the micro nanostructure on the surface into a vacuum furnace to be subjected to heat treatment. The method is suitable for the surface treatment of various steel materials, and has a wide application scope.

Owner:TSINGHUA UNIV

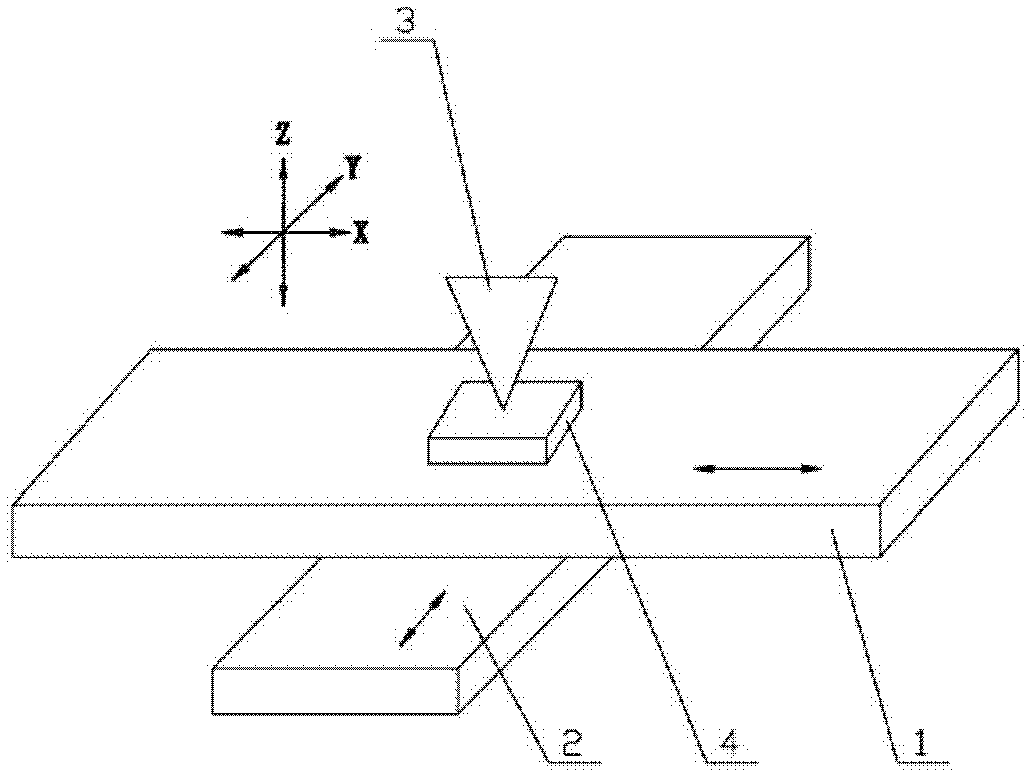

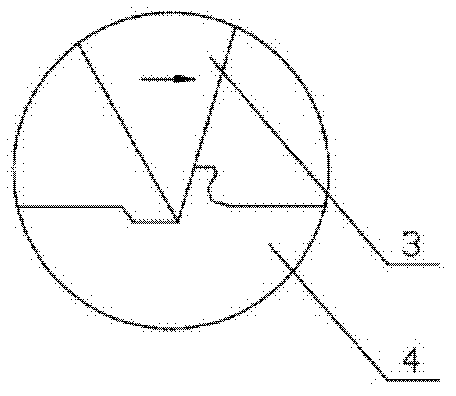

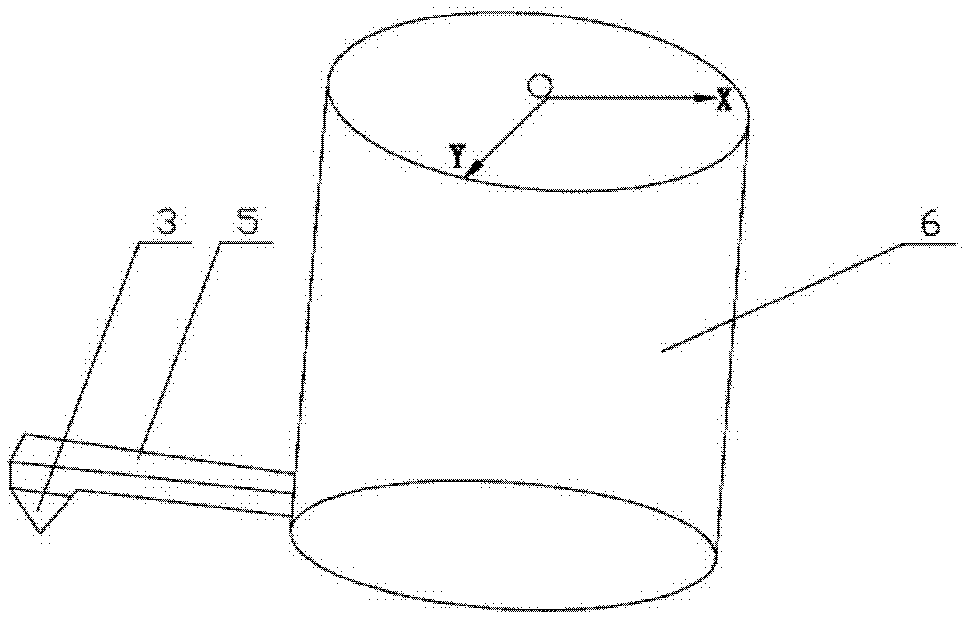

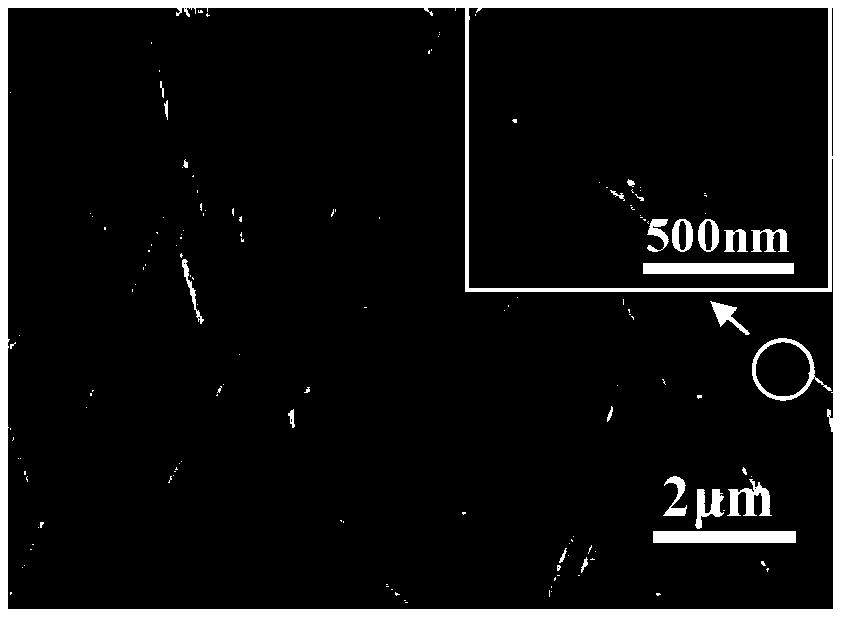

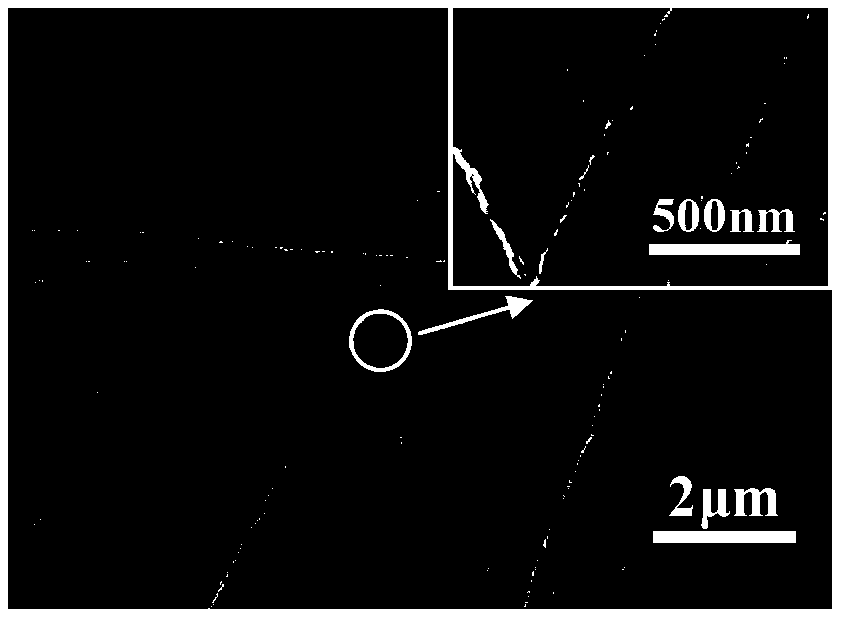

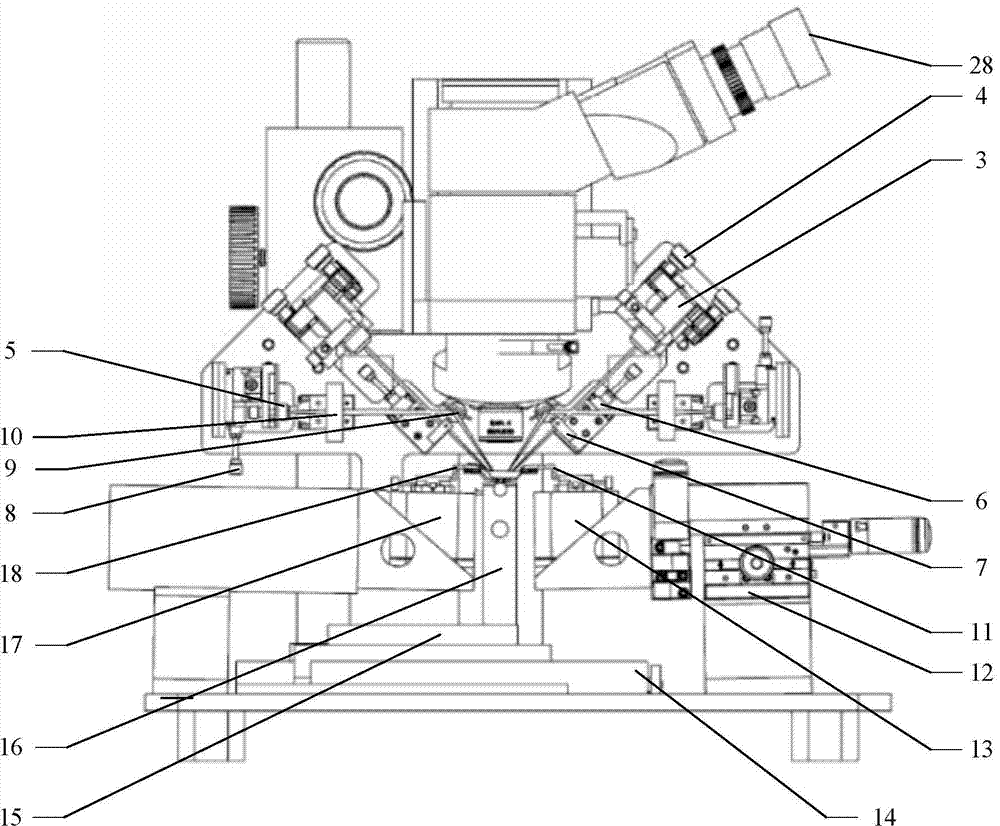

Method for millimeter-sized micro nanostructure nano carving and processing through adopting antifrictional metal (AFM) needle

InactiveCN102530850ARealize the integration of processing and testingSimple methodDecorative surface effectsChemical vapor deposition coatingIsoetes triquetraVertical load

The invention discloses a method for millimeter-sized micro nanostructure nano carving and processing through adopting an antifrictional metal (AFM) needle, which belongs to the field of millimeter-sized micro nanostructure processing. The method can solve the processing problem of a millimeter-sized and nano-precision micro nanostructure under lower cost. The method 1 is that: a sample to be processed is firstly placed on an X-Y two-dimensional precision workbench, and the AFM needle is contacted with the surface of the sample which is to be processed and has the vertical load smaller than 1muN through the approaching process of an AFM system; and a nano linear array structure is processed, and the parameter values of the processing length, the processing width, the processing space, the processing direction, the vertical load and the processing speed are set. The method 2 is different from the method 1 is that: an array microstructure which is formed by combining a plurality of same microstructures is processed; and firstly, the processing parameter is set, during the processing, a scanning earthenware pipe drives the AFM needle to move, and accordingly, square, round or equilateral triangular array microstructures are processed. The method adopts the AFM needle for the millimeter-sized micro nanostructure nano carving and processing of the sample to be processed.

Owner:HARBIN INST OF TECH

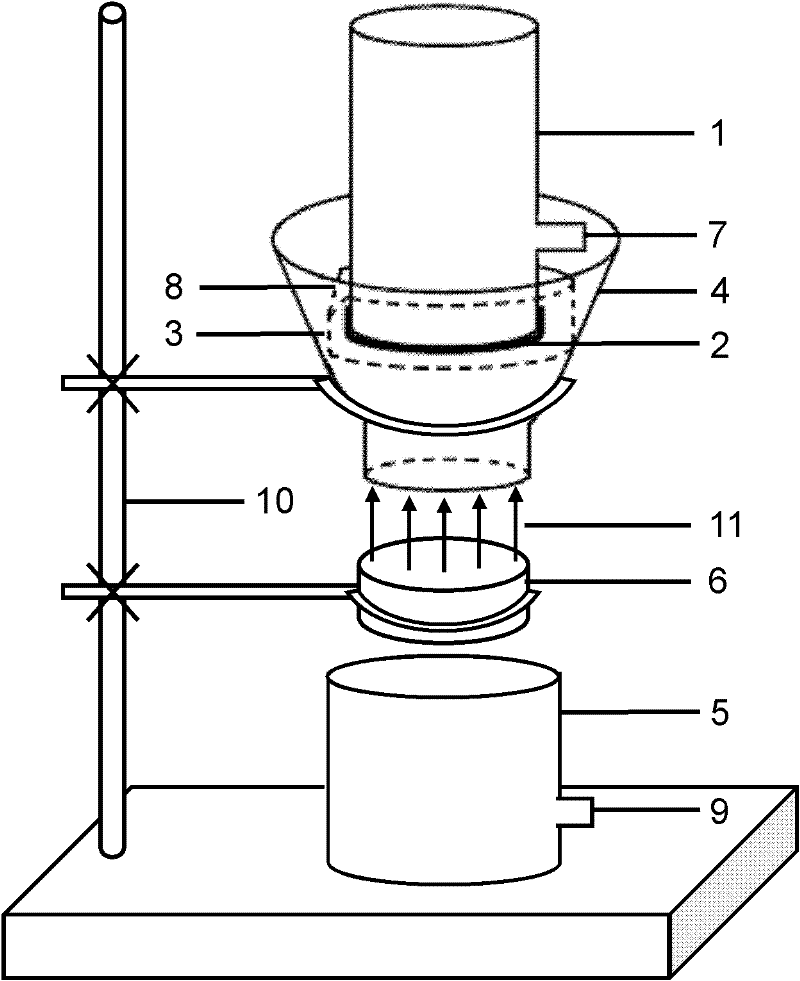

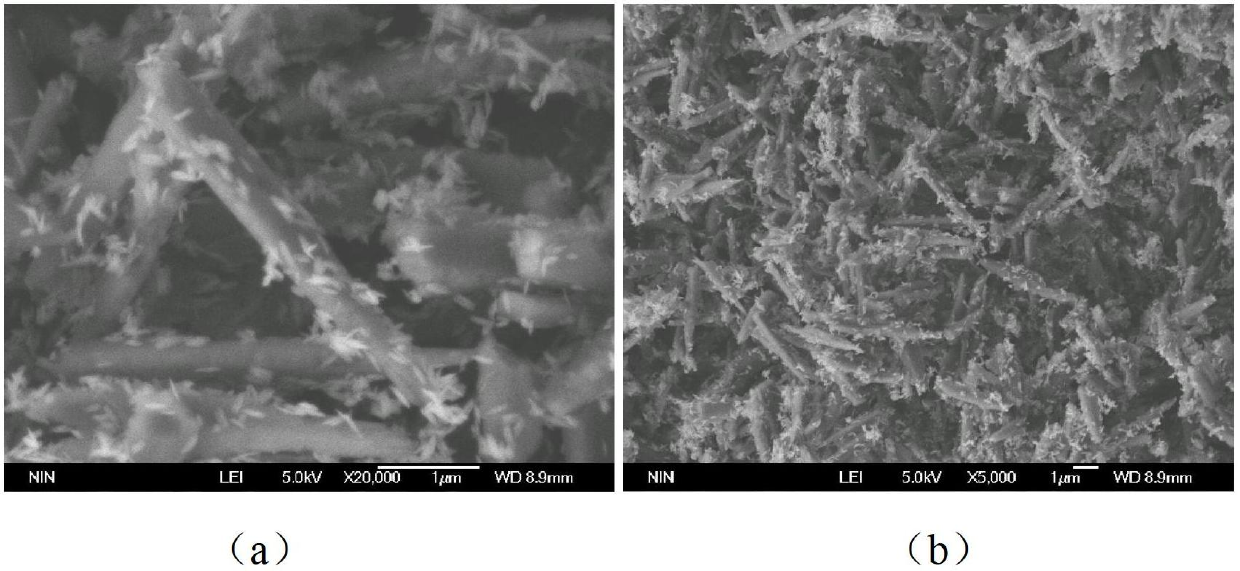

Hierarchical micro-nanostructure omentum based light-operated oil-water separator and its application method

InactiveCN102380230AWith underwater super oleophobic propertiesWith underwater self-cleaning propertiesEnergy based chemical/physical/physico-chemical processesLiquid separationUltraviolet lightsOil water

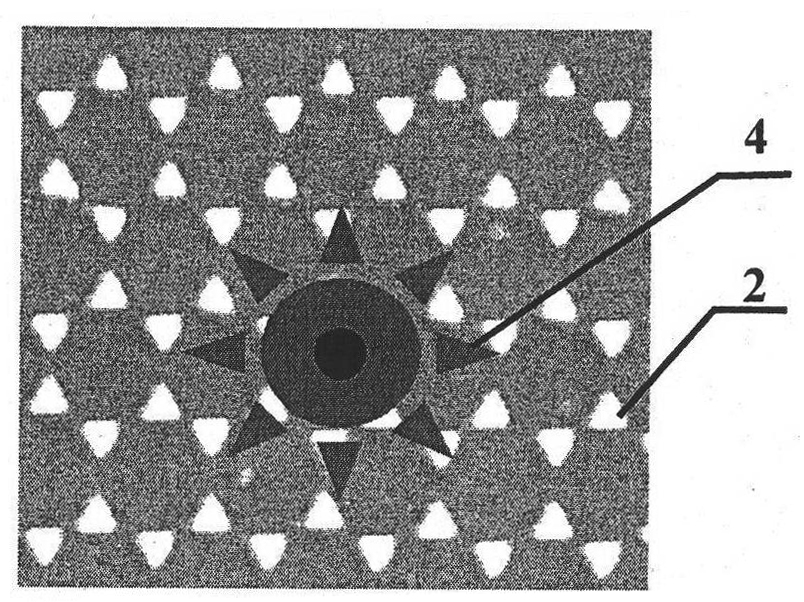

The invention brings forward a hierarchical micro-nanostructure omentum based light-operated oil-water separator and its application method. The oil-water separator comprises an oil-water separator with the hierarchical micro-nanostructure omentum, a constant water surface device, a drainage device, a water gathering device and a light source device. The oil-water separator with the hierarchical micro-nanostructure omentum is composed of an oil-water mixed liquid gathering device and the hierarchical micro-nanostructure omentum, which is made from a pore structured fabric net substrate material with a microstructure and a nanorods array structured material layer which is perpendicular to the surface of the pore structured fabric net substrate material. The hierarchical micro-nanostructureomentum can have superhydrophobicity after dark storage and can have superhydrophilicity by ultraviolet light. The hierarchical micro-nanostructure omentum based light-operated oil-water separator isstable, highly efficient and environmentally friendly. With the application of the light-operated oil-water separator for oil-water separation control, light-operated water can penetrate through the omentum instead of oil. In addition, the light-operated oil-water separator can be repeatedly used.

Owner:BEIHANG UNIV

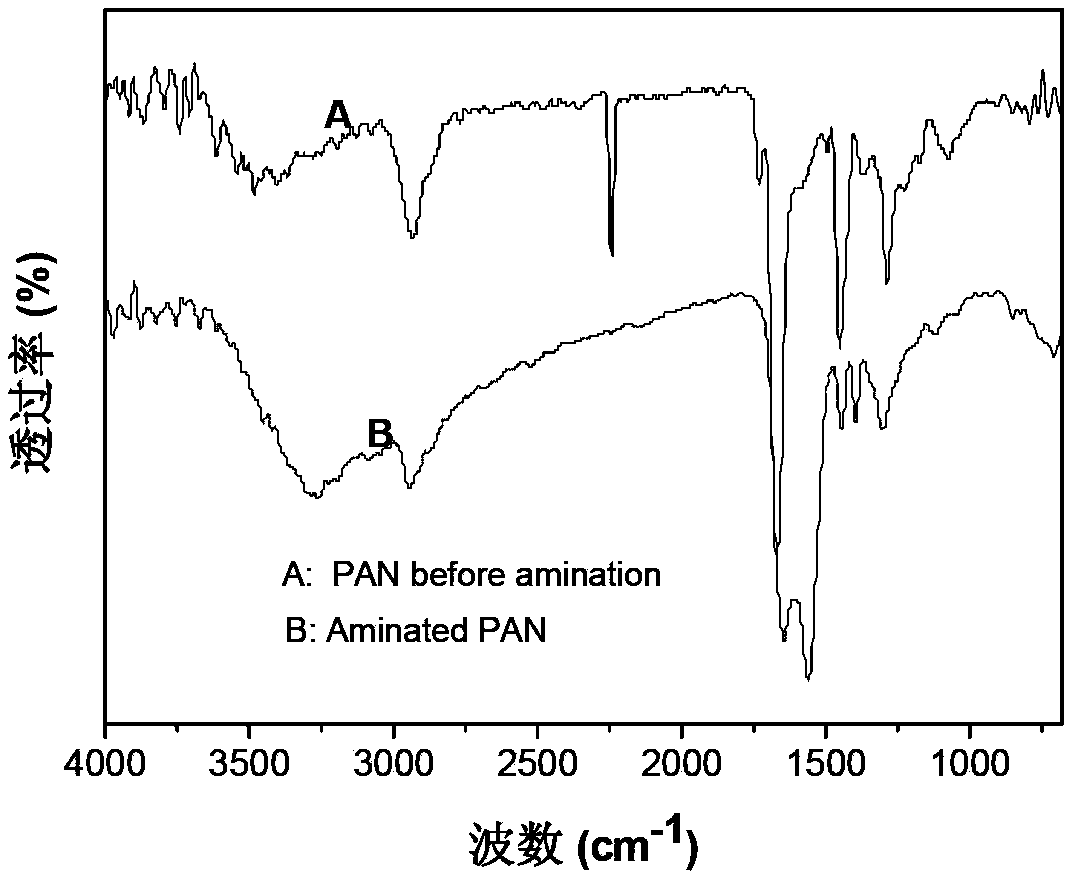

Preparation method of nano fiber affinity membrane for absorbing and separating La3+

InactiveCN103386298ASimple manufacturing methodRaw materials are easy to getSemi-permeable membranesOther chemical processesFiberSeparation technology

The invention relates to a preparation method of a nano fiber affinity membrane for absorbing and separating La3+. The preparation method comprises following steps: making a polymer solution go through electrostatic spinning to obtain a compound nano fiber membrane, processing the fiber membrane to obtain a porous, micro-nanostructure and high specific surface area nano fiber membrane, subjecting the nano fiber membrane to an amination treatment to obtain a porous, micro-nanostructure and high specific surface area aminated nano fiber membrane, subjecting the aminated nano fiber membrane to a treatment with a calixarene derivative solution and obtaining the product. The affinity membrane prepared according to the method mentioned above has a selective absorption property on La3+, is capable of regenerating, and the absorption effect is not affected after the membrane has been recycled for several times. The affinity membrane can be used in the absorption, extraction and separation technologies in mineral smelting and water processing industries.

Owner:DONGHUA UNIV

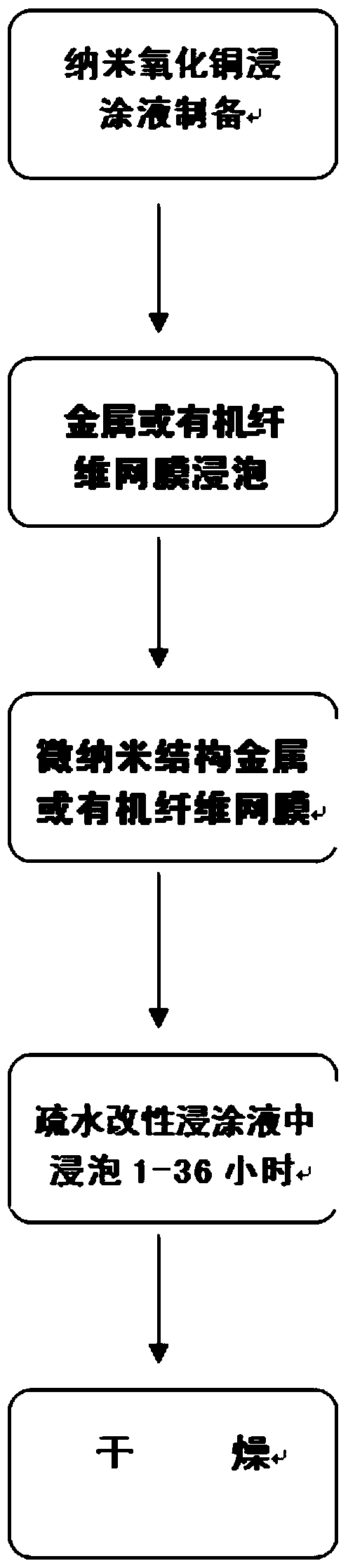

Production method of superhydrophobic/superlipophilic high-efficiency oil-water separation membrane

InactiveCN108771982AEfficient separationEasy to prepare in large areaSemi-permeable membranesFatty/oily/floating substances removal devicesMicro nanoFiber

The invention discloses a production method of a superhydrophobic / superlipophilic high-efficiency oil-water separation membrane. The production method comprises the following steps: constructing a copper oxide micro-nano layered structure on the surface of a metal net membrane or an organic fiber net membrane by using a chemical dip-coating technology; and carrying out superhydrophobic and superlipophilic chemical modification on the micro-nanostructure on the surface of the membrane by using a modifier through a dip-coating technology, and drying the modified membrane to obtain the superhydrophobic, superlipophilic and ultra-durable oil-water separation membrane. A preparation method of a chemical dip-coating solution used for constructing the copper oxide micro-nano layered structure comprises the following steps: dropwise adding a mixed solution of a complexing agent and a dispersant into a mixed solution of the dispersant and a cupric salt in order to prepare an organic copper saltcomplex; adding an aqueous solution of a precipitating agent under stirring until the pH value of the obtained system is 10-12, and carrying out a reaction to form a nano-copper oxide particle mixture; and dropwise adding an aqueous solution of a stabilizer under stirring in order to obtain the stable nano-copper oxide dip-coating solution. The production method has the advantages of no need of complicated devices construction processes, and easiness in industrial enforcement.

Owner:洛阳纳诺环保科技有限公司

Polyvinylidene fluoride super-hydrophobic self-cleaning coating and preparation method thereof

InactiveCN104774511AEasy to prepareEasy to operateCoatingsPhysical chemistryPolyvinylidene difluoride

Owner:TIANJIN POLYTECHNIC UNIV

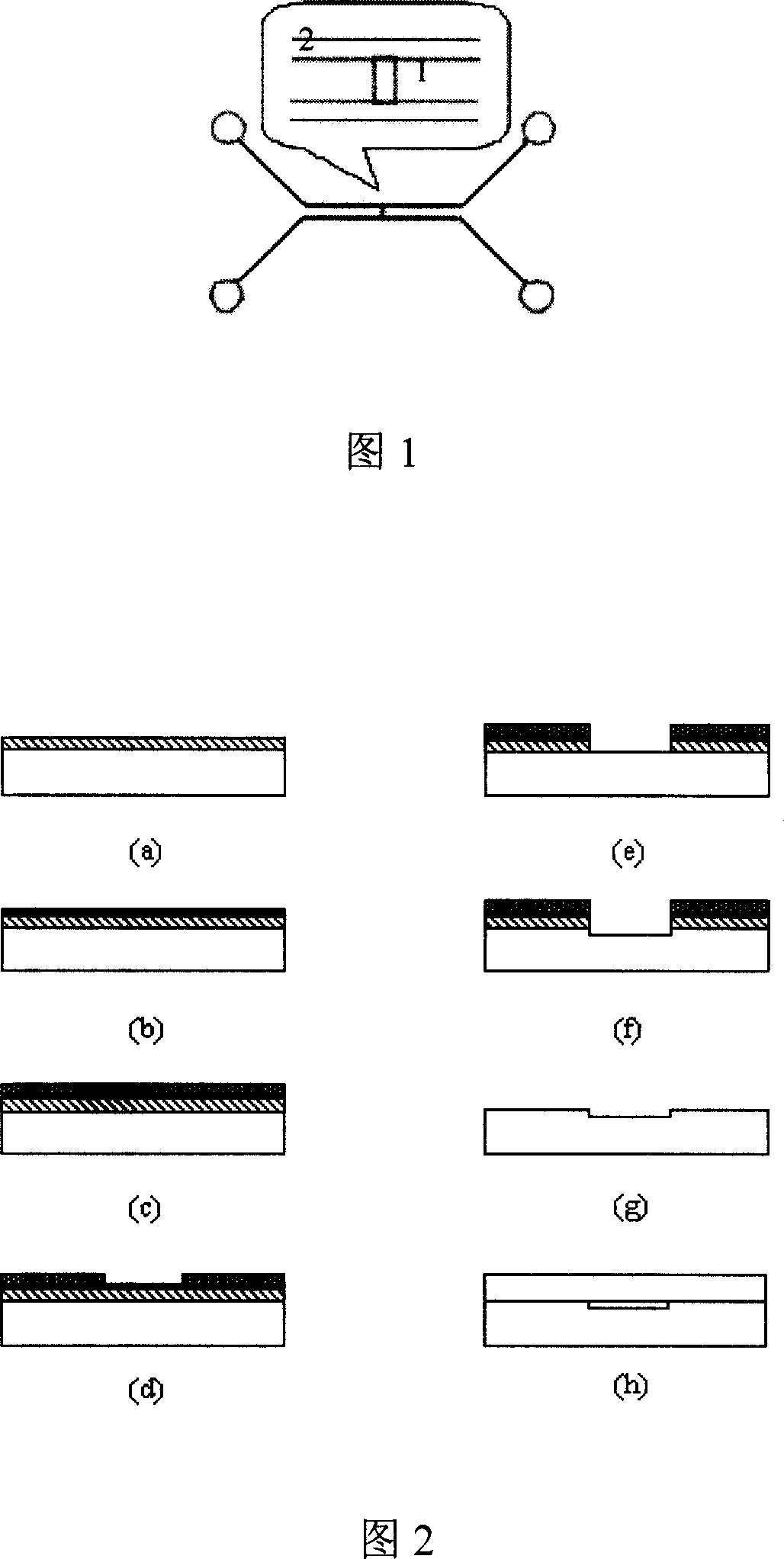

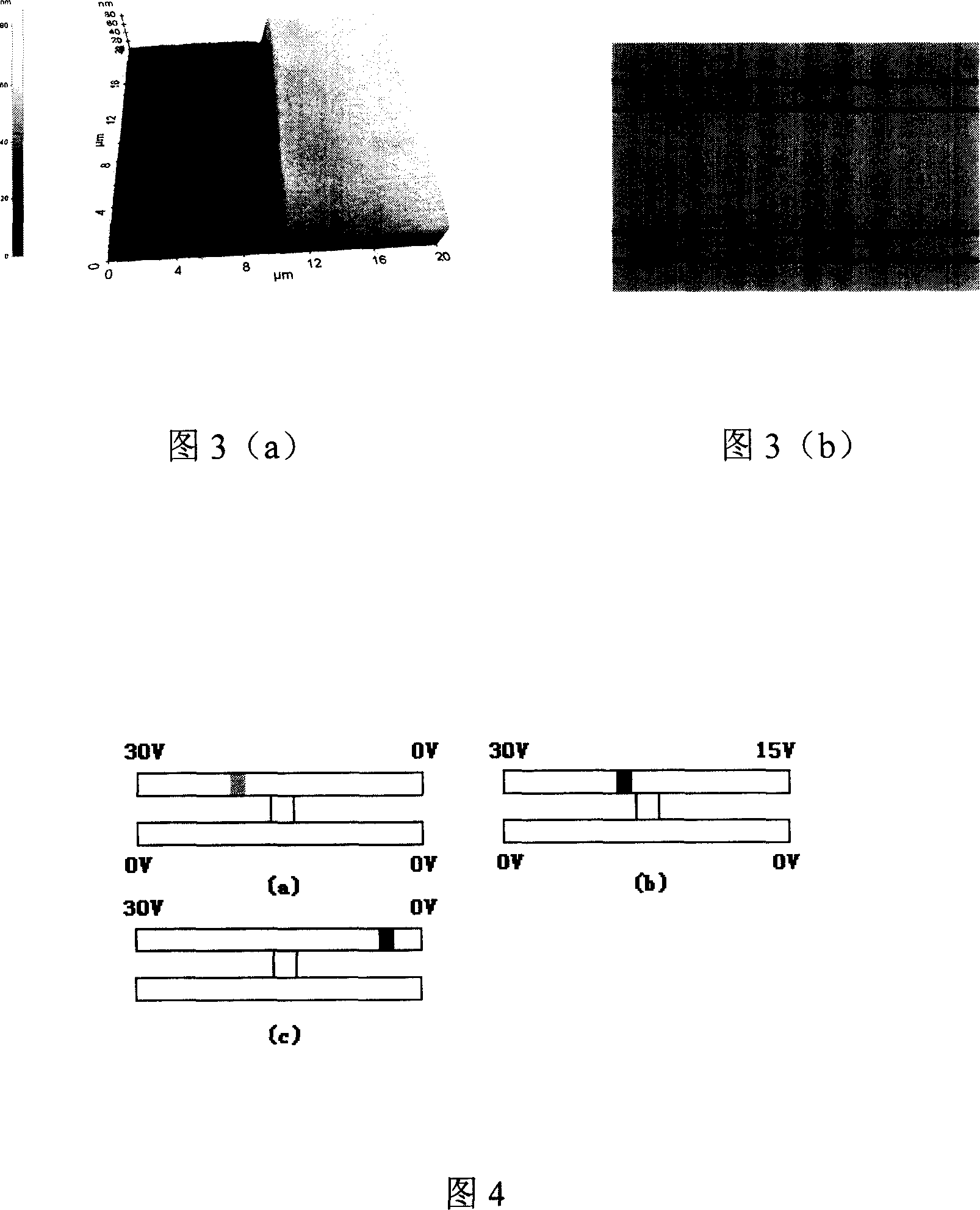

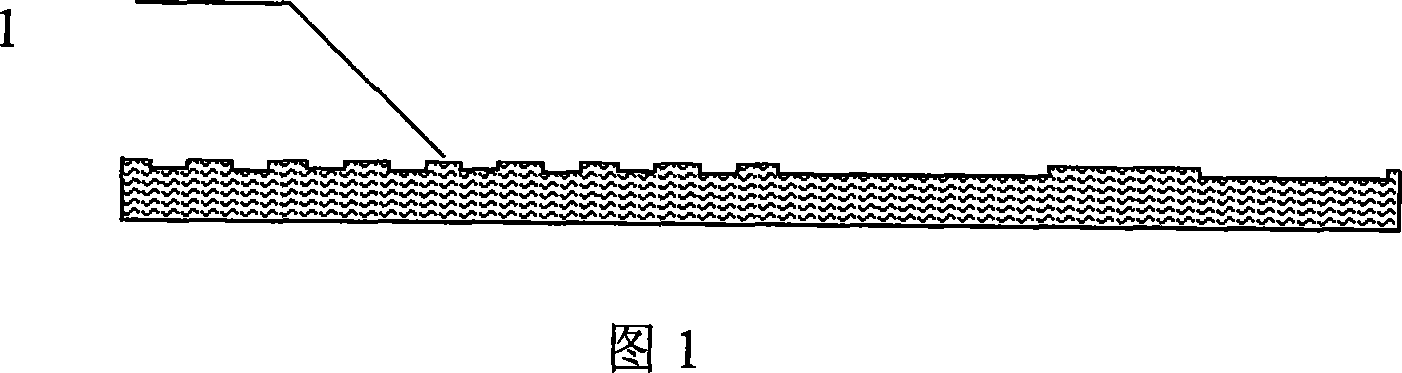

Sample enrichment chip, manufacturing method and enrichment method and on micronano structure

InactiveCN101000290ARich sourcesMature processing technologyComponent separationPreparing sample for investigationDebyeEnrichment methods

The invention relates to sample enrichment chip, manufacturing method and enrichment method based on micro nanostructure. Its feature is that the enrichment chip is used quartz glass as backing material, formed by enrichment nanometer channel and micro sample transmitting pipeline. It applies MEMS technique to process the channel and pipeline one the quartz glass, strictly control channel depth to make it satisfy ion falling demand, utilizes low temperature bonding method to process for the substrate and covering piece, fills sample into chip pipeline, adds direct voltage in the sample pool to form electric field in nanometer channel. Because of Debye layers in the channel are superposed, while ion falling zoon is formed beside the channel. The sample moved under the action of the electric field is enriched beside the channel to form sample enrichment zoon. The chip has small volume, will not destroy enrichment component while enriching.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

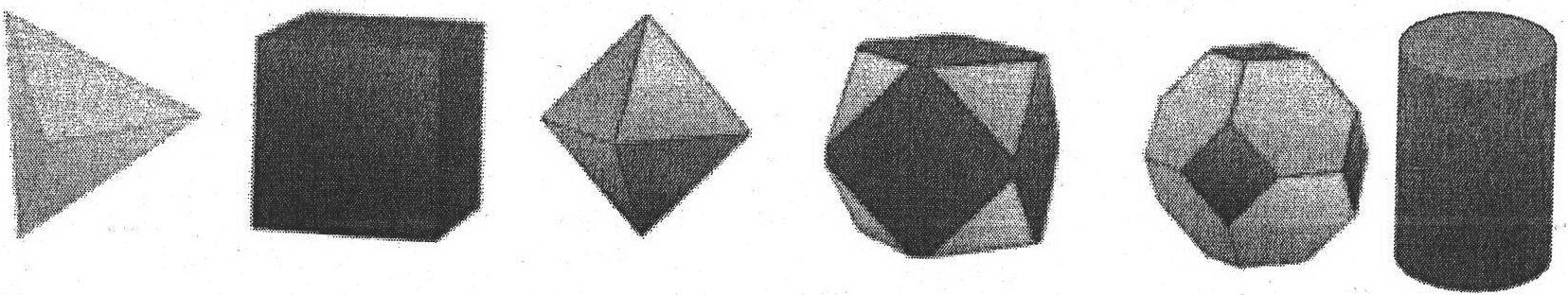

Large area micro nano structure soft impression method

A soft pressing method of large-scale micro-nanostructure includes processing out required micronanopattern structure on surface of hard substrate by photo-etching means, coating organic material PDMS on surface of finished hard template, dripping and spiral-coating organic slushing compound on surface of substrate, contacting structure surface of said template closely with polished surface of substrate, picking said template up from said substrate to leave micronanostructure of organic slushing compound on surface of said substrate and using dry means of etching process to remove off base resin or to transfer micronanopattern to surface of said substrate.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

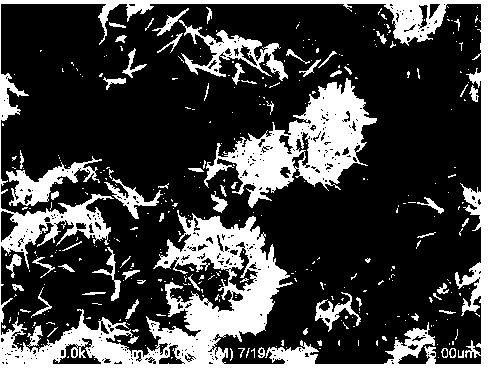

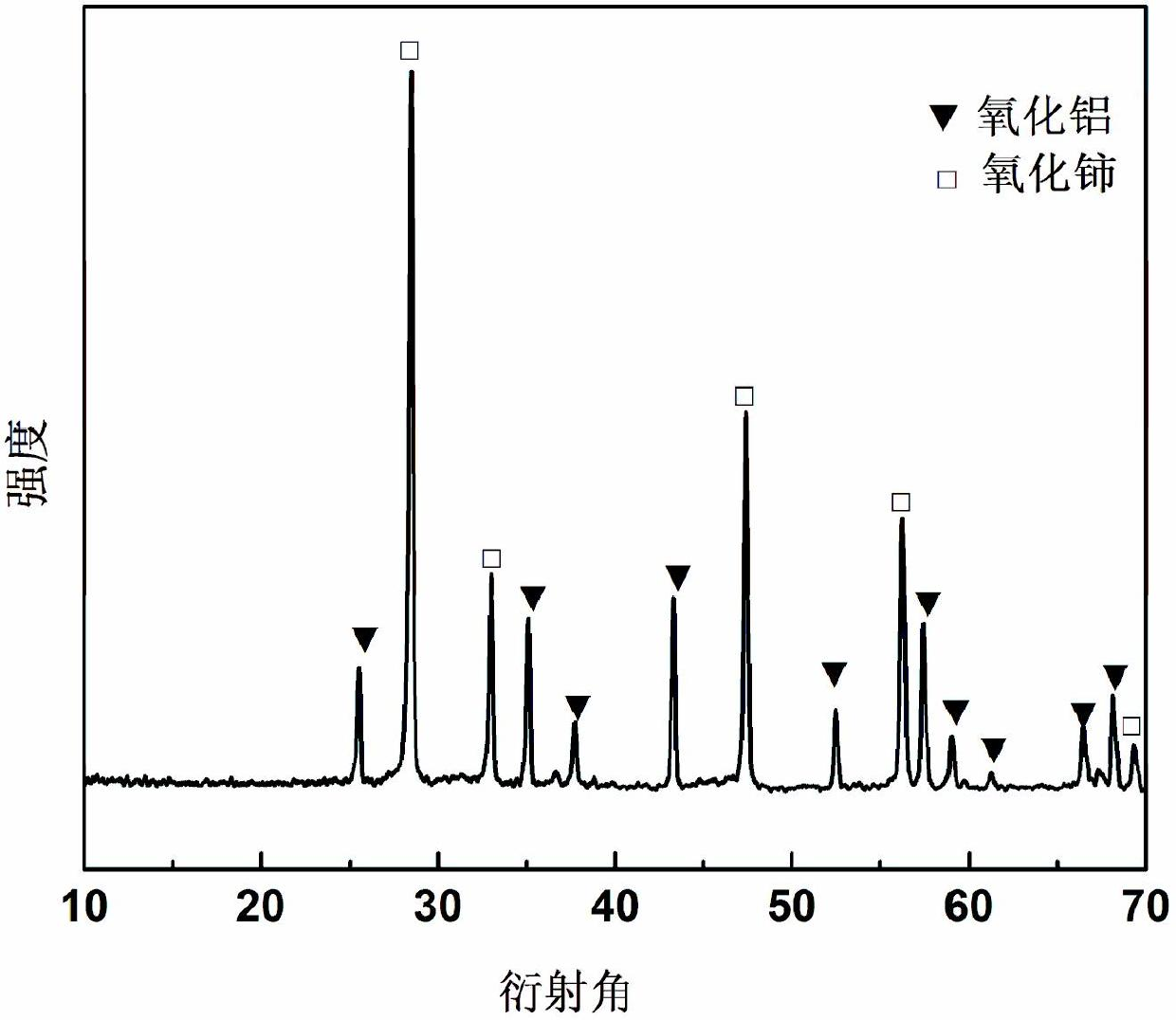

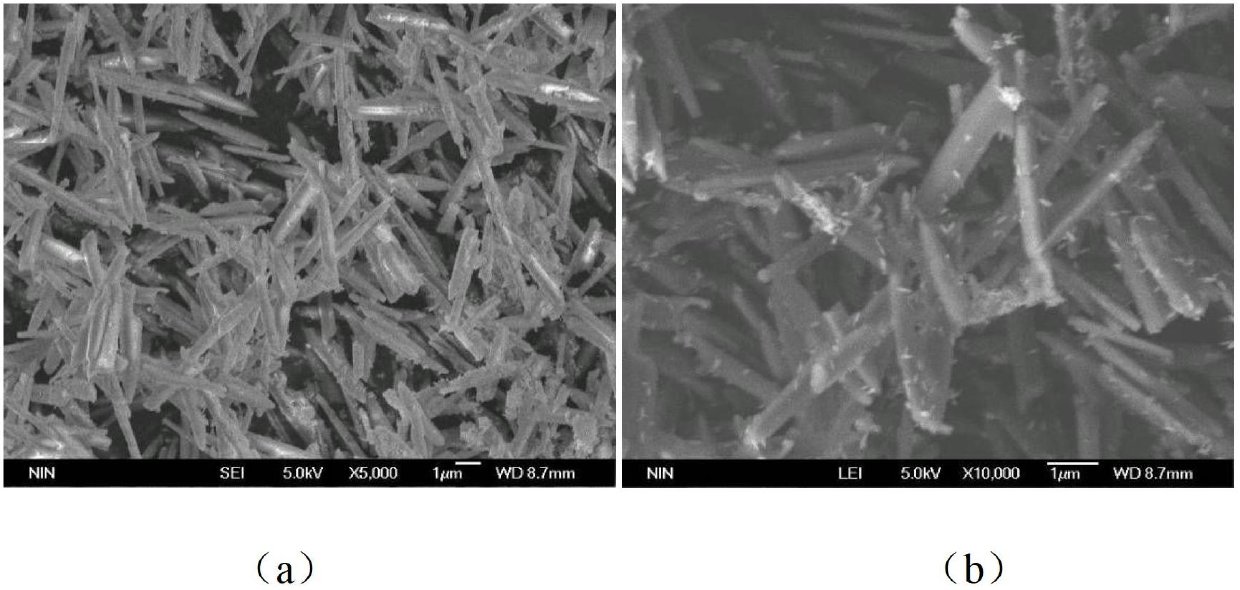

Cerium oxide/ aluminium oxide micro-nanostructure ceramic pigment and preparation method thereof

The invention discloses a cerium oxide / aluminium oxide micro-nanostructure ceramic pigment and a preparation method of the ceramic pigment. The ceramic pigment is composed of alumina fibers and cerium oxide particles according to a molar ratio of 1:20-3:10 and has uniform size and good dispersity; the lengths of the alumina fibers are 3-4mum; the sizes of the cerium oxide particles are 80-100nm; the dispersion concentration of the cerium oxide particles and the chromatic performance of the final product are controlled by adjusting the concentration of the cerium oxide; and the product is pink after being calcined for 2 hours at the temperature of 1200 DEG C. The cerium oxide / aluminium oxide micro-nanostructure ceramic pigment and the preparation method provided by the invention have the advantages of simple process, safety in operation and low cost.

Owner:SHAANXI UNIV OF SCI & TECH

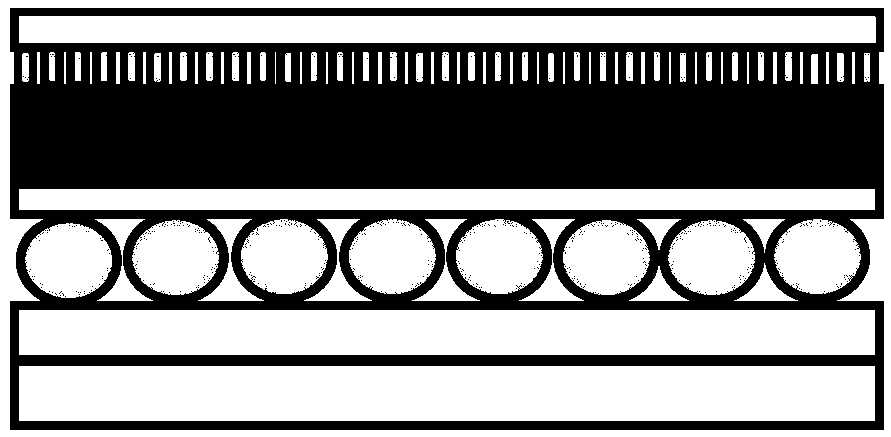

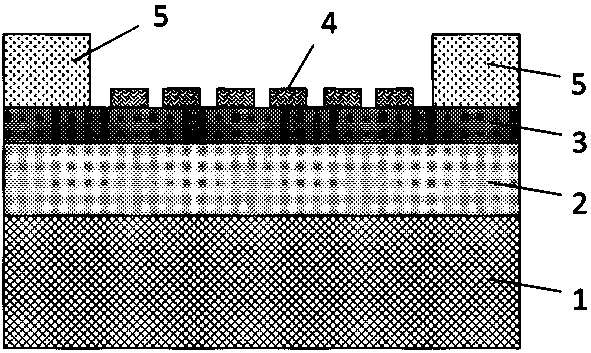

Perovskite solar cell with mixed light trapping structure and preparation method thereof

InactiveCN107591483AIncrease the optical pathPromote absorptionSolid-state devicesSemiconductor/solid-state device manufacturingMicro nanoGrating

The invention relates to a perovskite solar cell with a mixed light trapping structure and a preparation method thereof, and belongs to the technical field of perovskite solar cells. The perovskite solar cell comprises a substrate, a conductive electrode, a micro-nano particle light trapping layer, an electron transport layer, a perovskite light absorbing layer, a hole transport layer, a nano Ag optical grating and a metal electrode, wherein the conductive electrode, the micro-nano particle light trapping layer, the electron transport layer, the perovskite light absorbing layer, the hole transport layer, the nano Ag optical grating and the metal electrode are sequentially formed on the substrate, and the micro-nano particle light trapping layer is TiO2 micro-nano particles. The micro-nanostructure is introduced into the perovskite solar cell with the mixed light trapping structure, so that the light trapping capacity of the solar cell can be significantly improved, and the light absorption of the solar cell is enhanced through increasing scattering of the incident light and prolonging the light path of the incident light in the solar cell, so that the light current of the cell isincreased, and the conversion efficiency of the solar cell is effectively improved. Meanwhile, the nano Ag optical grating is introduced to a back electrode of the solar cell, so that a back reflection effect for the transmission light can be effectively increased by combining back reflection of a silver electrode, and thus the absorption of the cell for the incident light is further enhanced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

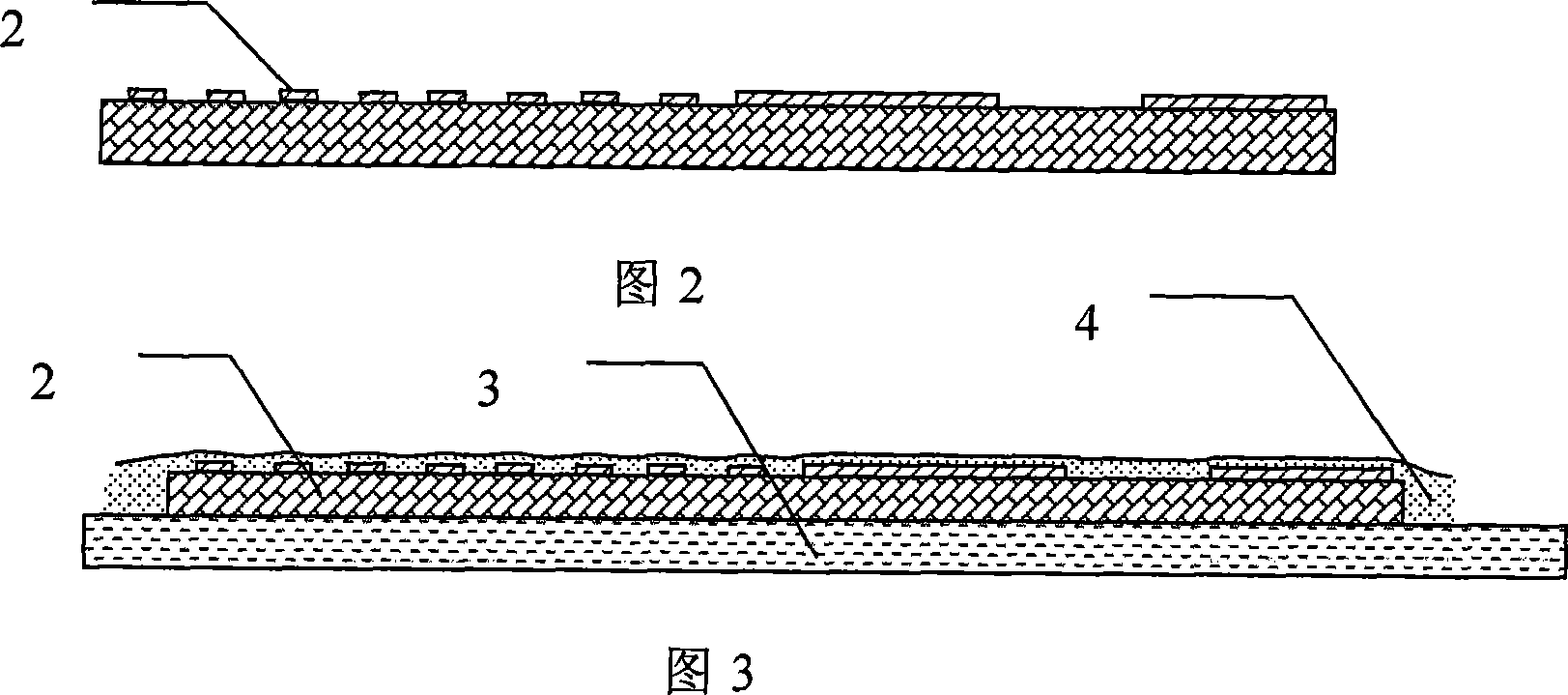

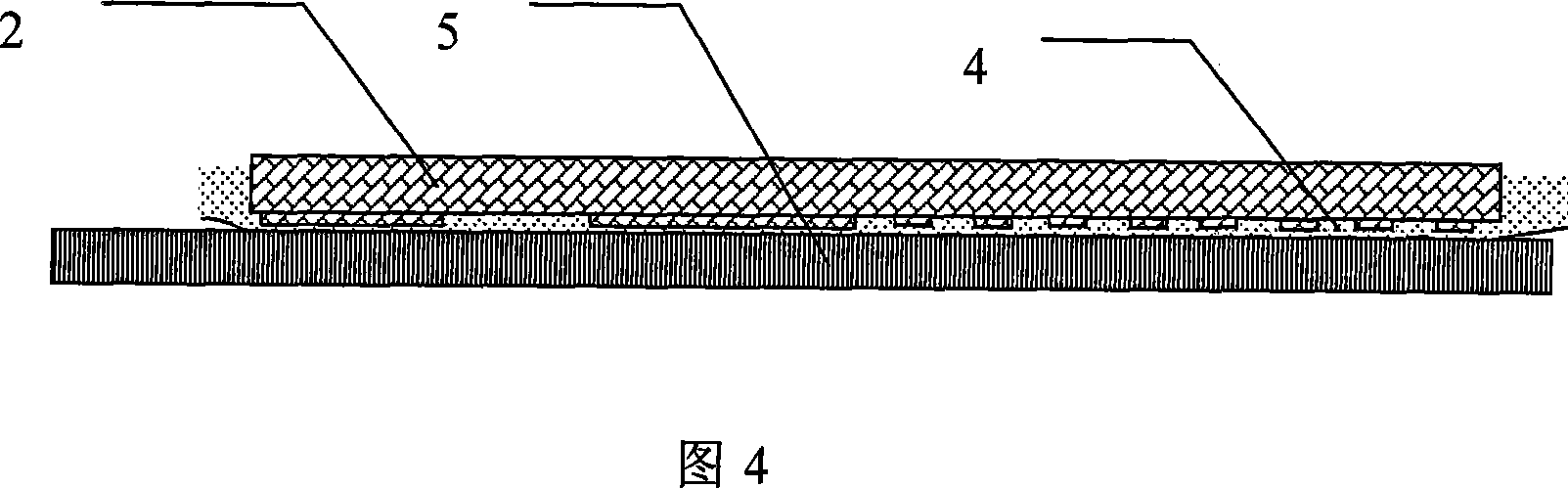

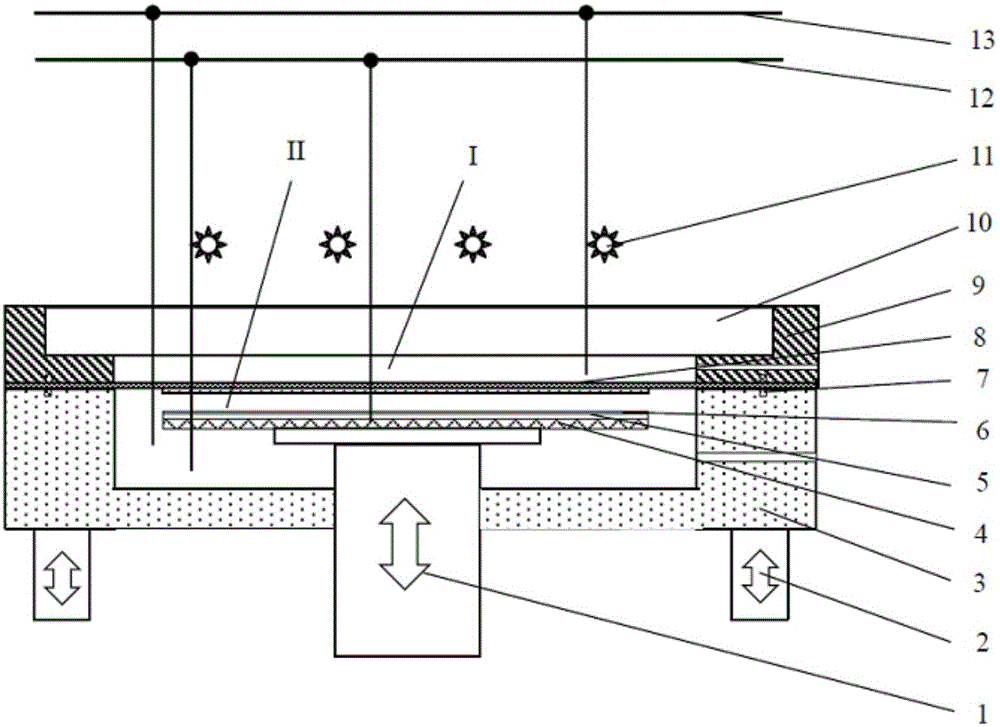

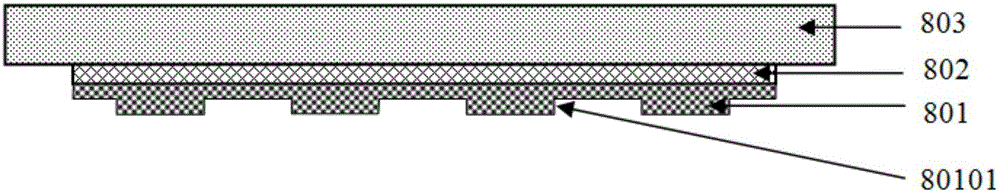

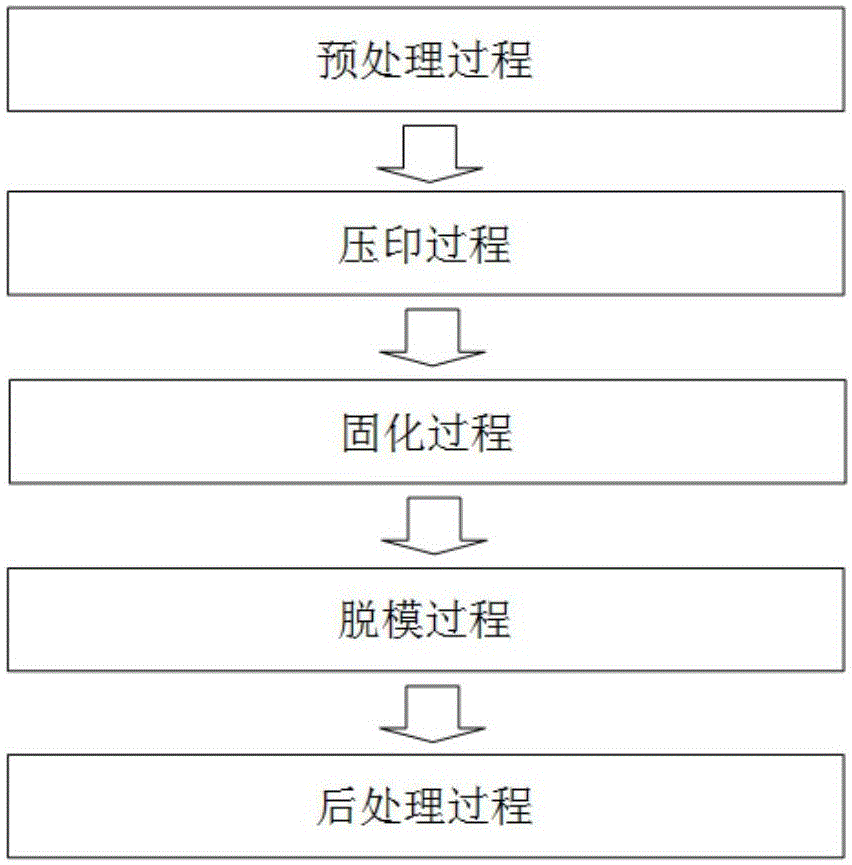

Large-size whole wafer nano-impressing device and impressing method thereof

The invention discloses a large-size whole wafer nano-impressing device and an impressing method thereof. The device comprises an upper cavity and a lower cavity, the lower cavity is driven by first lifting mechanisms to move up and down to make contact with or be separated from the upper cavity, the bottom of the upper cavity is provided with an elastic mold used for impressing, a wafer bearing platform is horizontally arranged in the lower cavity, and the bottom of the wafer bearing platform is provided with a second lifting mechanism; an upper cavity air inlet which is movably connected with a pressure pipeline is formed in the cavity wall of the upper cavity, a lower cavity air inlet which is movably connected with a vacuum pipeline and the pressure pipeline is formed in the cavity wall of the lower cavity, and a wafer bearing platform air inlet which is communicated with the vacuum pipeline is formed in the wafer bearing platform; the device further comprises an exposure light source. The large-size whole wafer nano-impressing device and the impressing method thereof have the advantages that high-efficiency low-cost batched manufacturing of large-area micro-nanostructures with super large size or unsmooth substrates or fragile substrates is achieved, and an industrial-level solution is provided for manufacturing large-size wafer-level large-area micro-nanostructures.

Owner:兰红波

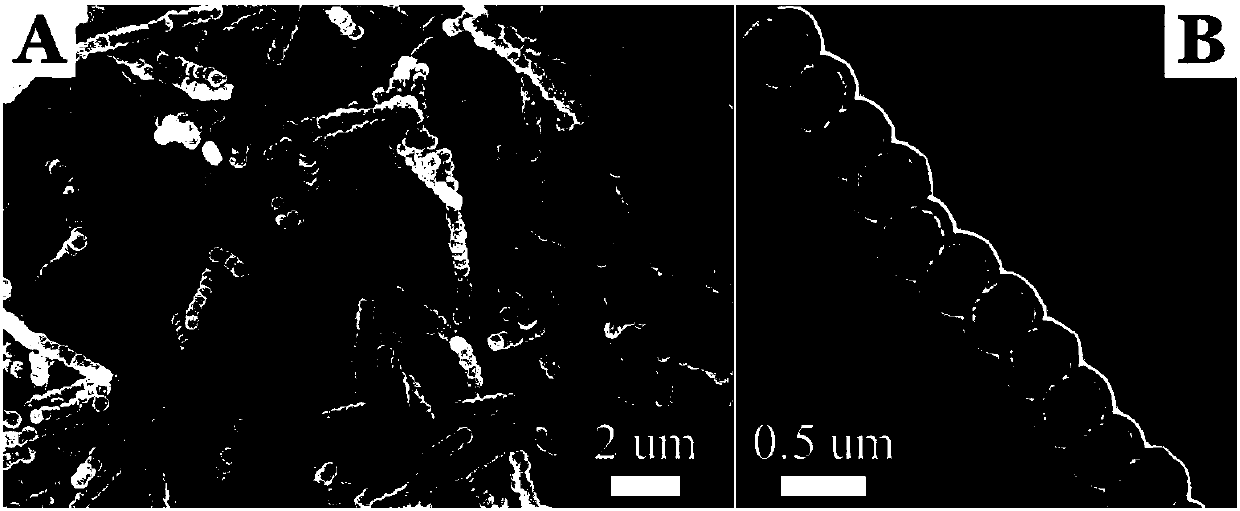

Bell-shaped Fe3O4@void@SiO2 nano-chain and preparation method

ActiveCN107638851AAccelerated dissipationExtended transfer timeCoatingsMicroballoon preparationReflection lossNanoparticle

The invention relates to a bell-shaped Fe3O4@void@SiO2 nano-chain and a preparation method. Under the induction action of an external magnetic field, magnetic Fe3O4 nano-particles are assembled and arranged, a polymer shell layer P (DVB-MAA) wraps the Fe3O4 nano-particles to form a core-shell Fe3O4@P (DVB-MAA) nano-chain, the Fe3O4@P (DVB-MAA) nano-chain is coated with a SiO2 shell layer by a sol-gel method, a double-shell-layer Fe3O4@P (DVB-MAA)@SiO2nano-chain is prepared, a structure of the Fe3O4@P (DVB-MAA)@SiO2nano-chain is effectively protected by the aid of recrystallization of salt, andpyrolysis is performed in the atmosphere of argon to obtain the bell-shaped Fe3O4@void@SiO2 nano-chain. Good microwave absorption property of materials is acquired by the aid of a special micro-nanostructure, a minimum reflection loss value of the materials is -45.03dB (13.57GHz), and an effective absorption frequency band can reach 5.5GHz or more. The nano-chain effectively solves the problem of narrow absorption frequency bands of existing wave-absorbing materials.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

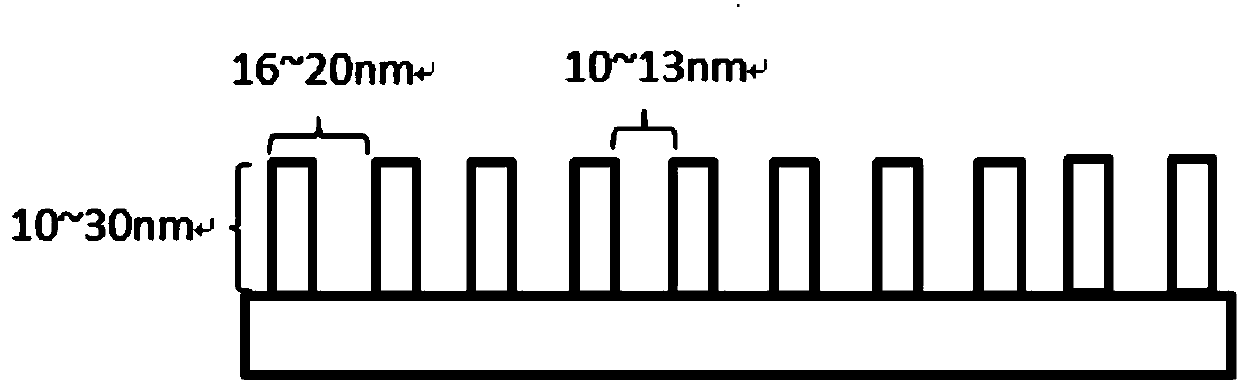

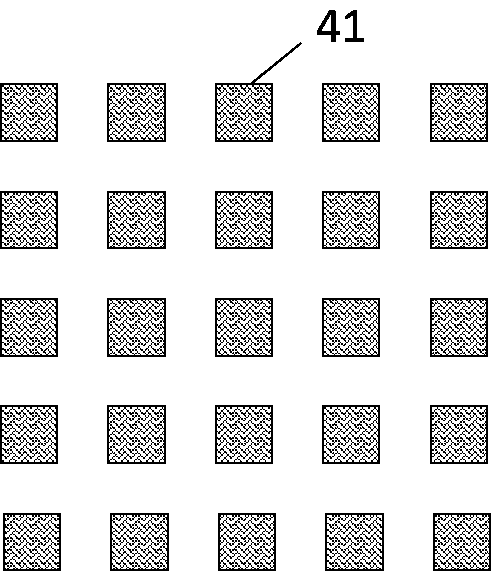

Graphene mid-infrared detector based on phonon exciton enhancement and preparation method thereof

PendingCN110098267APromote absorptionOvercoming the difficulty of enhancing the photoresponse in the mid-infrared bandFinal product manufactureSemiconductor devicesMid infraredSilicon dioxide

The invention relates to a graphene mid-infrared detector based on phonon exciton enhancement and a preparation method thereof, and belongs to the technical field of mid-infrared detection. The graphene mid-infrared detector comprises a silicon substrate, a silicon dioxide layer, a graphene layer and a molybdenum trioxide micro-nanostructure array covering the graphene layer which are laminated inturn from bottom to top, wherein the molybdenum trioxide micro-nanostructure array and the graphene layer form a phonon exciton enhanced heterostructure; and the edge of the graphene layer is provided with an electrode above, and the electrode extends an overlapping region of the molybdenum trioxide micro-nanostructure array and the graphene layer. In order to solve the technical problems, the graphene mid-infrared detector achieves the purposes of greatly improving the photoelectric conversion efficiency in the mid-infrared band and being simple in preparation method and low in cost.

Owner:深圳激子科技有限公司

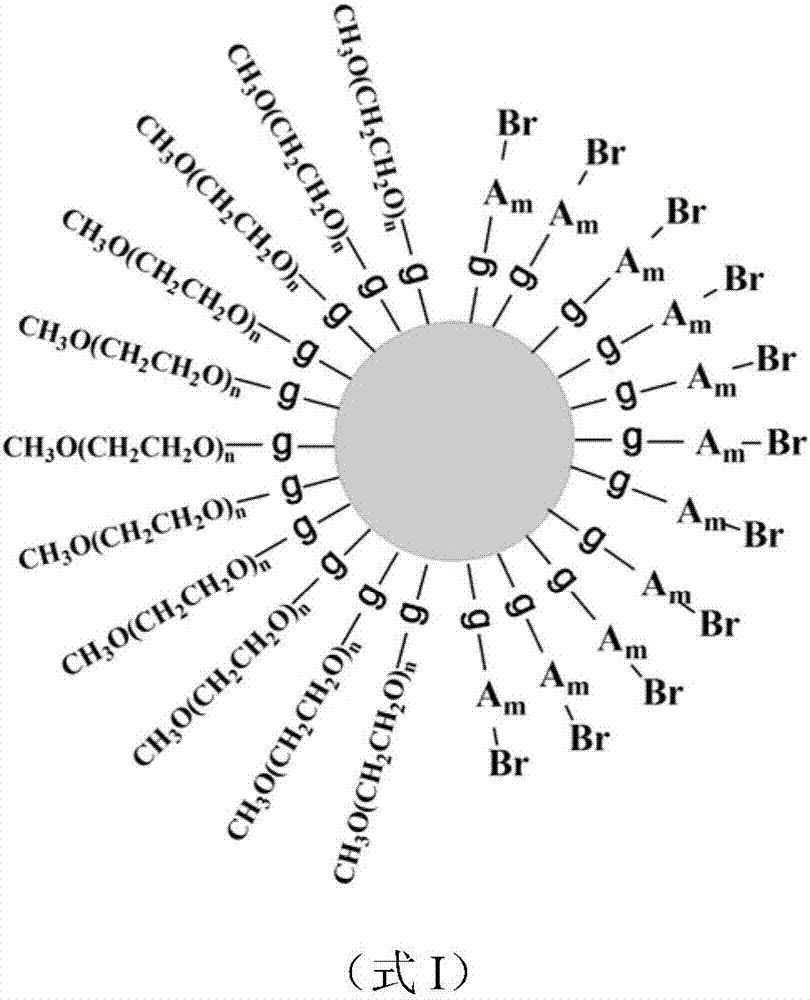

Modified nano-silica, PVDF micro-filtration membrane and application of PVDF micro-filtration membrane

ActiveCN107200848AImproved wettabilityImprove stabilityFatty/oily/floating substances removal devicesUltrafiltrationFiltration membraneIce water

The invention discloses modified nano-silica, a PVDF micro-filtration membrane and application of the PVDF micro-filtration membrane. A preparation method of the modified nano-silica comprises the following steps: at first, enabling reaction between nano-silica and an amino silane coupling agent to prepare aminated silica; adding paraffin to prepare paraffin balls of which the surfaces are covered with aminated silica; adding an acid capture agent, and dripping brominated alkyl acyl bromide or brominated alkyl acyl chloride under an ice-water bath condition to obtain a silica initiator; adding a monomer, cuprous bromide and aglucon, and enabling reaction to obtain polymer-grafted silica; and dispersing the product in an alpha-methoxy-omega-carboxyl polyethylene glycol solution, and performing stirring for reaction to obtain the modified nano-silica. Polymer chain segments, easily miscible with PVDF, on the surfaces of the modified nano-silica can fix the nano-silica particles after film forming, so that the stability of a micro-nanostructure on the surface of a film is enhanced, and the hydrophilic modified micro-filtration membrane has very good durability.

Owner:SUZHOU UNIV OF SCI & TECH

Enhancement method for raman scattering by using artificial metal micro-nano structure

InactiveCN101776603AEnhanced Raman ScatteringTake full advantage of the amplification effectNanostructure manufactureDecorative surface effectsMicro nanoMechanism of action

The present invention relates to an enhancement method for raman scattering by using an artificial metal micro-nanostructure. According to the character of the detected object and the interaction based on the difference between the nanostructure and the detected molecular, the scattering enhancement of the detected molecular is achieved by the use of independent enhancement output of the nano-monomer structure or the use of group effect of the interaction between the nano-double polymers or between the arrays. The method comprises the following steps: (1) setting a raman enhancement factor EF1 according to a determinate object, establishing a molecular scattering enhancement mode for use; (2) presetting a metal micro-nano structure parameter corresponding to the molecular scattering enhancement mode of the step (1), calculating to simulate a raman enhancement factor EF2 of the preset metal nano-monomer structure; (3) confirming the metal nano-monomer structure parameter if EF2 is more than or equal to EF1, if EF2 is less than or equal to EF1, repeating the step (2) until EF2 is more than or equal to EF1, and finally confirming the metal micro-nano structure parameter; and (4) realizing the fabrication of the metal micro-nano structure array by the method of microfabrication.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

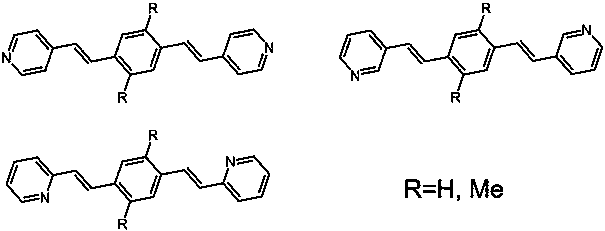

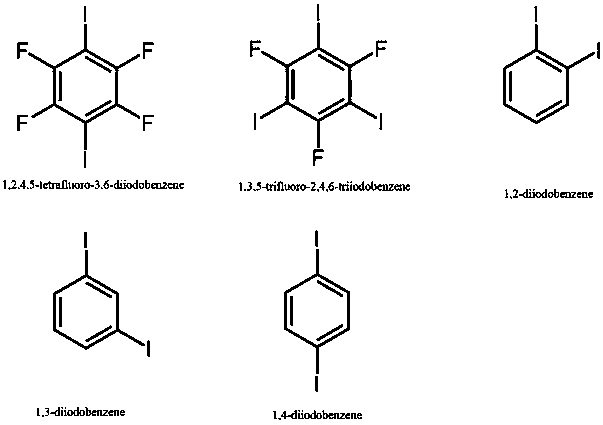

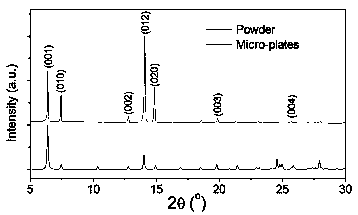

Two-dimensional eutectic organic single crystal micro crystal, preparation method and application thereof

ActiveCN109056074AAchieving asymmetric optical waveguide propertiesPolycrystalline material growthFrom normal temperature solutionsSingle crystalHalogen bond

The invention provides a two-dimensional eutectic organic single crystal micro crystal, a preparation method and application thereof. The method comprises the following preparation steps: selecting pyridine nitrogen-containing oligostyrene-based organic molecules as halogen bond donor molecules, and selecting iodobenzene organic molecules as halogen bond acceptor molecules, adding the halogen bonddonor molecules and the halogen bond acceptor molecules into a good organic solvent and sonicating for several minutes to prepare an organic solvent stock solution of the halogen bond donor moleculesand the halogen bond acceptor molecules; at room temperature, adding the organic solvent stock solution of the halogen bond donor molecules and the halogen bond acceptor molecules into a poor organicsolvent to shake uniformly, then dripping on a substrate, and drying the organic solvent through volatilization to obtain a two-dimensional organic eutectic micro nanostructure material. The two-dimensional eutectic organic single crystal micro crystal can be supposed to be used for preparing an optical logic device for multichannel input and output. The invention provides a new approach for realizing controllable preparation of the two-dimensional organic micro crystal, and the organic crystal can realize asymmetric photon transmission, thereby realizing the optical logic device with multiple input / output channels which take a two-dimensional organic micro nanostructure crystal as a carrier.

Owner:SUZHOU UNIV

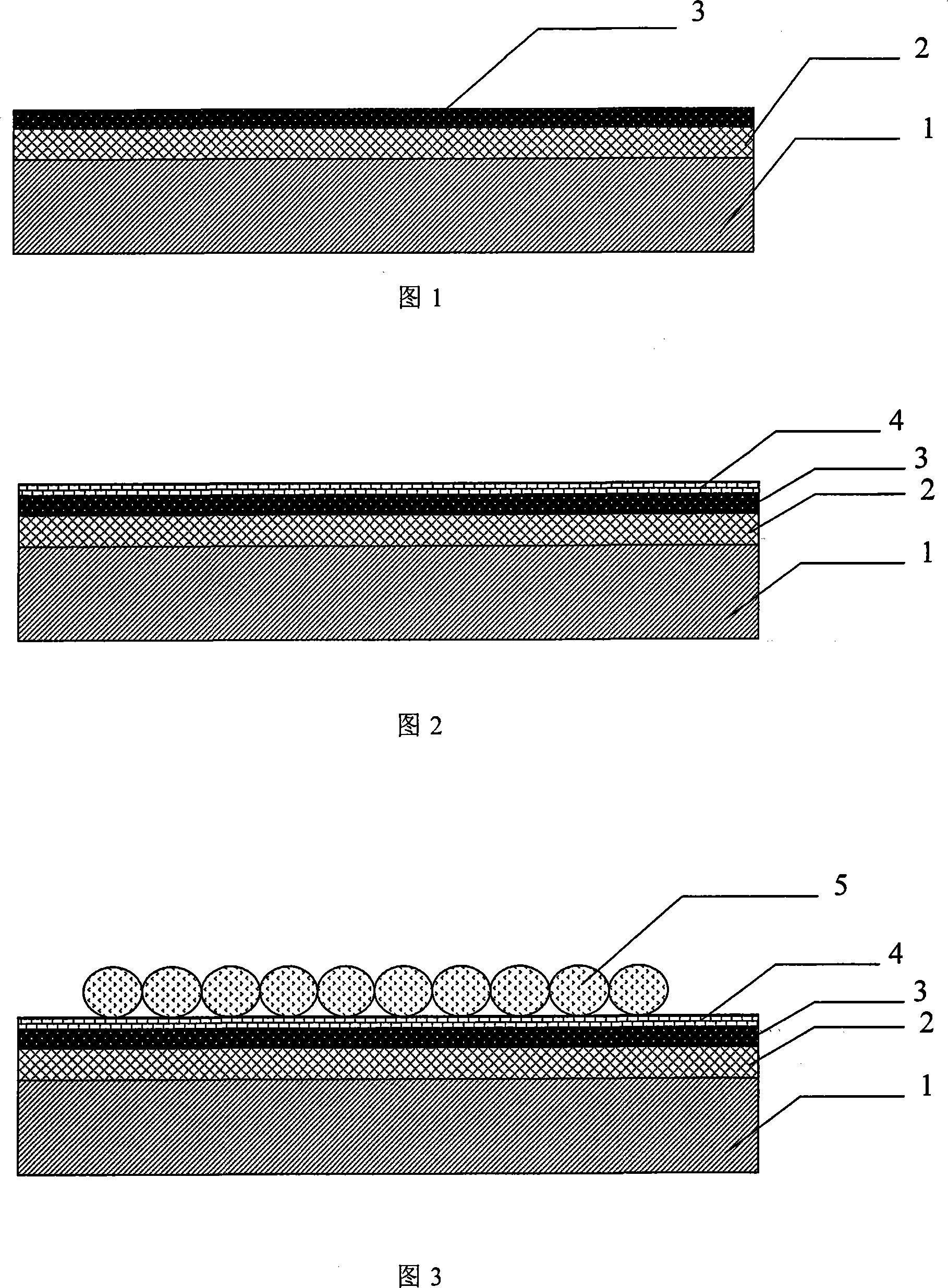

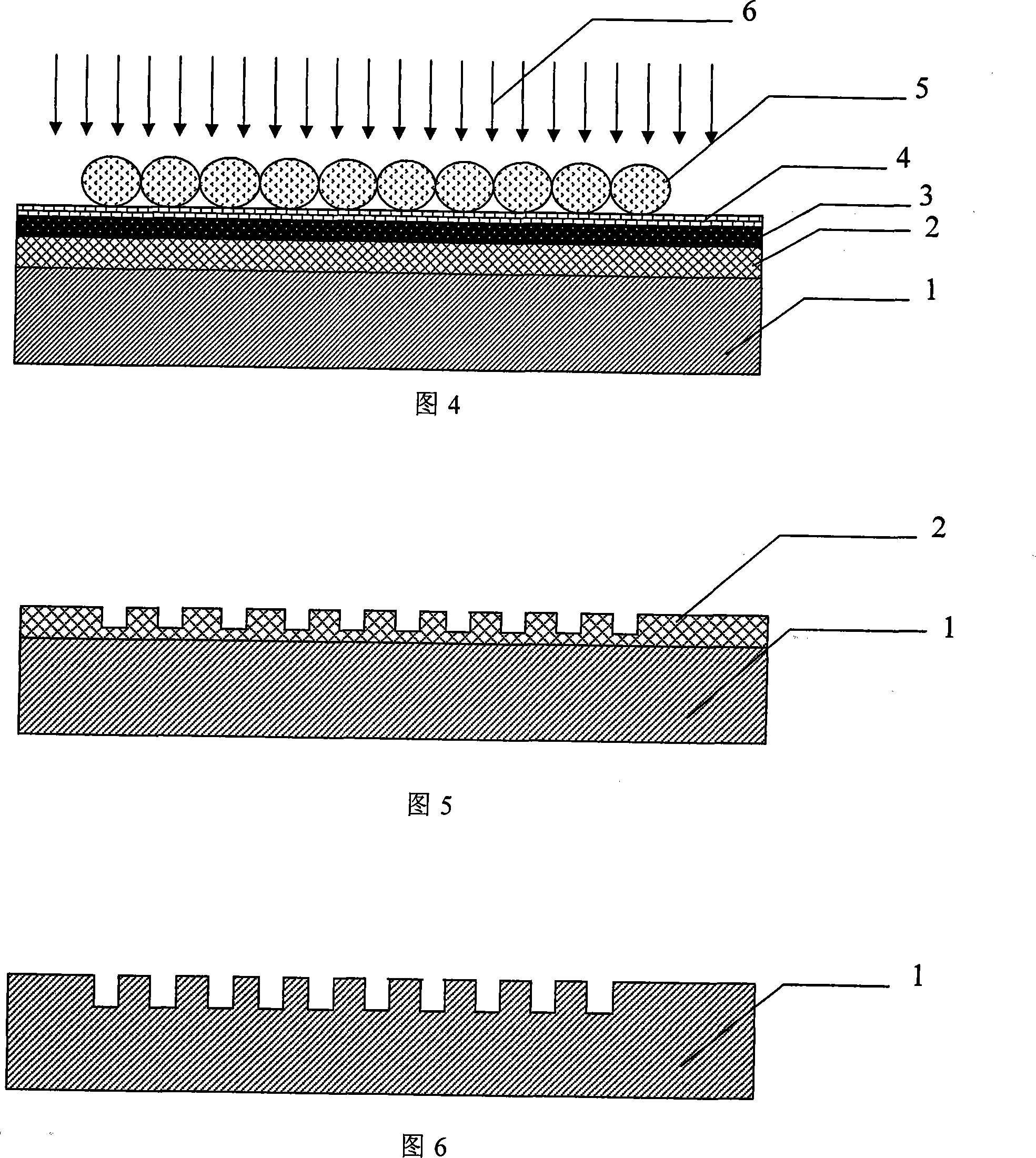

Sub-wavelength micro-nano structure using polystyrol ball to focused photoetching form

InactiveCN101158809AOvercome the problems of large caliber and small numerical apertureShorten the overall cycleDecorative surface effectsPhotomechanical apparatusResistMicro nano

The present invention provides a production method used for focusing lithography forming sub-wavelength micro-nanostructure of polystyrene sphere, and is characterized in that: surface of substrate material firstly selected is sequentially in a spinning manner coated with a layer of anti-corrosion agent, evaporated with a layer of metal structure, then in a spinning manner coated with a layer of interval layer, and finally assembled with a layer of the polystyrene sphere. The structure is exposed in exposure system, then the polystyrene sphere, the interval layer and the metal layer structure are removed, the substrate is positioned into developing agent for development and obtainment of target structure, and finally the structure is transmitted to the substrate by etch of the target structure. The present invention adopts the polystyrene sphere as a focusing lens, further reduces the cycle and dimension of the lens, has stimulation of surface plasma inside the metal in the focusing and exposure as the metal structure is evaporated on the surface of the exposed anti-corrosion agent, improves resolution of a focusing focal spot, reduces the characteristic size of the forming targeted structure, and provides an effective method for the production of the sub-wavelength micro-nanostructure.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

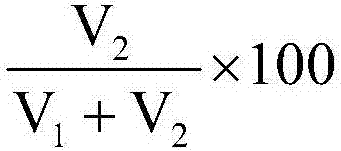

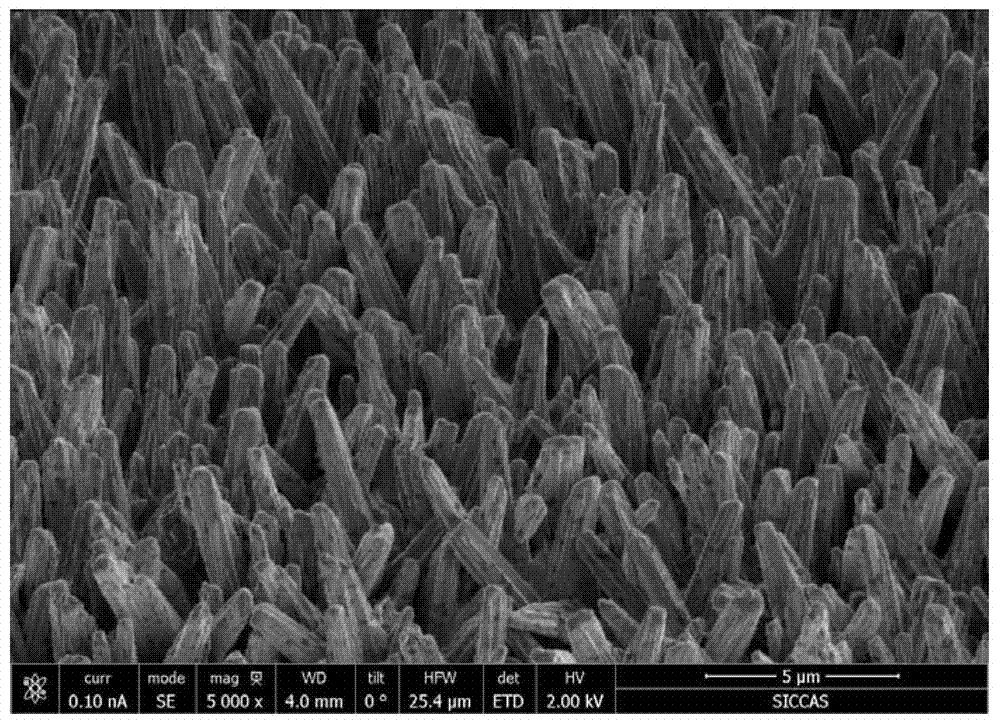

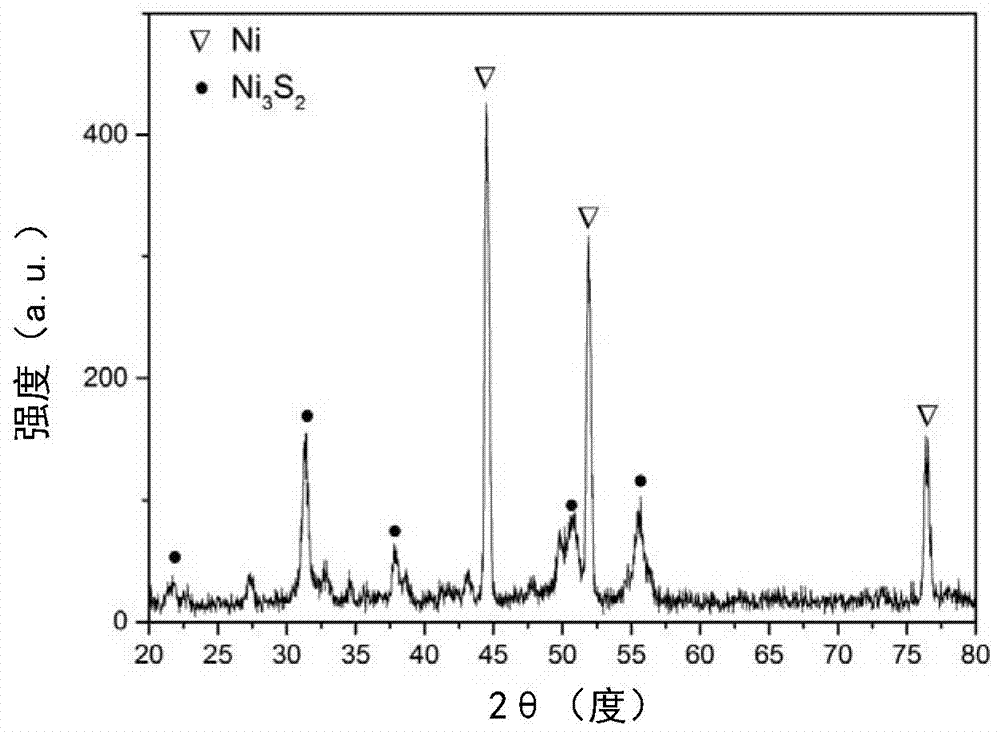

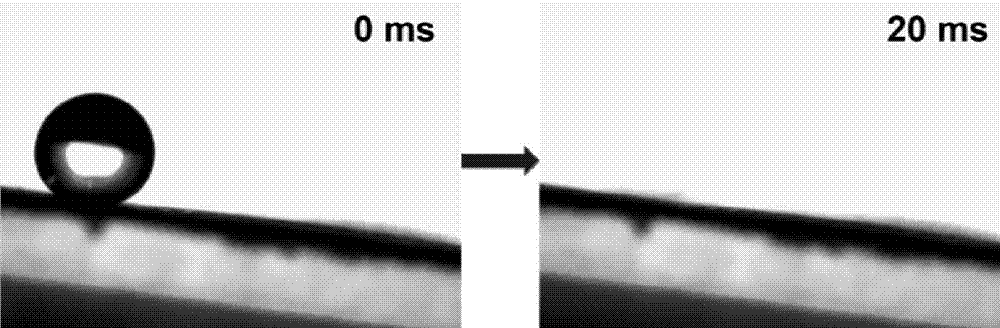

Super-hydrophobic and superoleophilic metal nickel net as well as preparation method and application thereof

ActiveCN107362587ALow costEasy to handleNon-miscible liquid separationMetallic sulfideMicro nanostructure

The invention relates to a super-hydrophobic and superoleophilic metal nickel net as well as a preparation method and application thereof. The super-hydrophobic and superoleophilic metal nickel net comprises a nickel net and a metal sulfide coating with a micro-nanostructure; the metal sulfide coating is generated on the surface of the nickel net in situ, is modified by a surface modifier and is an Ni3S2 coating or a composite coating of Ni3S2 and MoS2; the surface modifier is a silane coupling agent or / and a mercaptan long-chain compound.

Owner:中国科学院上海硅酸盐研究所苏州研究院 +1

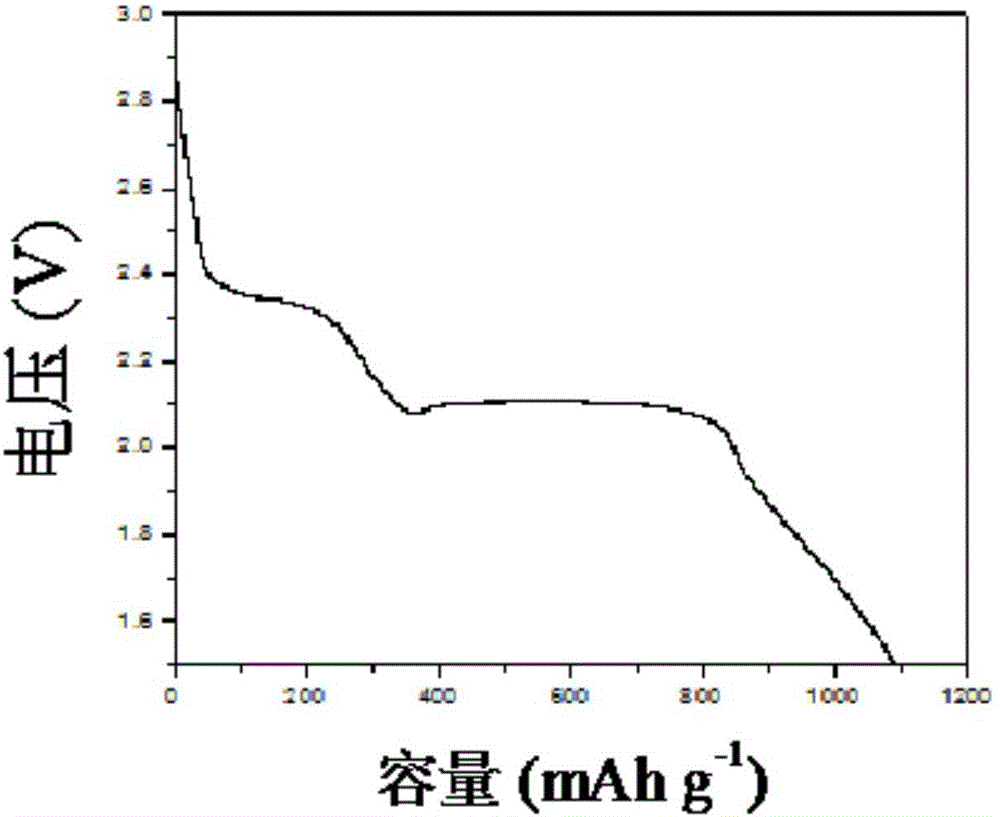

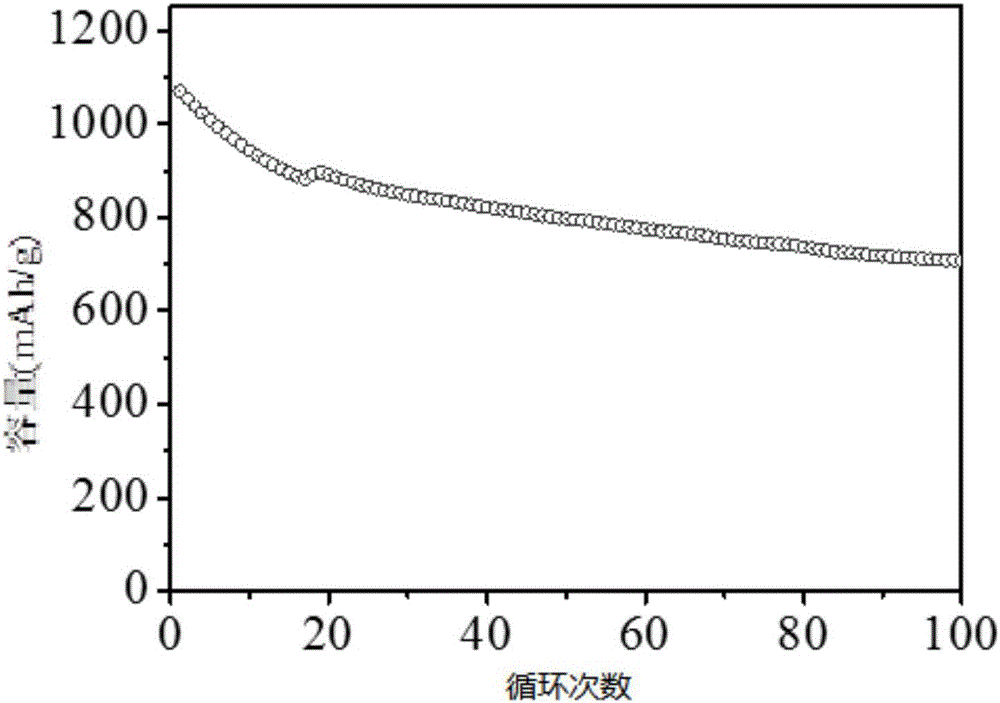

Graphene-like carbon material/sulphur composite cathode material for lithium-sulphur battery, and preparation method and application thereof

InactiveCN106058173AHigh active substance sulfur utilizationIncrease sulfur loadMaterial nanotechnologyCell electrodesPorous grapheneComposite cathode

The invention discloses a graphene-like carbon material / sulphur composite cathode material for a lithium-sulphur battery, and a preparation method and application thereof. The cathode material is formed by a three-dimensional porous graphene-like carbon material having a micro-nanostructure and elemental sulphur in a composite manner. The preparation method disclosed by the invention is simple to operate and low in cost; the utilization rate of the prepared composite cathode material for the lithium-sulphur battery is high; and the cycle performance of the lithium-sulphur battery is greatly improved.

Owner:CENT SOUTH UNIV

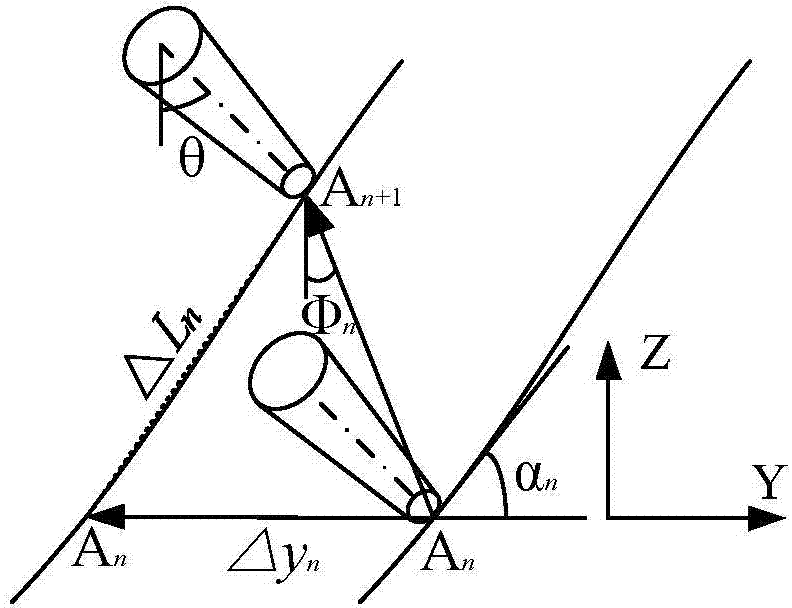

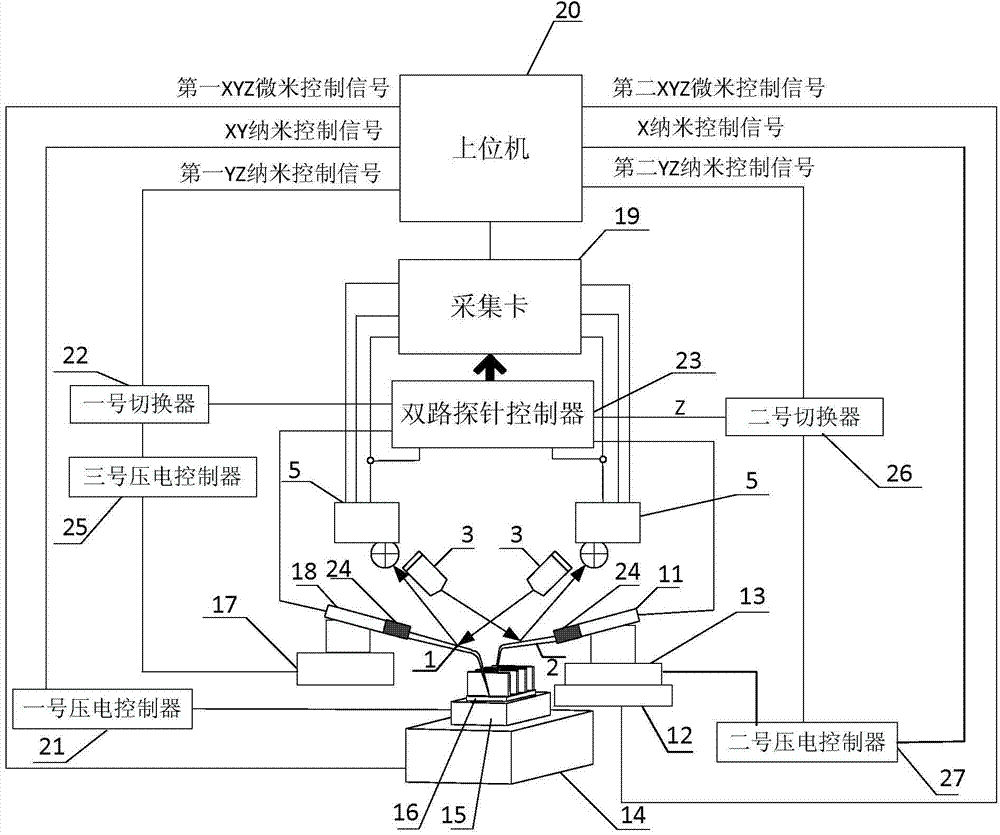

Probe servo angle control method and control mode, imaging system based on control module and imaging method of system

The invention discloses a probe servo angle control method and a control mode, an imaging system based on the control module, and an imaging method of the system, and relates to a technology of performing micro-nanostructure surface scanning imaging through an atomic force microscope, and aims to solve the problem that the traditional atomic force microscope cannot perform continuously controllable resolution three dimension scanning imaging on structure surfaces, such as an outward inclined surface with a large dip angle, a vertical side wall surface, an inward inclined surface and the like. By controlling the tip of a probe to be close to the surface of a sample in real time in a YZ plane along a vector forming an angle phi with an XZ surface, so as to perform scanning, and the phi can be automatically and dynamically adjusted according to scanned sample surface information, so that the uniform resolution scanning of surfaces with different angles is realized, and micro-nanostructure property detection and detection efficiency are convenient to improve, so that an important tool is provided for the super-large scale integrated circuit and ultra-large scale integrated circuit detection.

Owner:HARBIN INST OF TECH

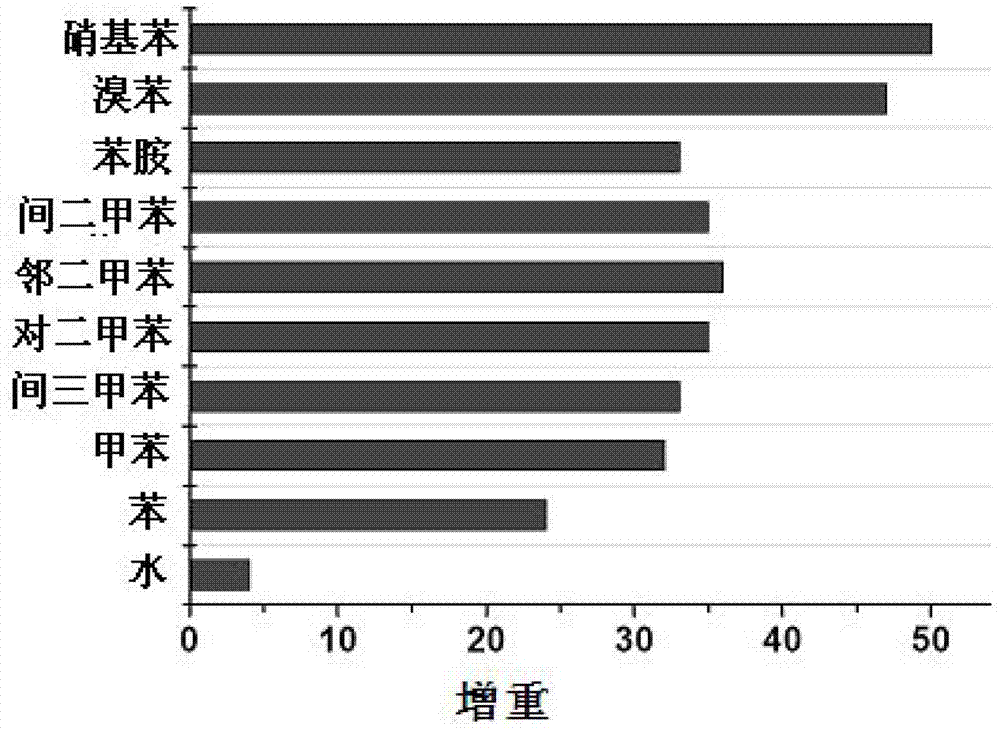

Elastic hydrophobic material and synthetic method as well as application thereof

InactiveCN103242557AExcellent selective adsorption\separation performanceThe preparation process route is simpleOther chemical processesWater contaminantsOrganic solventOrganic matter

The invention discloses an elastic hydrophobic material, a preparation method thereof and application of the material to removal of organic compounds in water. In particular, acetylenyl benzene and benzene halide are polymerized in a sponge, a polymer forms a hydrophobic micro-nanostructure inside the sponge, and an elastic highly hydrophobic material is finally formed. The material can selectively adsorb / separate oil or non-polar organic solvents in a water body, simultaneously has better elasticity and can separate the organic compounds by way of extrusion after the adsorbed organic compounds are saturated. The synthetic process of the material is simple, has low requirements for equipment and can achieve industrial scale production. The material has high efficiency of removing organic matters in water, has a simple regeneration process, is low in cost and has extensive application prospects.

Owner:DALIAN UNIV OF TECH

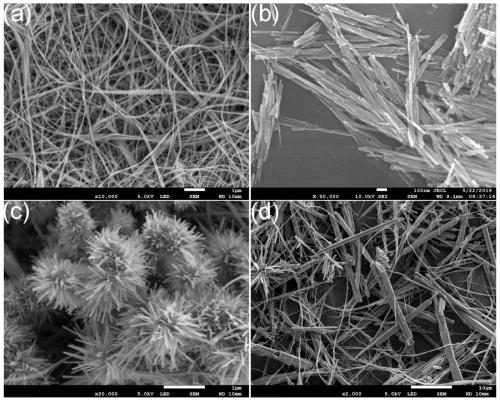

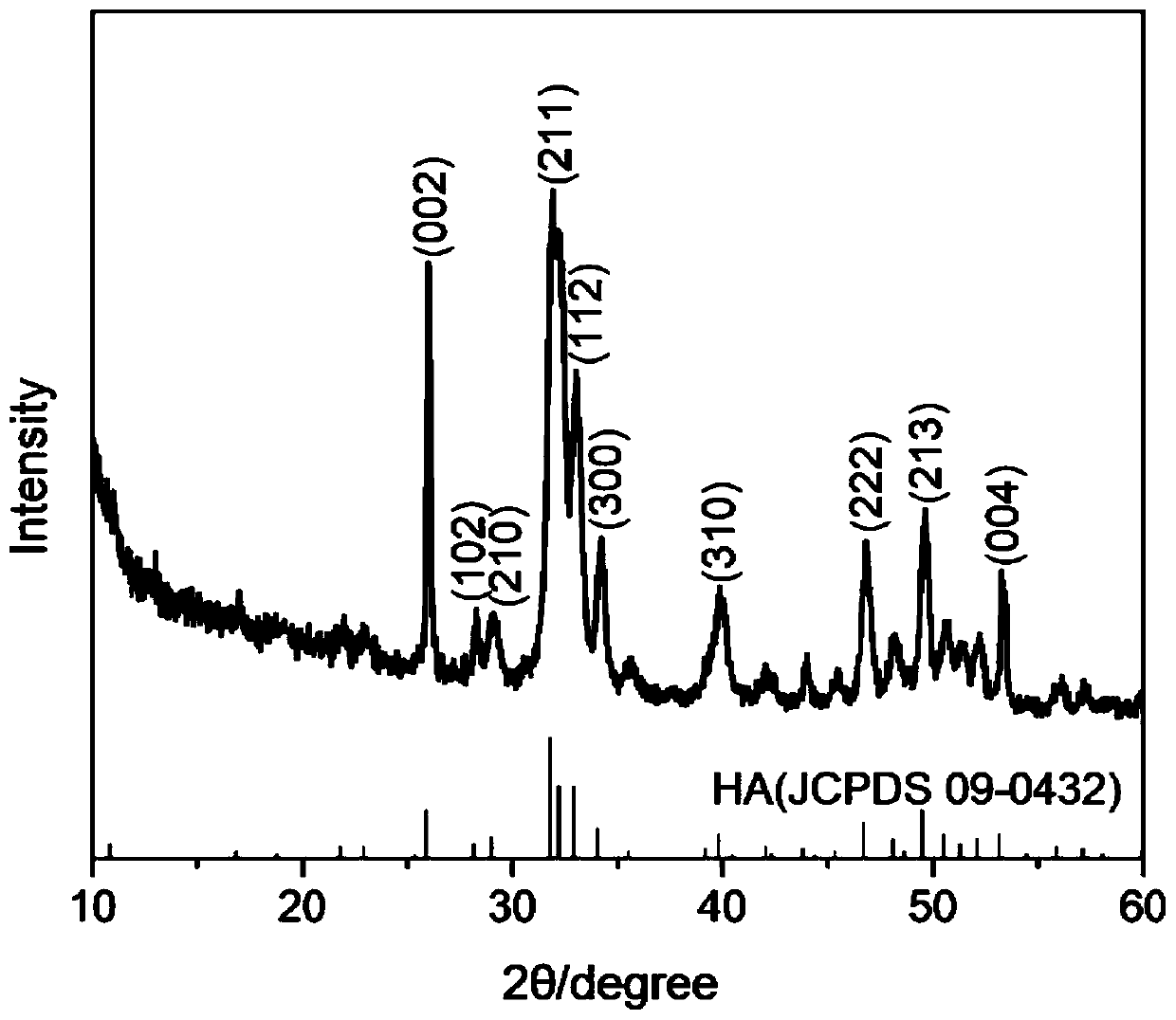

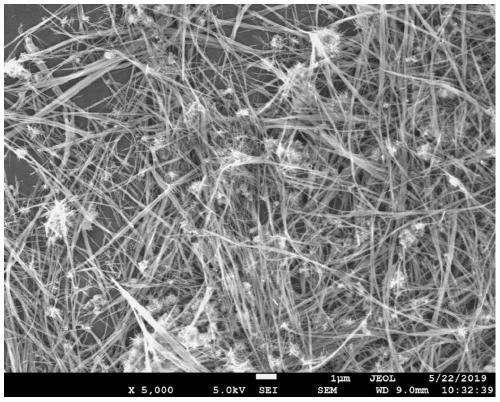

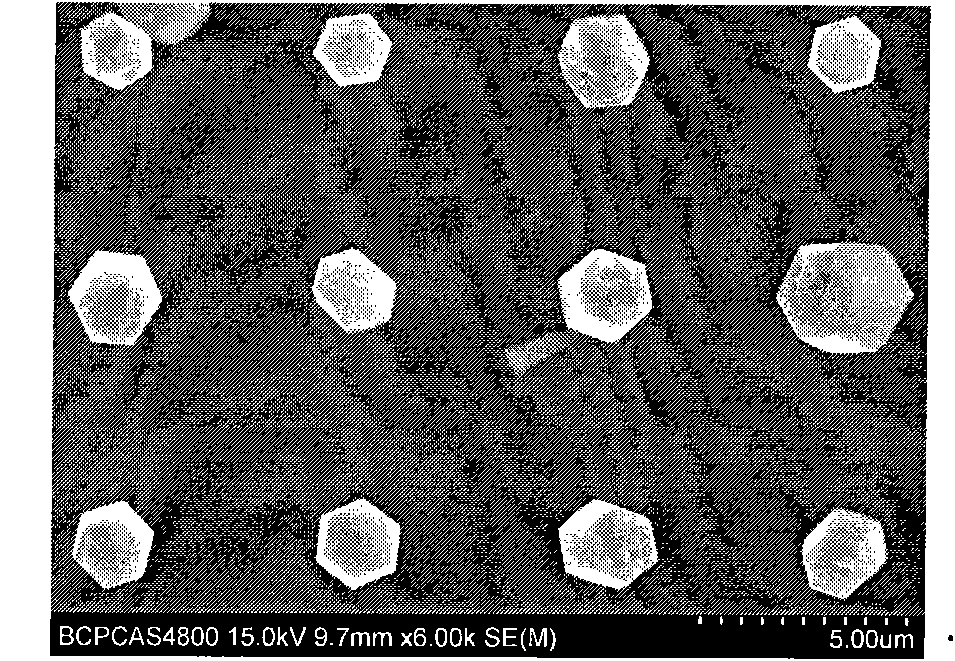

Method for regulating morphology of hydroxyapatite micro-nanomaterial by using phosphorus source

The invention relates to a method for regulating the morphology of a hydroxyapatite micro-nanomaterial by using a phosphorus source. The method comprises the following steps: mixing anhydrous ethanoland palmitic acid, adding an aqueous solution of a soluble calcium salt and an aqueous solution of a strong alkali, and performing magnetic stirring until uniformity in order to prepare a calcium palmitate precursor; adding an aqueous solution of various phosphorus sources such as a phosphate dodecahydrate, a trimetaphosphate, a tripolyphosphate, and a hexametaphosphate to obtain a reaction solution, adding the reaction solution into a hydrothermal kettle, and carrying out a solvothermal reaction; and washing and drying the obtained reaction product to obtain the hydroxyapatite micro-nanomaterial with various morphologies such as a ultra-long nanowire, a nano-short rod, a petal-like microsphere and a micro-tube. The method can be used to conveniently and quickly obtain the hydroxyapatite micro-nanostructure with the controlled morphology, and the hydroxyapatite micro-nanomaterial can be applied to many fields of bone tissue repairing, suture, hemostatic dressings, adsorption bioactivesubstances, drug loading and release, bone filling and cell / drug loaded implants according to actual needs.

Owner:SHANDONG JIAOTONG UNIV

Method for preparing ZnO nanorod/microrod crystals with accurate controllable growth position on substrate

InactiveCN101913907APrecisely control the size rangeVacuum evaporation coatingSputtering coatingMicro nanoResist

The invention provides a method for preparing ZnO nanorod / microrod crystals with an accurate growth position on a substrate. Due to the unique structure and performance, a ZnO crystalline material with a micro-nanostructure shows special application potential and is applied in the fields of electronic devices, photo-electronic devices, chemical sensors, biological power generation, ultraviolet detection and the like in recent years. The method comprises the following steps of: pre-modifying a ZnO seed crystal layer on the substrate; preparing a photo-resist layer which has a shape size of less than 2 mu m and serves as a template layer on the substrate; synthesizing the ZnO micro-nanorod crystals by using precursor solution containing sodium citrate and ethanolamine serving as two growth modifiers; and successfully preparing the ZnO nanorod / microrod crystals with the accurate controllable growth position on monocrystaline, polycrystalline or amorphous substrate on which the seed crystal layer is pre-modified. The method realizes position control of the ZnO micro-nano-crystalline material on the substrate and is a necessary step for realizing industrial application of devices of the ZnO micro-nano-crystalline material.

Owner:BEIJING JIAOTONG UNIV

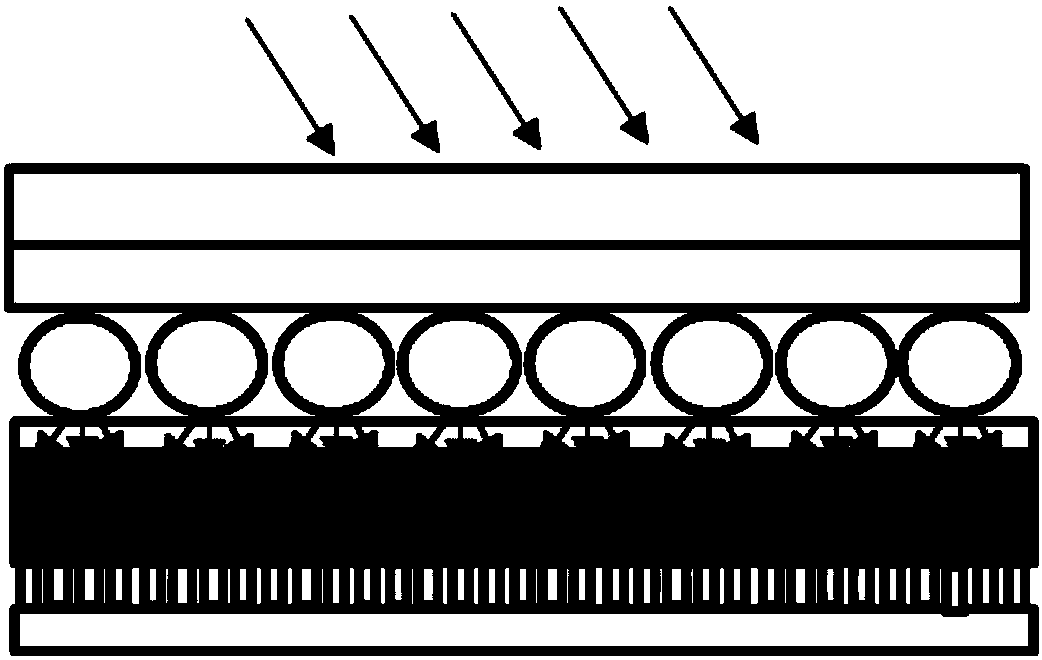

Method for manufacturing oil-water separation net with super-hydrophilic underwater super-oleophobic property

ActiveCN108970418ASpecial wettabilityEfficient separationSemi-permeable membranesMembranesUnderwaterOil water

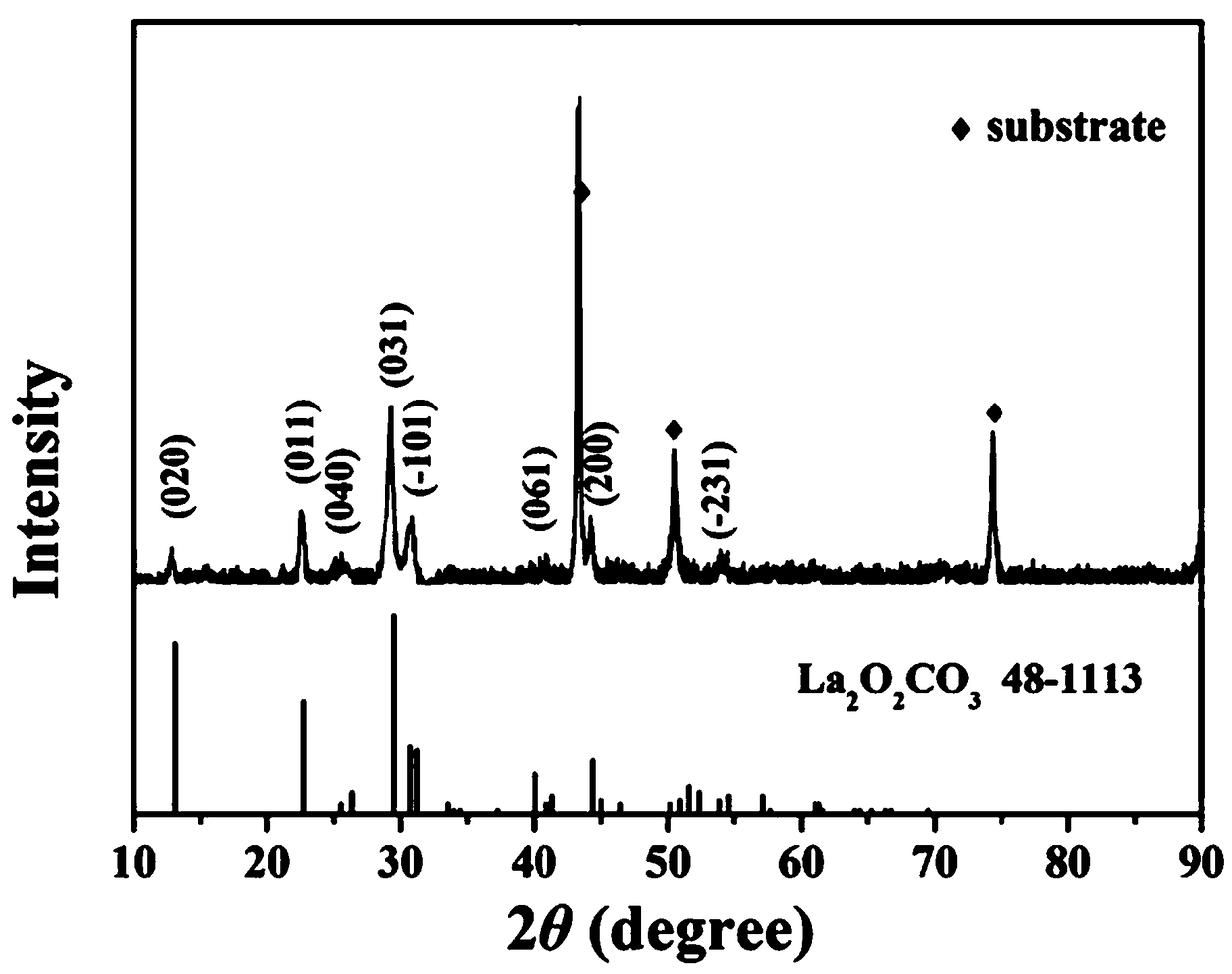

The invention belongs to the technical field of surface functionalization modification of materials, and particularly relates to a method for manufacturing an oil-water separation net membrane with super-hydrophilic underwater super-oleophobic property. According to the method, a (400-1800)-mesh stainless steel wire mesh serves as a base, a micro-nanostructure lanthanum carbonate (La2O2CO3) whichhas hydrophilic property is formed on the stainless steel wire mesh using a hydrothermal method, and finally annealing treatment is carried out at 550 DEG C to obtain the stainless steel wire mesh with the super-hydrophilic underwater super-oleophobic property. The method is simple to operate, has readily available materials, can be used for separation of oil-water mixtures, can be reused, and does not cause secondary pollution.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com