Sub-wavelength micro-nano structure using polystyrol ball to focused photoetching form

A polystyrene ball, micro-nano structure technology, applied in the direction of micro-structure technology, micro-structure device, manufacturing micro-structure device, etc., can solve the problem of large target structure period and feature size, difficulty in forming nano-structure, and limitation of pattern size, etc. problems, to achieve the effect of reducing cycle and feature size, low cost, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the scope of protection of the present invention is not limited to the following examples, but should include all content in the claims.

[0035] The concrete process of the embodiment of the present invention is as follows:

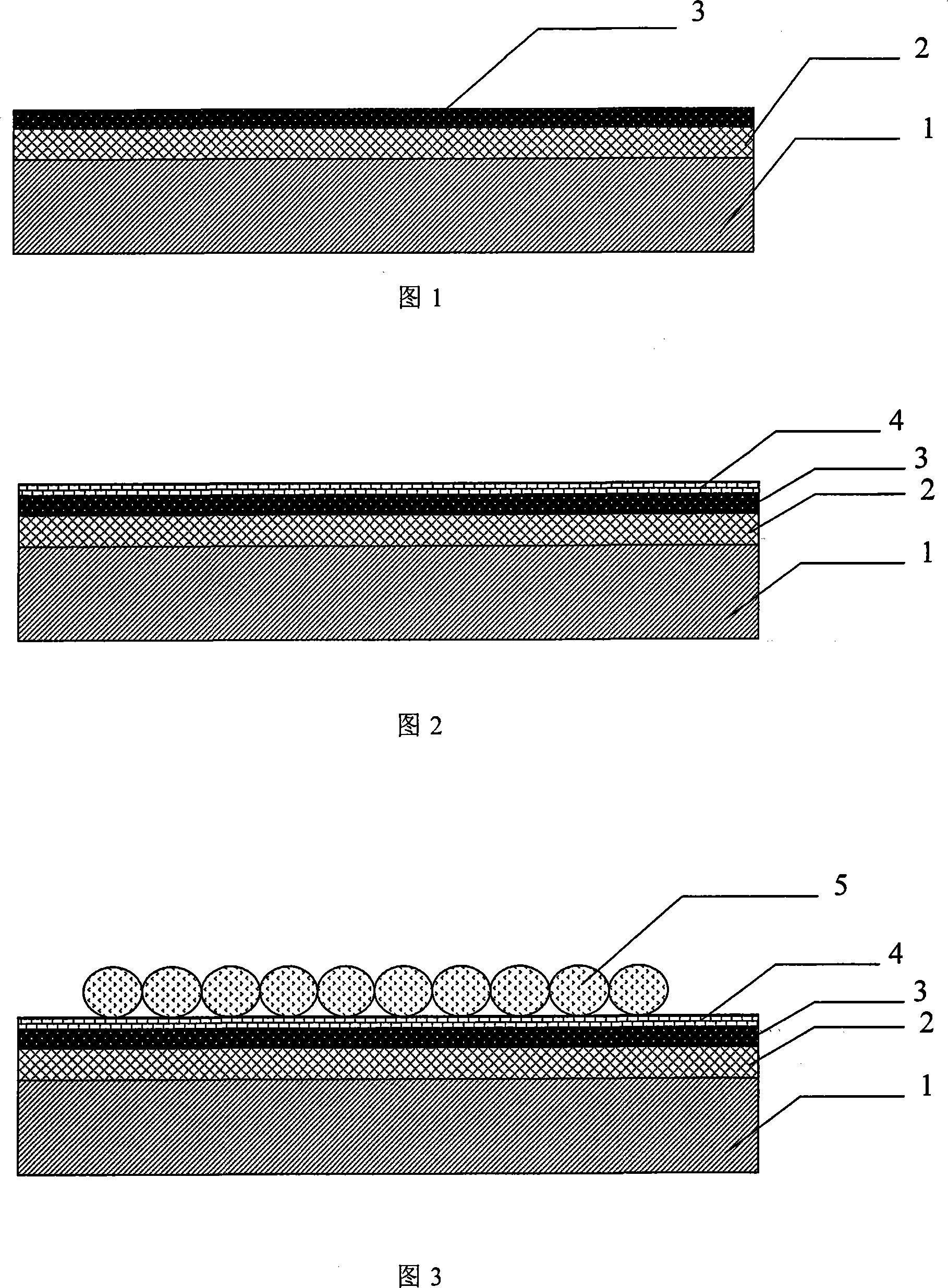

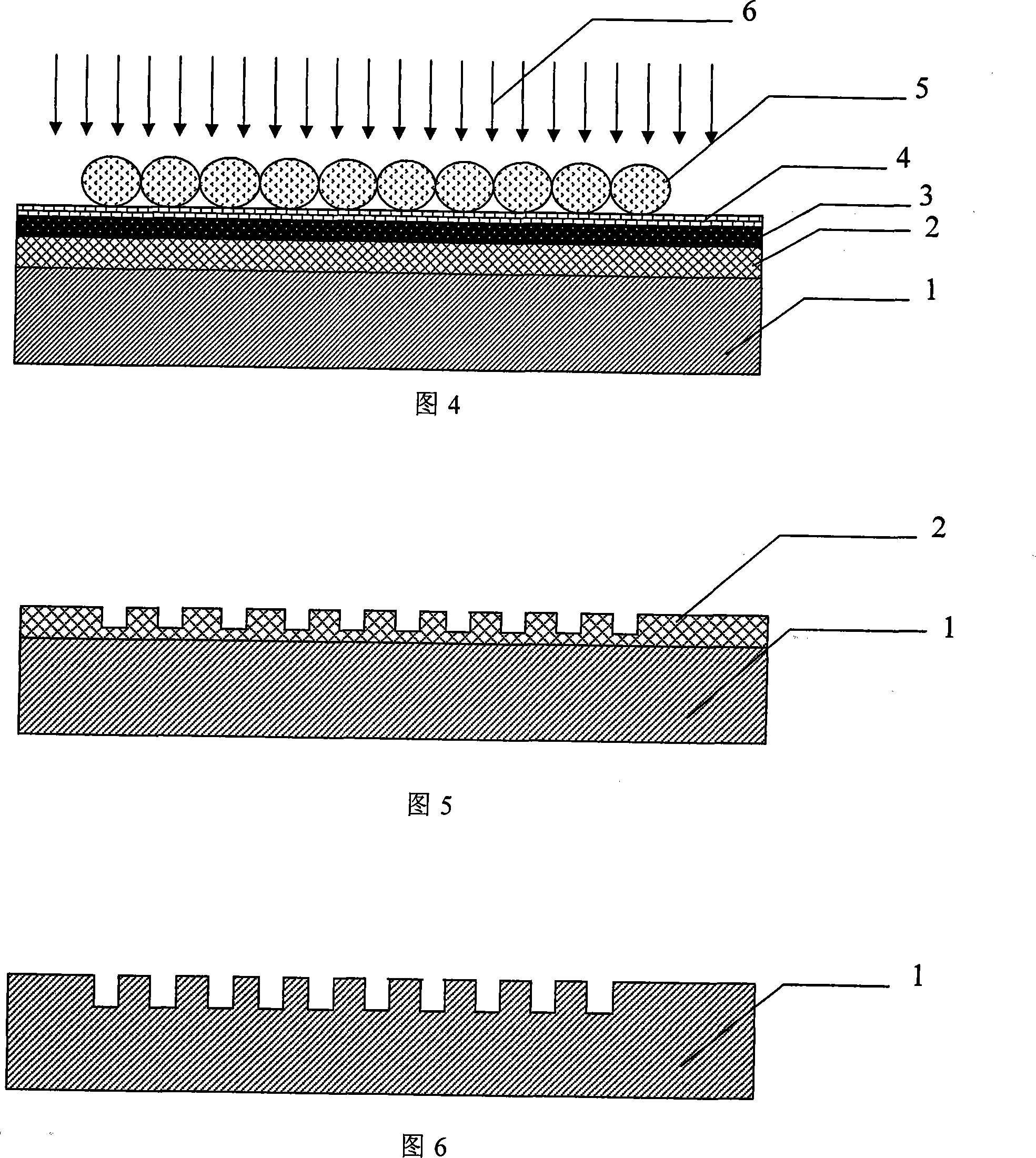

[0036] (1) Select silica S according to needs i o 2 The substrate was cleaned with acetone and ethanol, dried with high-pressure nitrogen, a layer of 200nm resist AZ3100 was spin-coated on the substrate surface, and a 40nm silver layer structure was deposited on the resist surface, as shown in the figure 1 shown;

[0037] (2) A polystyrene ball with a diameter of 3um is selected, and its focal length is calculated to be 2um.

[0038] (3) Spin-coat a layer of PMMA gap layer on the surface of the silver layer, its thickness is 1.8um, and its thickness is selected to make the focus of the incident light fall on the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com