Preparation method of lithium titanate negative electrode material with micro-nanostructure

A negative electrode material and micro-nano structure technology, applied in the field of preparation of lithium titanate negative electrode materials, can solve the problems of high raw material, solvent and operation requirements, complicated operation process, etc., and achieve good dispersion, high stability, and excellent large rate Effect of Discharge Characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

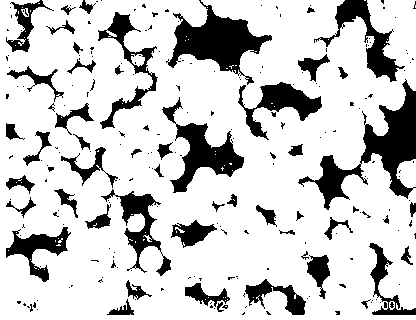

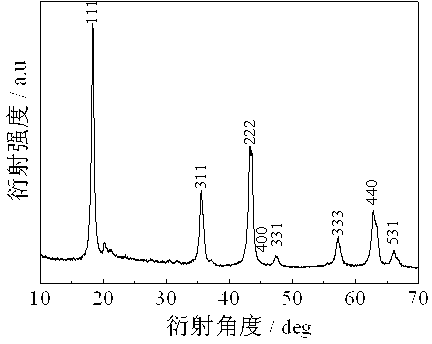

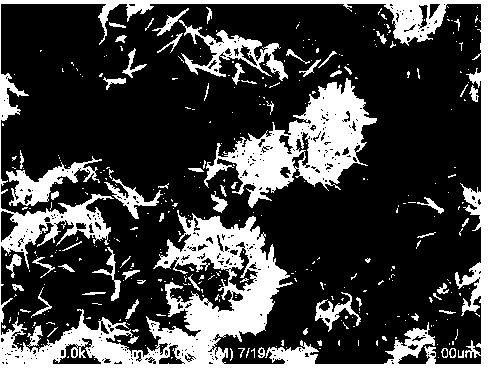

[0026] Example 1: Take 100ml of absolute ethanol into a 250ml three-necked flask, add 0.4ml of 0.1M PEG4000 solution to it, and then slowly drop 2ml of tetrabutyl titanate into it. Access N 2 , Under agitation, react for 2h, stand for 8h, filter to obtain white precipitate, wash the precipitate three times with absolute ethanol, and dry it in a vacuum oven at 60°C to prepare spherical titanium dioxide precursor. figure 1 It is the prepared spherical titanium dioxide precursor. Weigh 0.15g of titanium dioxide precursor, add it to 15ml of ethanol and water mixed solution (volume ratio is 1:1), then add 0.0629g of LiOH·H to it 2 O, after stirring for 15 minutes, transfer to a 50ml hydrothermal reactor, react at 180°C for 12 hours to obtain a white powder, and put it in a muffle furnace at 500°C for two hours to prepare pure phase lithium titanate with micro-nano structure Powder. figure 2 Shown is the XRD pattern of the obtained lithium titanate powder. It can be seen that the po...

Embodiment 2

[0027] Example 2: Take 100ml of absolute ethanol into a 250ml three-necked flask, add 0.4ml of 0.1M PEG1000 solution to it, and then slowly drop 2ml of isopropyl titanate into it. Access N 2 , Under agitation, react for 2h, stand for 8h, filter to obtain white precipitate, wash the precipitate three times with absolute ethanol, and dry it in a vacuum oven at 60°C to prepare spherical titanium dioxide precursor. Weigh 0.15g of titanium dioxide precursor, add it to 15ml of ethanol and water mixed solution (volume ratio is 3:2), then add 0.065g of LiOH·H to it 2 O, after stirring for 15 minutes, transfer to a 50ml hydrothermal reactor, react at 180°C for 5 hours to obtain a white powder, and place it in a muffle furnace at 500°C for 1 hour to prepare pure phase lithium titanate with micro-nano structure Powder.

Embodiment 3

[0028] Example 3: Take 100ml of absolute ethanol into a 250ml three-necked flask, add 0.4ml of 0.1M PEG10000 solution to it, and then slowly drop 2ml of butyl titanate into it. Access N 2 , Under stirring, react for 4h, stand for 2h, filter to obtain white precipitate, wash the precipitate three times with absolute ethanol, and dry it in a vacuum oven at 60°C to prepare spherical titanium dioxide precursor. Weigh 0.15g of titanium dioxide precursor, add it to 15ml of ethanol and water mixed solution (volume ratio 4:1), then add 0.0629g of LiOH·H to it 2 O, after stirring for 15 minutes, transfer to a 50ml hydrothermal reactor, react at 150°C for 12 hours to obtain a white powder, and place it in a muffle furnace at 450°C for 4 hours to prepare pure phase lithium titanate with micro-nano structure Powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com