Graphene-like carbon material/sulphur composite cathode material for lithium-sulphur battery, and preparation method and application thereof

A composite positive electrode material, graphene carbon technology, applied in nanotechnology for materials and surface science, battery electrodes, lithium batteries, etc., can solve the problems of small specific capacity of sulfur electrodes, low sulfur loading, and poor cycle performance , to achieve the effect of high sulfur load, large sulfur load and improved cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

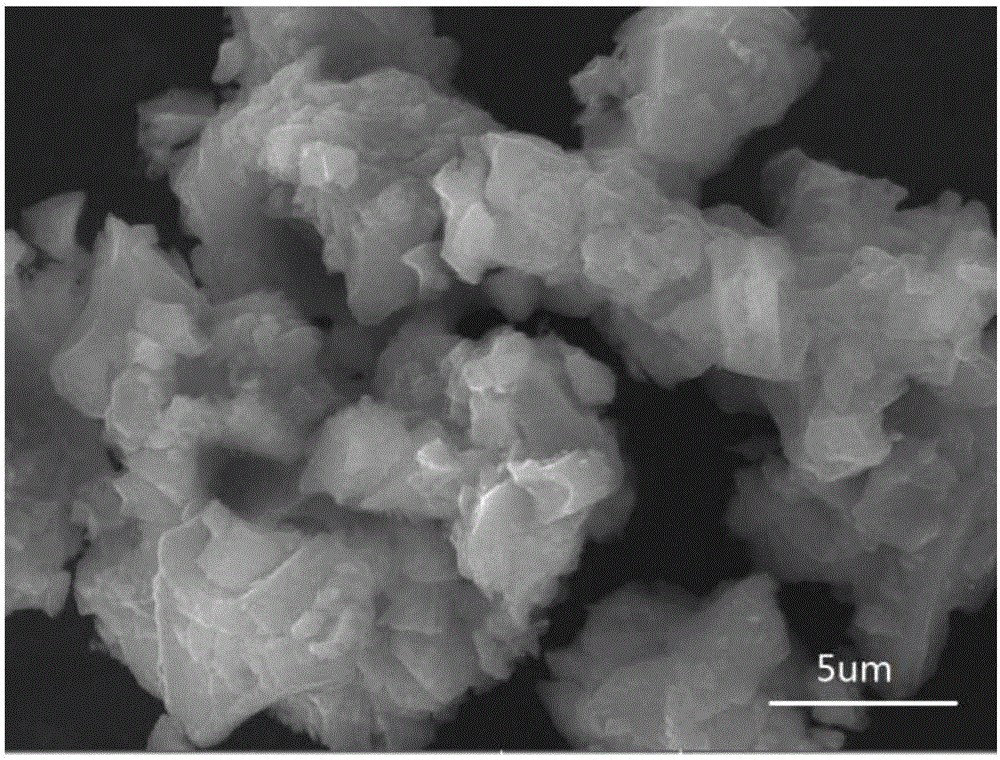

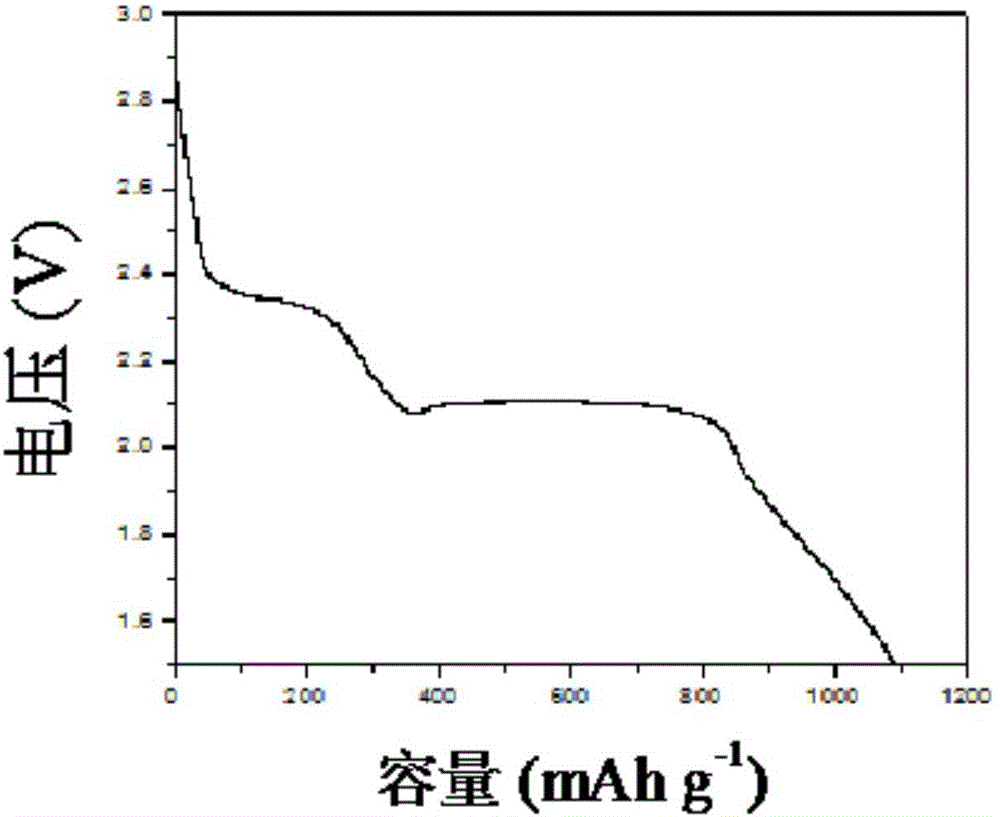

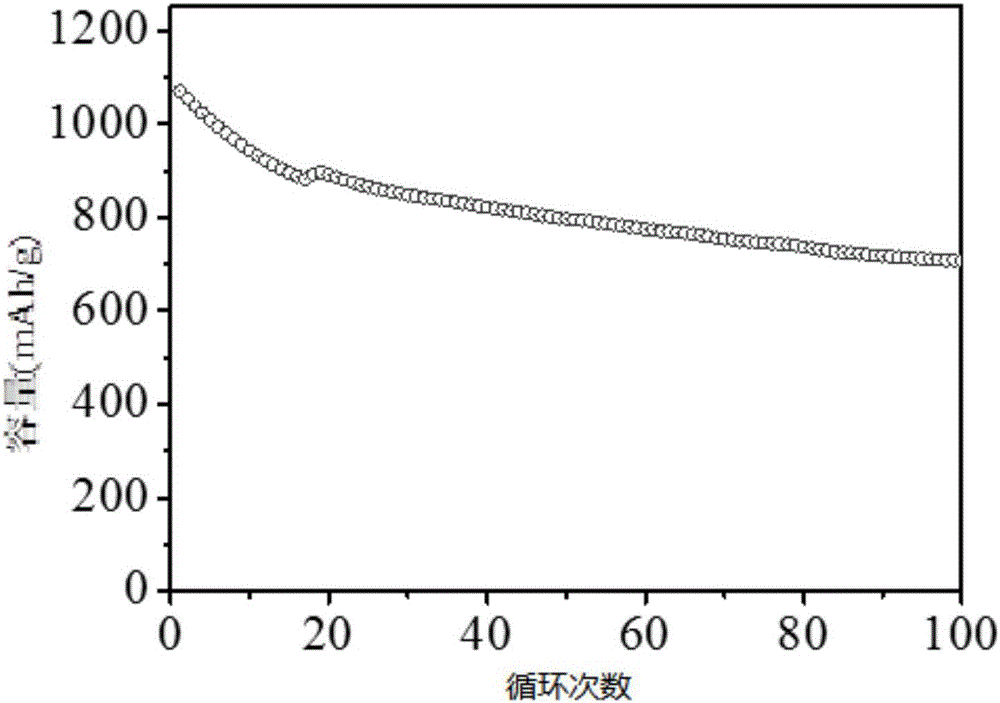

[0044] Add 2.0 g of macroporous anion exchange resin into 2 L of KOH solution with a concentration of 3 g / L, and react with mechanical stirring at room temperature for 10 h. After filtering, it was transferred to a tube furnace, and under the protection of nitrogen, it was heated to 800°C at a heating rate of 10°C / min, and kept for 6 hours. After carbonization, a three-dimensional porous graphene-like carbon material with micro-nano structure was obtained. The BET test found that its specific surface area is 3002m 2 / g, the pore diameter of the micropores is ≤2nm, and the proportion of micropores to the entire pore structure is 70%. The three-dimensional porous graphene-like carbon material with micro-nano structure and sulfur powder were mixed by high-speed ball milling at a mass ratio of 2:8 for 2 hours, and then under the protection of argon, the temperature was raised to 155°C and kept for 24 hours to obtain a graphene-like carbon material / sulfur composite cathode materi...

Embodiment 2

[0049] Add 2.0 g of macroporous anion exchange resin into 2 L of NaOH solution with a concentration of 4 g / L, and react with mechanical stirring at room temperature for 10 h. After filtering, it was transferred to a tube furnace, and under the protection of nitrogen, it was heated to 900°C at a heating rate of 5°C / min, and kept for 8 hours. After carbonization, a three-dimensional porous graphene-like carbon material with a micro-nano structure was obtained. The BET test found that its specific surface area is 1870m 2 / g, the pore diameter of the micropores is ≤2nm, and the proportion of micropores to the entire pore structure is 50%. The three-dimensional porous graphene-like carbon material with micro-nano structure and sulfur powder were mixed by high-speed ball milling at a mass ratio of 2:8 for 2 hours, and then under the protection of argon, the temperature was raised to 155°C and kept for 24 hours to obtain a graphene-like carbon material / sulfur composite cathode mate...

Embodiment 3

[0051] Add 2.0g of macroporous anion exchange resin to 3L of Na with a concentration of 1.8g / L 2 CO 3 In the solution, the reaction was mechanically stirred at room temperature for 24h. After filtration, it was transferred to a tube furnace, and under the protection of nitrogen, it was heated to 1100°C at a heating rate of 15°C / min, and kept for 7 hours. After carbonization, a three-dimensional porous graphene-like carbon material with a micro-nano structure was obtained. The BET test found that the specific surface area of the material is 1666m 2 / g, the pore diameter of the micropores is less than or equal to 2nm, and the proportion of micropores to the entire pore structure is 60%. The three-dimensional porous graphene-like carbon material with micro-nano structure and sulfur powder are mixed by high-speed ball milling at a mass ratio of 2:8 for 2 hours, then heated to 155 °C under the protection of argon, and kept for 24 hours to obtain a graphene-like carbon material / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com