Patents

Literature

115results about How to "Increase sulfur load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of nitrogen-rich multimode beehive carbon-sulfur composite anode material

ActiveCN103746098ALarge specific surface areaHigh nitrogen contentPositive electrodesLi-accumulatorsArgon atmosphereOxide composite

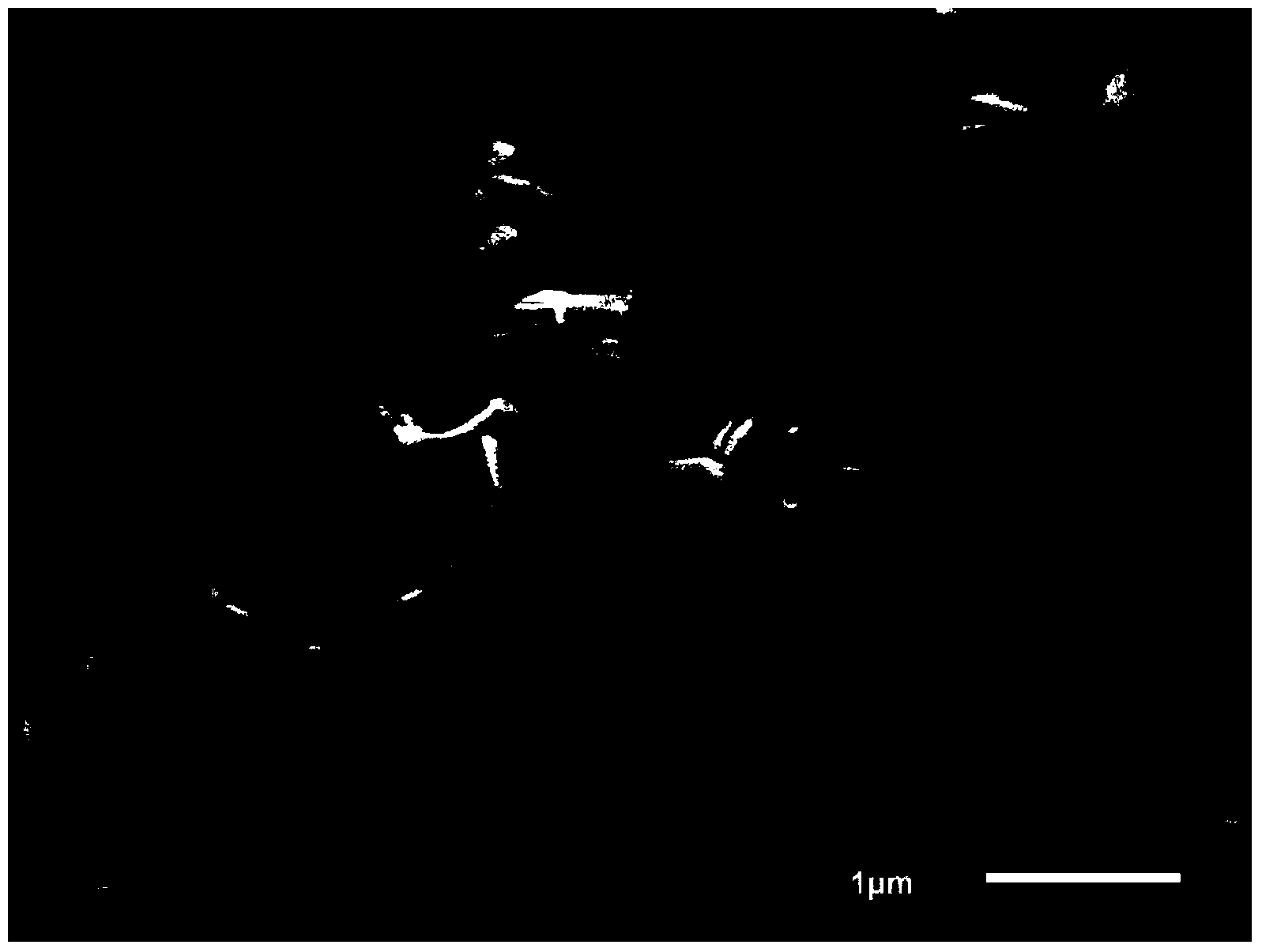

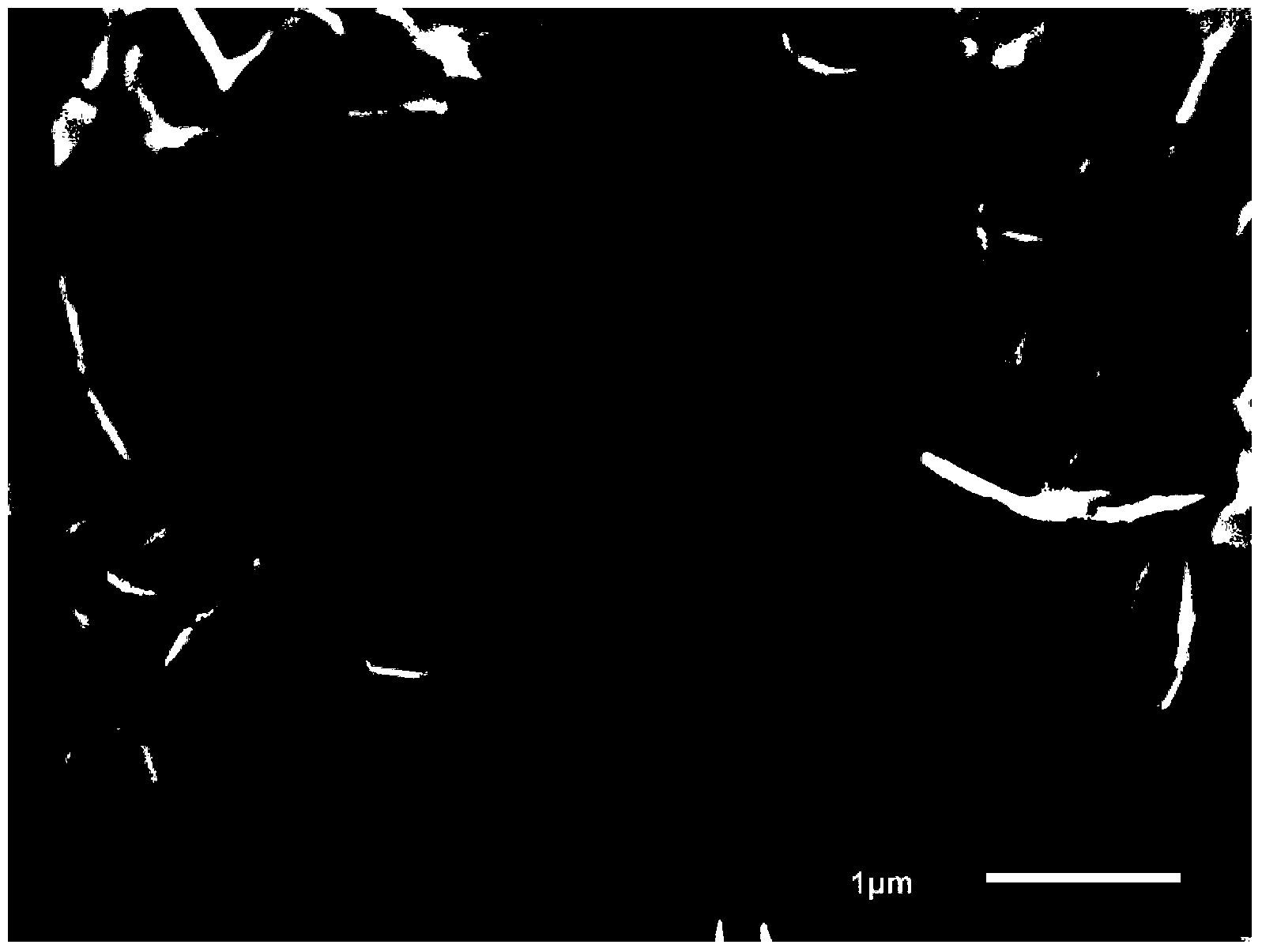

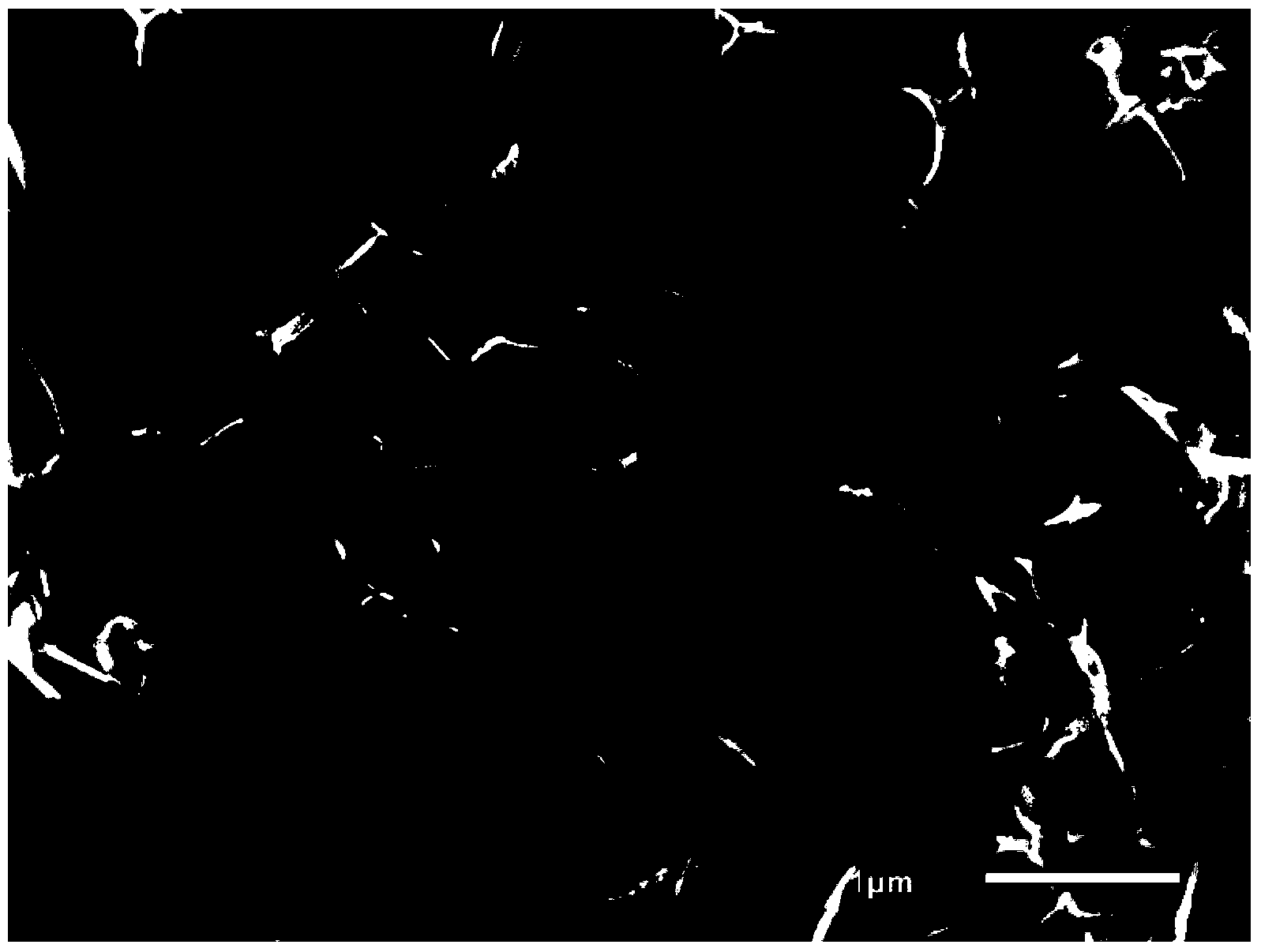

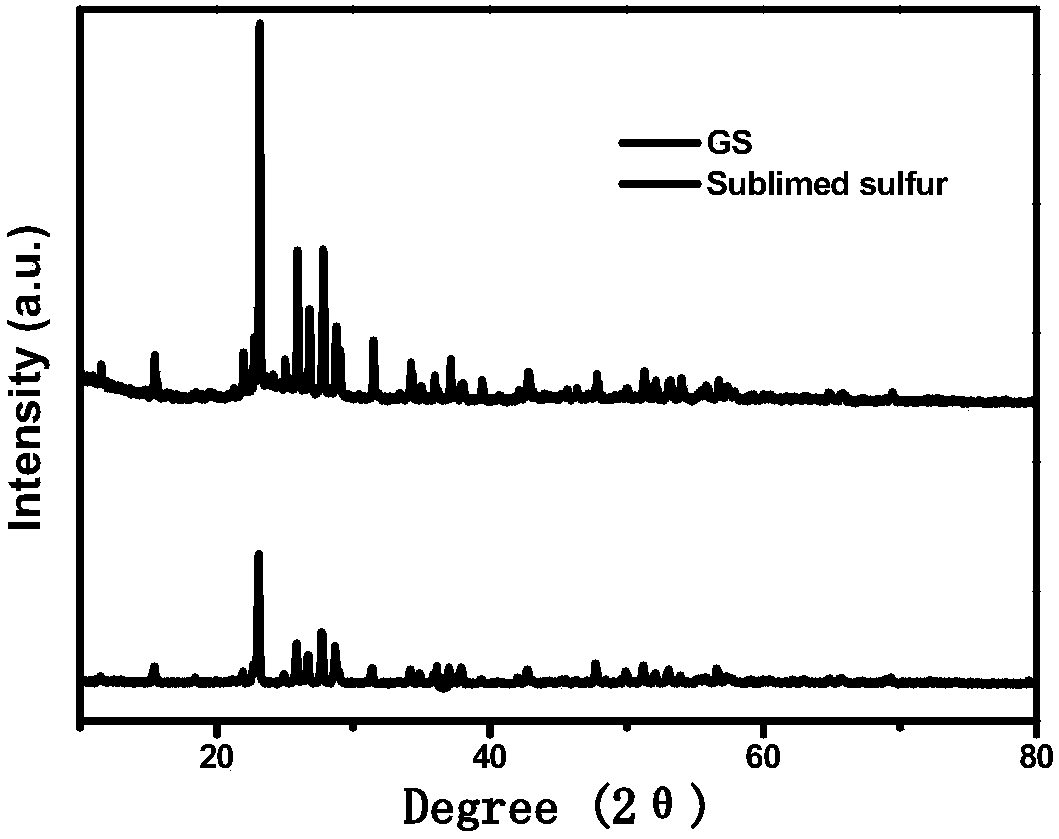

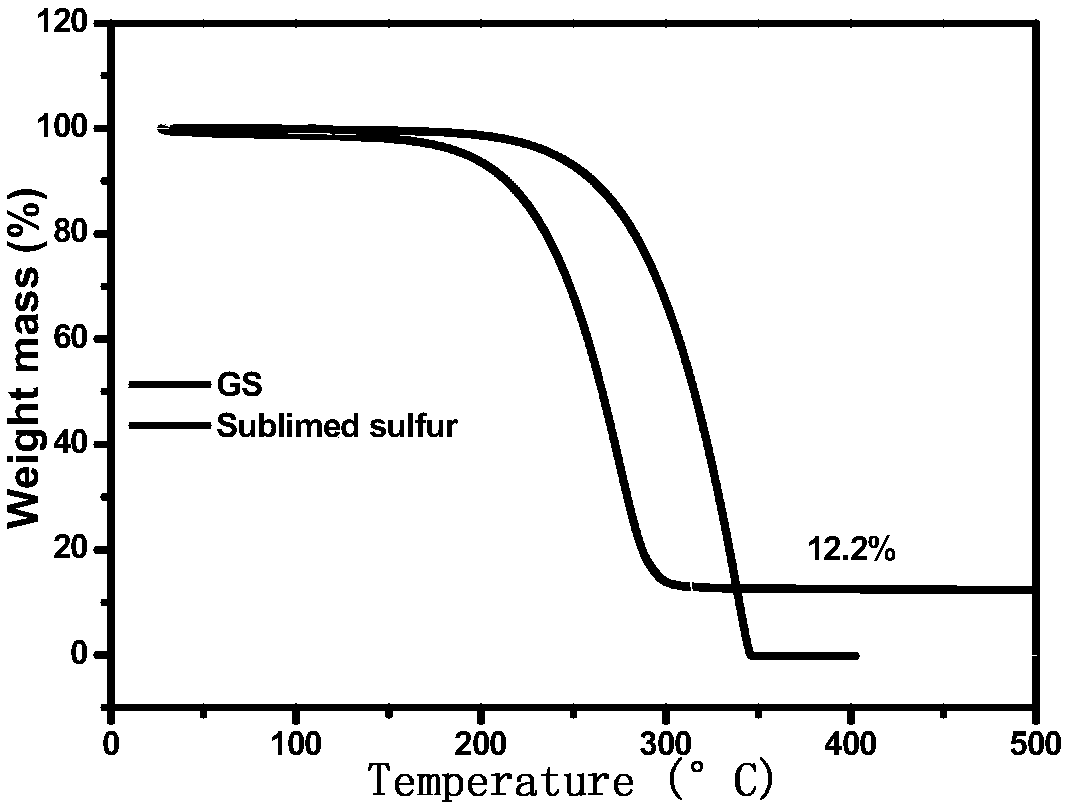

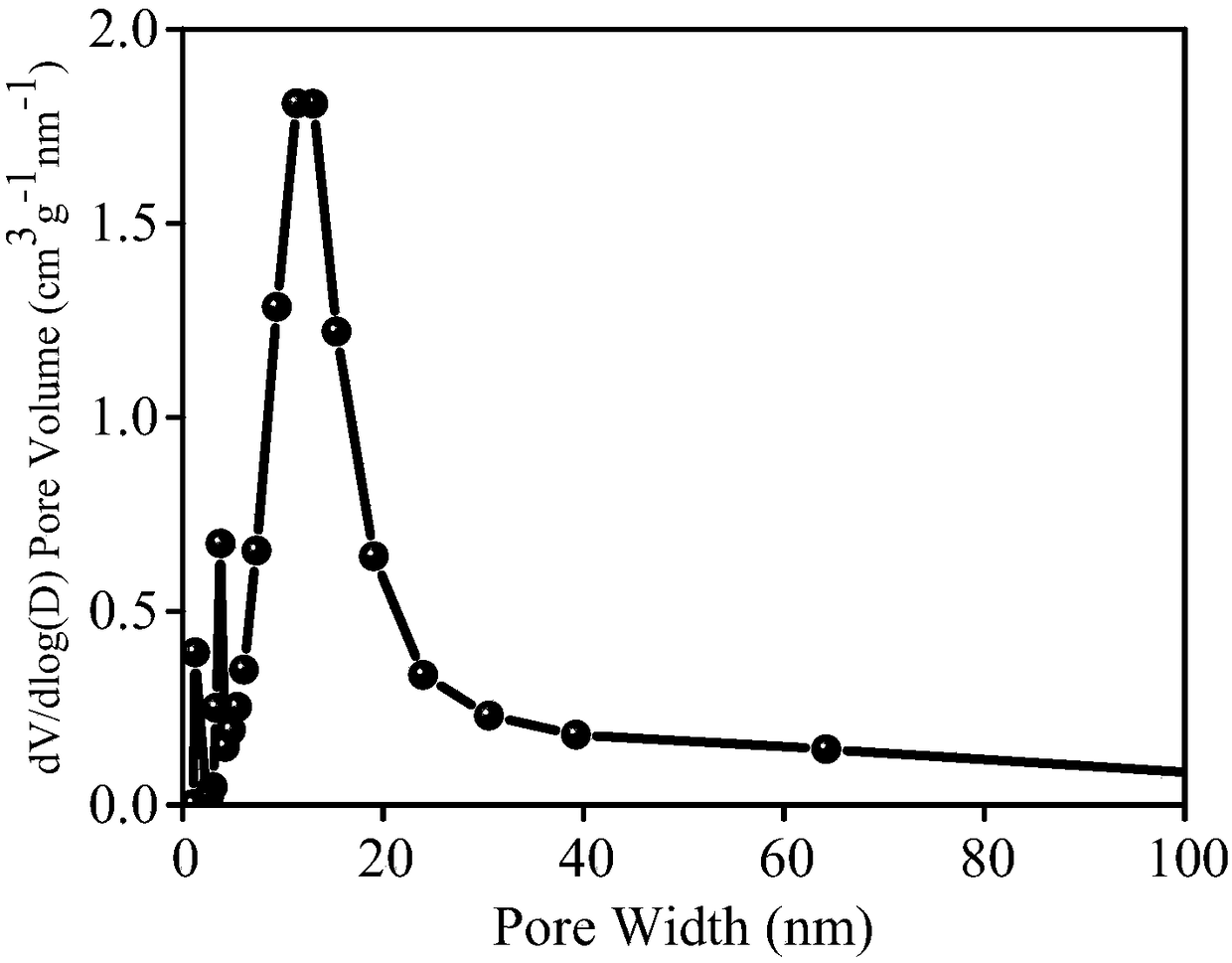

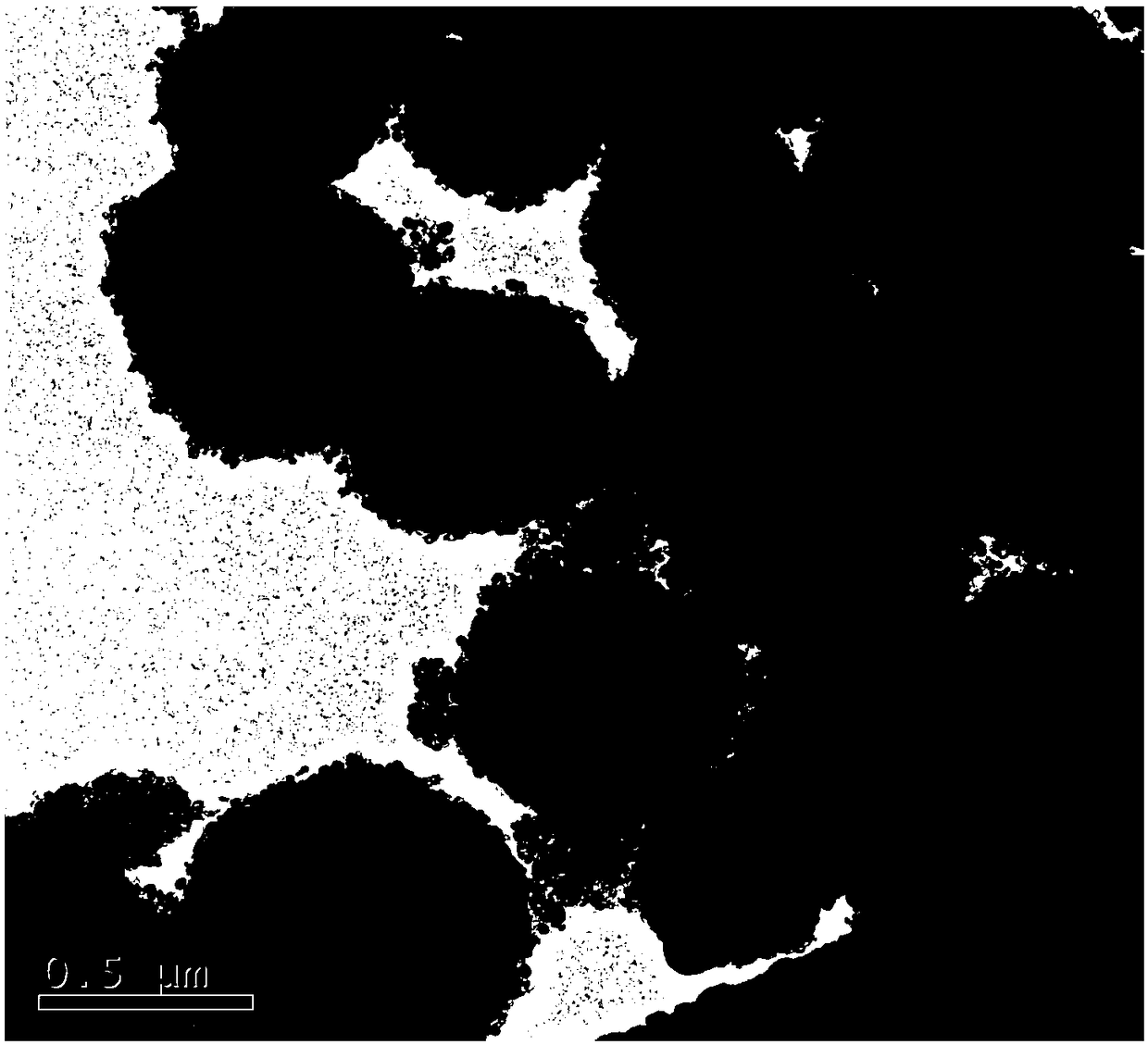

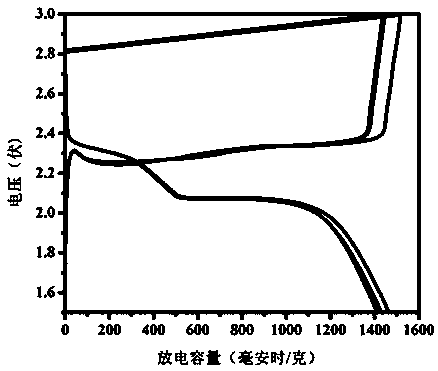

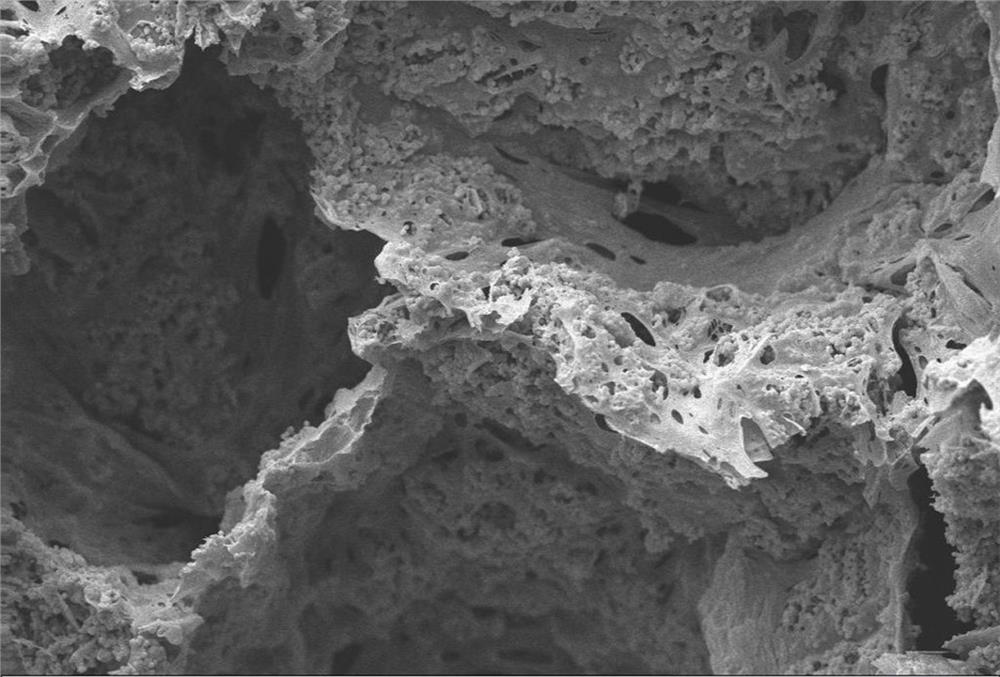

The invention relates to a preparation method of a lithium sulphur battery composite anode material. The preparation method is as follows: preparing a mixed solution of carbon tetrachloride, a nitrogen source and carbonate, heating and flowing back to obtain a nitrogen-rich polymerization / carbonic acid salt compound; high temperature pyrolyzing in a nitrogen or argon atmosphere after drying the compound, so as to form the nitrogen-rich carbon / oxide compound; adding dilute acid to remove vestigial oxide, so as to form the nitrogen-rich multimode beehive carbon material of a multilevel porthole structure; uniformly mixing the nitrogen-rich multimode beehive carbon and sublimed sulfur, heat preserving under vacuum condition, injecting sulfur gas to the nitrogen-rich multimode beehive carbon material, so that the lithium sulphur battery composite positive material can be obtained. The composite anode material provided by the invention is alveolate, and has the advantages that portholes are abundant, sulfur content is high, sulfur particle can be distributed uniformly in the nitrogen-rich multimode beehive carbon material of the multilevel porthole structure, and the carbon sulfur particles can be combined more tightly, the material mechanical stability is high, discharge specific capacity is high, cycle performance is excellent, and technological process is simple, pollution is avoided, cost is low, and the method is liable to large scale production and application.

Owner:CENT SOUTH UNIV

Preparation method of S/TiO2 composite material for anode of sodium-sulfur battery

ActiveCN103840143AImprove conductivityIncrease profitElectrode carriers/collectorsLi-accumulatorsSulfur electrodeHYDROSOL

The invention provides a preparation method of an S / TiO2 composite material for an anode of a sodium-sulfur battery. The preparation method comprises the following steps: dissolving butyl titanate, a template agent and a hydrolysis inhibitor into absolute ethyl alcohol; adding a mixed solution of de-ionized water and the absolute ethyl alcohol to form semi-transparent sol; transferring the sol into a high-pressure reaction kettle to react; calcining a solid product in air to remove the template agent to obtain meso-porous titanium dioxide; dispersing the meso-porous titanium dioxide into a sodium thiosulfate solution dissolved with a surfactant; adding hydrochloric acid to react; washing the solid product by a lot of the de-ionized water and drying; and eating under the protection of an inert atmosphere to obtain the S / TiO2 composite material. The meso-porous titanium dioxide prepared by the preparation method is large in specific surface area, high in porosity and strong in adsorption capability; the electrical conductivity of sulfur can be improved and a lot of nano sulfur and polysulfide can be contained; the polysulfide can be effectively prevented from being dissolved and diffused in electrolyte, and the utilization rate of the sulfur is improved; meanwhile, the structure of the meso-porous titanium dioxide is stable and a pore channel cannot be easily damaged, so as to have buffering effects on volume expansion and retraction in a charging / discharging process of a sulfur electrode.

Owner:CENT SOUTH UNIV

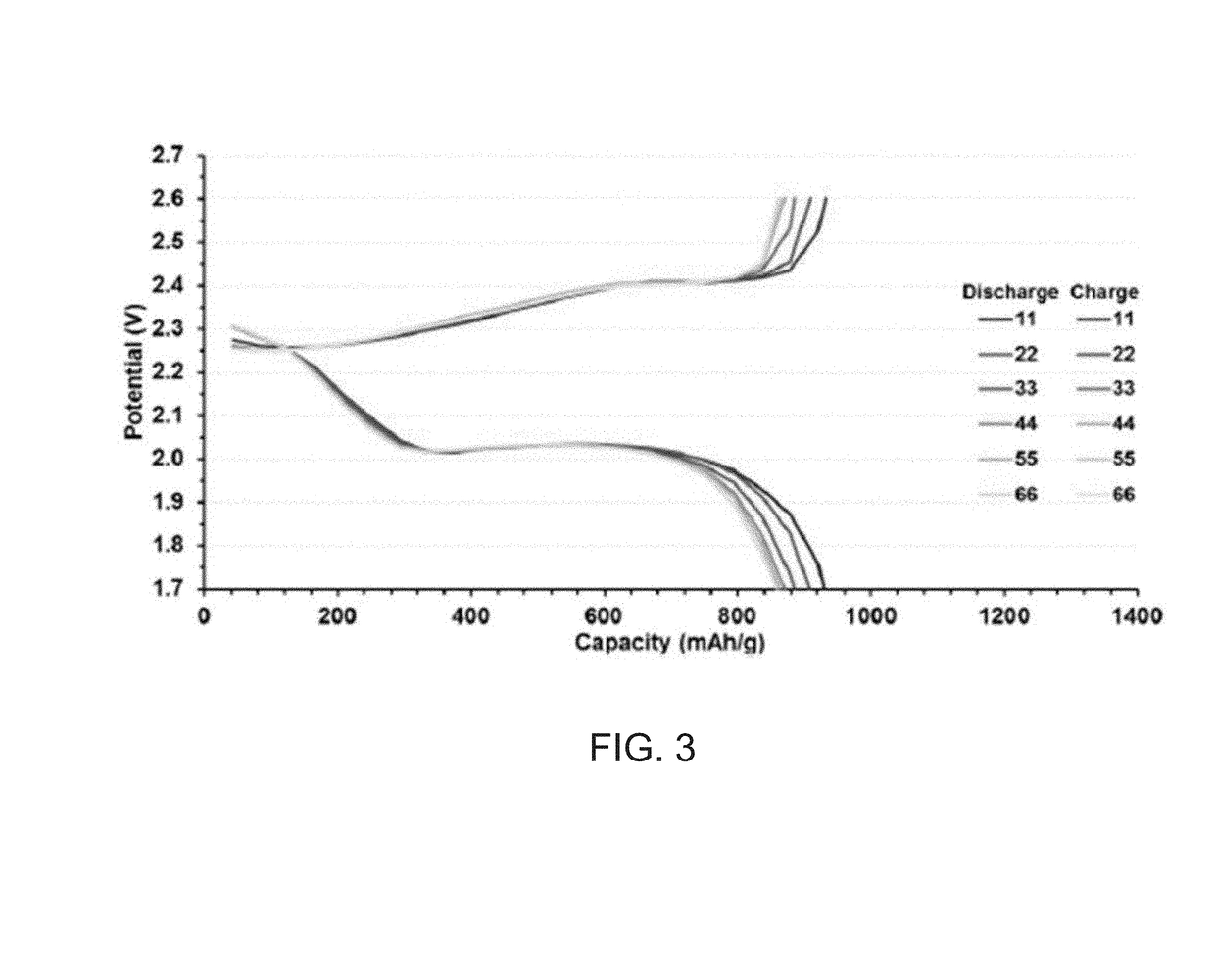

CATHODE MATERIALS FOR Li-S BATTERIES

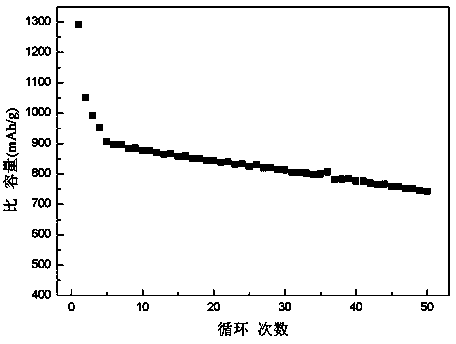

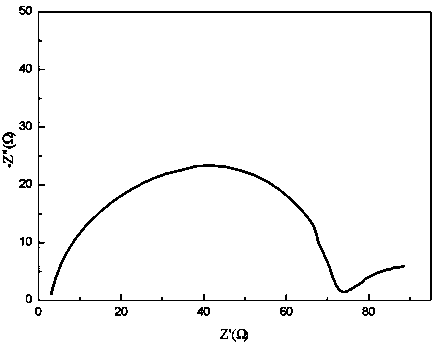

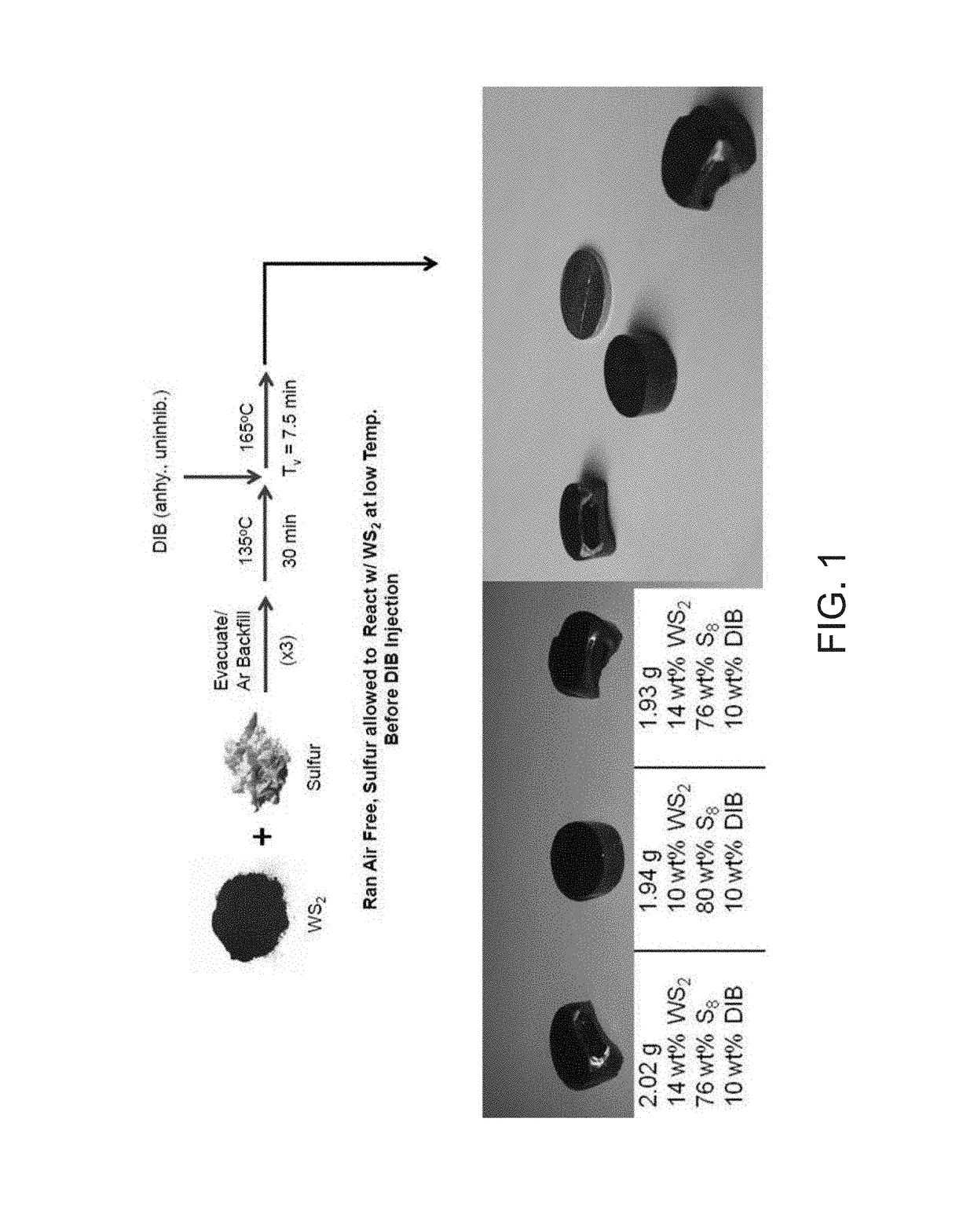

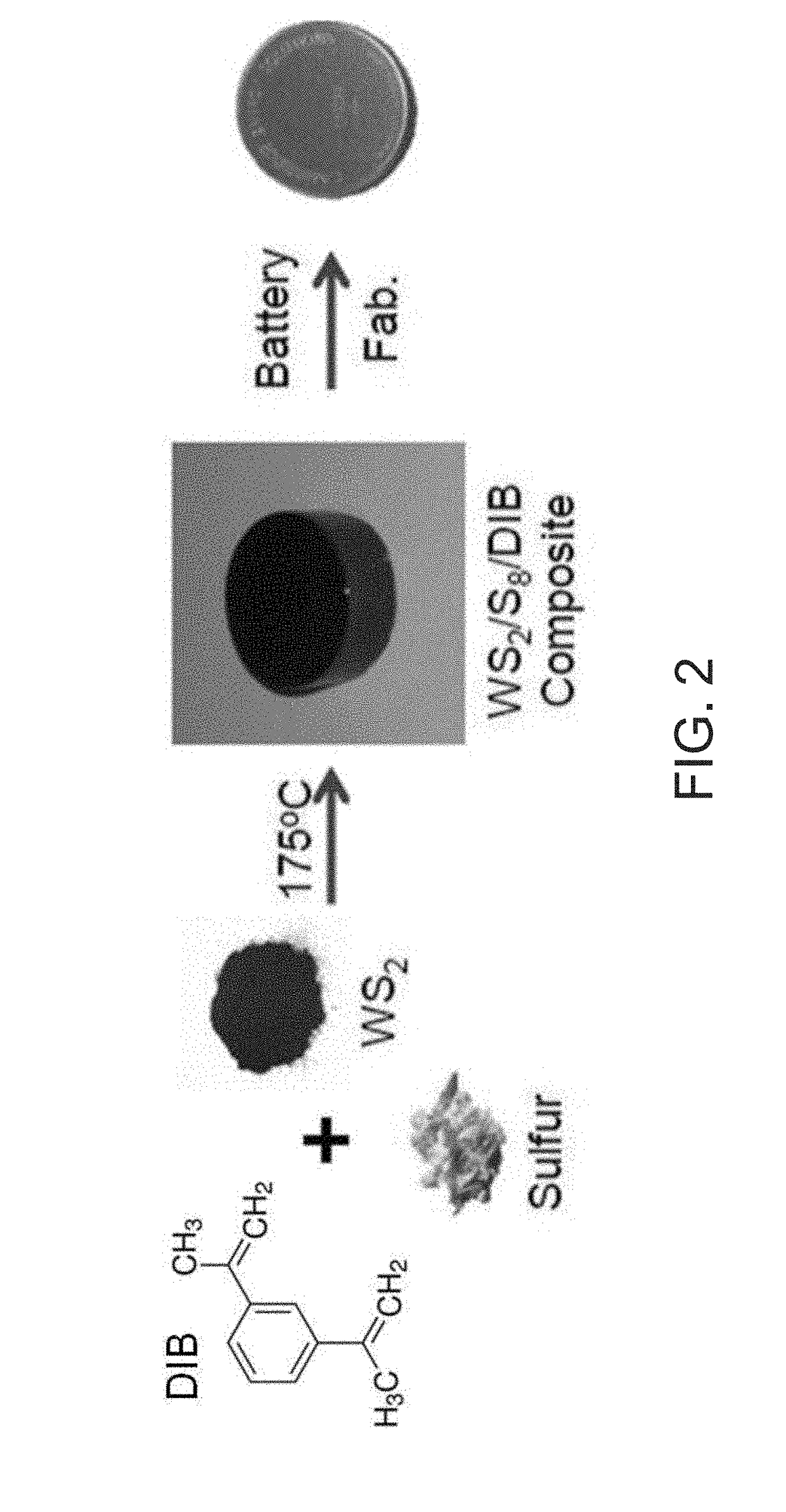

ActiveUS20180079865A1Improves Li-S battery performanceMaintain good propertiesBiocideOrganic active ingredientsElectrical batteryElectrochemical cell

Compositions and methods of producing composite materials for use as a cathode in electrochemical cells. Elemental sulfur is mixed with tungsten sulfide (WS2) to form a composite mixture. Organic comonomers may be added to the composite mixture. The composite mixture is reacted to form the composite material. Electrochemical cells with cathodes containing the composite material demonstrated improved battery performance.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

Preparation and application of covalent organic skeleton/titanium carbide nano-sheet composites

ActiveCN109244388AImprove conductivityIncrease sulfur loadMaterial nanotechnologyCell electrodesNew energyButton battery

The invention relates to the preparation and application of a covalent organic skeleton / titanium carbide nano-sheet composite material, and belongs to the technical field of development and research of new energy materials. The Ti3C2 nano-sheets with single layer or few layers are mixed with organic monomer and solid catalyst and sealed in a vacuum quartz tube, and a covalent organic skeleton / Ti3C2 nano-sheet composite material is obtained by the ionothermal method. The covalent organic skeleton / Ti_3C_2 nanocomposite was coated on aluminum as working electrode after carrying sulfur, lithium metal is used as counter electrode and reference electrode, organic microporous membrane is used as separator, organic solution is used as electrolyte, and a button cell is assembled in the glove box filled with high purity argon. Compared with the prior art, the present invention can be used as a two-dimensional electrode material, is widely used in the energy field such as lithium sulfide batteryand the like, and has excellent charging / discharging performance.

Owner:TONGJI UNIV

Method for preparing lithium-sulfur battery cathode material

ActiveCN110190262AHighlight substantiveImprove adsorption capacityPositive electrodesLi-accumulatorsMolecular sieveLithium–sulfur battery

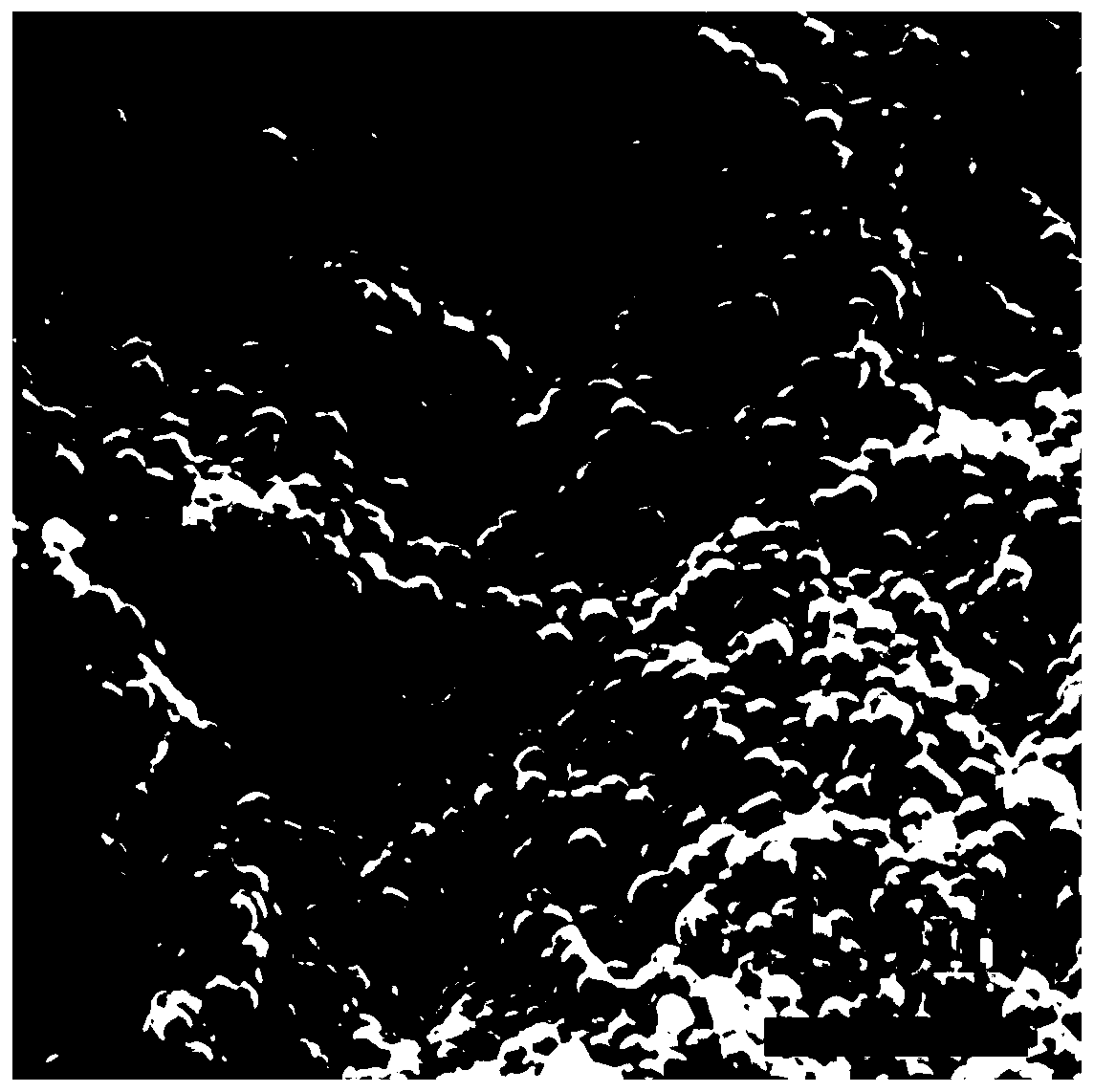

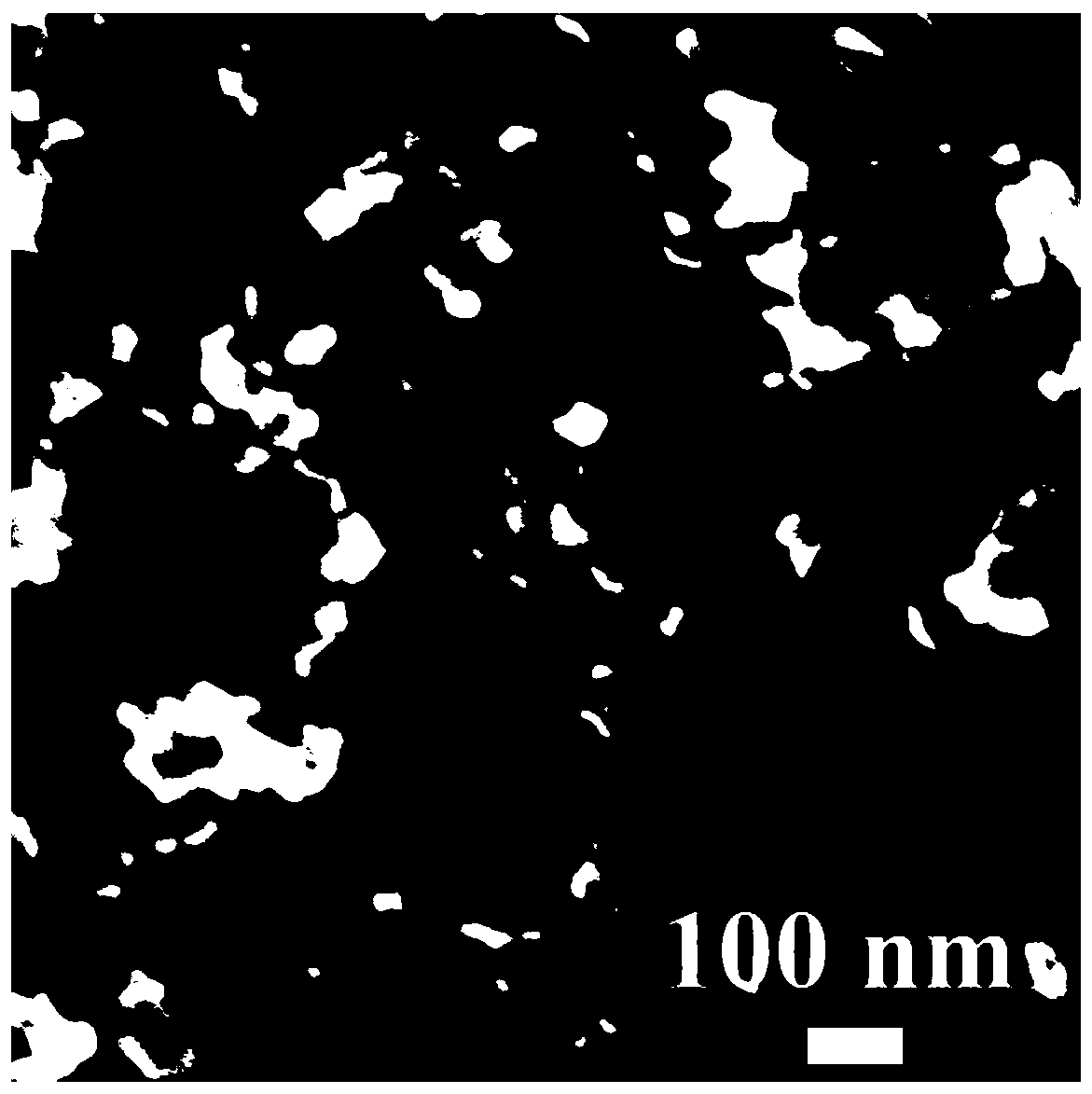

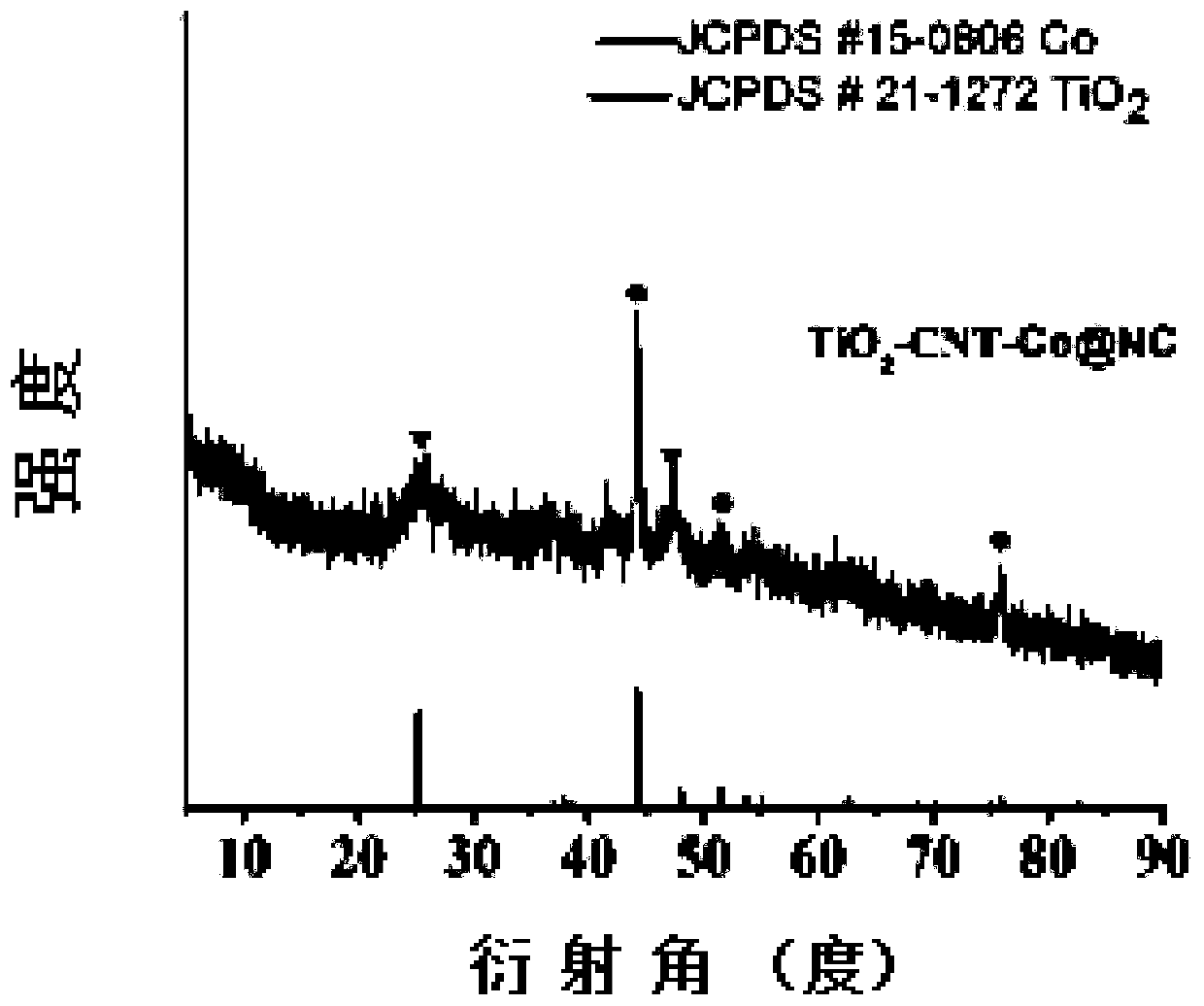

The invention relates to a method for preparing a lithium-sulfur battery cathode material, which relates to an electrode consisting of active materials. The method comprises the following steps of: firstly, preparing a multi-metal imidazole type molecular sieve framework TiO2-Co-ZIF-8 growing in a three-dimensional ordered titanium dioxide framework, then obtaining cobalt nano-particles TiO2-CNT-Co@NC coated with porous N-doped carbon and serially loaded on the three-dimensional ordered titanium dioxide framework through in-situ growth, and compounding the nano-particles and the with sublimedsulfur powder to obtain the S / TiO2-CNT-Co@NC lithium-sulfur battery cathode material. The method for preparing a lithium-sulfur battery cathode material overcomes the defects of low utilization rate of active substances, poor conductivity and shuttle effect in the prepared cathode material of the lithium-sulfur battery in the prior art.

Owner:HEBEI UNIV OF TECH

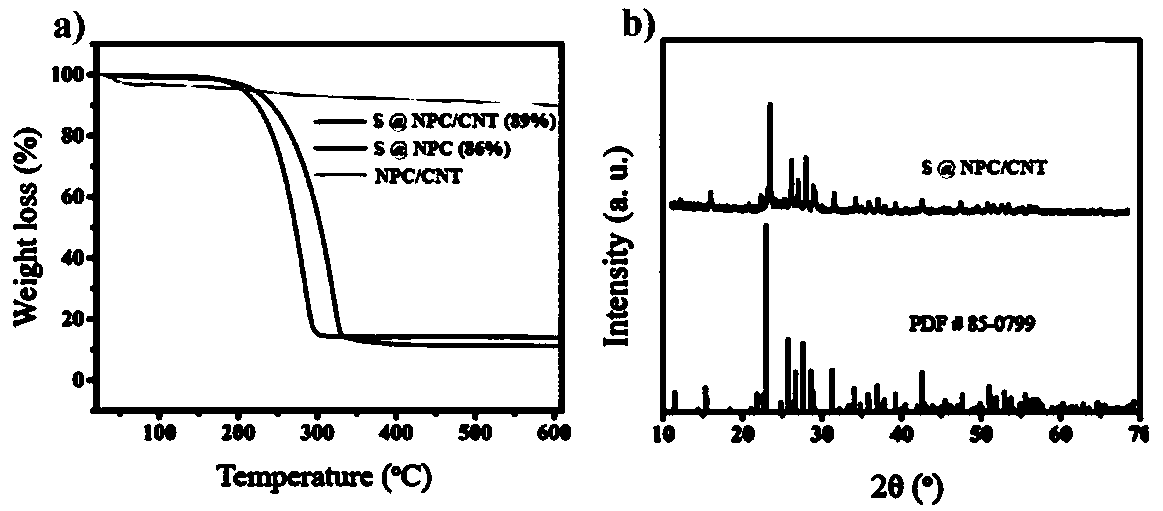

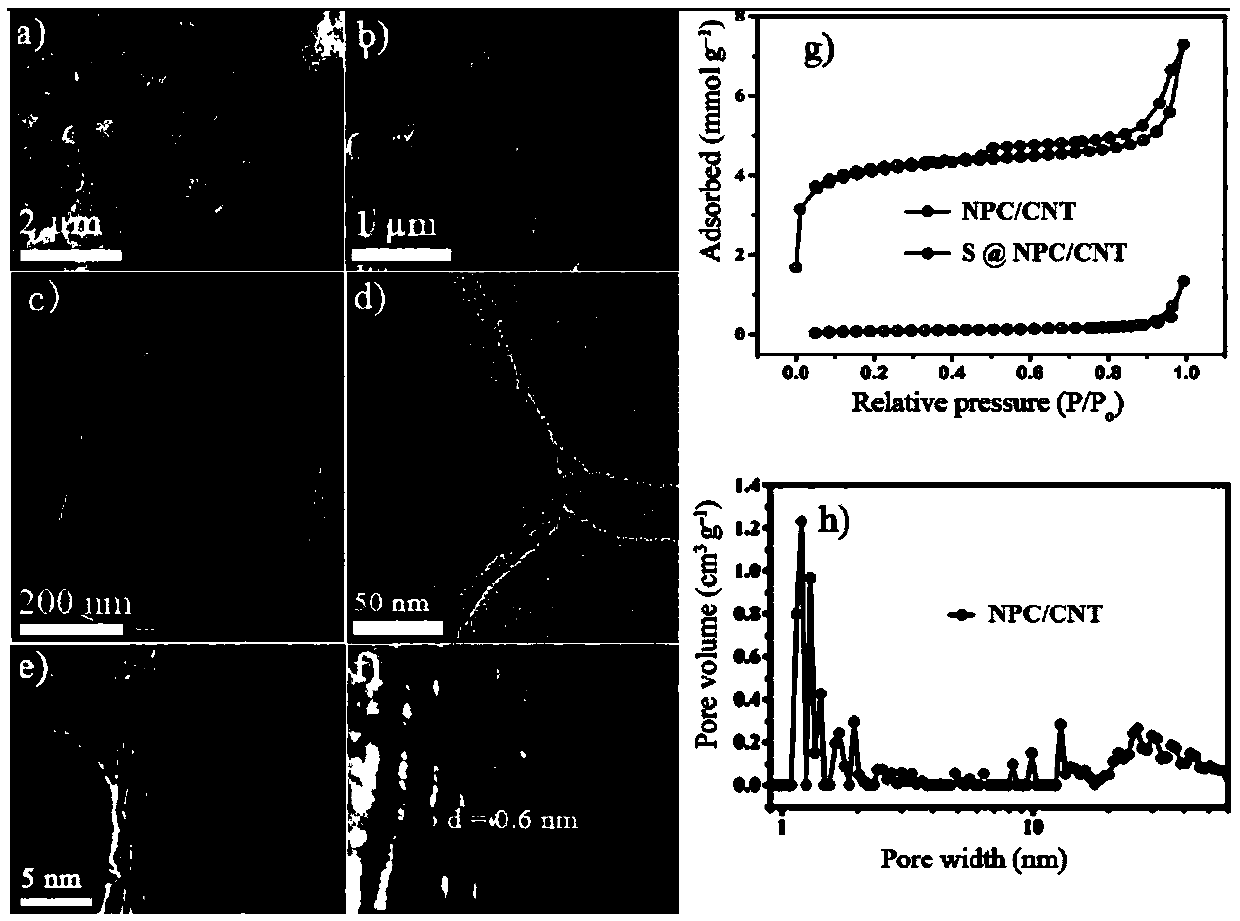

S@NPC/CNT composite material and preparation method and application thereof

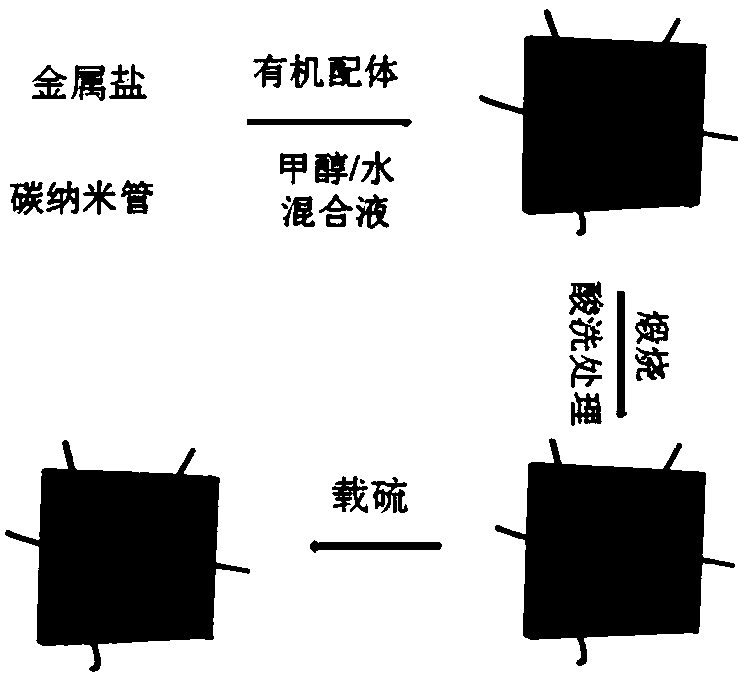

InactiveCN109686951AInhibition of dissolutionStop the spreadCell electrodesDiffusion methodsPorous carbon

The invention discloses an S@NPC / CNT composite material and a preparation method and application thereof. The S@NPC / CNT composite material is obtained from an NPC / CNT composite material by sulfur loading. The NPC / CNT composite material is composed of nitrogen doped porous carbon and carbon nanotubes in the interweaving mode. The nitrogen doped porous carbon is a carbon material derived from a Zn / Co-bimetallic organic framework. The nitrogen doped carbon material is obtained by stirring, drying, calcining and acid treatment of a methyl alcohol and water mixed solution containing zinc and / or cobalt transition metal salt, organic ligand and a carbon material, and finally the high sulfur loaded S@NPC / CNT composite material is prepared by a melt diffusion method. The material exhibits extremelyhigh sulfur content. In addition, the invention also discloses the application of the high sulfur loaded nitrogen doped carbon material prepared by the method in a lithium sulfur battery. The composite material is used for an anode material of the lithium sulfur battery. The obtained battery has high area capacity and good electrochemical performance. The efficient method for preparing the nitrogen doped carbon material with high performance and high sulfur content is provided.

Owner:CENT SOUTH UNIV

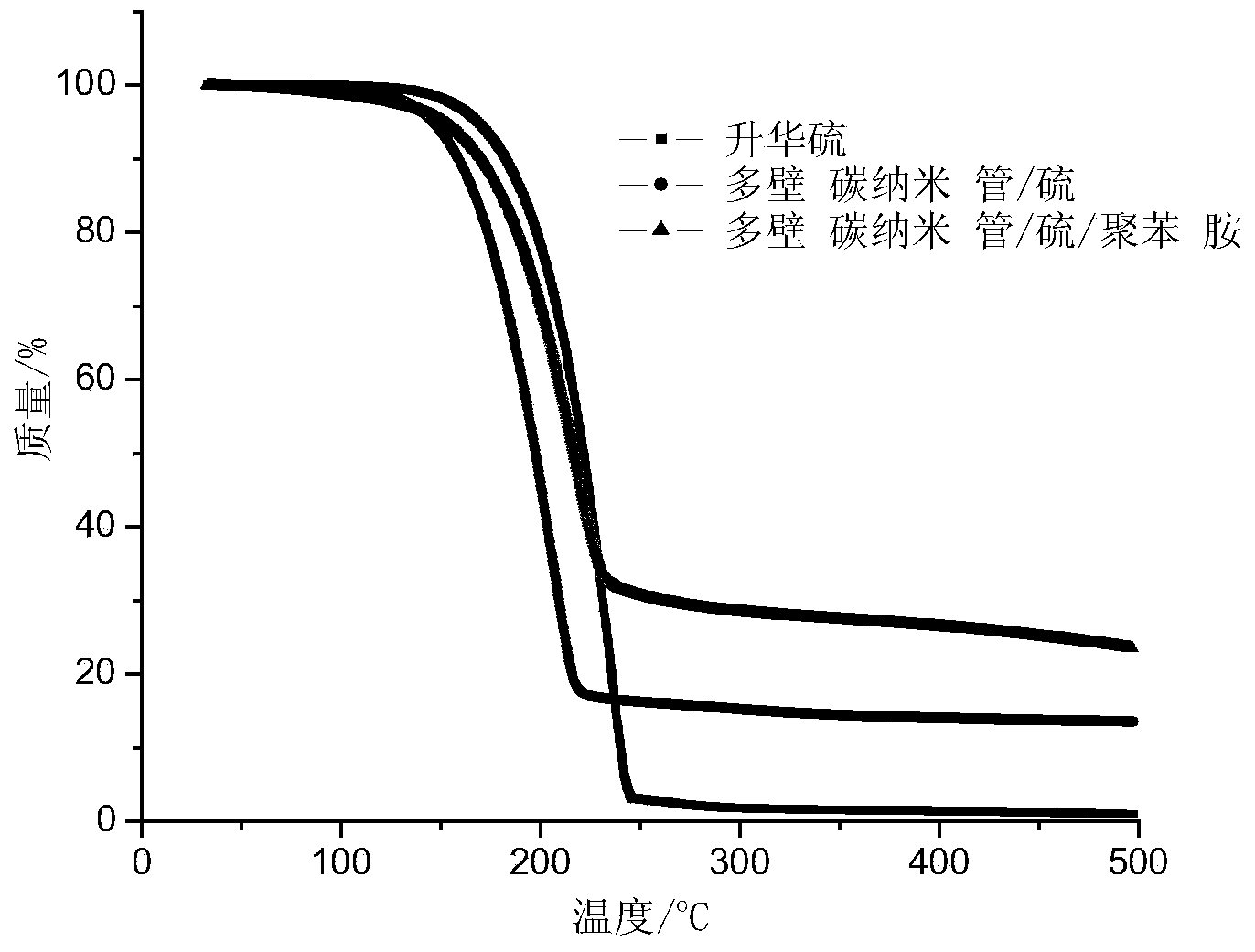

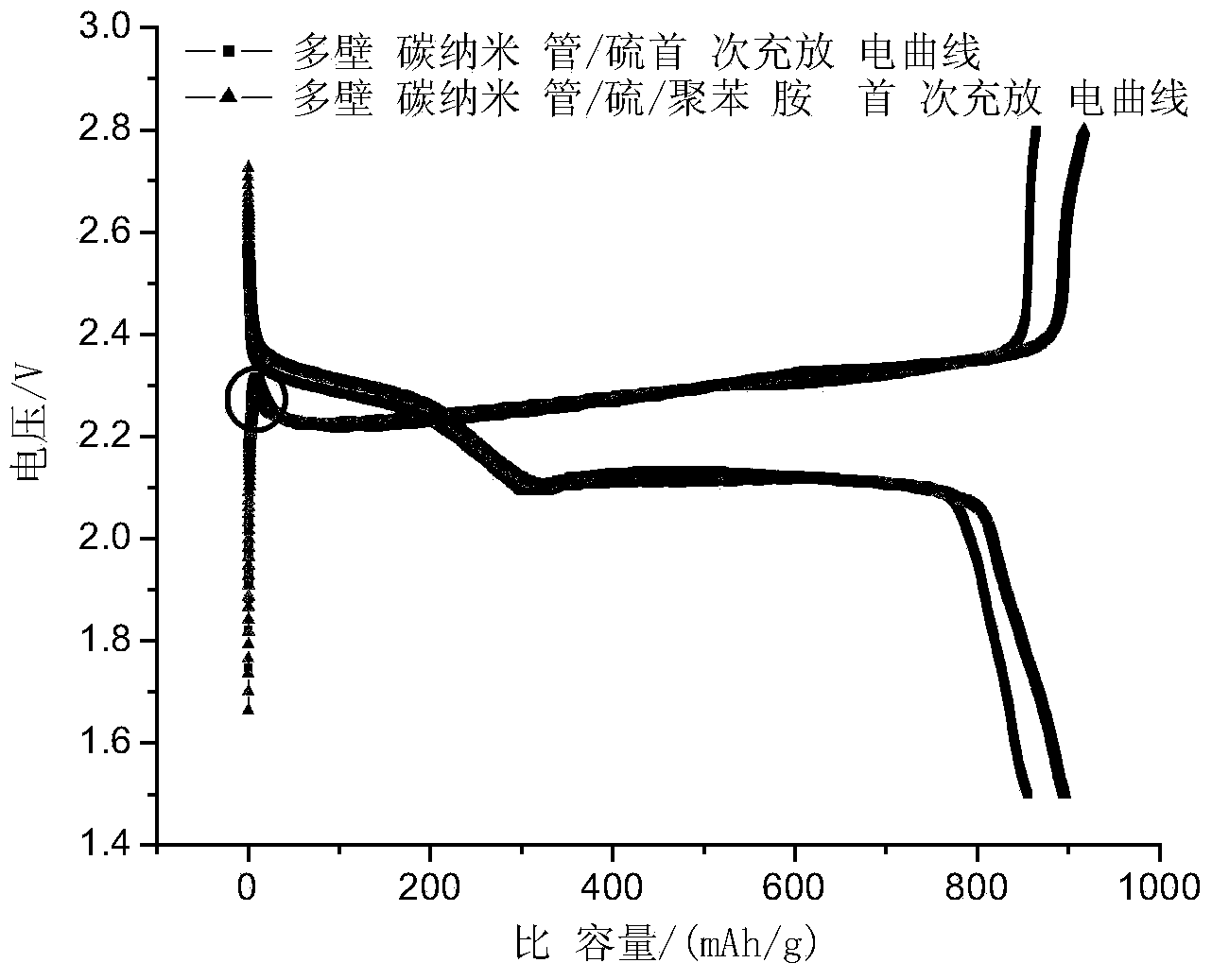

Lithium-sulfur battery composite cathode material, and preparation method and application thereof

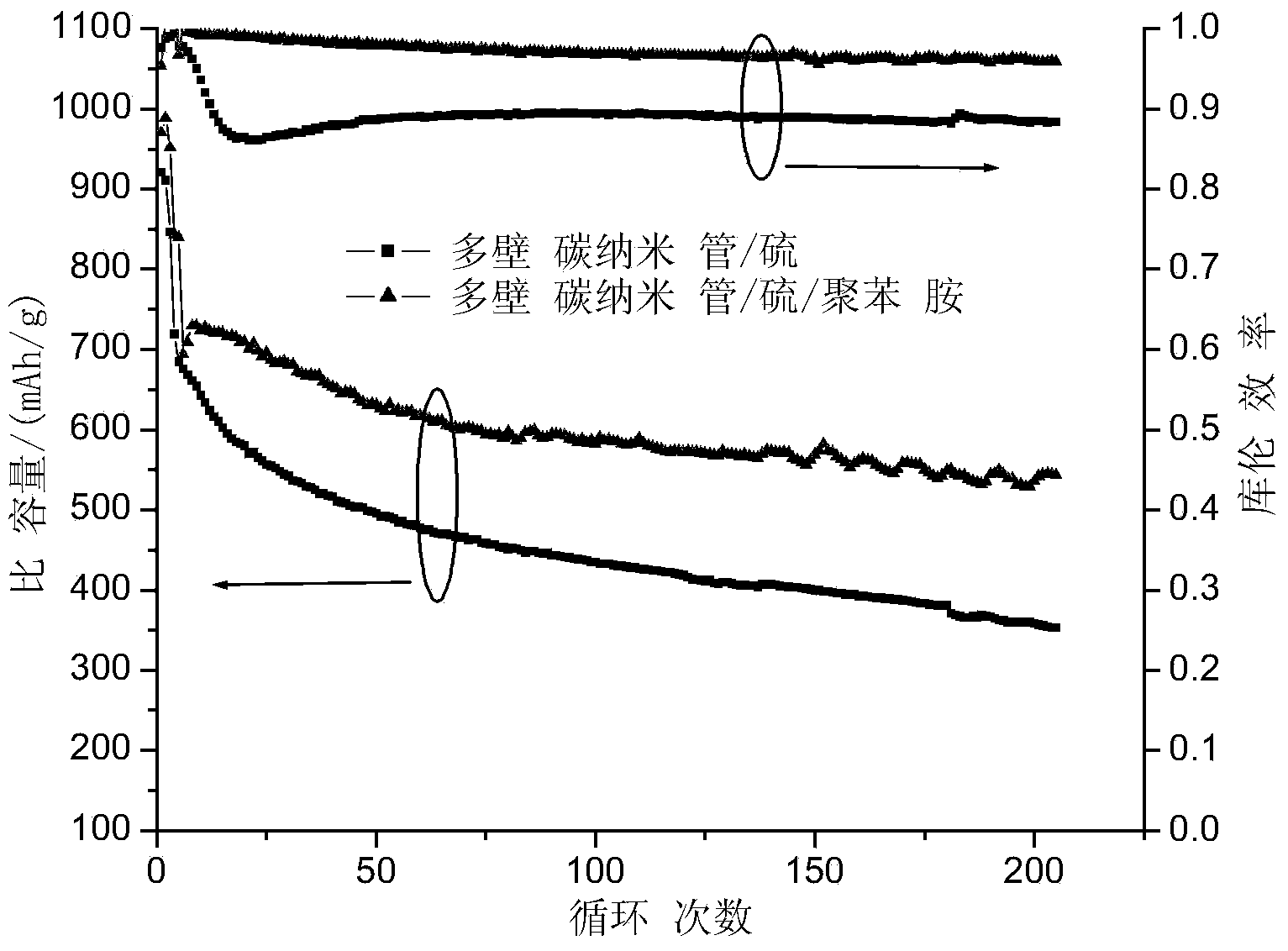

ActiveCN104362316AImprove cycle stabilityHigh capacity retentionCell electrodesIn situ polymerizationPolyaniline composite

The invention belongs to the field of electrochemistry and discloses multiwalled carbon nanotube / sulphur / polyaniline composite cathode material, a preparation method thereof, and the application thereof to the preparation of lithium sulphur batterypositive plates. The material adopts multiwalled carbon nanotube / sulphur / polyaniline composite cathode material and a sandwich structure; multiwalled carbon nanotube / sulphur composite material is coated with conductive polyaniline through in-situ polymerization, so that the multiwalled carbon nanotube / sulphur / polyaniline composite cathode material is formed; the multiwalled carbon nanotube / sulphur composite material is prepared through chemical co-deposition. The method is simple in technology, low in cost and high in consistency and stability of products. The material is high in electronic and ionic conductivity and high in sulphur carrying capacity, and can be applied to the preparation of lithium battery composite positive plates; the positive plate is high in cycling stability and capacity retention ratio.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Lithium-sulfur battery composite cathode material, preparation method thereof and application of lithium-sulfur battery

ActiveCN108666537AImprove electronic conductivityHigh Li-ion conductivityCell electrodesSecondary cellsSolventCurrent collector

The invention discloses a lithium-sulfur battery composite cathode material, a preparation method thereof and a lithium-sulfur battery. The composite cathode material is formed by compositing raw materials comprising an elemental sulfur, metal-nonmetal element co-doped conductive graphitized carbon material and a lithium-conducting polymer; during the preparation process, the metal-nonmetal co-doped conductive graphitized carbon material, the lithium-conducting polymer and the solution with the elemental sulfur are stirred and mixed, then the solvent is volatilized, and heat-treated, thereby obtaining the composite cathode material having high conductivity and capable of improving the utilization rate of an active substance sulfur. The preparation method is simple, the process conditions are mild, the production cost of the lithium-sulfur battery cathode material is greatly reduced, and industrial production requirements are met; the lithium-sulfur battery made of the composite cathodematerial has a high discharge specific capacity, a stable cycle performance and a high safety performance, without the need for a current collector, and without need to add a conductive agent and a binder.

Owner:CENT SOUTH UNIV

Preparation method of sulfurizing porous nanometer material for high-efficiency hydrargyrum removal

InactiveCN102247823AReduce viscosityReduce surface tensionOther chemical processesDispersed particle separationDry iceRoom temperature

The invention relates to high-efficiency sulfurizing hydrargyrum-removing porous nanometer carbon and a preparation method thereof, belonging to the field of chemistry. The preparation method comprises the following steps of: mixing porous nanometer carbon and sulfur, and then placing into a closed pressure vessel with dry ice or liquid carbon dioxide together; heating the closed pressure vessel to 31-200 DEG C to make the carbon dioxide reach a supercritical state, keeping for 1-48 hours, or heating the carbon dioxide to the supercritical state, then injecting into the closed pressure vesselcontaining a mixture of the porous nanometer carbon and the sulfur, and keeping for 1-48 hours; and then cooling to room temperature, and evacuating the carbon dioxide so as to prepare the sulfurizing porous nanometer carbon, wherein the mass percent of the sulfur contained in the sulfurizing porous nanometer carbon is 2-50 percent. According to the invention, high sulfurizing quantity and the quantity as well as the specific surface area of the sulfur available during hydrargyrum removal are furthest ensured by tactfully adopting the gas-liquid dual property of the supercritical carbon dioxide, and therefore an optimal hydrargyrum removing effect is achieved; in addition, the advantages of simple process, high efficiency, environment friendliness and low cost are achieved.

Owner:叶向荣 +1

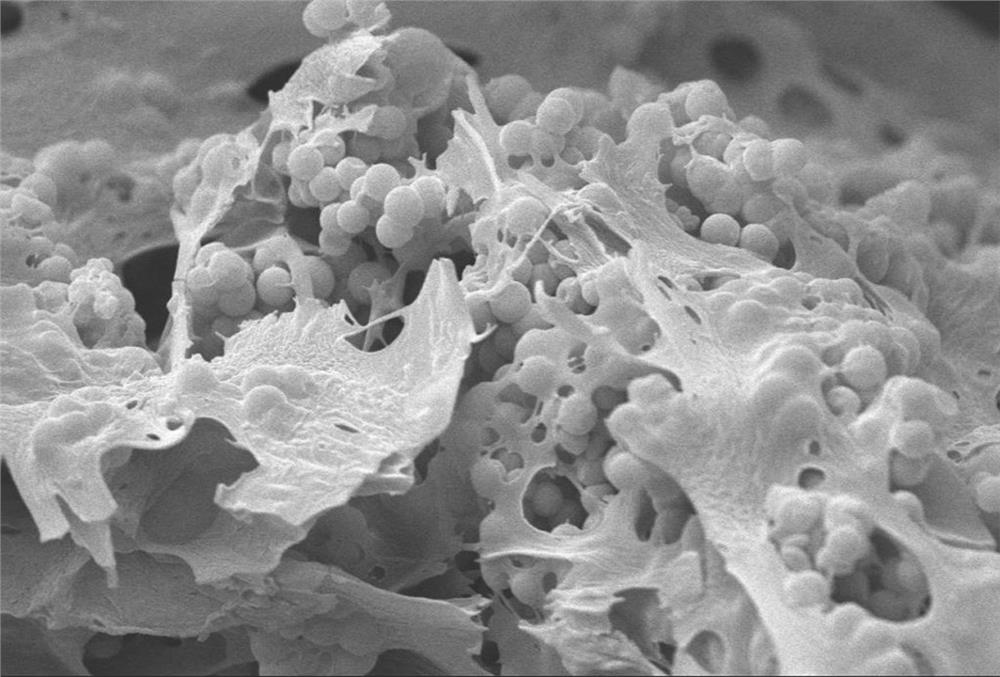

Nitrogen doped porous carbon/sulfur composite positive material as well as preparation method and application thereof

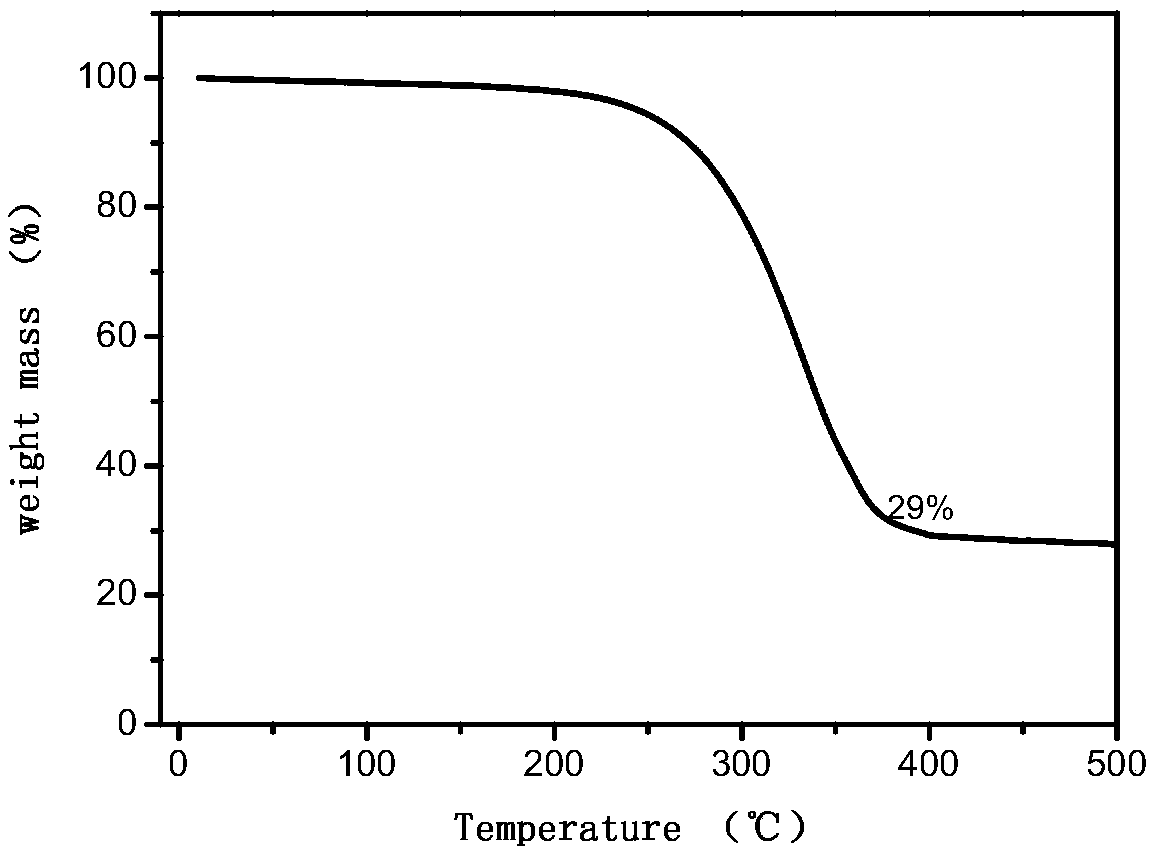

ActiveCN104409733AImprove electronic conductivityImprove ionic conductivityCell electrodesSecondary cellsPorous carbonDissolution

The invention belongs to the field of electrochemical energy and discloses a nitrogen doped porous carbon / sulfur composite positive material as well as a preparation method and an application thereof in preparation of a lithium-sulfur battery positive plate. The nitrogen doped porous carbon / sulfur composite positive material disclosed by the invention is prepared by adopting a sulfur-ammonium chemical precipitation method; three-dimensional wedged nitrogen-containing porous carbon and sulfur particles form a core-shell structure, so that the electronic and ionic conductivity of the composite positive material are improved; meanwhile, the sulfur bearing capacity is also improved, dissolution and diffusion of polysulfides are limited, and thus the circulation stability and the capacity retention rate of a composite electrode prepared from the nitrogen doped porous carbon / sulfur composite positive material disclosed by the invention can be effectively increased. The preparation method can be used for accurately controlling the content of loaded sulfur without complex pretreatment and post-treatment procedures, so that the process cost is greatly lowered, the process operation is simplified, and the consistency and the stability of the composite material are improved as well.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Lithium sulfur battery positive electrode material with high sulfur load as well as preparation method and application thereof

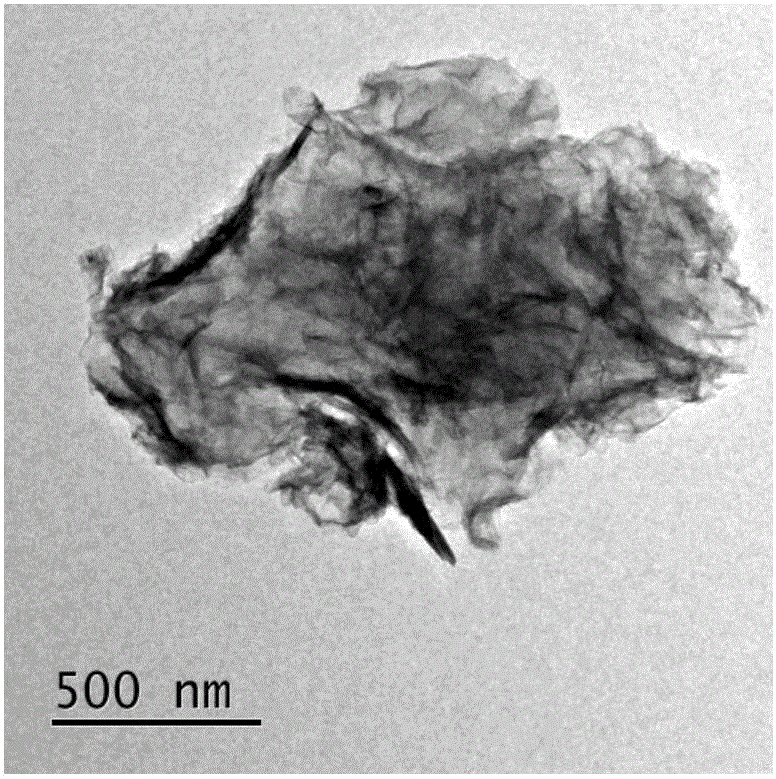

ActiveCN108232171AIncrease sulfur loadGood sulfur loading stabilityCell electrodesSecondary cellsSulfurLithium–sulfur battery

The invention discloses a lithium sulfur battery positive electrode material with high sulfur load as well as a preparation method and application thereof. The preparation method of the lithium sulfurbattery positive electrode material with high sulfur load comprises the following step of performing hydrothermal reaction on dispersion liquid containing g-C3N4, graphene oxide, sodium thiosulfate and inorganic acid, thereby obtaining a sulfur / graphene composite material with sulfur load amount of 60-88%. The method is simple to operate, is low-cost, is beneficial for industrial production; andthe composite material is taken as the lithium sulfur battery positive electrode material for preparing a lithium sulfur battery, so that circulating stability is good and specific discharge capacityis high.

Owner:CENT SOUTH UNIV

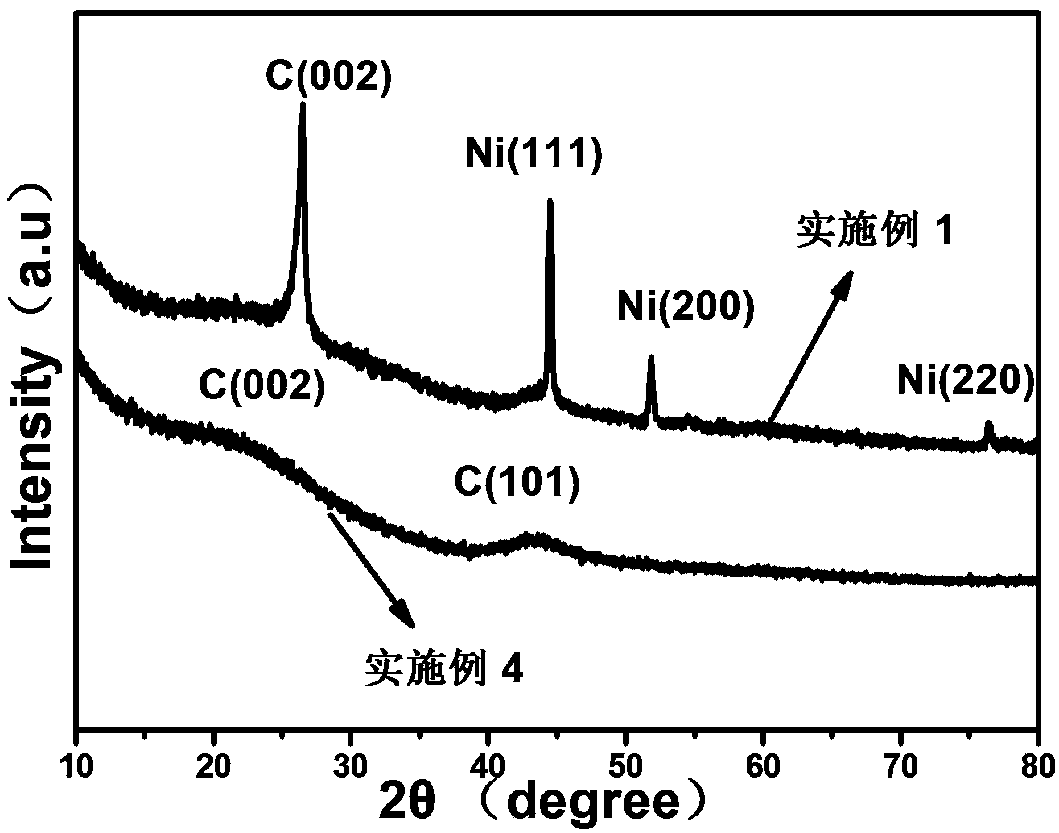

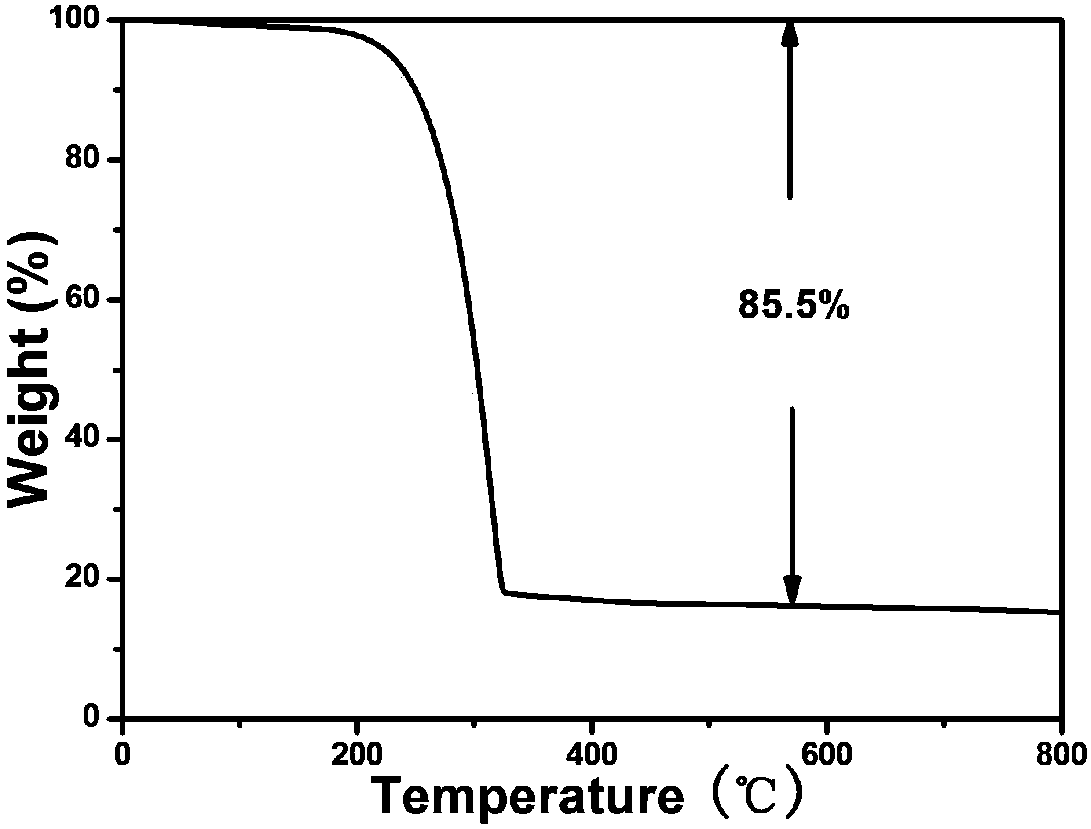

Thin-wall local graphitization porous carbon sphere material, preparation method thereof and application thereof in lithium sulfur battery

The invention discloses a thin-wall local graphitization porous carbon sphere material, a preparation method thereof and application thereof in a lithium sulfur battery. The porous carbon sphere material is a local graphitization porous carbon nanosphere with thin wall holes; the preparation method of the thin-wall local graphitization porous carbon sphere material comprises the steps that water-base resin, water-soluble inorganic salt, a surface active agent and transition metal salts are dissolved into water to obtain a spraying solution; the spraying solution is sprayed and dried to obtaina local graphitization porous carbon nanosphere precursor; the local graphitization porous carbon nanosphere precursor is subjected to pyrolysis to obtain the thin-wall local graphitization porous carbon sphere material. The preparation method is simple in technology and good in repeatability, the prepared thin-wall local graphitization porous carbon sphere material has the advantages of being good in electrical conductivity, large in aperture, high in specific surface area and the like, the thin-wall local graphitization porous carbon sphere material is applied to a lithium sulfur battery sulfur carrier, the high specific capacity, long cycling stability and high rate capability are achieved, and the wide application prospect is achieved.

Owner:CENT SOUTH UNIV

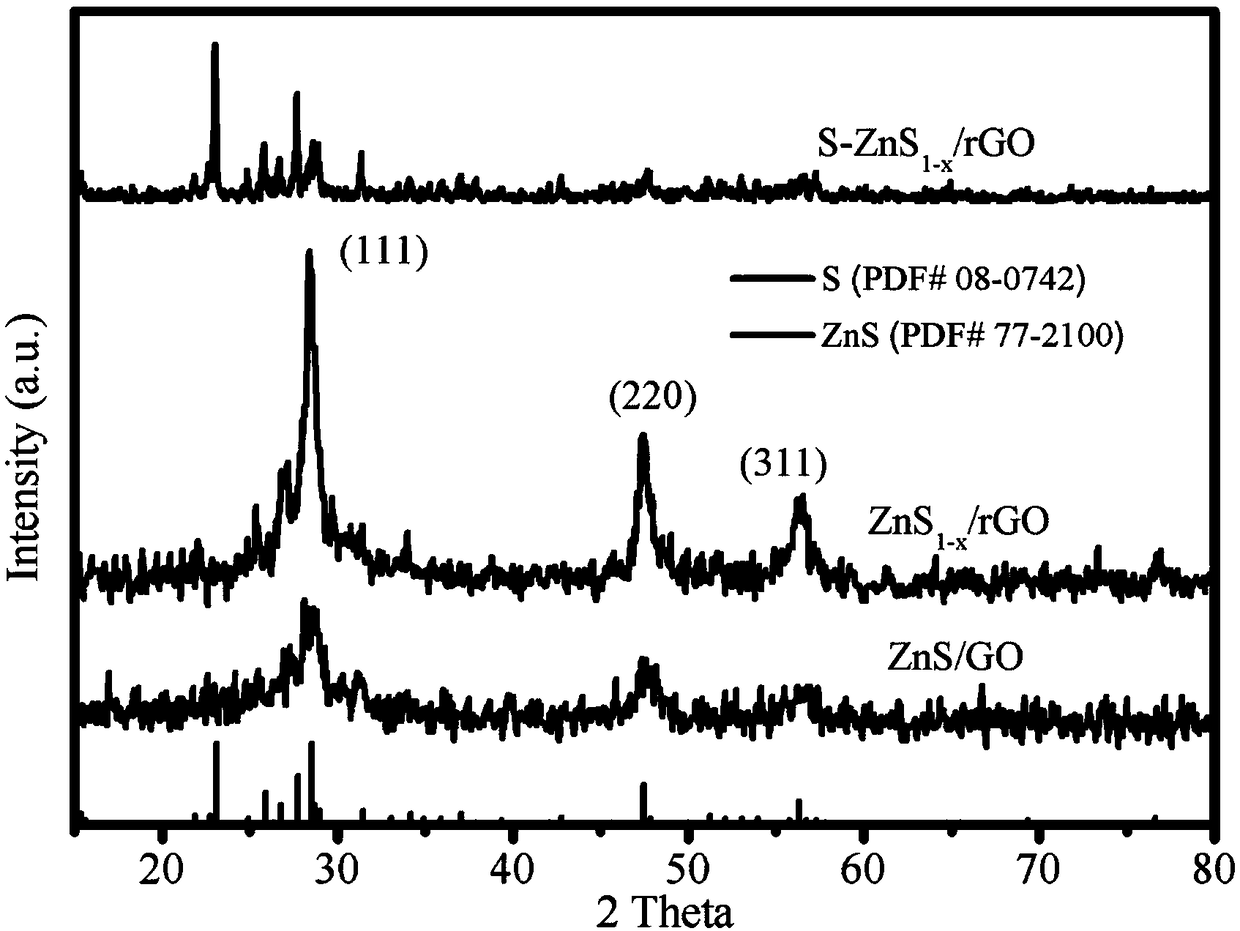

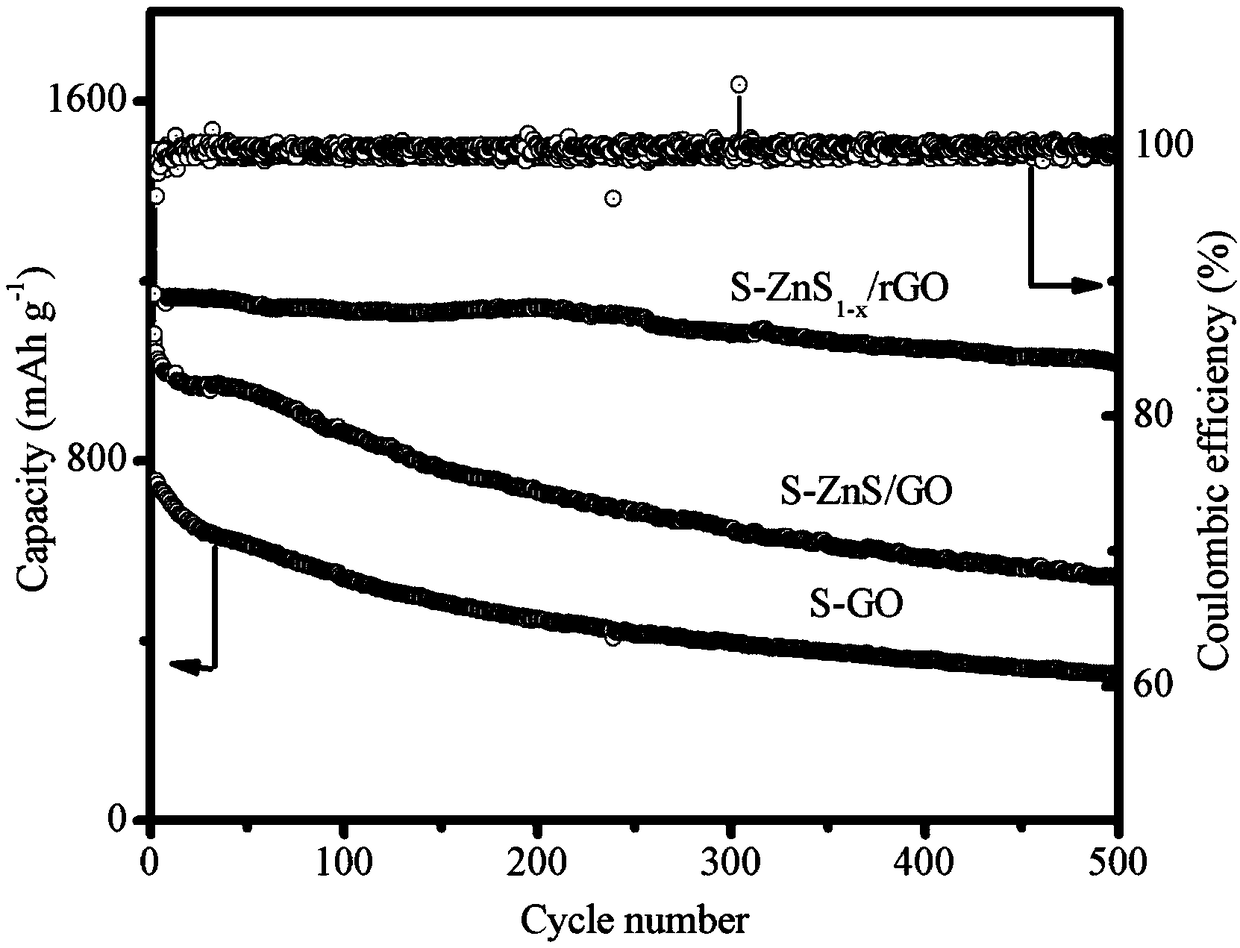

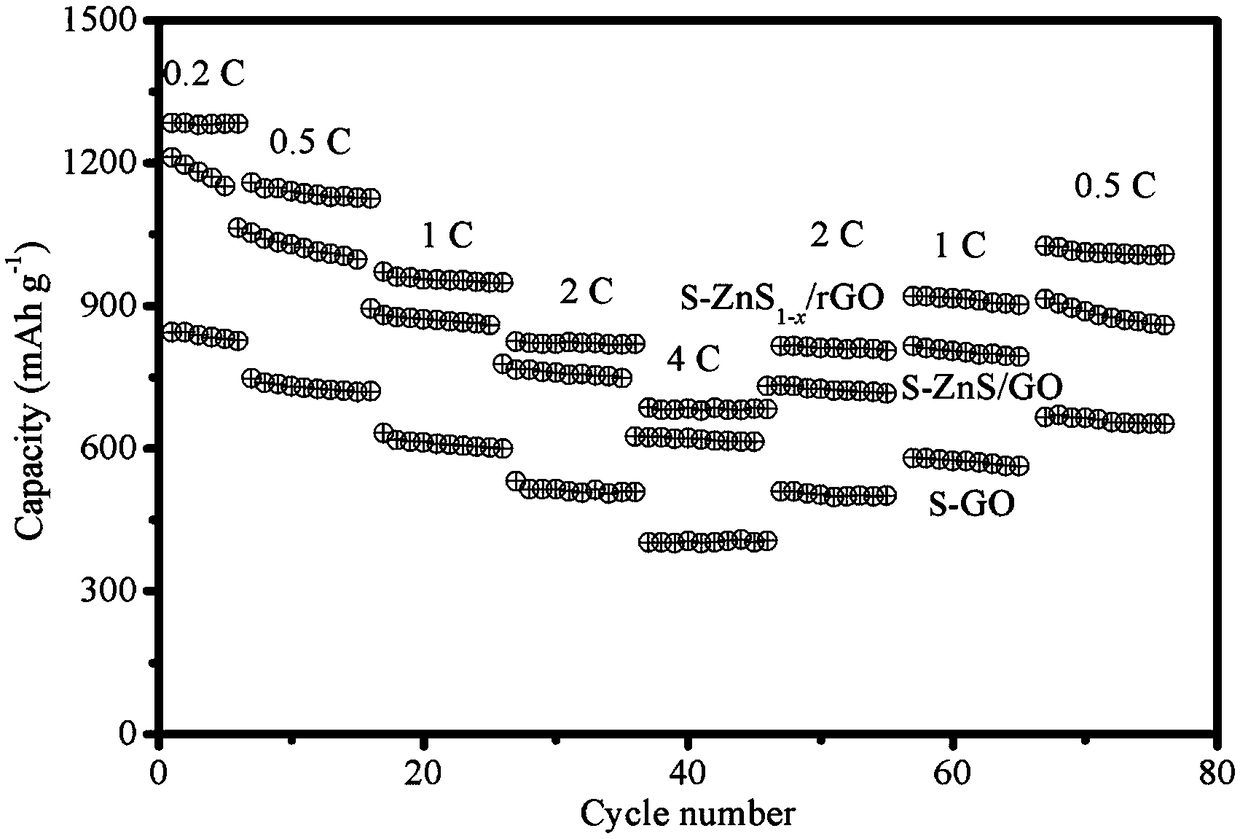

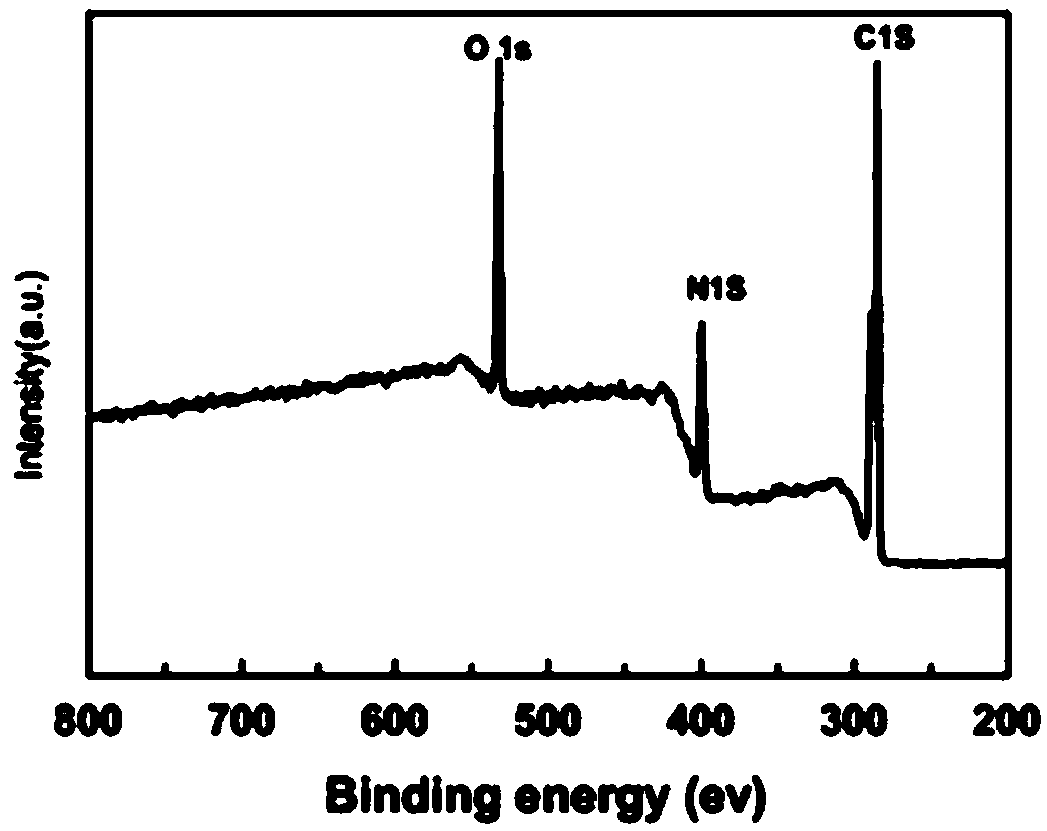

Zinc sulfide/rGO (reduced graphene oxide) composite material containing sulphur vacancy as well as preparation method and application thereof

InactiveCN109326786AImprove electrochemical activityImprove electrochemical performancePositive electrodesLi-accumulatorsNew energyZinc nitrate

The invention belongs to the technical field of new energy materials, and particularly relates to a zinc sulfide / rGO (reduced graphene oxide) composite material as well as a preparation method and application thereof. The preparation method of the zinc sulfide / rGO composite material containing the sulphur vacancy comprises the following steps: ZnS / GO is prepared as follows: carbon disulfide is added into a ethylenediamine water solution drop by drop, and the mixture is named as a solution A; graphene oxide GO is added into an ethylene glycol solution to be subjected to ultrasonic treatment, and the mixture is named as a solution B; the solution B is added into the solution A and continuously stirred, and then a mixed solution is obtained; a zinc nitrate solution is added dropwise into themixture while stirring; the mixed product is heated and cooled to room temperature, and then subjected to centrifuging and washing, and the dried product is ZnS / GO; then the ZnS / GO prepared in the step (1) is reduced at high temperature under the condition of argon-hydrogen combination gas, and ZnS<1-x> / rGO containing the sulphur vacancy is obtained. The invention adopts a simple and safe one-potwet chemical sulphur loading method and abandons a traditional fusing diffusing method, the loss is reduced, and the loading capacity of active sulphur is as high as 90%.

Owner:UNIV OF JINAN

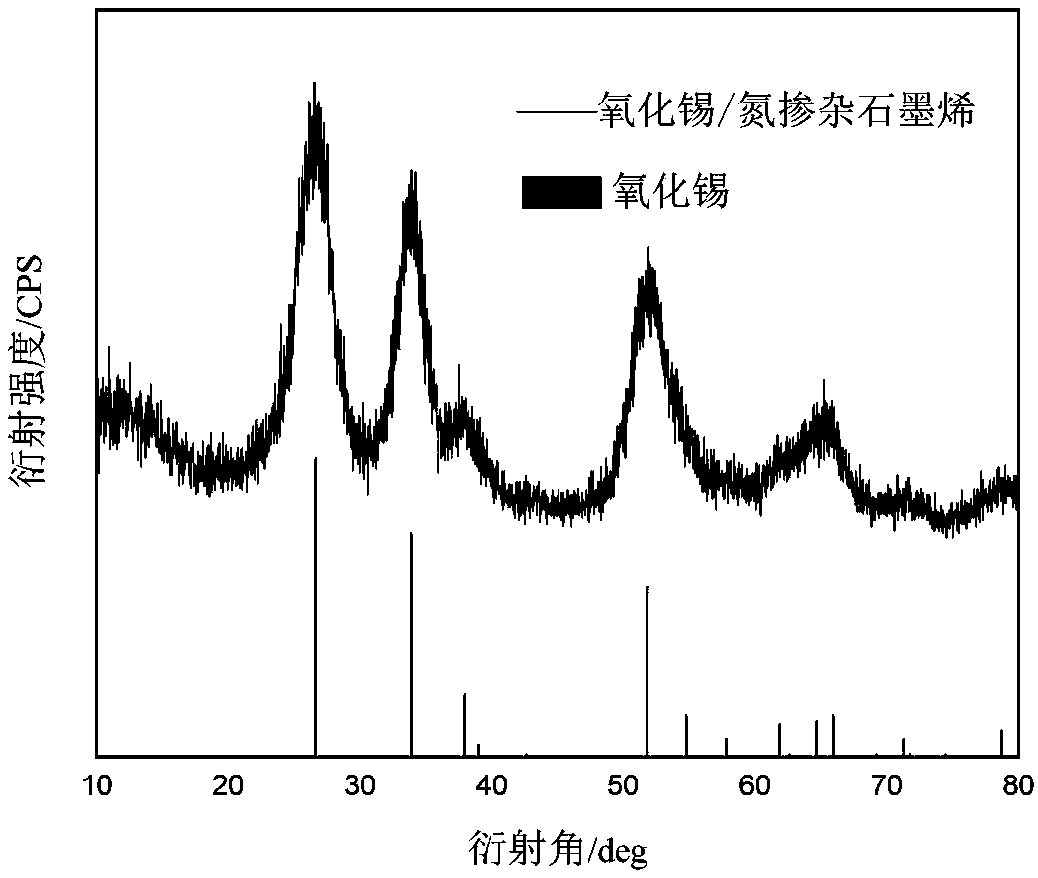

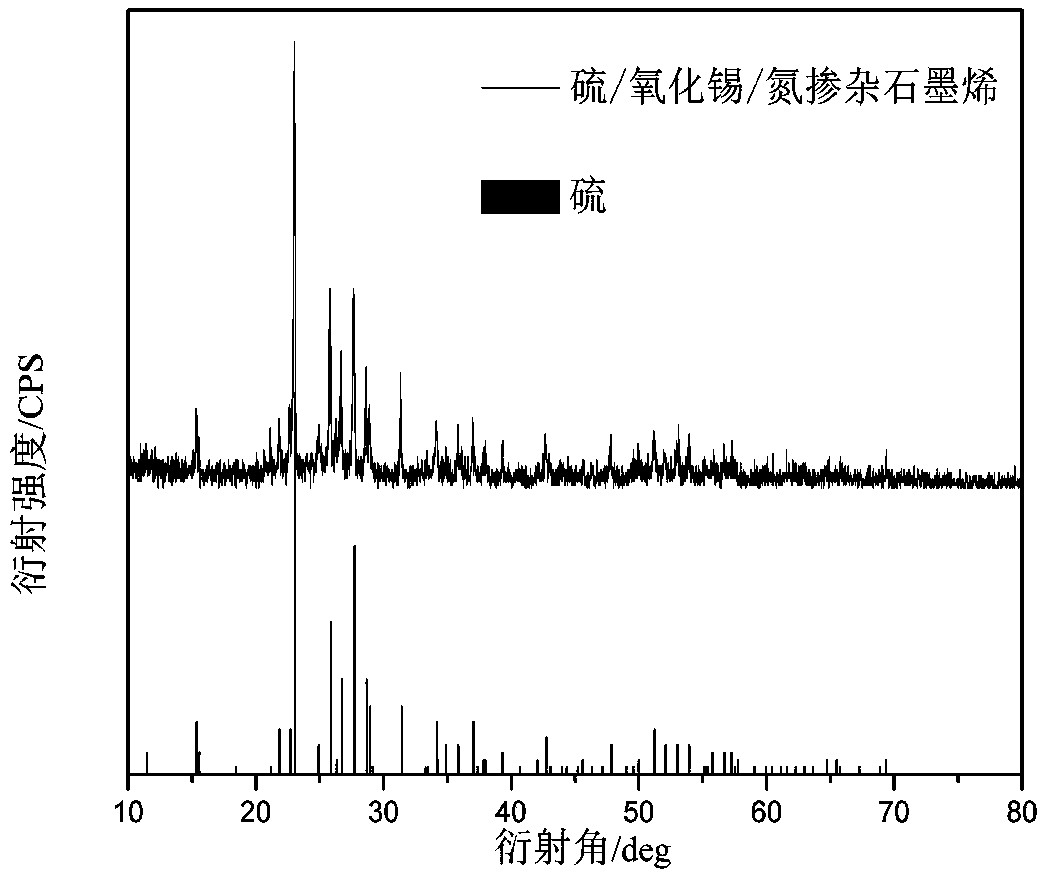

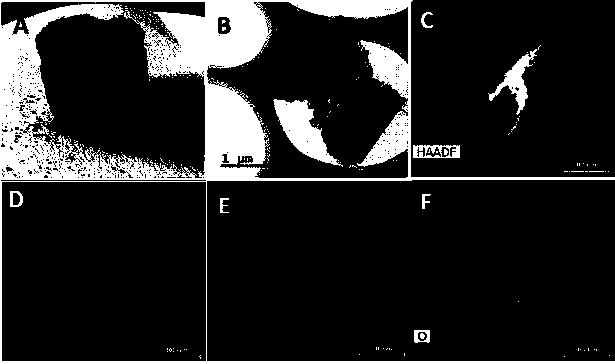

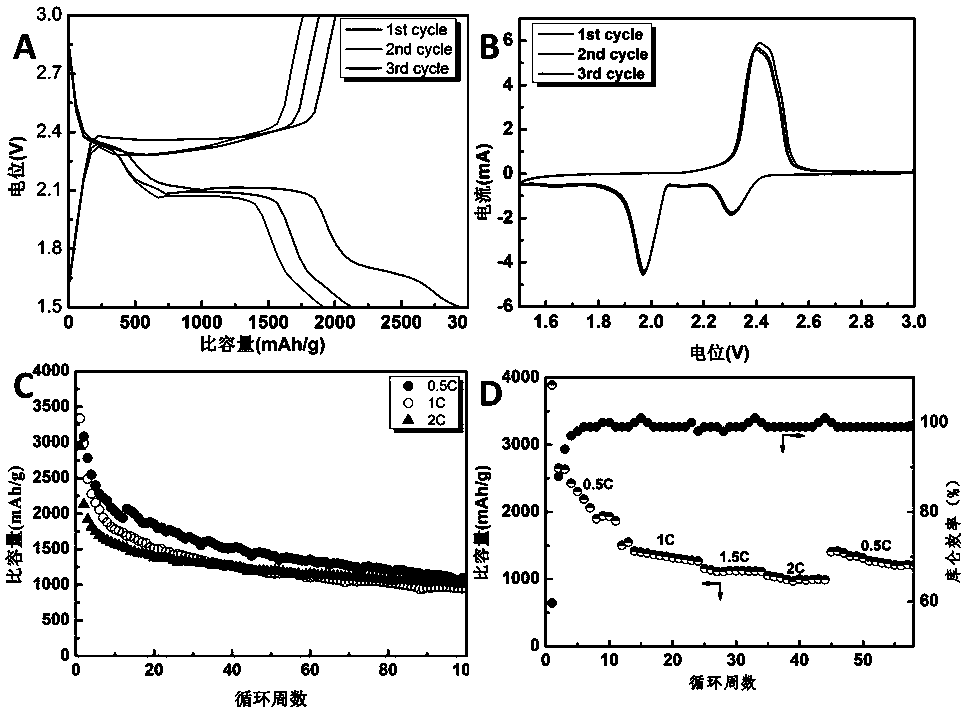

Sulfur/tin oxide/graphene battery cathode material, preparation method and lithium sulfur battery

InactiveCN109119616ALarge specific surface areaIncrease loadMaterial nanotechnologyCell electrodesNitrogen doped grapheneTin

The invention relates to the technical field of nanometer materials, in particular to a sulfur / tin oxide / graphene battery cathode material, a preparation method and a lithium sulfur battery. The invention discloses a preparation method of a sulfur / tin oxide / graphene battery cathode material, comprising the following steps: Step 1, nitrogen doped graphene and a tin salt solution are hydrothermallyreacted to obtain a graphene-tin oxide nano-composite material; and Step 2: the graphene-tin oxide nano-composite material and elemental sulfur are mixed to obtain a mixture, and a vacuum melting diffusion reaction is carried out on the mixture to obtain a sulfur / tin oxide / graphene battery cathode material. The invention also discloses a sulfur / tin oxide / graphene battery cathode material preparedby the method and a lithium sulfur battery thereof. The invention solves the technical problems that the elemental sulfur in the prior art cannot be effectively utilized in the cathode material of thelithium sulfur battery, thereby leading to short service life, and poor conductivity, cycle stability and safety performance of the lithium sulfur battery.

Owner:GUANGDONG UNIV OF TECH

Lithium sulphur battery anode material and preparation method thereof

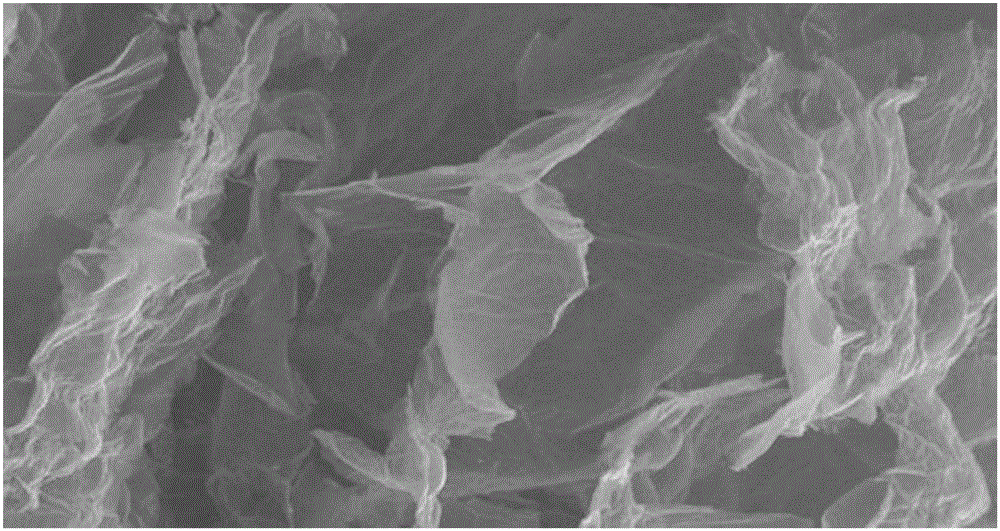

InactiveCN108232135AStrong interactionShorten the conduction pathMaterial nanotechnologyCell electrodesLithiumFreeze-drying

The invention relates to a lithium sulphur battery anode material and a preparation method thereof. The lithium sulphur battery anode material is a reduction oxidized graphene aerogel nested sulphur nano particle composite material with a three-dimensional net-shaped structure. The preparation method of the lithium sulphur battery anode material comprises the steps that, gel is formed by online reducing a oxidized graphene gel and sulphur gel mixture, the gel is frozen and dried, and the reduction oxidized graphene aerogel nested sulphur nano particle composite material with the three-dimensional net-shaped structure is obtained. The preparation method specifically comprises the steps that oxidized graphene serves as an initial raw material, mixed gel of oxidized graphene and sulphur is prepared, reduction oxidized graphene gel is prepared by adopting an online reduction method at the room temperature to wrap the sulphur nano particle composite material, the internally wrapped solventis removed through freeze drying, and the reduction oxidized graphene aerogel nested sulphur nano particle composite material is obtained. The lithium suplhur battery anode material can effectively prevent dissolution and inhibition shuttle effects of polysulfide, and can enhance the charging and discharging stability of the lithium sulphur battery.

Owner:襄阳华虹高科新材料有限公司

Preparation method of carbon gel-loaded sulfur positive electrode material for lithium-sulfur battery

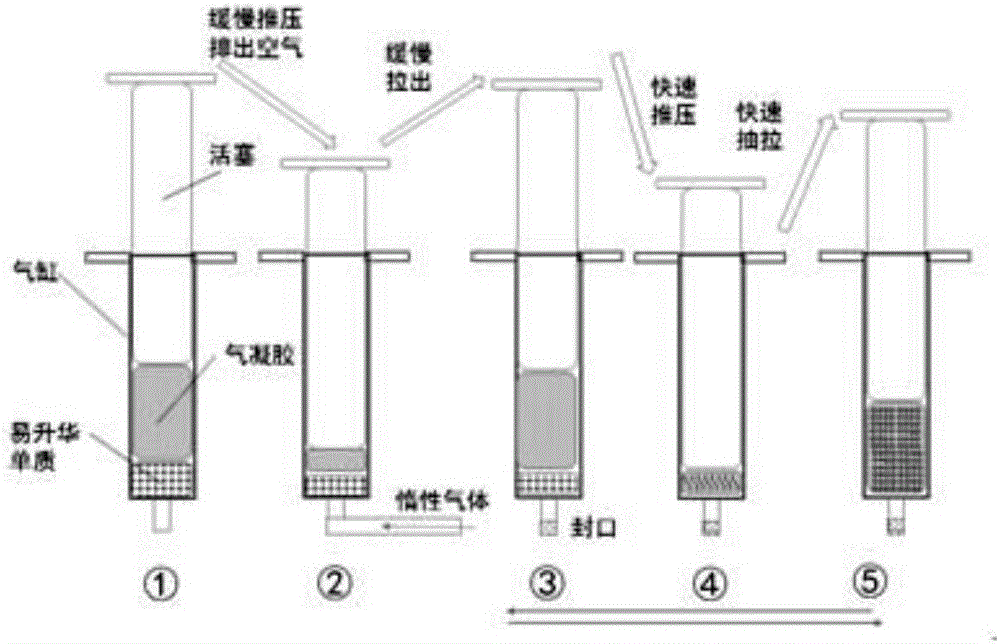

ActiveCN106532043AHeating without a heat sourceEasy accessCell electrodesSulfurLithium–sulfur battery

The invention discloses a preparation method of a carbon gel-loaded sulfur positive electrode material for a lithium-sulfur battery. The method comprises the steps of putting sulfur into a piston to seal the bottom of an air cylinder, stacking a carbon gel material at the upper part and enclosing the carbon gel material into the piston; exhausting air in the air cylinder and the carbon gel material and introducing an inert gas through an outlet of the air cylinder; sealing the outlet of the air cylinder, quickly pushing the piston, heating the inert gas in the air cylinder for heated sublimation of the sulfur due to sudden compression and entering channels of an aerogel material under the pressure of the piston; quickly drawing the piston to the initial length of the aerogel material, cooling the inert gas due to volume expansion, condensing a gas-phase easy-to-sublimate material along with drop in the temperature to form nanoscale particles and uniformly dispersing the nanoscale particles into the channels of the aerogel material; and obtaining the carbon gel material with high sulfur loads and then carrying out slicing and performing to obtain the positive electrode material. The preparation method is simple; and the obtained positive electrode material is high in sulfur loads and uniform in elemental sulfur distribution, and has excellent electrochemical properties.

Owner:XIAN UNIV OF TECH

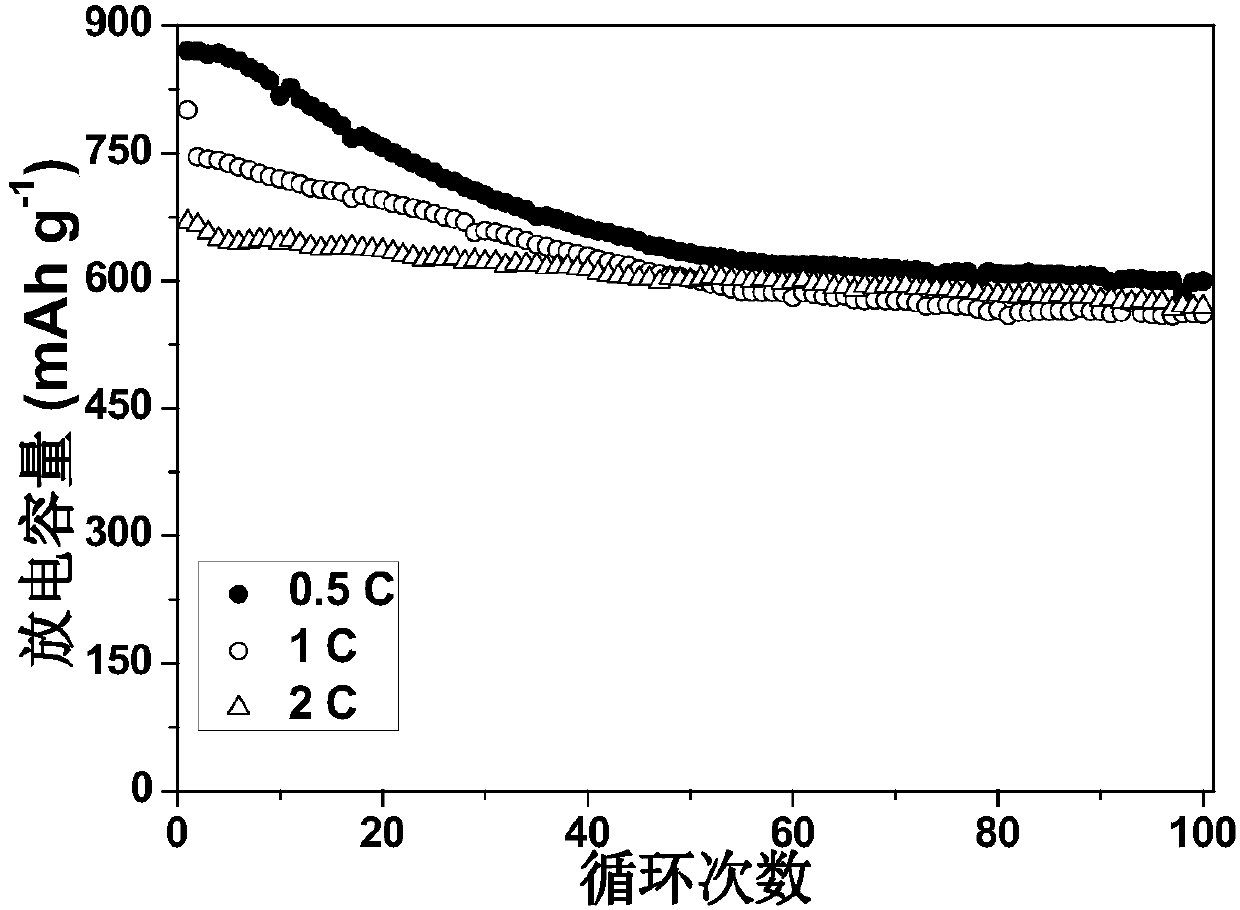

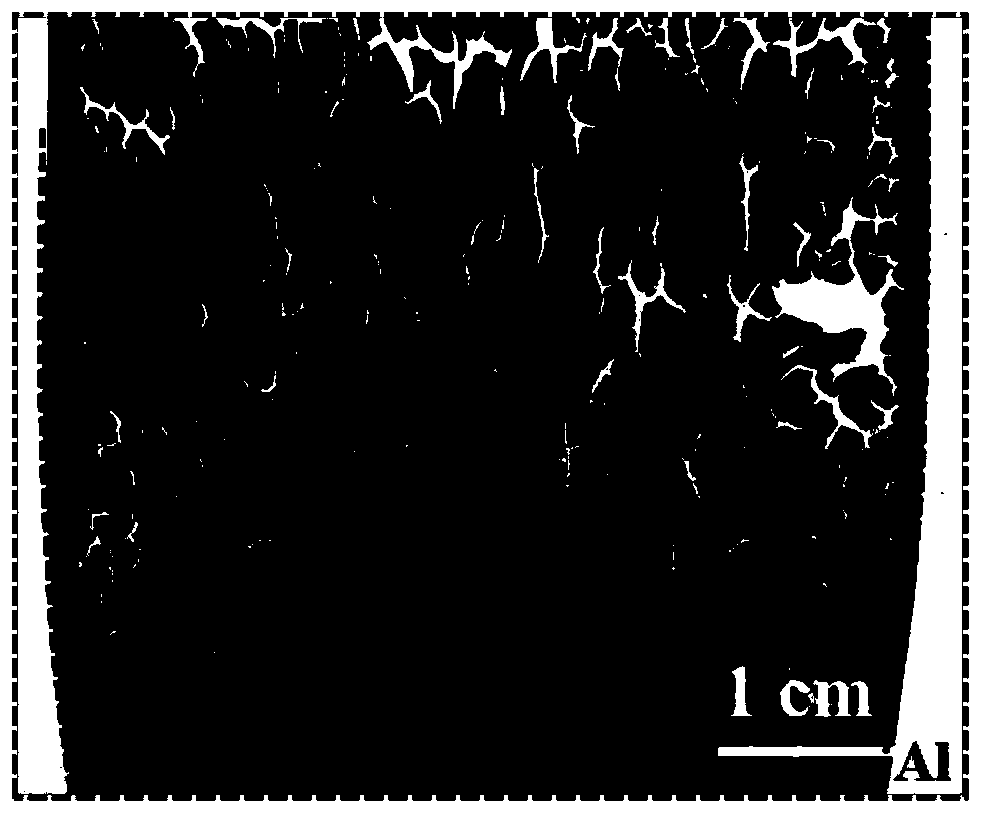

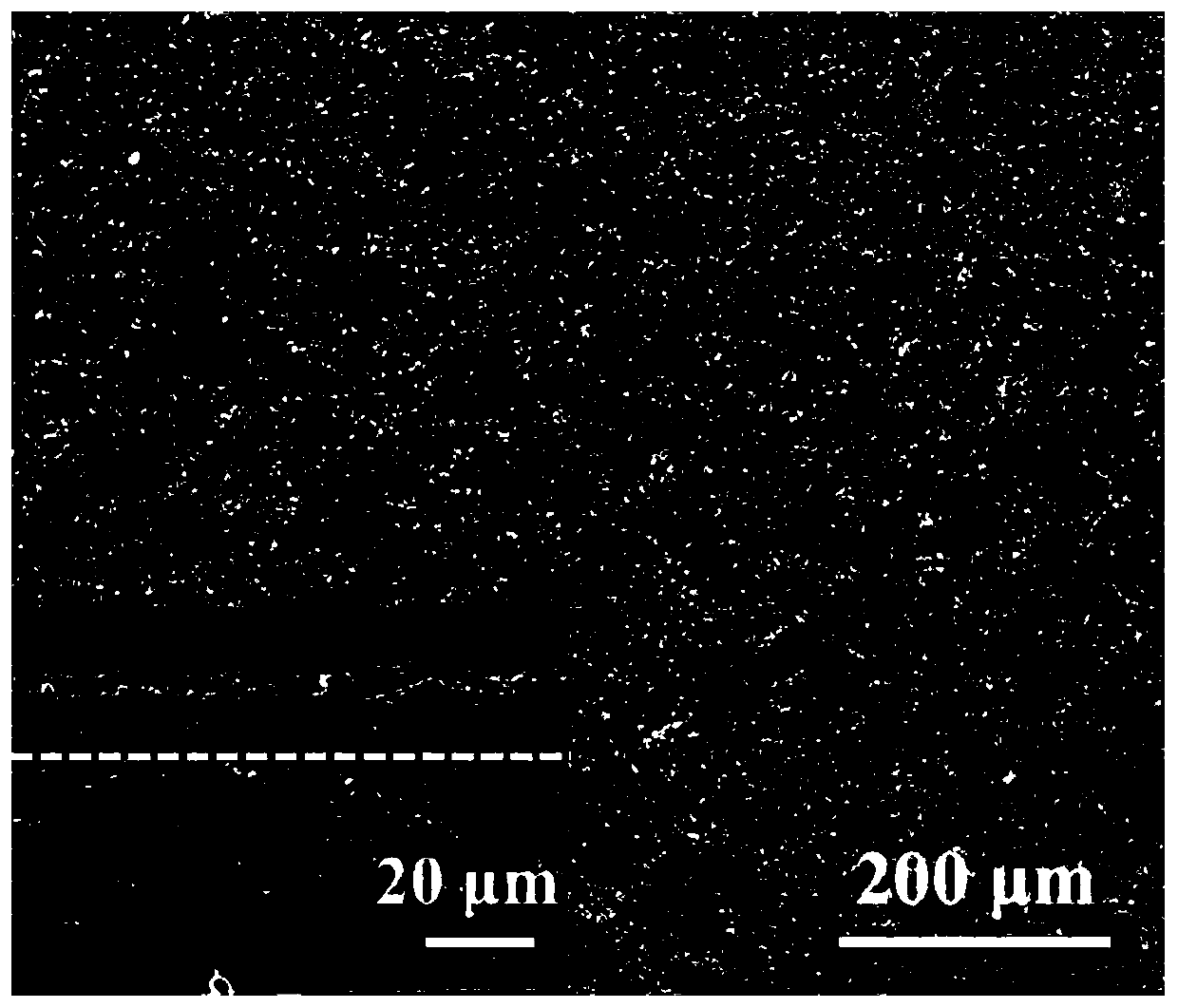

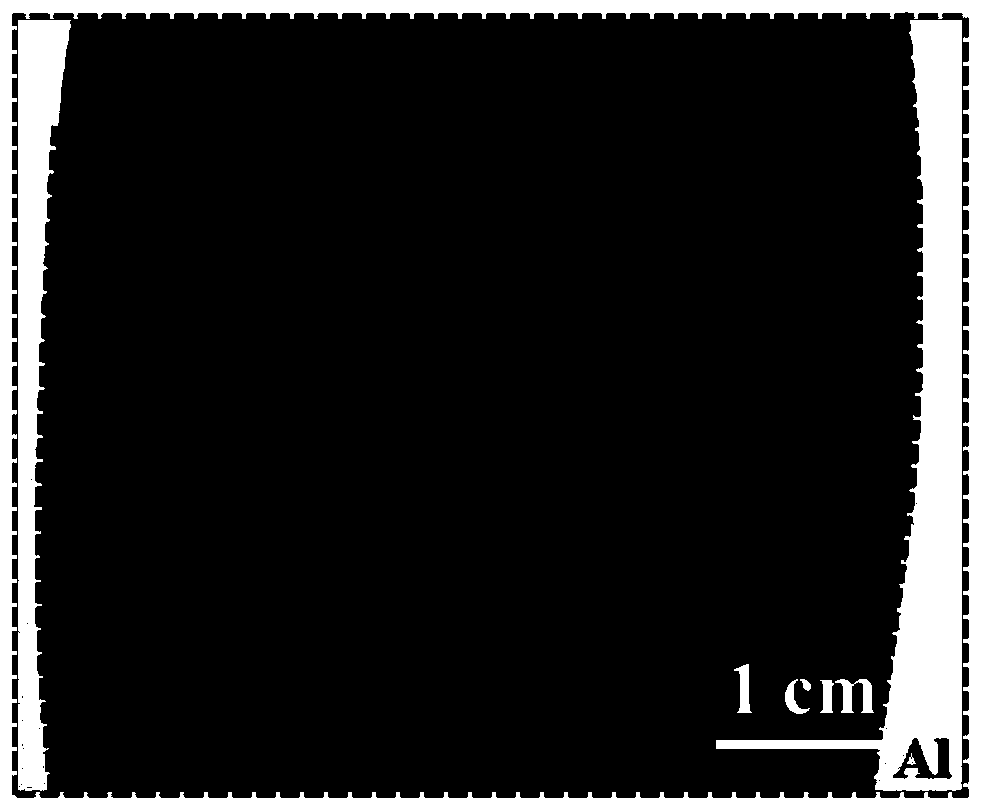

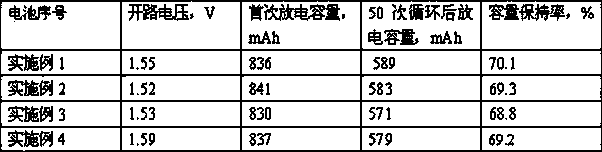

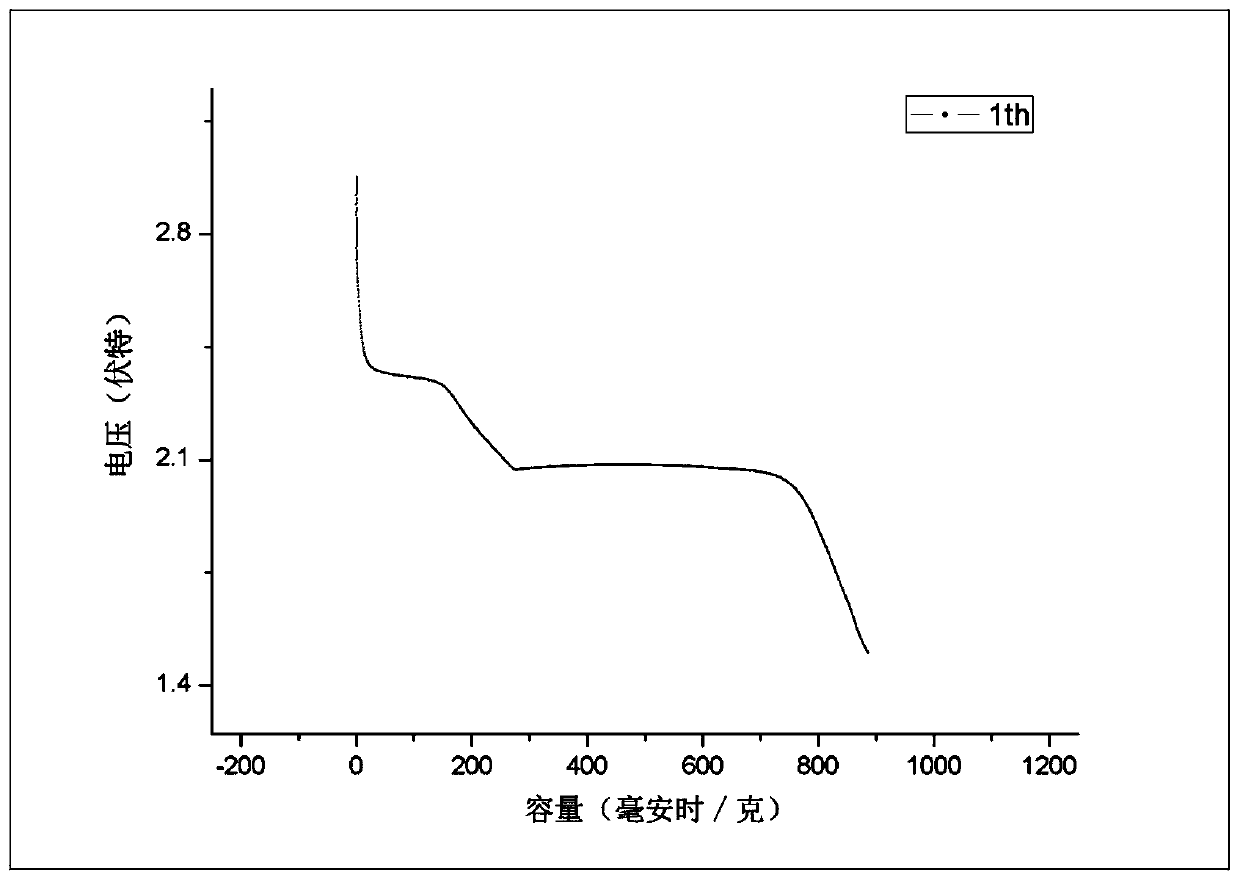

Positive electrode material for lithium-sulfur secondary battery and preparation method of positive electrode material

InactiveCN107658436ALarge specific surface areaHigh Sulfur LoadingCell electrodesLi-accumulatorsDiffusion methodsLithium sulfur

The invention relates to a positive electrode material for a lithium-sulfur secondary battery and a preparation method of the positive electrode material. Particularly, an activated carbon material with ultra-high specific surface area and large pore volume is prepared by adopting biomass waste mangosteen peel as a raw material through pre-carbonization and potassium hydroxide activation methods;and a carbon / sulfur composite material is further prepared by adopting the activated carbon material as a carrier through a melting diffusion method. A test result shows that the initial discharge specific capacity of a positive electrode prepared from the carbon / sulfur composite material with the sulfur bearing capacity of 65% under the current of 0.5C is 870.5mAhg<->, the discharge specific capacity of the positive electrode after 100 cycles is 599.6mAhg<-1> and the discharge capacity after 100 cycles under the current of 2C is 569.2mAhg<->. The carbon / sulfur composite positive electrode material prepared by adopting the biomass waste mangosteen peel as the raw material is high in sulfur bearing capacity, good in chemical stability, high in specific capacity, good in rate capability, simple in preparation method and suitable for the lithium-sulfur secondary battery.

Owner:TONGJI UNIV

Preparation method of lithium-sulfur battery positive electrode

InactiveCN110752349AHigh specific capacityAvoid local agglomeration of materialsElectrode manufacturing processesLi-accumulatorsElectrical batteryElectrically conductive

The invention provides a preparation method of a lithium-sulfur battery positive electrode. The preparation method comprises the following steps: uniformly mixing an active substance sulfur, a conductive agent and a binder to obtain a mixture, then adding a dispersing solvent into the mixture, and uniformly mixing to obtain electrode slurry; uniformly coating a positive electrode current collectorwith the electrode slurry to obtain a wet electrode coated with the slurry; freezing the wet electrode coated with the slurry in a low-temperature environment of -80 to -5 DEG C for 1-5 hours until the wet electrode is frozen and formed, so that the dispersing solvent in the wet electrode is solidified and crystallized to obtain a solidified electrode; placing the solidified electrode in a vacuumenvironment with the vacuum degree of 0.1-100Pa for 1-5 hours, so that solid-phase sublimation of ice crystals in the solidified electrode is carried out to obtain a solid-phase sublimated electrode;and carrying out rolling treatment on the solid-phase sublimated electrode, and controlling the porosity of the electrode to be 50-70% to obtain the lithium-sulfur battery positive electrode. The preparation method is simple, and the problem of electrode cracking in the preparation of a high-sulfur-carrying positive electrode by adopting a traditional hot drying method is effectively solved.

Owner:TONGJI UNIV

Carbon-sulfur composite positive electrode for lithium-sulfur battery and preparation method of carbon-sulfur composite positive electrode

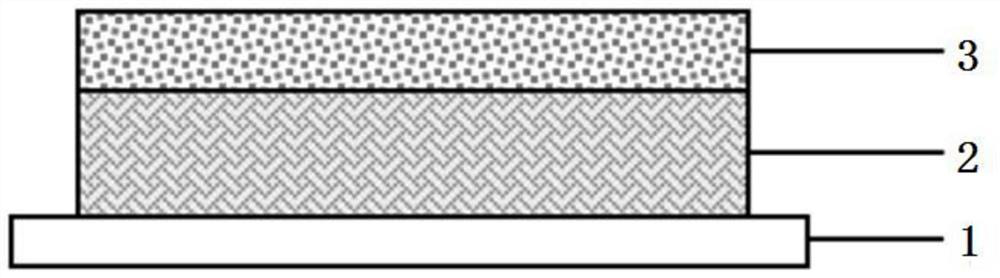

ActiveCN112072067AImprove cycle lifeOvercoming the low sulfur content in the cathodePositive electrodesLi-accumulatorsCarbon layerLithium–sulfur battery

The invention discloses a carbon-sulfur composite positive electrode for a lithium-sulfur battery and a preparation method of the carbon-sulfur composite positive electrode, and belongs to the technical field of lithium-sulfur batteries. The carbon-sulfur composite positive electrode consists of a carbon-sulfur composite layer and a conductive carbon layer which are sequentially coated on the current collector; the carbon-sulfur composite layer is composed of a sulfur material, a carbon material I and an aqueous binder, and the conductive carbon layer is composed of a carbon material II and anorganic binder. According to the double-layer carbon-sulfur composite positive electrode prepared by the method, the construction of a high-sulfur-capacity, high-sulfur-content, high-specific-capacity and long-cycle-life high-energy-density lithium-sulfur battery can be realized. The preparation method of the composite positive electrode is simple and convenient to operate, low in cost and easy to amplify, the design and preparation of the positive electrode of the lithium-sulfur battery are effectively promoted, and a new possibility is provided for the practicability of the lithium-sulfur battery with high energy density.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Spherical-like nitrogen-doped reduced graphene oxide material and application thereof

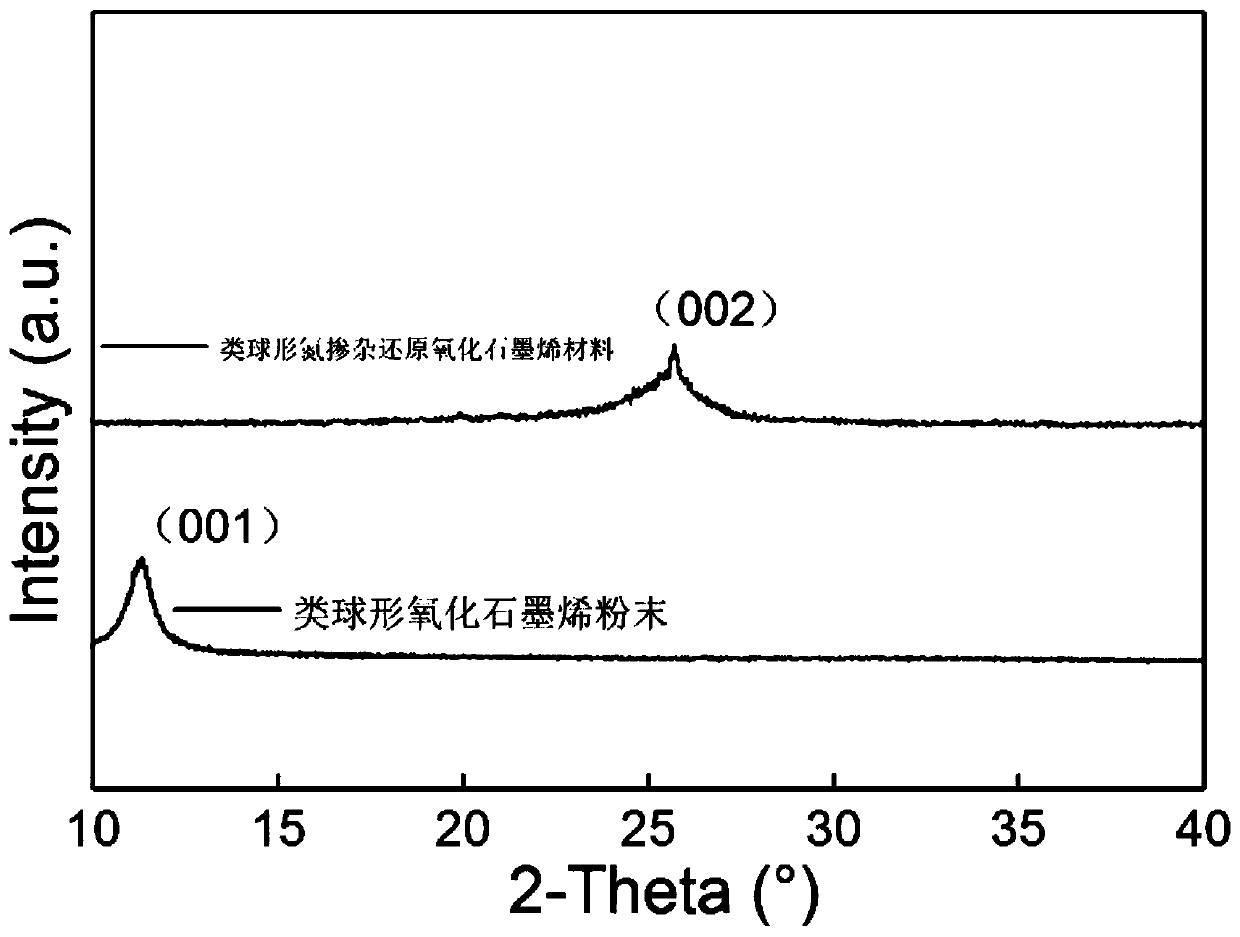

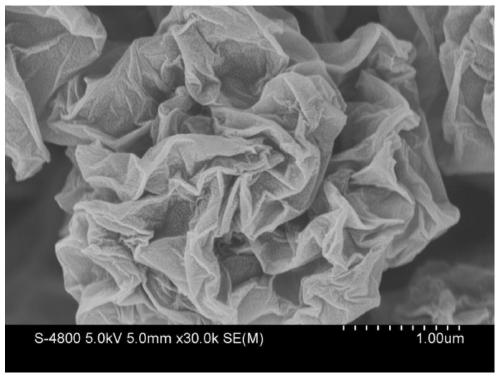

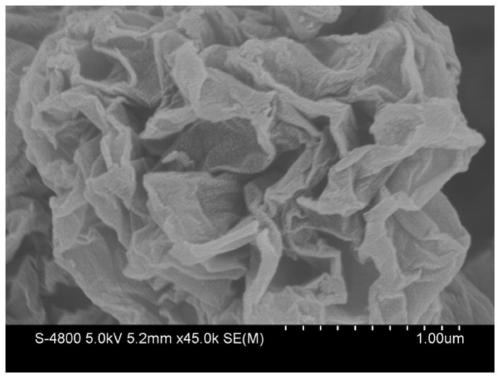

InactiveCN110323443AThe process is simple and easy to controlIncrease productivityCell electrodesGrapheneNitrogen dopedMaterials science

The invention relates to a spherical-like nitrogen-doped reduced graphene oxide material and an application thereof, and belongs to the field of battery materials. The preparation method comprises thefollowing steps of carrying out diluting on a graphene oxide water solution and then performing ultrasonic homogenization treatment, and carrying out spray drying treatment to obtain spherical-like graphene oxide powder; and next, performing grinding and mixing with a nitrogen source, and carrying out heat preserving for 0.5-6 hours at the temperature of 600-1,200 DEG C to obtain the product. Thespherical-like nitrogen-doped reduced graphene oxide material has the advantages of high conductivity, high wrinkle, large specific surface area and hierarchical pore structure; rich functional groups can be introduced by virtue of doped nitrogen atoms, so that the adverse effects caused by serious stacking of the graphene are avoided. The material and the sulfur are compounded to serve as a positive electrode material of a lithium sulfur battery, so that the uniform dispersion of the active substance can be realized, the sulfur carrying amount can be increased, the conductivity of the electrode can be improved, the " shuttle effect " can be reduced, and finally the electrochemical performance of the sulfur positive electrode is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

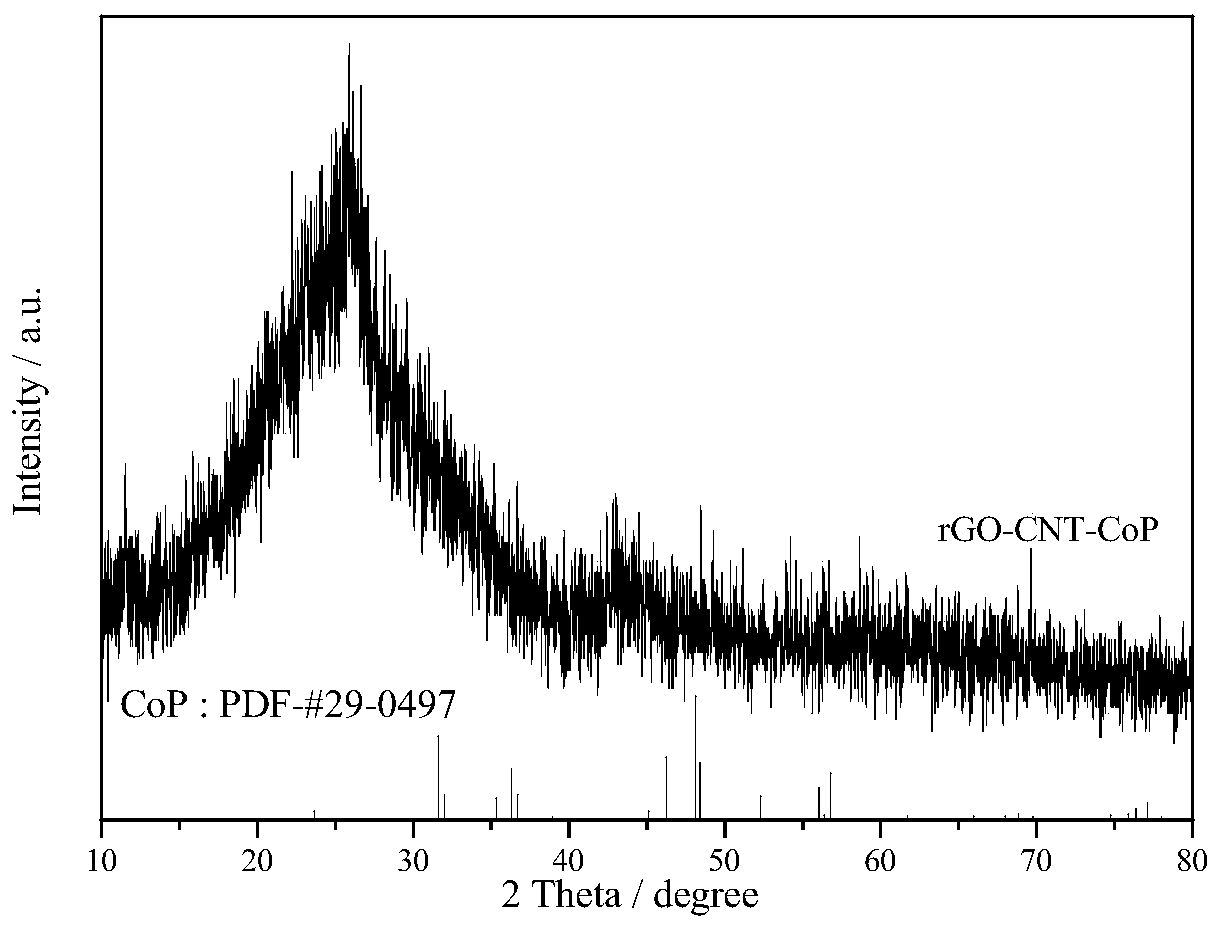

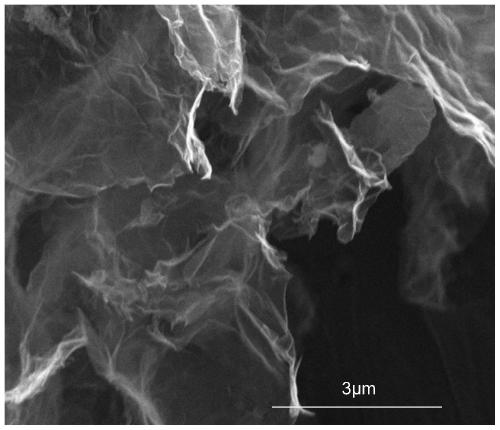

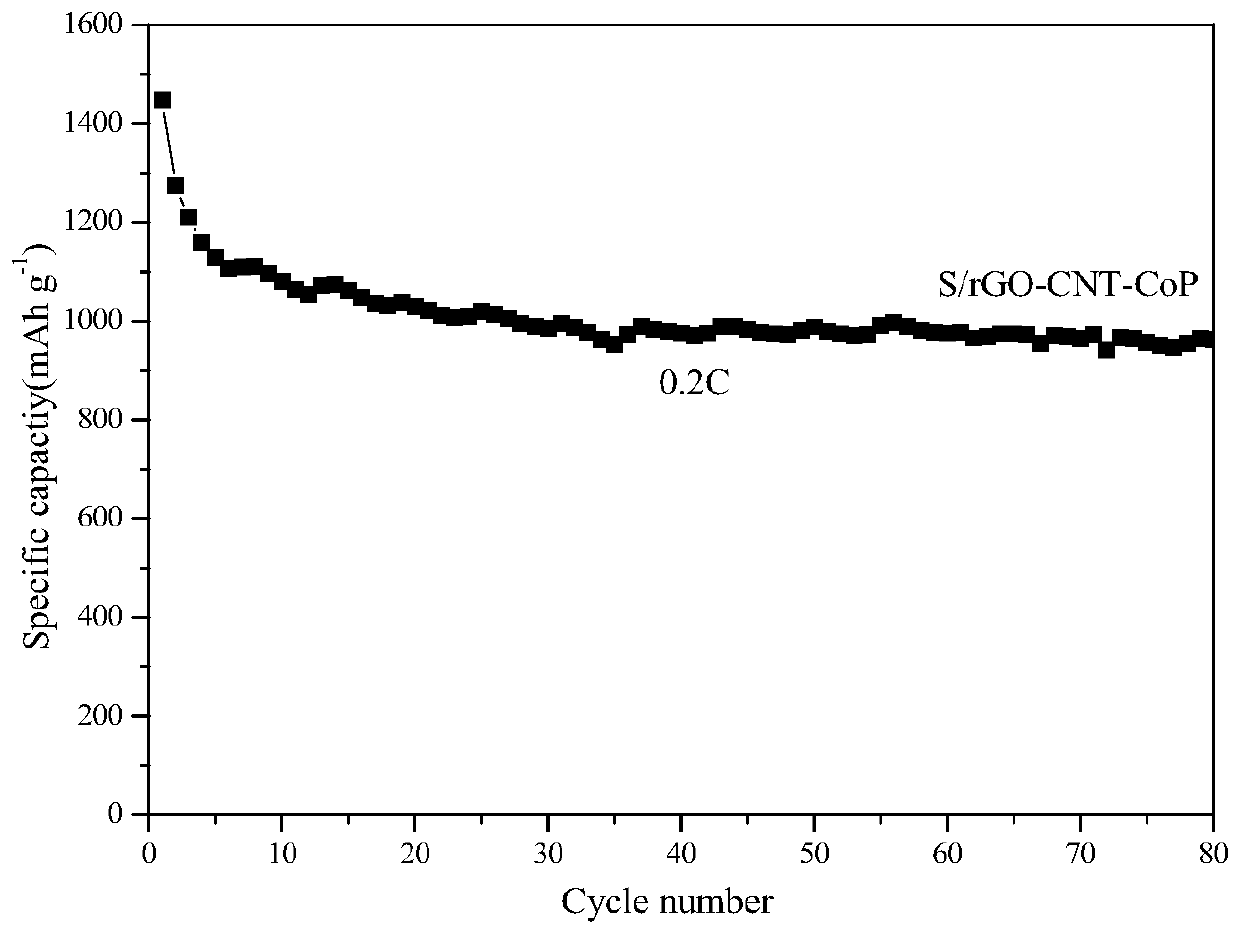

Amorphous cobalt phosphide/nanocarbon composite material and preparation method and application thereof

ActiveCN111517298ALarge specific surface areaRich pore structureMaterial nanotechnologyCell electrodesCarbon compositesNew energy

The invention belongs to the technical field of new energy materials, and particularly relates to an amorphous cobalt phosphide / nanocarbon composite material and a preparation method and application thereof. The composite material is high in specific surface area, rich in pore structure and excellent in conductivity; the conductive carbon network can provide channels for transmission of electronsand ions. The composite material can realize high sulfur loading capacity and high sulfur utilization rate, and can adapt to huge volume change of sulfur in charging and discharging processes. Compared with cobalt phosphide in a high crystalline state, the amorphous cobalt phosphide nanosheet can effectively physically and chemically adsorb polysulfide, reduce the shuttle effect, expose enough catalytic active sites, provide a large number of defect sites, promote electrochemical conversion of polysulfide to the final discharge product and improve the catalytic kinetics of the reaction.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

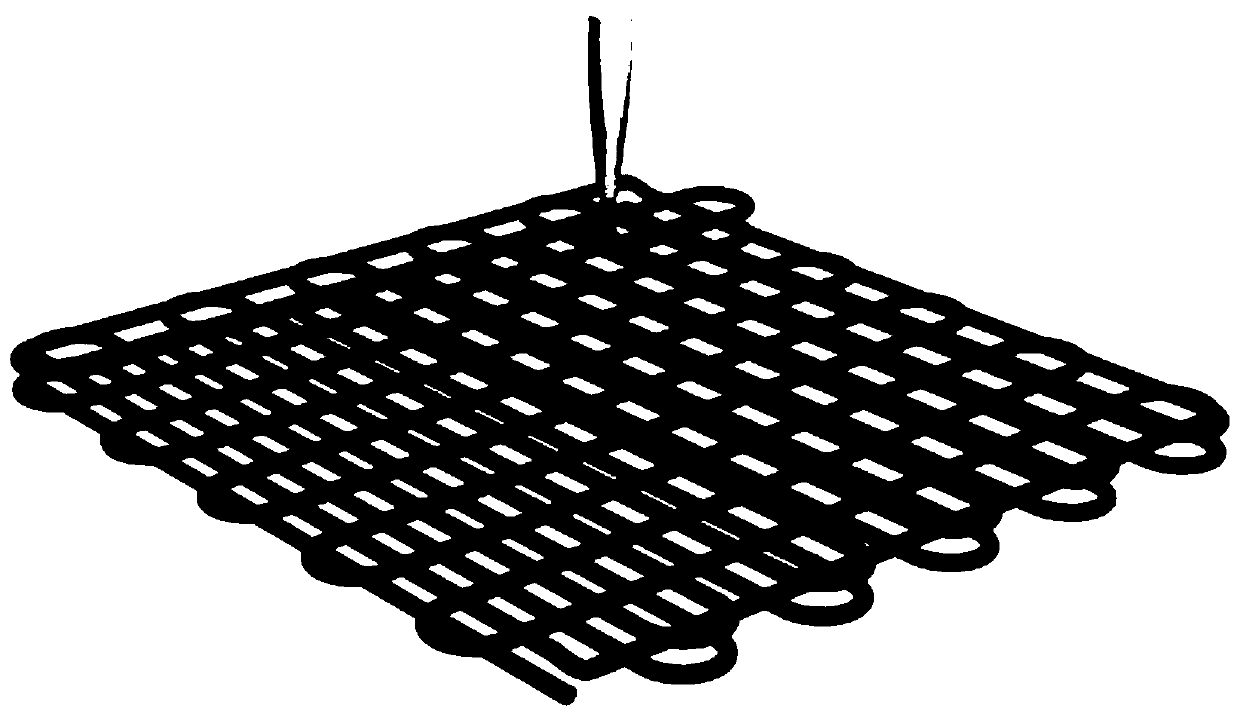

3D printing positive electrode material, preparation method and application thereof

ActiveCN111477843AIncrease sulfur loadStrictly control the sulfur loadAdditive manufacturing apparatusSecondary cells3d printLithium–sulfur battery

The invention discloses a 3D printing positive electrode material, a preparation method and application thereof. The preparation method comprises the following steps: uniformly mixing an active substance, a conductive agent, a binder and a solvent to prepare electrode slurry; by using a 3D printing technology, placing the electrode slurry on the inner layer of a coaxial printing needle head, placing a graphene oxide solution on the outer layer of the coaxial printing needle head, and carrying out coaxial printing to obtain a composite positive electrode material; and carrying out drying and heat treatment on the composite positive electrode material to obtain the 3D printing positive electrode material. The invention provides a preparation method of a novel positive electrode material. According to the invention, by using a 3D printing method, the traditional concept of preparing a positive electrode material containing a current collector by utilizing a coating method is broken through, the obtained electrode material does not need an aluminum foil as the current collector, the positive electrode material with high sulfur loading capacity, no current collector, high-efficiency ions and high electron transmission efficiency and integrated structure is realized, and the positive electrode material has potential application in the field of lithium-sulfur battery application.

Owner:江西省纳米技术研究院

Polypyrrole, mesoporous carbon and sulfur composite electrode material and secondary cell

InactiveCN104362313AFacilitated DiffusionIncrease transfer rateNon-aqueous electrolyte accumulatorsCell electrodesComposite electrodeSulfur

The invention relates to a secondary aluminum cell adopting a polypyrrole, mesoporous carbon and sulfur composite electrode material as a positive electrode. A preparation method of the polypyrrole, mesoporous carbon and sulfur composite material comprises the following steps: ordered mesoporous carbon is prepared with a template method; the activated ordered mesoporous carbon is taken as a carrier to prepare a polypyrrole and mesoporous carbon composite material with a three-dimensional porous structure with a chemical in-situ polymerization method; and then the surface and pores of the polypyrrole and mesoporous carbon composite material are coated with sulfur through heat treatment so as to obtain the polypyrrole, mesoporous carbon and sulfur composite electrode material. The prepared secondary aluminum cell has high specific capacity, good circulating stability and low cost, the preparation method is simple, and the polypyrrole, mesoporous carbon and sulfur composite electrode material is suitable for industrial production.

Owner:NANJING ZHONGCHU NEW ENERGY

Preparation method and application of single crystal mesoporous Mo3N2 for positive electrode material of lithium-sulfur battery

InactiveCN111485280AOvercome conductivityOvercoming Shuttle Effect DeficienciesMaterial nanotechnologyPolycrystalline material growthNanowireNano structuring

The invention relates to a preparation method of single-crystal mesoporous Mo3N2 for a positive electrode material of a lithium-sulfur battery, wherein the preparation method comprises the steps: preparing a single-crystal MoO3 nanowire by a hydrothermal method, and preparing a single-crystal mesoporous Mo3N2 nanostructure with high specific surface area by a topological reaction method by using the single-crystal MoO3 nanowire as a starting material. Molybdenum nitride has a large number of pores, the sulfur loading capacity is improved, and the shuttle effect is inhibited. The molybdenum nitride effectively solves the problem of the volume expansion effect of the lithium-sulfur battery while significantly improving the sulfur loading capacity of the positive electrode material. Non-toxicreactants and a hydrothermal method and a topological reaction method which are simple to operate are adopted, and non-toxic and harmless sublimed sulfur powder is loaded for preparing the positive electrode material of the lithium-sulfur battery, so that the method has remarkable advantages in the aspects of environmental protection, industrial production, products and application.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

Method for preparing sulfur/carbon composite cathode material for lithium-sulfur battery on basis of palm fiber

InactiveCN107123801AImprove surface propertiesImprove adsorption capacityCell electrodesLi-accumulatorsCarbon compositesPotassium hydroxide

The invention discloses a method for preparing a sulfur / carbon composite cathode material for a lithium-sulfur battery on the basis of a palm fiber. The method comprises the following steps: carbonizing the palm fiber, mixing the palm fiber and potassium hydroxide, performing high-temperature activation to obtain activated carbon, and compounding the activated carbon and elemental sulfur to obtain the sulfur / carbon composite cathode material. The activated carbon in the composite cathode material has the characteristics of large specific surface area and pore volume and rich micropore content, is of a special heteroatom doped and multiwalled porous tubular array structure, and is compounded with sulfur to achieve the sulfur carrying capacity of 65 percent or more, high electrical conductivity and convenience for electron migration and simultaneously relieve the damage of the volume change of the active substance sulfur in an electrochemical process to an electrode structure; when the composite cathode material is used for the lithium-sulfur battery, the lithium-sulfur battery has the advantages of high specific capacity and high cycling stability.

Owner:CENT SOUTH UNIV

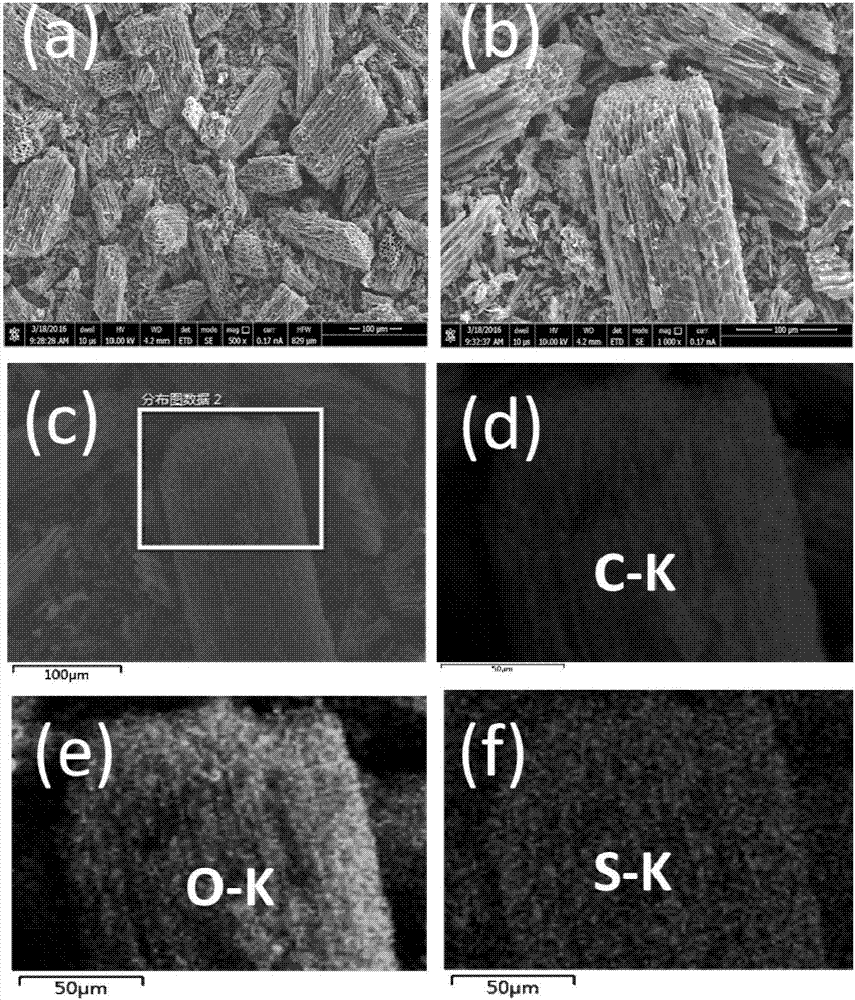

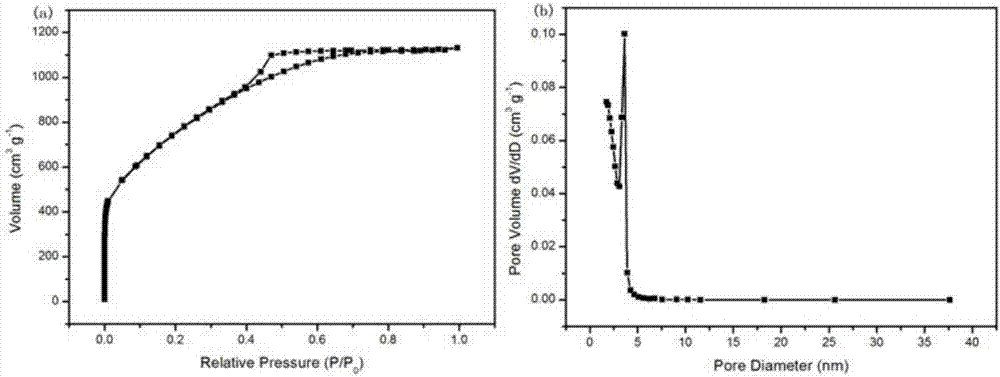

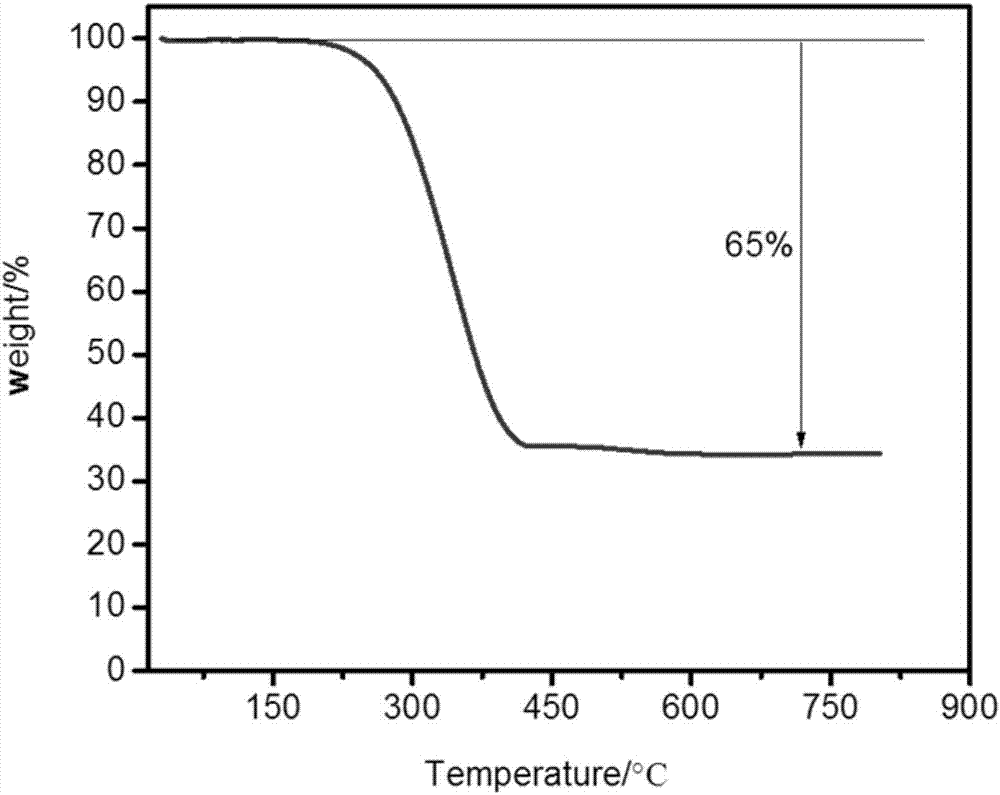

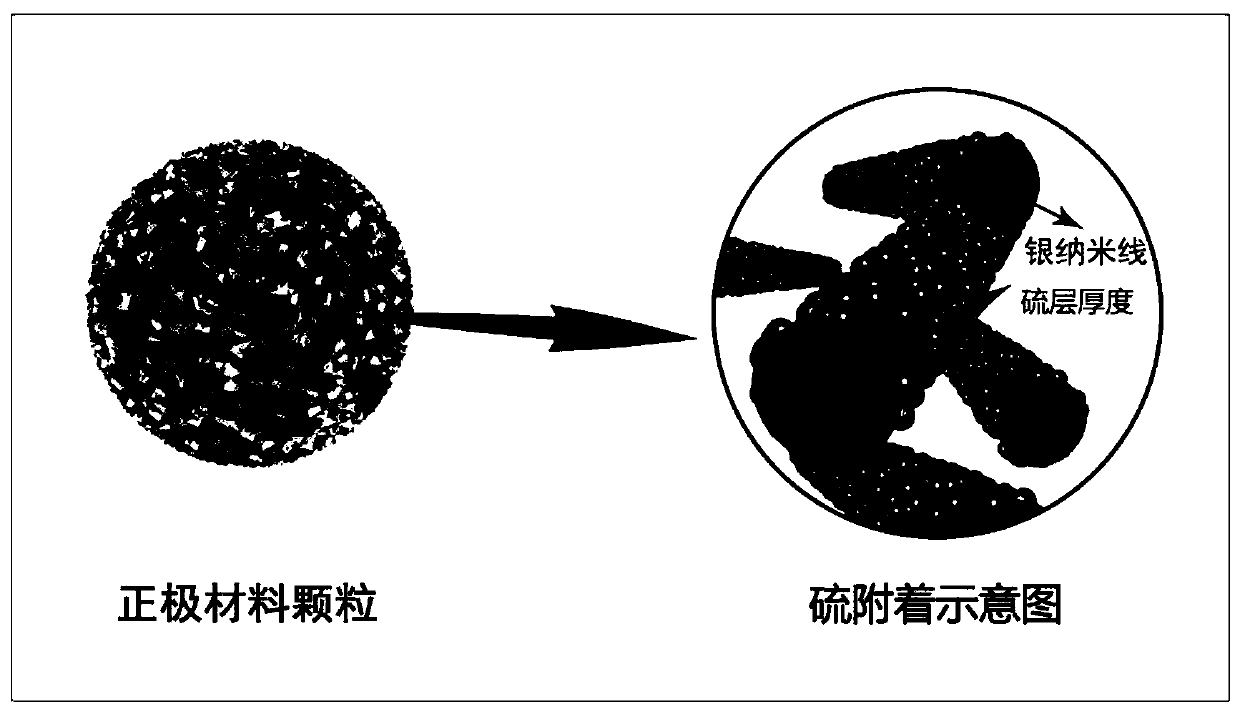

Controllable preparation method of nano cathode material for lithium-sulfur primary battery

ActiveCN110010876AGrowth inhibitionPromote growthMaterial nanotechnologyCell electrodesAlcoholMass ratio

The invention relates to a controllable preparation method of a nano cathode material for a lithium-sulfur primary battery. The method comprises the steps of: the step 1, preparing silver nanowires; and the step 2, preparing a silver nanowire / sulfur composite material: putting the silver nanowires washed in the step 1, absolute ethyl alcohol and nano sulfur powder according to the mass ratio of 1:(1-3):(1-3) into a ball mill for ball milling for 2-4h at the 100-500 rpm, putting the mixture obtained through ball milling into a tubular furnace under the protection of a nitrogen atmosphere for heat treatment for 5-10h at a temperature in a range of 100-200 DEG C to prepare the silver nanowire / sulfur composite material. The problem is solved that a prepared lithium-sulfur primary battery cathode material is not high in conductivity and not high in sulfur-carrying capacity in the prior art, and the electrochemical performances of the lithium-sulfur primary battery are improved.

Owner:深圳市高能达电池有限公司

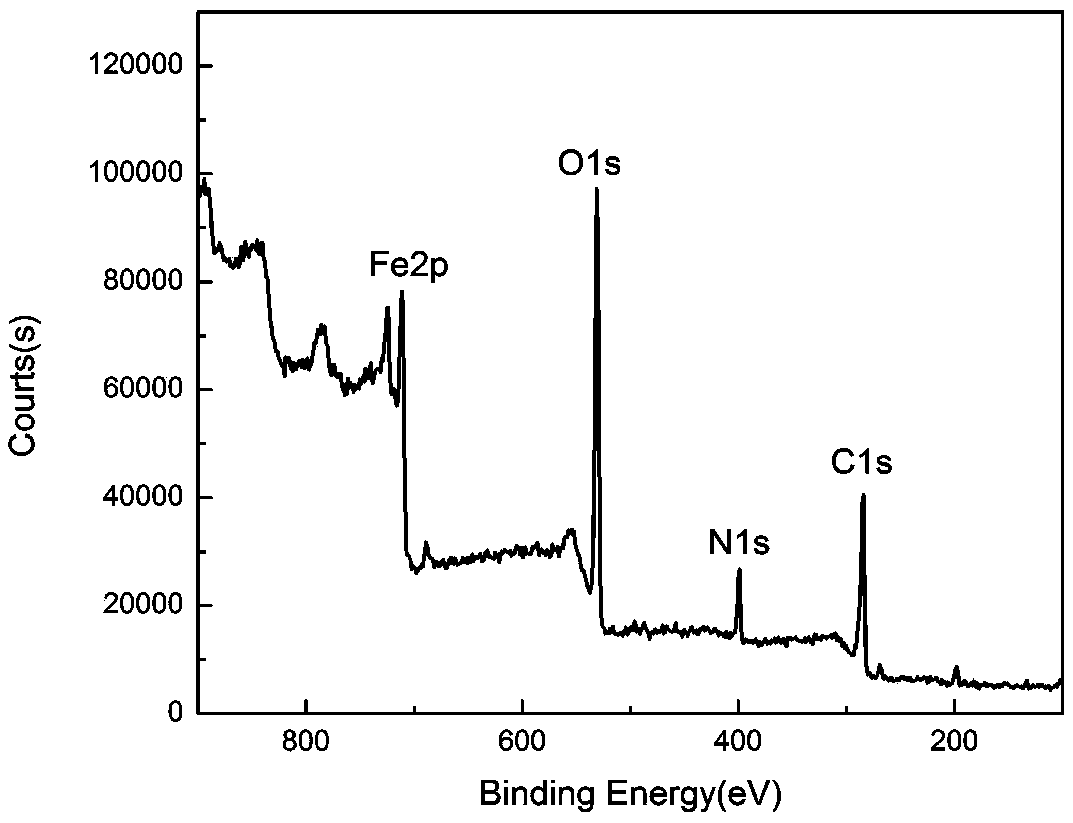

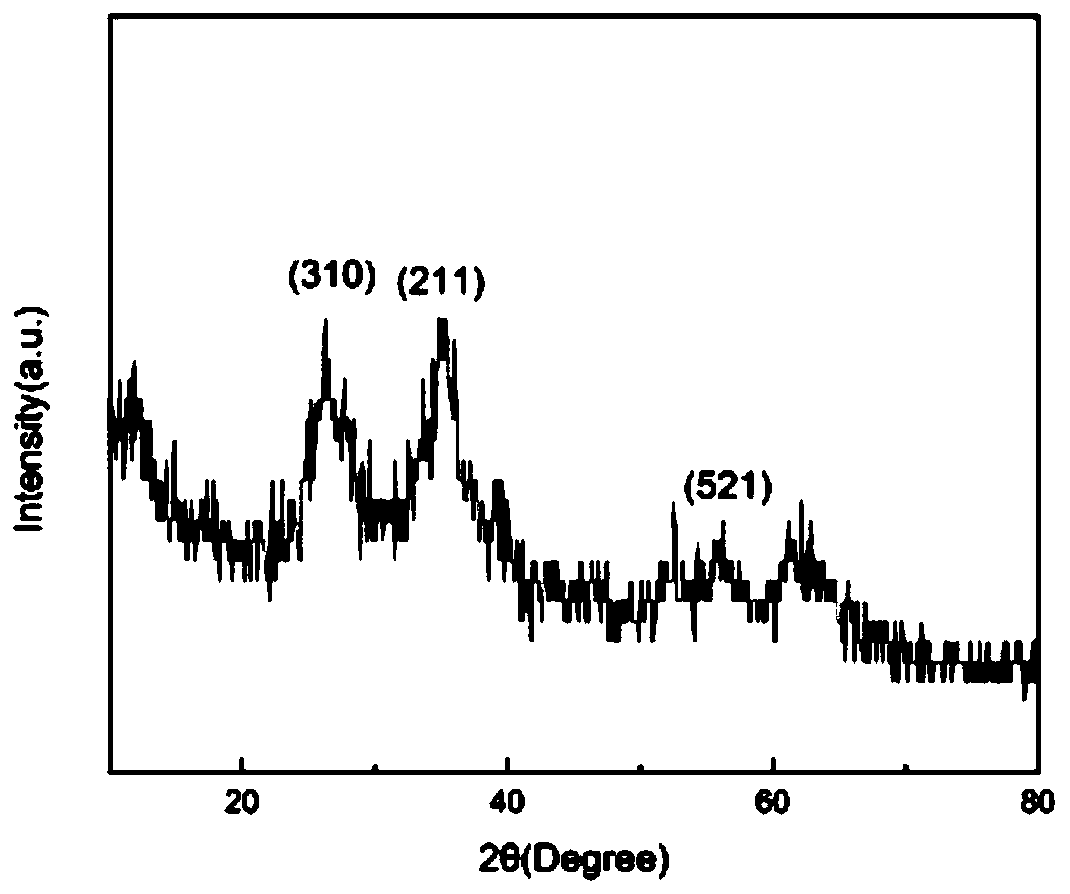

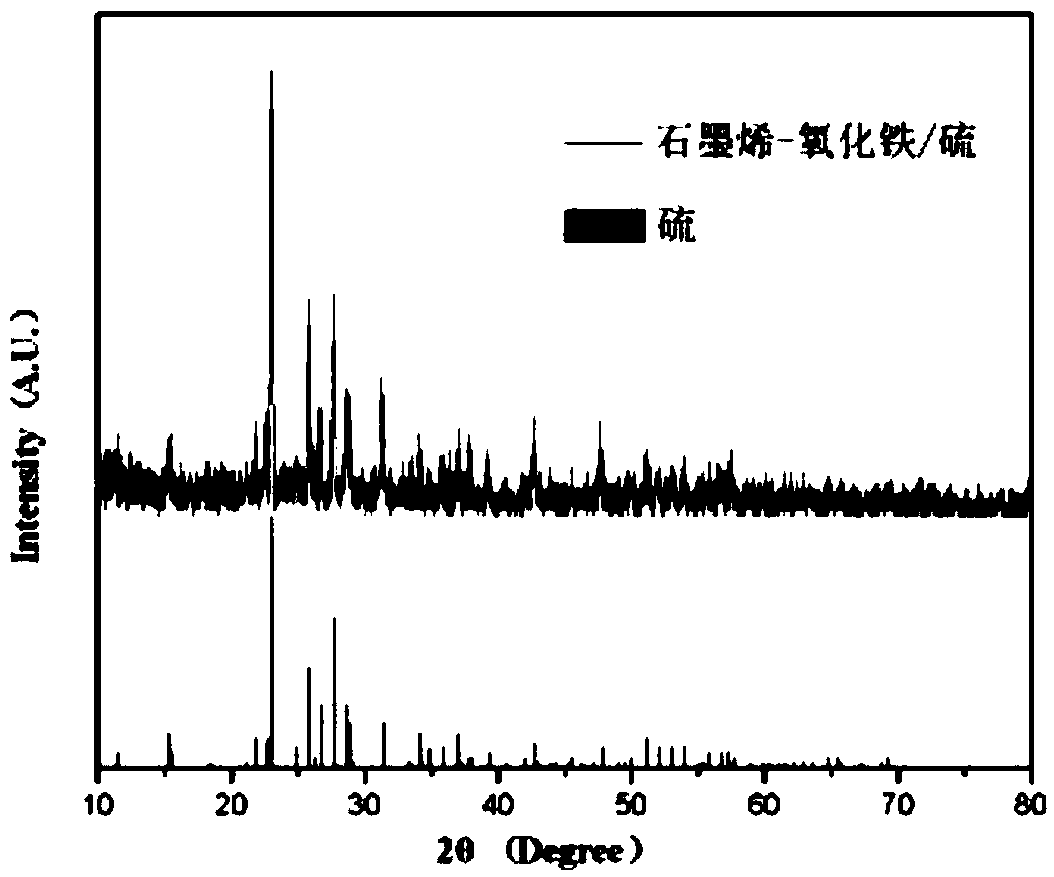

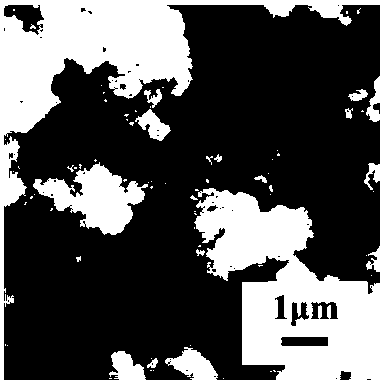

Sulfur/iron oxide/graphene battery cathode material, preparation method and lithium sulfur battery

InactiveCN109148861AIncrease loadIncrease contentMaterial nanotechnologyCell electrodesLithium sulfurNitrogen doped graphene

The invention relates to the technical field of nanometer materials, in particular to a sulfur / iron oxide / graphene battery cathode material, a preparation method and a lithium sulfur battery. The invention discloses a preparation method of a sulfur / iron oxide / graphene battery cathode material, comprising the following steps: step 1, the nitrogen doped graphene and the ferric salt solution are hydrothermally reacted to obtain graphene-iron oxide nanocomposites; Step 2: the sulfur / iron oxide / graphene battery cathode material is prepared by vacuum melt diffusion reaction from the mixture of graphene-iron oxide nanocomposite and elemental sulfur. The invention also discloses a sulfur / iron oxide / graphene battery cathode material prepared by the abovementioned method and a lithium sulfur batterythereof. The invention solves the technical problems that the elemental sulfur in the prior art cannot be effectively utilized in the lithium sulfur battery cathode material, thereby leading to shortservice life, and poor conductivity, cycle stability and safety performance of the lithium sulfur battery.

Owner:GUANGDONG UNIV OF TECH

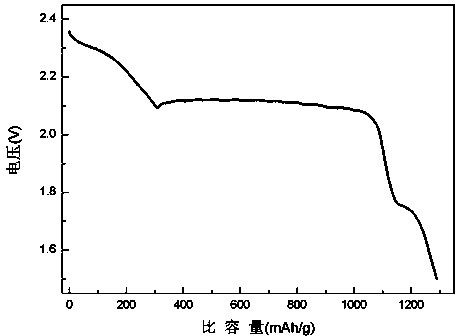

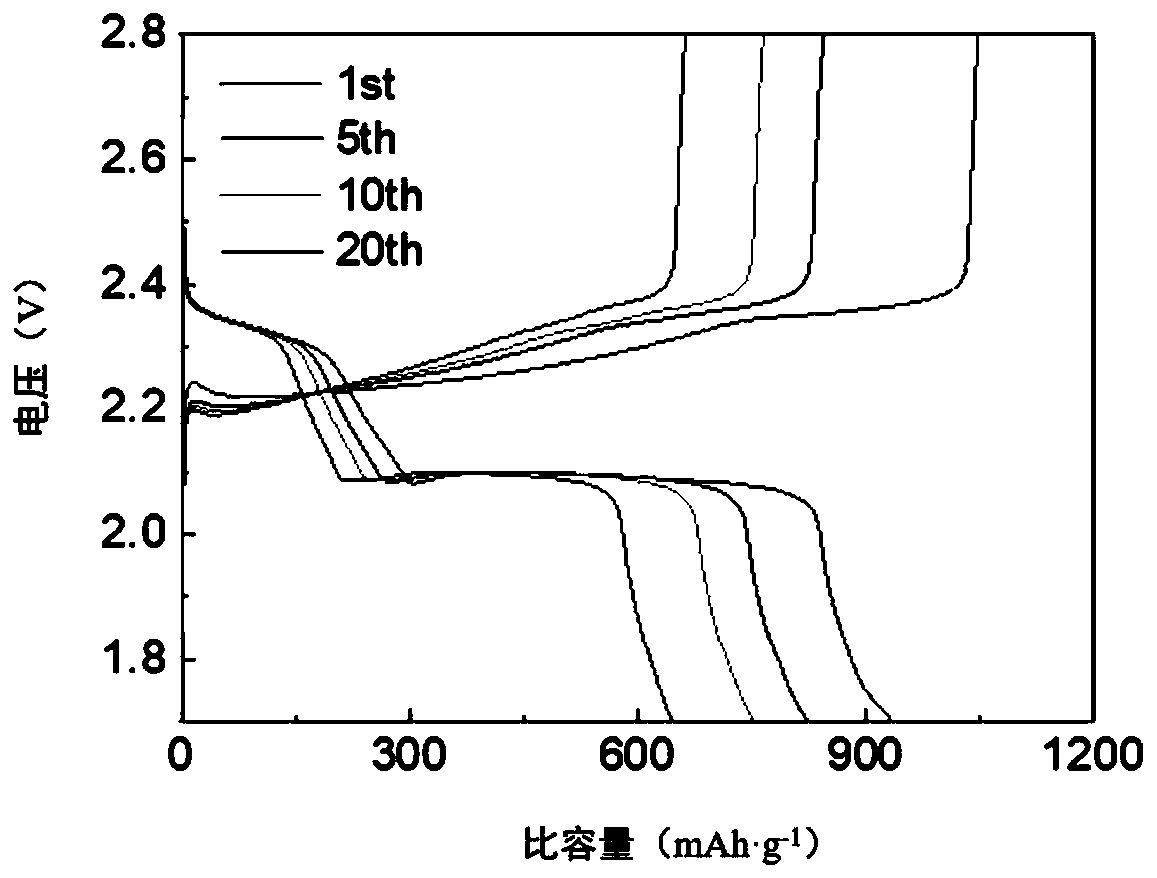

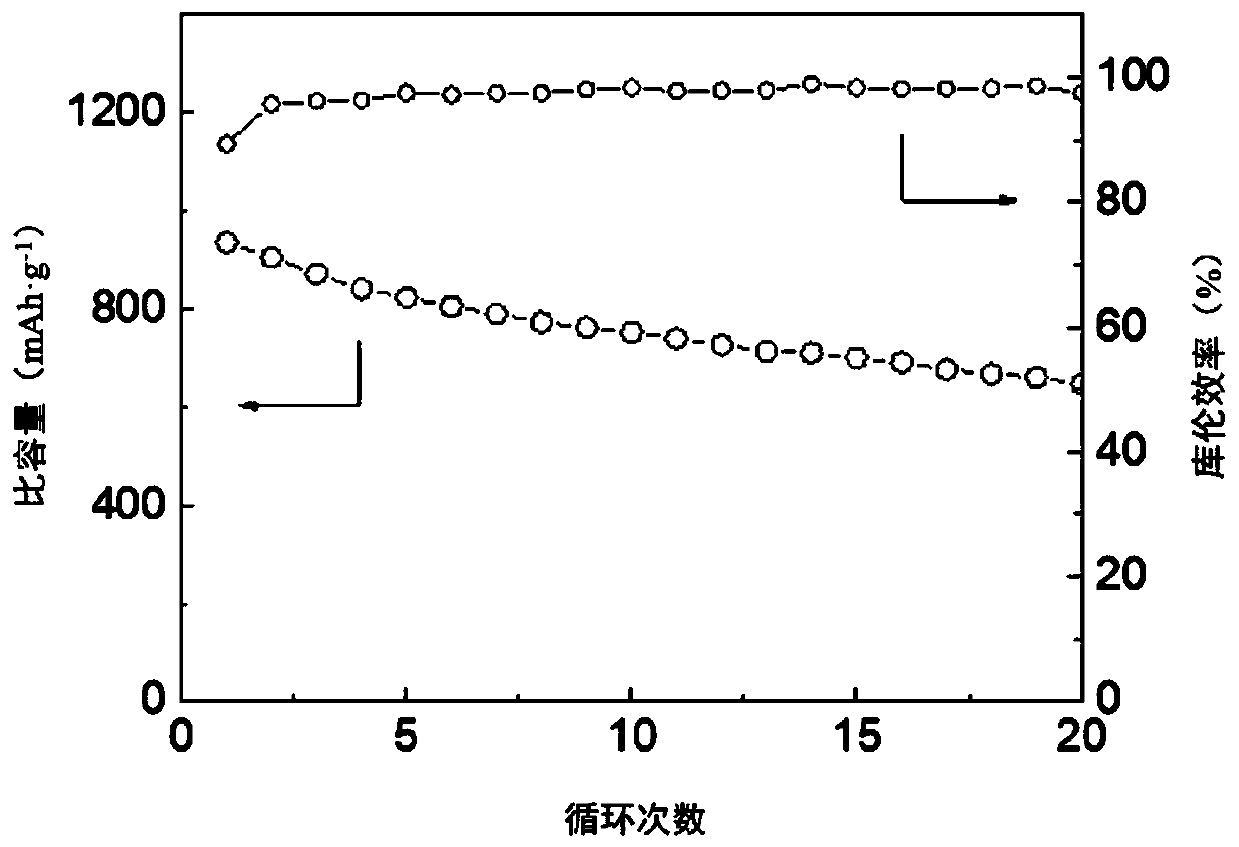

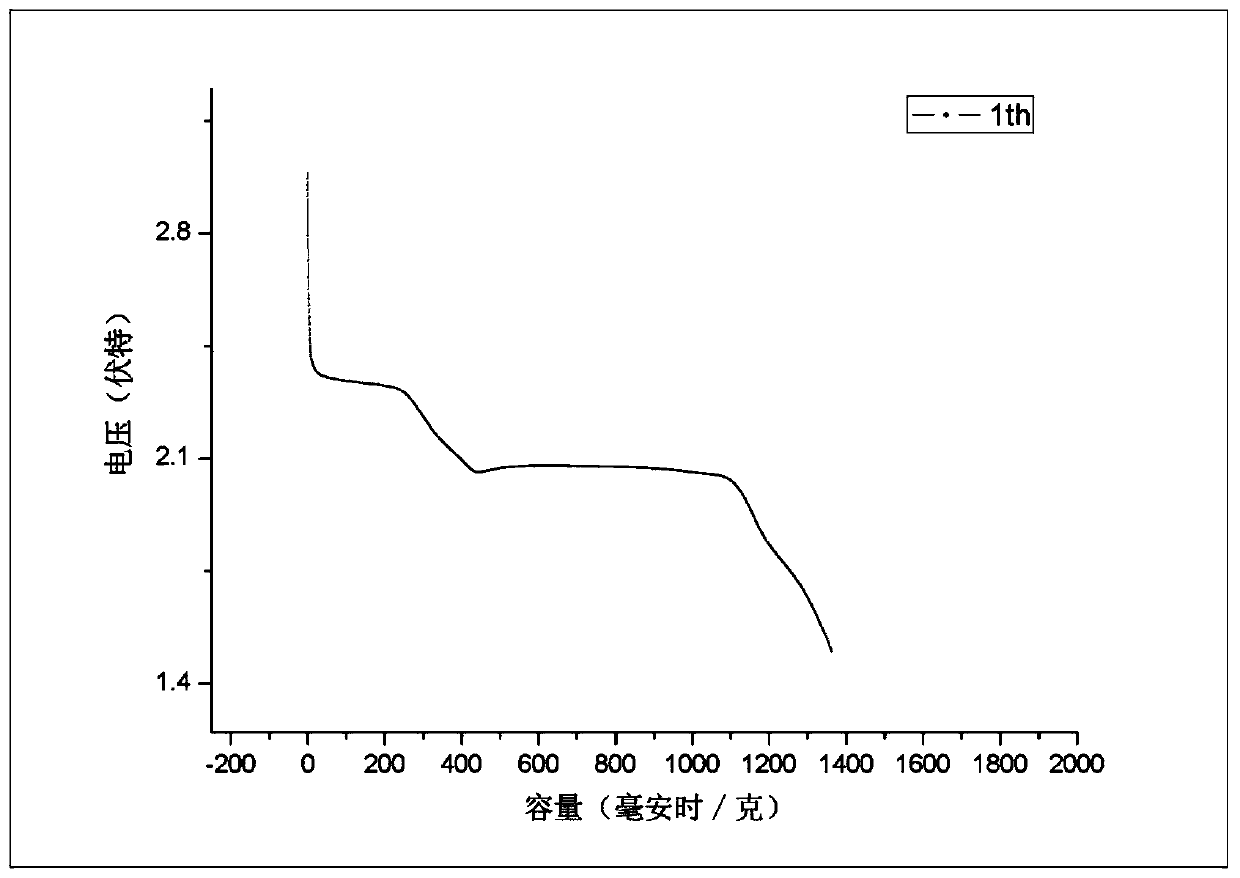

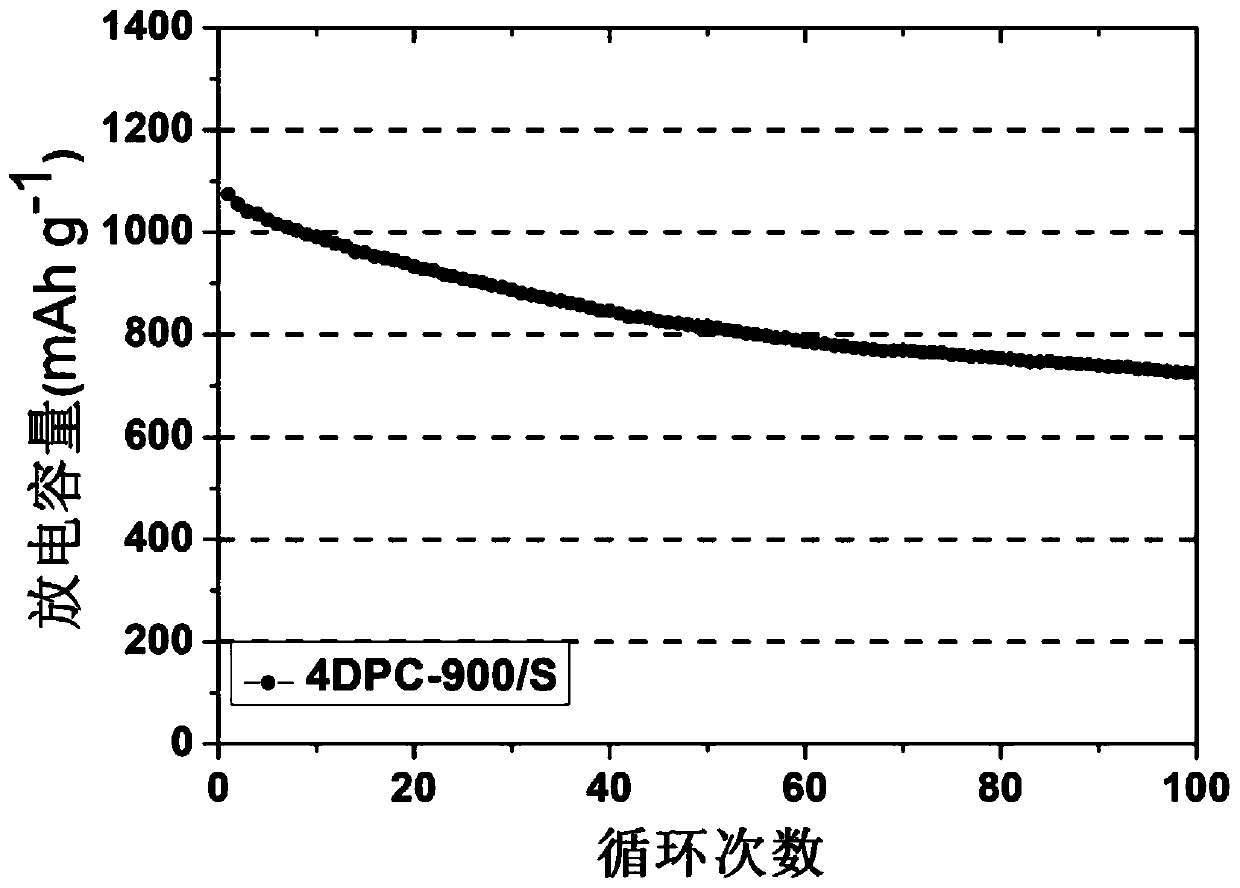

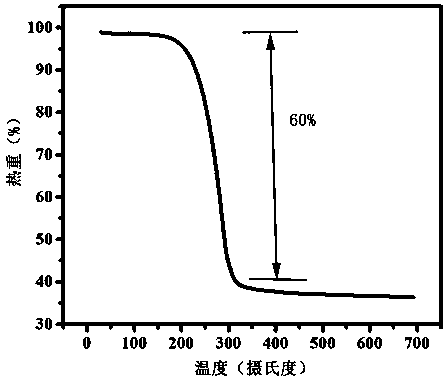

Anode material for lithium-sulfur rechargeable battery and preparation method of anode material

InactiveCN109755505AExcellent discharge specific capacityExcellent magnification performanceCell electrodesLi-accumulatorsDiffusion methodsCarbonization

The invention relates to an anode material for a lithium-sulfur rechargeable battery and a preparation method of the anode material. According to the specific method, biomass waste, namely a durian shell is adopted as a raw material, and after pre-carbonization, potassium hydroxide activation and other methods are adopted, an activated carbon material with an ultrahigh specific surface area and alarge pore volume is prepared; and the activated carbon material is used as a carrier, and a fused diffusion method is further adopted to prepare a carbon / sulfur composite. It is shown by an electrochemical test that the first discharge specific capacity, under a 0.5C current, of an anode prepared from the carbon / sulfur composite with sulfur capacity of 60wt.% is 1,074.23mAhg<-1>; after 100 timesof circulation, the discharge specific capacity of the anode is still 724.74mAhg<-1>; and the carbon / sulfur composite anode material, which is prepared by using the biomass waste, namely the durian shell as the raw material, has the advantages of being high in sulfur capacity, good in chemical stability, high in specific capacity, excellent in rate capability, simple in preparation method and thelike and can be well applied to the lithium-sulfur rechargeable battery.

Owner:TONGJI UNIV

Sulfur/dual layer titanium dioxide composite material and preparation method and applications thereof

InactiveCN108305997AImprove conductivitySolve the volume expansion effectCell electrodesSecondary cellsCyclic stabilityVolume expansion

The invention provides a sulfur / dual layer titanium dioxide composite material and a preparation method and applications thereof. Dual layer titanium dioxide nano spheres are designed and then doped by sulfur to prepare the sulfur / dual layer titanium dioxide composite material. The obtained sulfur / dual layer titanium dioxide composite material can be used as a cathode material of a lithium-sulfurbattery; the amount of loaded sulfur of the cathode material is increased, the discharge-charge intermediate product can be adsorbed, thus the volume expansion and shuttling effect during the discharge-charge process can be reduced, and the electrochemical properties and circulation stability of the composite material are good.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

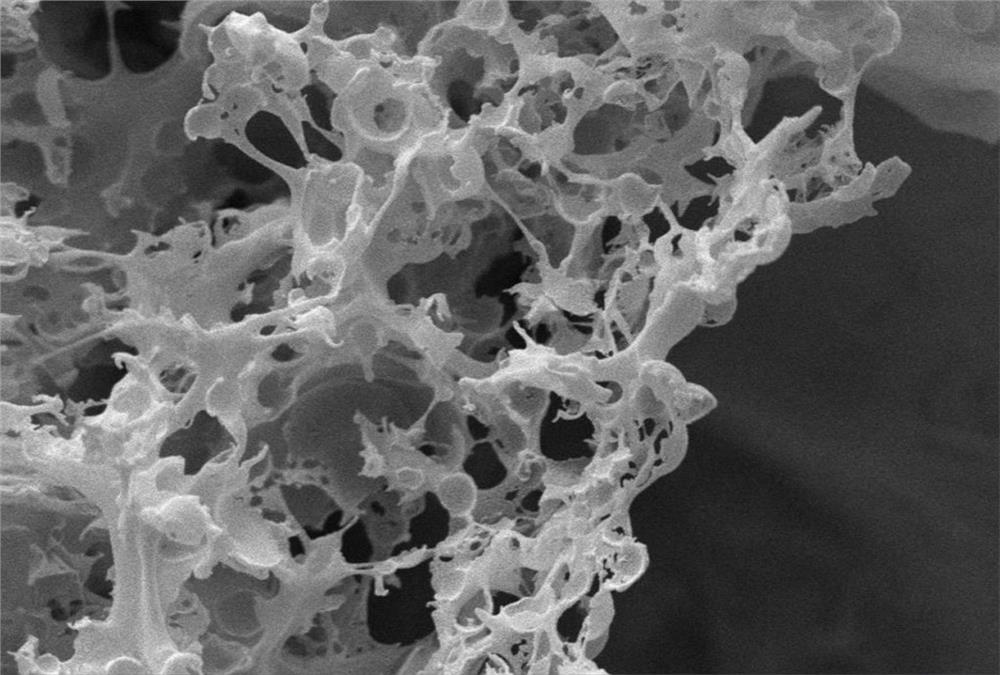

Preparation method of three-dimensional porous carbon aerogel material and application of three-dimensional porous carbon aerogel material in lithium-sulfur battery

ActiveCN112010279ARich hierarchical pore structureImprove conductivityPositive electrodesCarbon preparation/purificationElectrical batteryPorous carbon

The invention belongs to the technical field of lithium-sulfur batteries, and particularly relates to a preparation method of a three-dimensional porous carbon aerogel material. The preparation methodcomprises the following steps: (1) adding melamine and triethanolamine into a formaldehyde aqueous solution to prepare a melamine-formaldehyde prepolymer, (2) adding lignin into water, firstly adjusting the pH value to fully dissolve the lignin, and then adjusting the pH value to separate out the lignin in the form of nanoparticles, (3) uniformly mixing hydrophilic silicon dioxide with the solutions obtained in the previous two steps, (4) slowly adding methylbenzene into the solution obtained in the step (3) to obtain emulsion, polymerizing the emulsion into hard gel, and soaking the hard gelin ethanol to replace an inner phase, and (5) sintering at high temperature, etching off silicon dioxide by using hydrofluoric acid, and drying. The method is simple, the production cost is low, andthe prepared carbon aerogel material has a three-dimensional network and a hierarchical pore structure, is applied to a lithium-sulfur battery positive electrode, can realize sulfur fixation and catalytic action while enhancing sulfur conductivity, realizes high sulfur load, can greatly improve the cycling stability, rate capability and coulombic efficiency of the lithium-sulfur battery positive electrode, and has relatively high practical application value.

Owner:SOUTH CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com