Preparation method of lithium-sulfur battery positive electrode

A lithium-sulfur battery and cathode technology, which is applied in the field of preparation of lithium-sulfur battery cathodes, can solve the problems of surface tension and volume shrinkage electrode cracks, dilute the theoretical energy density of lithium-sulfur batteries, and reduce the volumetric energy density of lithium-sulfur batteries. Avoid local agglomeration of materials, good electrode structure and compositional homogeneity, and promote the effect of dissolution and reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of lithium-sulfur battery cathode provided by the invention comprises the following steps:

[0035] Step 1, uniformly mixing the active material sulfur, conductive agent, and binder to obtain a mixture, then adding a dispersing solvent to the mixture and mixing uniformly to obtain an electrode slurry;

[0036] Step 2, uniformly coating the electrode slurry on the positive electrode current collector to obtain a wet electrode coated with the slurry;

[0037] Step 3, placing the wet electrode coated with the slurry in a low temperature environment of -80°C to -5°C and freezing it for 1h to 5h until the wet electrode is frozen and formed, so that the dispersion solvent in the wet electrode is solidified and crystallized to obtain a solidified electrode;

[0038] Step 4, placing the coagulation electrode in a vacuum environment with a vacuum degree of 0.1 Pa to 100 Pa for 1 h to 5 h to sublimate the ice crystals in the solid phase of the coagulation ele...

Embodiment 1

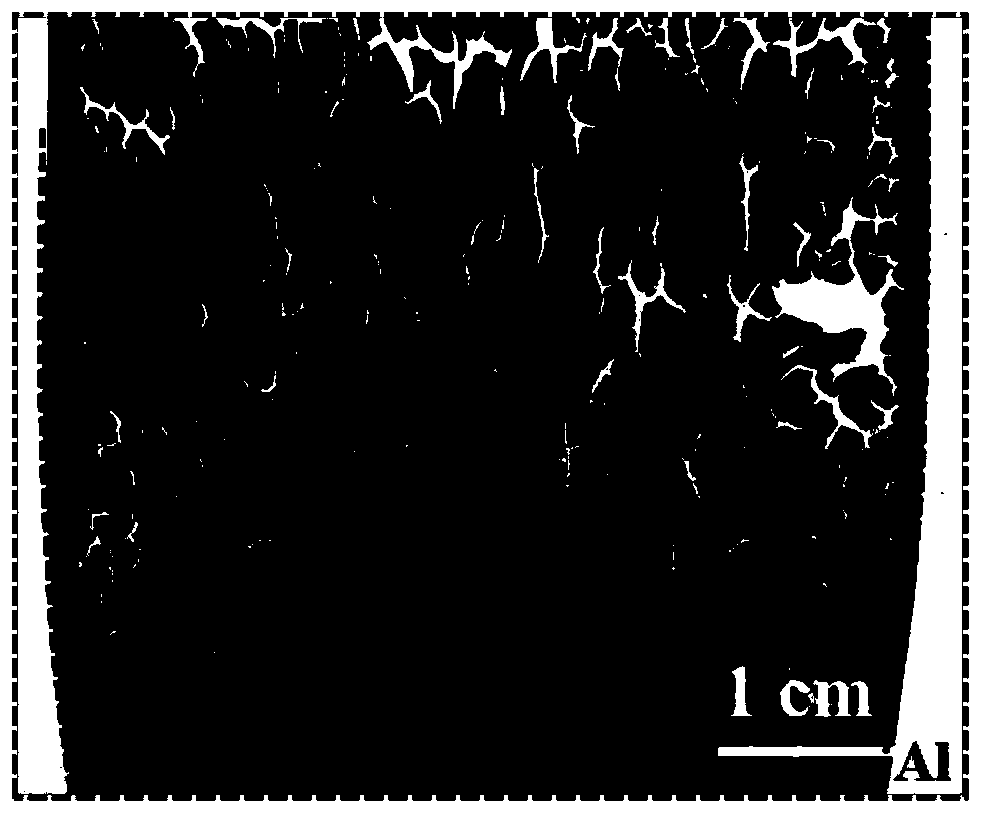

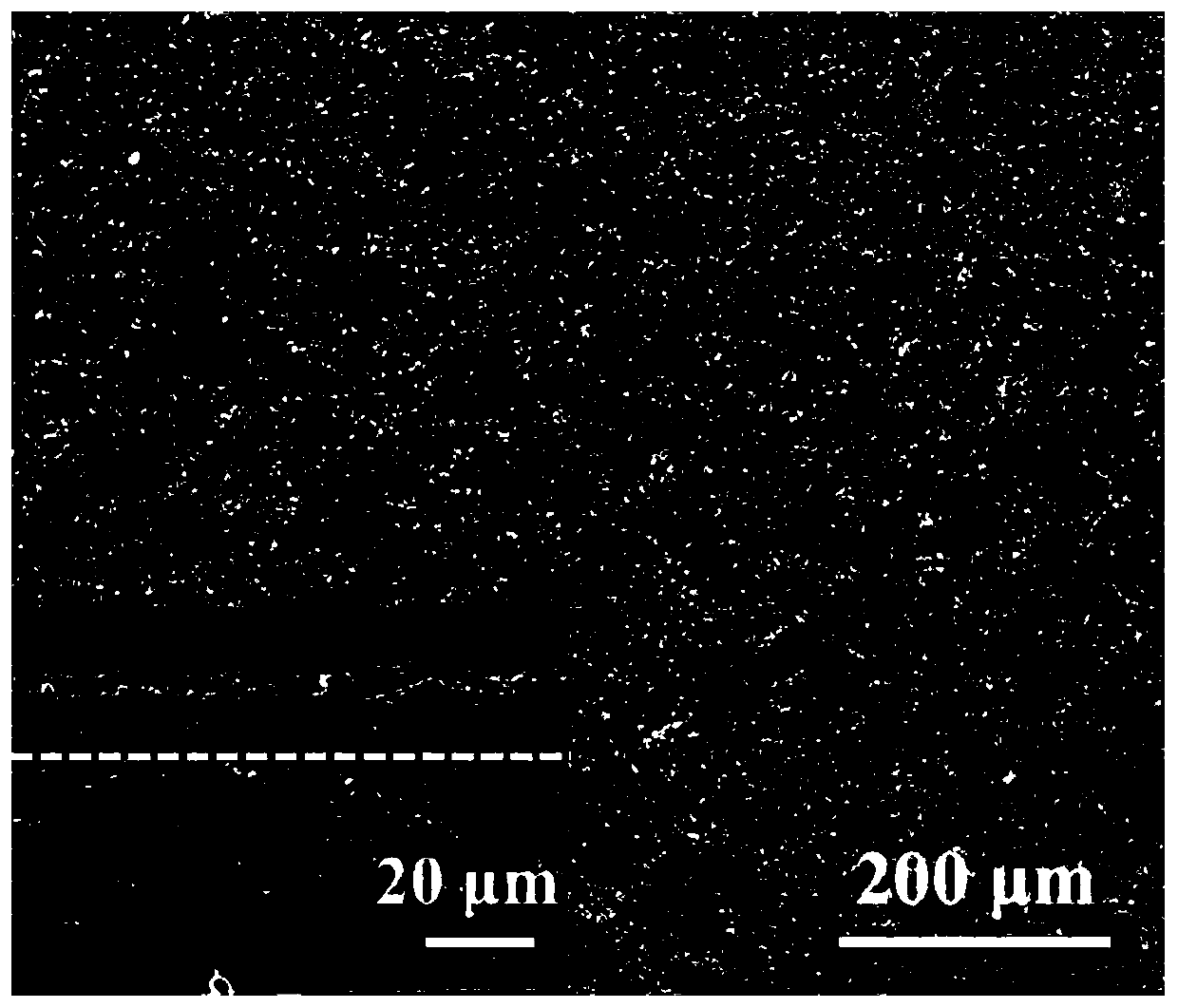

[0055] Mix 2g commercial sublimated sulfur powder, 0.53g Ketjen black (ECP 200JD), 2.66g styrene-butadiene rubber and carboxymethyl cellulose mixed binder aqueous solution (the mass ratio of SBR and CMC is 1:1, the binder aqueous solution is solid Phase content is 5%), and successively add 50ml ball mill tank (sulfur, Ketjen black, binder mass ratio is 75:20:5), then add appropriate amount of ball mill beads and 8g water therein, then at 350 rpm The ball milled at a high speed for 2 hours, and then the evenly milled electrode slurry was evenly coated on the aluminum foil of the current collector with an automatic coating machine, and the coating thickness was controlled at 200 microns to obtain a wet electrode, and then the prepared wet electrode was quickly The electrode is placed in a freezing environment of minus 40 degrees to solidify the water solvent into ice crystals. The freezing time is 2 hours. Finally, the frozen solidified electrode is taken out and placed in a vacu...

Embodiment 2

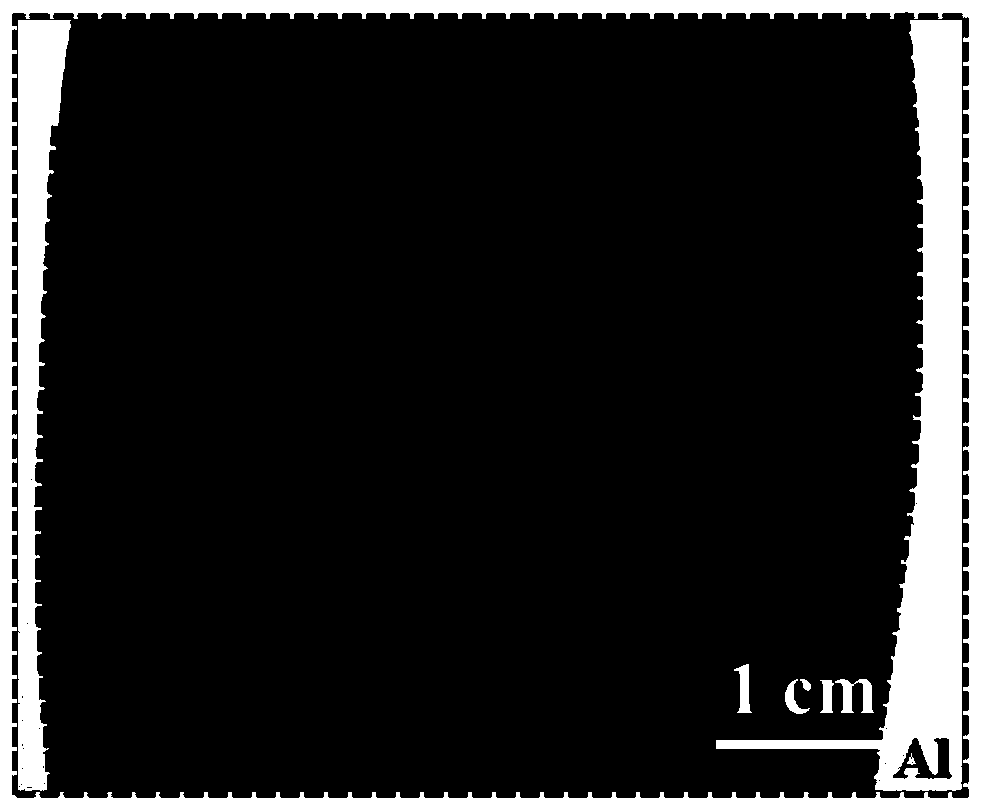

[0065] Add 2g commercial sublimated sulfur powder, 0.875g Ketjen black (ECP 600JD), 1.66g LA133 binder aqueous solution (the solid phase content of the binder aqueous solution is 15%) into a 50ml ball mill jar (sulfur, Ketjen black, binder The agent mass ratio is 64:28:8), and then add appropriate amount of ball milling beads and 8g of water, and then ball mill at a speed of 350 rpm for 2 hours, and then use an automatic coating machine to obtain the uniform electrode slurry obtained by ball milling Evenly and evenly coated on the aluminum foil of the current collector, the coating thickness is controlled at 300 microns to obtain a wet electrode, and then the prepared wet electrode is quickly placed in a freezing environment of minus 30 degrees to solidify the water solvent into ice crystals, and the freezing time is 2 hours, and finally take out the frozen solidified electrode and place it in a vacuum environment with a vacuum degree of 0.1 Pa for 2 hours to sublimate the prev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com