Positive electrode material for lithium-sulfur secondary battery and preparation method of positive electrode material

A lithium-sulfur secondary battery and cathode material technology, which is applied in battery electrodes, lithium storage batteries, non-aqueous electrolyte storage batteries, etc., can solve the problem of reducing the utilization rate of cathode active materials. cycle performance and other issues, to achieve the effects of good cycle performance and rate performance, long service life and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

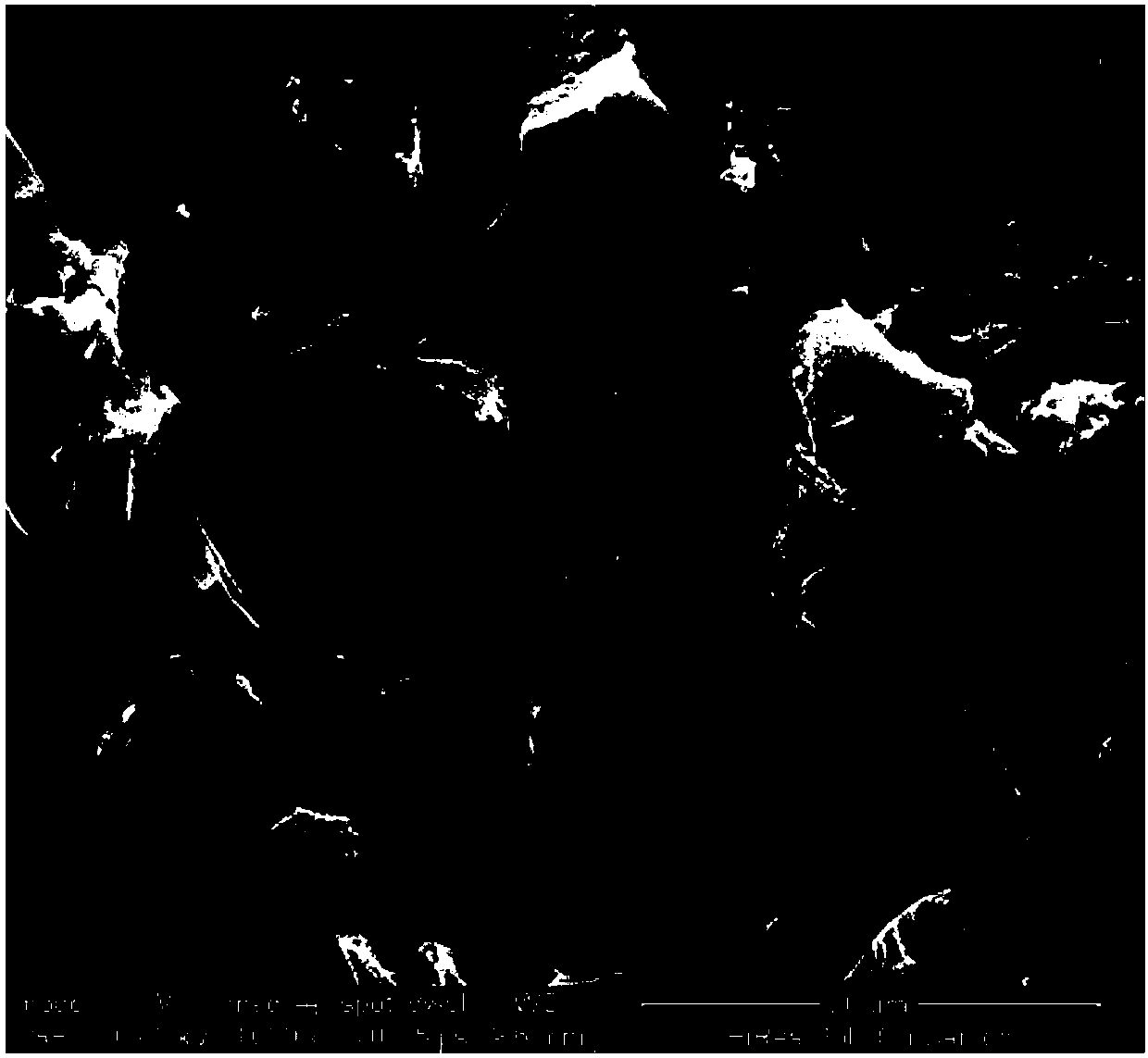

[0027] Cut the waste mangosteen skin into small pieces, wash it with deionized water, and dry it in a blast drying oven at a temperature of 110°C for 12 hours. The dried product is pre-carbonized and the temperature is pre-carbonized. The temperature is 500°C, the reactor is filled with nitrogen (purity above 99%), and the carbonization reaction time is 3 hours. Then, the pre-carbonized product and the potassium hydroxide aqueous solution are mixed, and the quality of the pre-carbonized mangosteen bark and potassium hydroxide The ratio is 1:4. After fully stirring and mixing, first heat it on a magnetic stirrer with heating function to evaporate most of the water, and then place it in a blast drying oven at a temperature of 110°C for 12 hours. Then, The mixture of pre-carbonized product and potassium hydroxide is transferred to a tube furnace, heated to 800°C in a nitrogen atmosphere (purity above 99%) and kept for 3 hours, naturally cooled to room temperature, and washed with h...

Embodiment 2

[0032] The preparation method is similar to that of Example 1, except that:

[0033] (1) The temperature used for pre-carbonization is 300℃, and the time is 7h;

[0034] (2) In potassium hydroxide activation, the mass ratio of potassium hydroxide to pre-carbonized mangosteen bark is 3:1; the activation temperature is 600°C, and the activation time is 5h;

[0035] (3) The mass ratio of activated carbon material carrier to sulfur element is 6:4. The grinding is carried out in a ball milling tank. The rotating speed is 200rpm and the grinding time is 3h. The ground mixture is placed in a vacuum environment at a temperature of 140℃. The cathode material can be obtained by keeping the temperature for 24 hours and cooling.

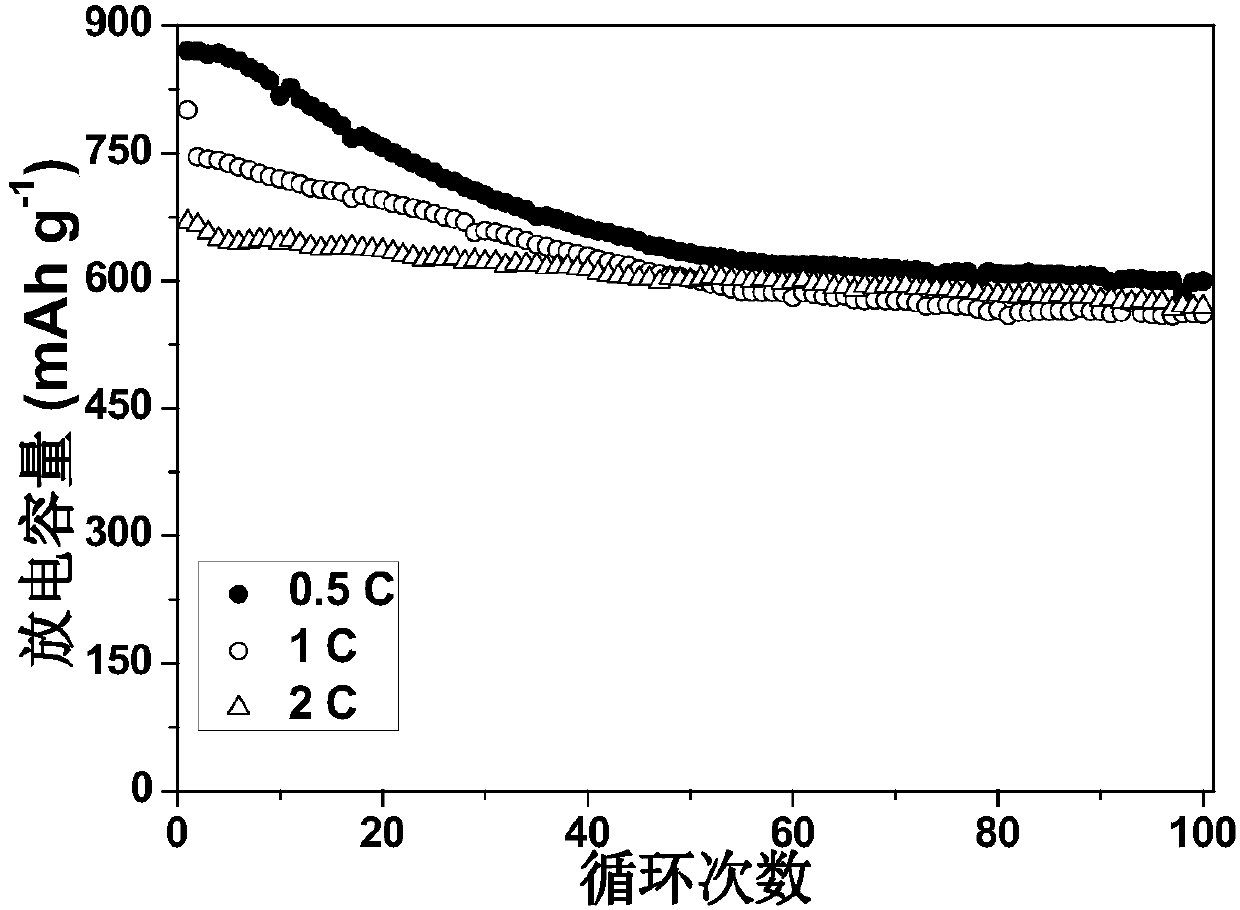

[0036] The positive electrode material obtained above was made into electrode sheets according to the same method as in Example 1, and then installed in a lithium-sulfur secondary battery. It was verified that the positive electrode material has a high specific discharg...

Embodiment 3

[0038] The preparation method is similar to that of Example 1, except that:

[0039] (1) The temperature used for pre-carbonization is 500℃, and the time is 1h;

[0040] (2) In potassium hydroxide activation, the mass ratio of potassium hydroxide to pre-carbonized mangosteen bark is 5:1; the activation temperature is 900°C, and the activation time is 1h;

[0041] (3) The mass ratio of the activated carbon material carrier to the sulfur element is 2:8, and the grinding is carried out in a ball milling tank with a rotation speed of 500 rpm and a grinding time of 0.5 h. The ground mixture is placed in a vacuum environment at 200 ℃ The positive electrode material can be obtained by keeping the temperature for 6 hours and cooling.

[0042] The positive electrode material obtained above was made into electrode sheets according to the same method as in Example 1, and then installed in a lithium-sulfur secondary battery. It was verified that the positive electrode material has a high specific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com