Controllable preparation method of nano cathode material for lithium-sulfur primary battery

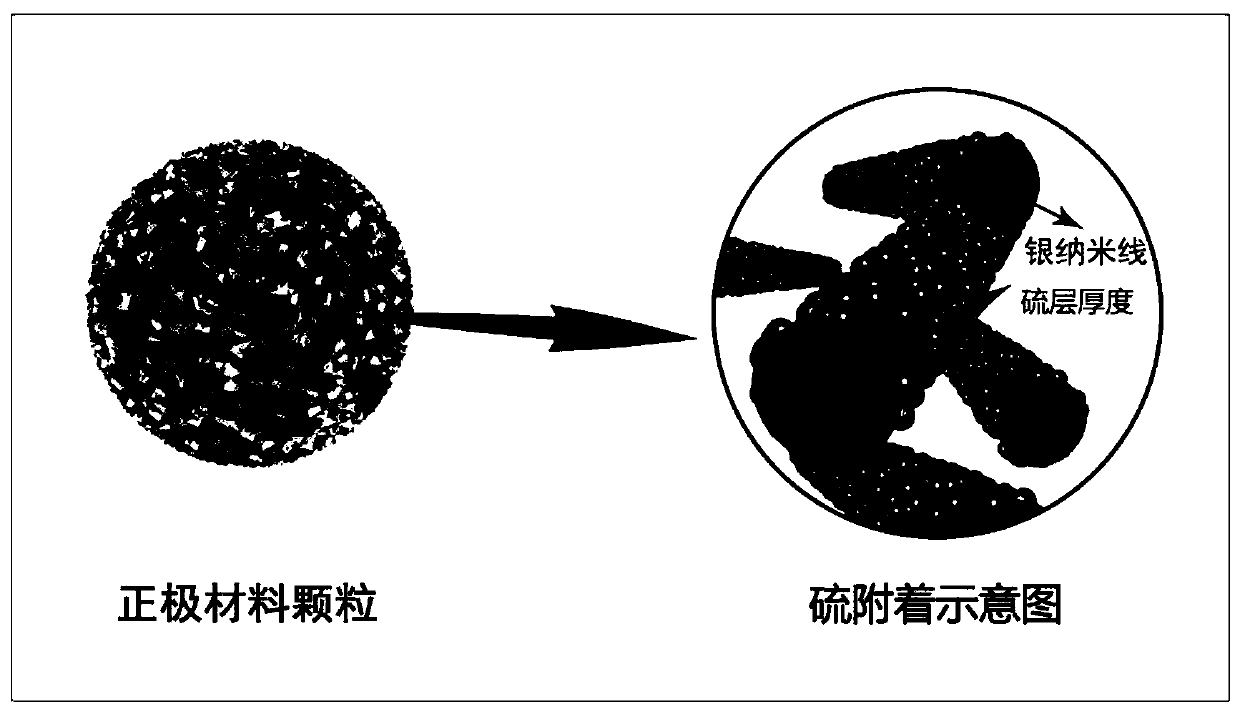

A cathode material and battery technology, which is applied in the field of controllable preparation of nano-anode materials for lithium-sulfur primary batteries, can solve the problems of short macroscopic size, large diameter of silver nanowires, and low specific capacity of batteries, and achieve high sulfur loading, Morphology controllable composition, structure stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

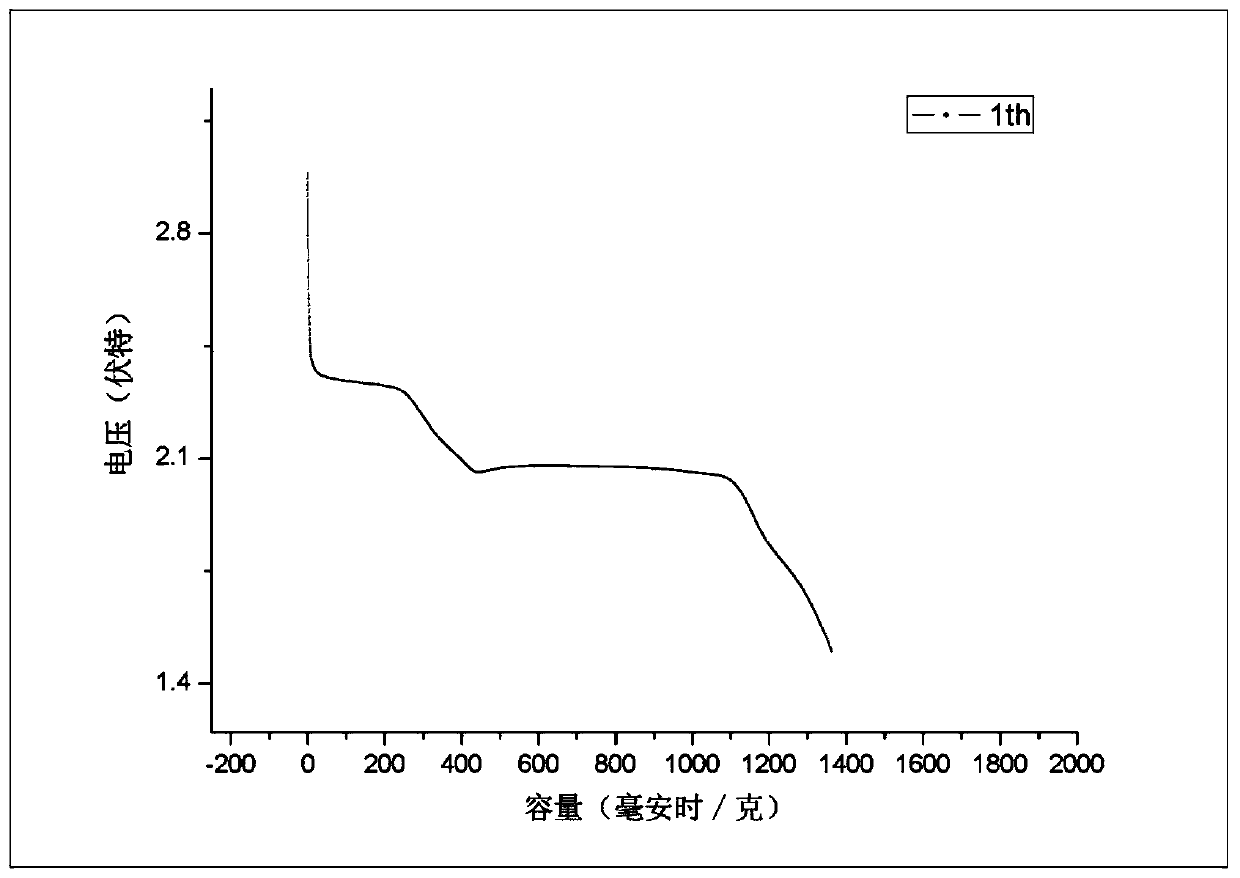

Embodiment 1

[0037] The first step is to prepare silver nanowires

[0038] Dissolve 0.1g of PVP in 6.2g of ethylene glycol to form a solution, and write it as solution A, and dissolve 1mg of NaCl in 3g of ethylene glycol to form a solution, and write it as solution B; dissolve 0.12g of silver nitrate in 6.2g of ethylene glycol The solution was prepared into solution, which was marked as solution C; put A in a round-bottomed flask, drip solution B into solution A under stirring conditions of 150℃ and 300rpm, and add 1 drop of silver nitrate solution, and then immediately lower the temperature to 100℃, and add the remaining solution C dropwise at a rate of 1 drop per second; continue the reaction for 6 hours until the solution becomes silver-gray and opaque to complete the reaction; the reaction solution after the reaction is completed and the acetone in a volume ratio of 1:4 Mix in proportion and centrifuge, then discard the supernatant; mix the product and the aqueous solution of N,N-dimethyl...

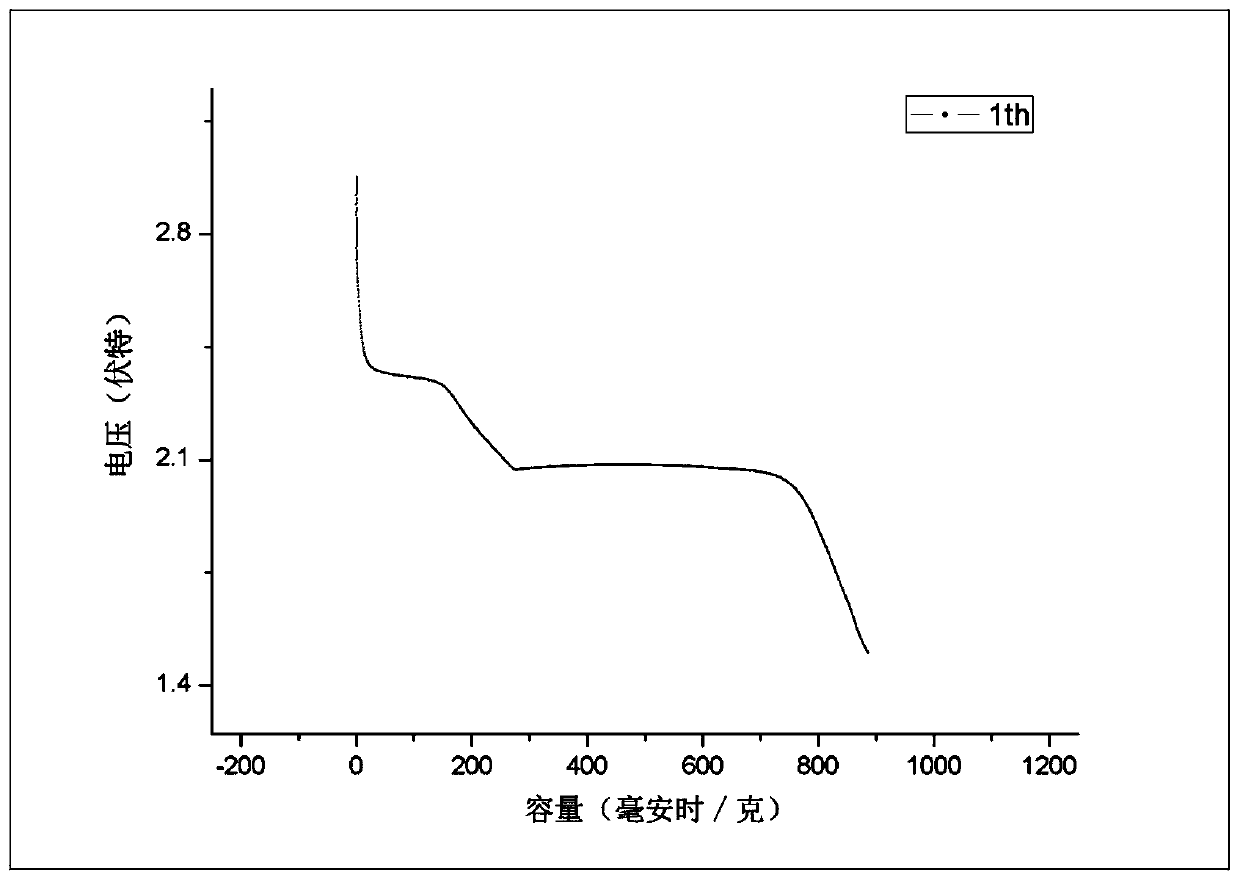

Embodiment 2

[0047] Others are the same as in Example 1, except that in the second step, the mass ratio of silver nanowires, absolute ethanol and nano-sulfur powder is 1:1:3.

[0048] image 3 When the silver nanowire / sulfur composite material prepared in this embodiment is used as the positive electrode of a lithium-sulfur battery, the first constant current discharge curve at a current density of 0.1C. At a discharge current density of 0.1C, the first constant current discharge specific capacity of the battery can still reach 890mAh / g, and the sulfur content is 60wt.%. Compared with Example 1, although the sulfur utilization efficiency has dropped by 28%, and the same The consumption of elemental lithium increased by 39%, but the consumption of silver nanowires decreased by 53.5%.

Embodiment 3

[0050] Others are the same as in Example 1, except that the first step is the addition of 0.5 g of PVP. The increase in the amount of PVP makes the diameter of the silver nanowires prepared in this embodiment smaller than that in Example 1, but the prepared silver nanowires are also shorter. The performance of the positive electrode material prepared in this example is close to that of example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com