Method for preparing lithium-sulfur battery cathode material

A technology for cathode materials and lithium-sulfur batteries, applied in the field of electrodes, can solve the problems of poor conductivity of cathode materials, low utilization rate of active materials, shuttle effect, etc., and achieve the goal of increasing sulfur loading, stabilizing the production process, and inhibiting the shuttle effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The first step, the preparation of polystyrene pellets:

[0040] Preparation of polystyrene pellets by emulsion polymerization;

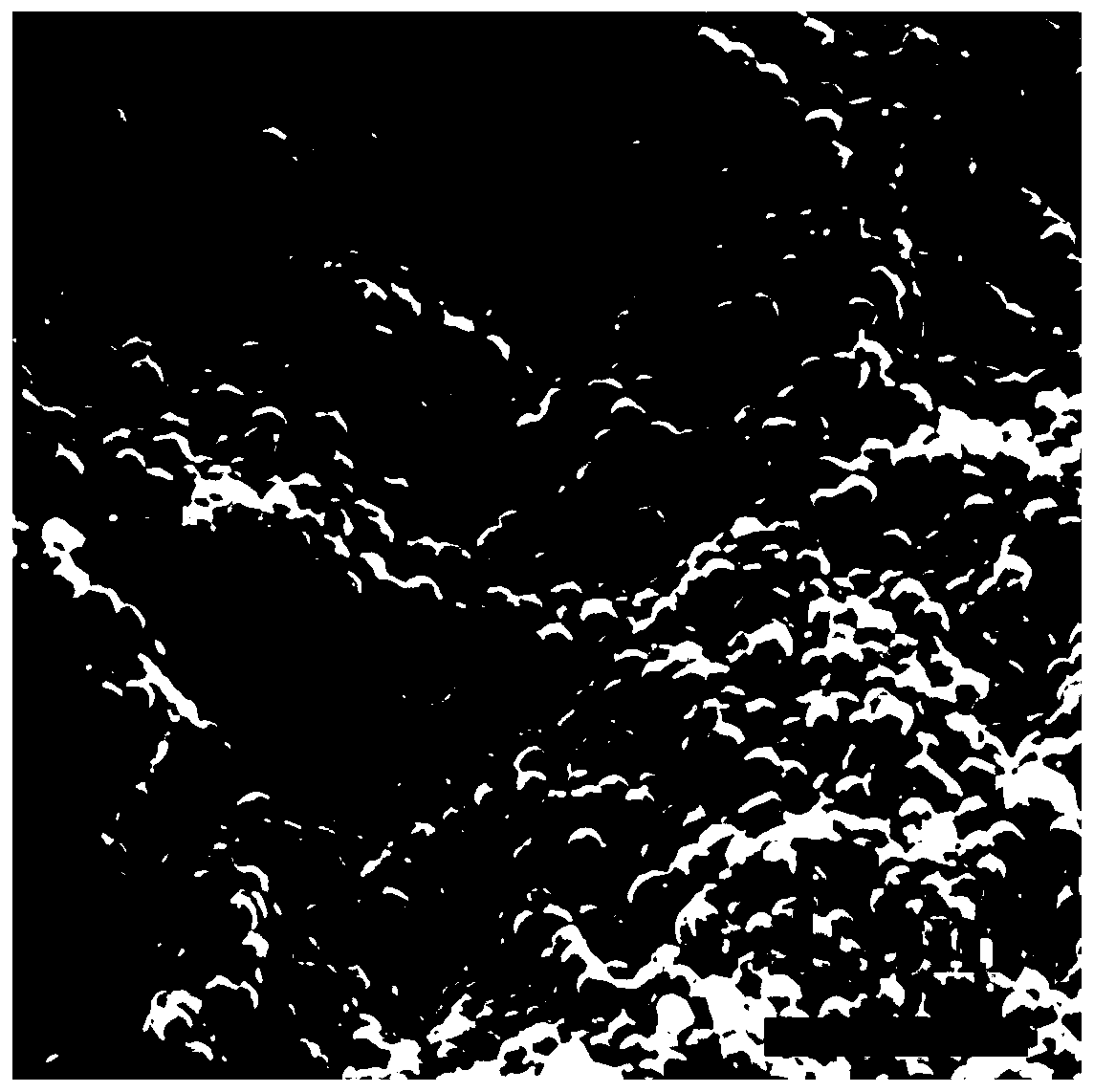

[0041] figure 1 It is a scanning electron micrograph of the polystyrene pellets prepared in this example. The figure shows that the polystyrene spheres are arranged in a three-dimensional order and uniformly, and the diameter of the spheres is about 100nm.

[0042] The second step, the preparation of three-dimensional ordered titania framework:

[0043] First add sulfuric acid with a mass percent concentration of 3% into anhydrous methanol, then add tetrabutyl titanate to prepare a solution, and the amounts of the three are anhydrous methanol: tetrabutyl titanate: mass percent concentration is 3% sulfuric acid = 5: 5: 1, the solution thus prepared is dripped with the polystyrene pellets prepared in the first step to 3 mL: 1 mg, and the solution is soaked in a ratio of 1 mg. Use a mechanical pump to vacuum filter the filter flask to a vacu...

Embodiment 2

[0055] The first step, the preparation of polystyrene pellets:

[0056] Preparation of polystyrene pellets by emulsion polymerization;

[0057] The second step, the preparation of three-dimensional ordered titania framework:

[0058]First add sulfuric acid with a mass percent concentration of 3% into anhydrous methanol, then add tetrabutyl titanate to prepare a solution, and the amounts of the three are anhydrous methanol: tetrabutyl titanate: mass percent concentration is 3% sulfuric acid = 4: 4: 1, the solution thus prepared is dripped with the polystyrene pellets prepared in the first step to 1 mL: 1 mg for solution impregnation operation, the specific method is, in a fume hood Use a mechanical pump to vacuum filter the filter bottle to a vacuum degree of -0.08MPa, add the solution thus prepared dropwise to the polystyrene pellets prepared in the first step above, and add dropwise while suction filtering, dropwise The acceleration rate is 3 drops / second. The polystyrene p...

Embodiment 3

[0066] The first step, the preparation of polystyrene pellets:

[0067] Preparation of polystyrene pellets by emulsion polymerization;

[0068] The second step, the preparation of three-dimensional ordered titania framework:

[0069] First add sulfuric acid with a mass percent concentration of 3% into anhydrous methanol, then add tetrabutyl titanate to prepare a solution, and the amounts of the three are anhydrous methanol: tetrabutyl titanate: mass percent concentration is 3% sulfuric acid = 6: 6: 1, the solution thus prepared is dripped with the polystyrene pellets prepared in the first step to 2 mL: 1 mg for solution impregnation operation, the specific method is, in a fume hood Use a mechanical pump to vacuum filter the filter flask to a vacuum degree of -0.09MPa, add the solution thus prepared dropwise to the polystyrene pellets prepared in the first step above, and add dropwise while suction filtering, dropwise The acceleration rate is 1 drop / second. The polystyrene pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com