Lithium sulphur battery anode material and preparation method thereof

A cathode material, a technology for lithium-sulfur batteries, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc. It is not easy to scale production and other problems, to achieve the effect of speeding up diffusion, buffering volume expansion, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

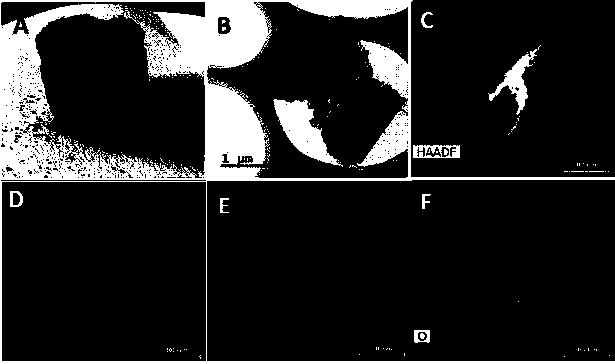

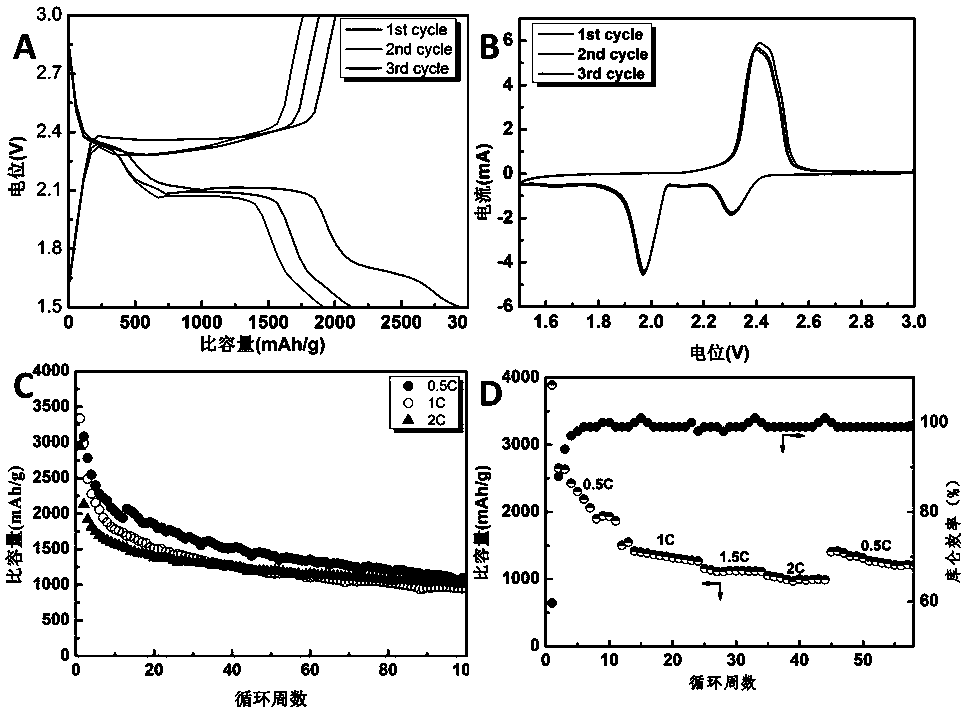

[0026] The preparation method of the positive electrode material of the lithium-sulfur battery is to form a gel by online reducing the mixture of graphene oxide sol and sulfur sol, and then freeze-dry to obtain the composite material of reduced graphene oxide airgel nested sulfur nanoparticles with a three-dimensional network structure Specifically, graphene oxide is used as a starting material to prepare a mixed sol of graphene oxide and sulfur, and an online reduction method at room temperature is used to prepare a reduced graphene oxide gel-coated sulfur nanoparticle composite material, and the internally coated sulfur nanoparticle composite is removed by freeze-drying. Solvent, obtained reduced graphene oxide airgel nested sulfur nanoparticle composite material;

[0027] Among them, graphene oxide is graphene oxide formed by chemical oxidation and exfoliation of graphite powder, which contains many carboxyl and hydroxyl functional groups on its surface; on this basis, some ...

Embodiment 1

[0038] The reduced graphene oxide airgel-embedded sulfur nanoparticle composite material with a three-dimensional network structure was prepared by the following steps:

[0039] (1) Using graphite as raw material, prepare pure graphene oxide flakes by oxidizing and exfoliating graphite using the relatively mature Hummer technology;

[0040] (2) Prepare sulfur sol by peptization method, that is, dissolve sublimated sulfur in ethanol solvent to form solution a, and then disperse the graphene oxide flakes prepared in the above step (1) in distilled water at a concentration of 0.1 mg / mL, record Be solution b, then add solution a dropwise to solution b under stirring conditions to form graphene oxide sulfur mixed sol;

[0041] (3) Using a hydrazine hydrate reducing agent, inject 1 ul / ml reducing agent into the graphene oxide sulfur mixed sol in the above step (2) with a syringe, so that the graphene oxide in the mixed sol is partially reduced to form reduced graphite oxide Graphen...

Embodiment 2

[0046] The reduced graphene oxide airgel-embedded sulfur nanoparticle composite material with a three-dimensional network structure was prepared by the following steps:

[0047] (1) Using graphite as raw material, prepare pure graphene oxide flakes by oxidizing and exfoliating graphite using the relatively mature Hummer technology;

[0048] (2) Prepare sulfur sol by peptization method, that is, dissolve sublimated sulfur in ethanol solvent to form solution a, and then disperse the graphene oxide flakes prepared in the above step (1) in distilled water at a concentration of 0.5 mg / mL, record Be solution b, then add solution a dropwise to solution b under stirring conditions to form graphene oxide sulfur mixed sol;

[0049] (3) Using ammonia water as a reducing agent, inject 0.5ul / ml reducing agent into the graphene oxide sulfur mixed sol in the above step (2), so that the graphene oxide in the mixed sol is partially reduced to form a reduced graphene oxide gel. Gel, solvent wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com