High temperature self-repairing conductive silver adhesive and preparation method thereof

A technology of conductive silver glue and self-healing microcapsules, which is applied in the field of conductive glue, can solve the problems of large devices, few self-healing conductive glue patents, and failure of conductive glue, so as to achieve low preparation cost and long-term use effect , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

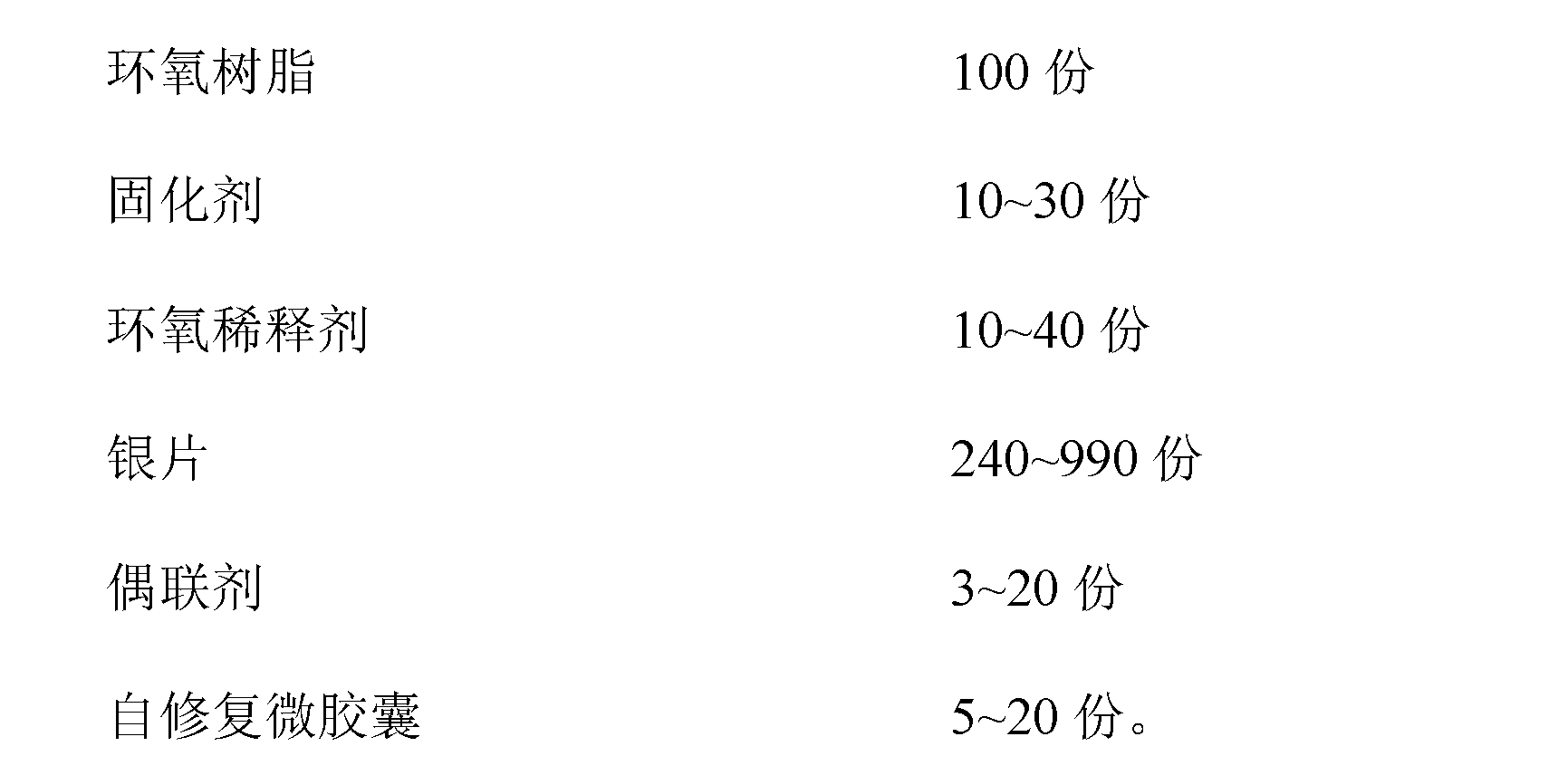

Method used

Image

Examples

Embodiment 1

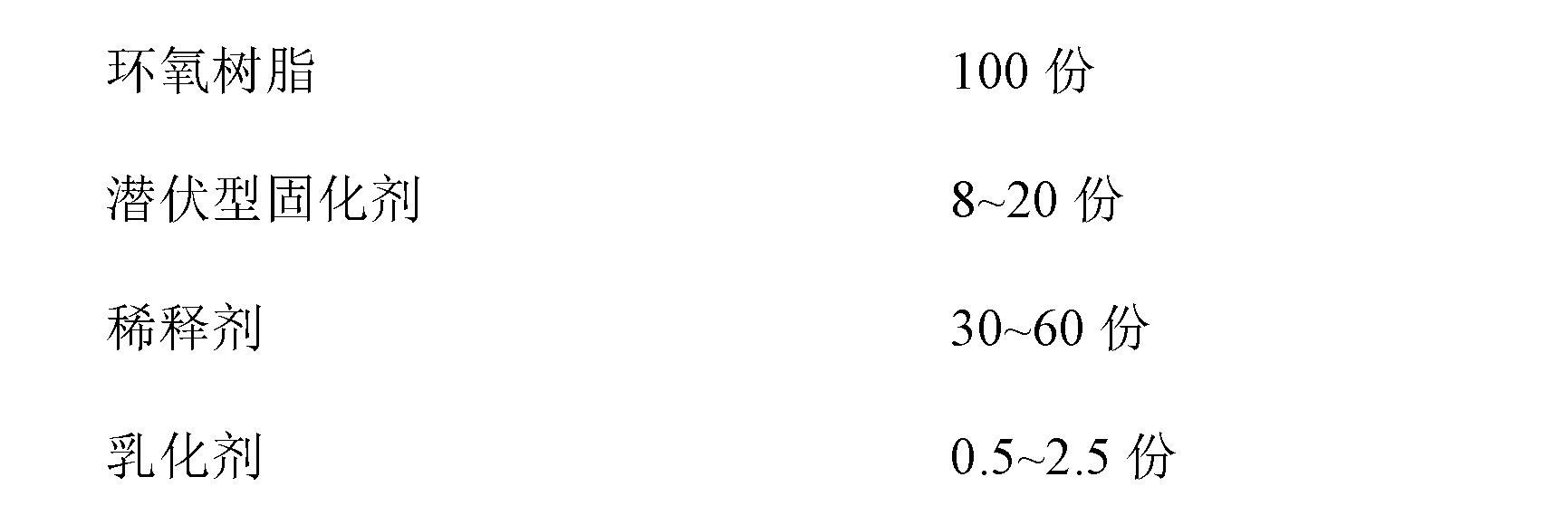

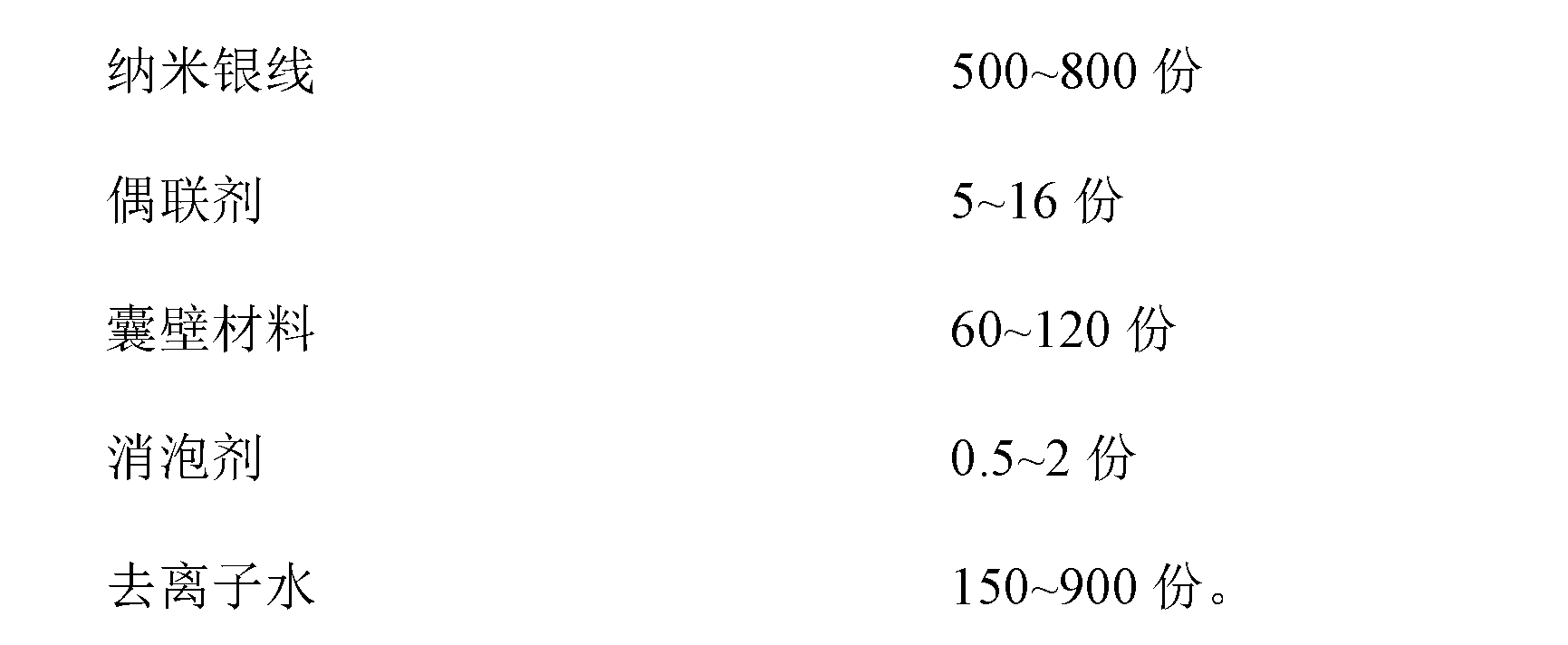

[0040] (1) Preparation of self-healing microcapsules

[0041] According to the components specified in Example 1 in Table 1, the epoxy resin containing diluent and latent curing agent was mixed with emulsifier, heated and stirred in a water bath at 50° C., and the stirring speed was 1000 rpm. Slowly add deionized water dropwise to the solution, stir for 1~2h and then ultrasonically disperse for 10min to form an epoxy resin emulsion. Add the dried silver nanowires, coupling agent, and defoamer into the epoxy resin emulsion, and stir at a stirring speed of 1000 rpm for 10 minutes to form a uniform epoxy resin-silver nanowire emulsion. The prepolymerization solution of the capsule wall material (the ratio of cyanuric ah, formaldehyde, and deionized water is 7:11:12) is adjusted to a pH value of 8~9 with NaOH solution in a flask, and stirred at a stirring speed of 1000rpm for 1h. Add 120g of epoxy resin-nano-silver wire emulsion to 20g of the above-mentioned capsule wall material...

Embodiment 2

[0045] (1) Preparation of self-healing microcapsules

[0046] According to the components specified in Example 2 in Table 1, the epoxy resin containing diluent and latent curing agent was mixed with emulsifier, heated and stirred in a water bath at 60° C., and the stirring speed was 1500 rpm. Slowly add deionized water dropwise to the solution, stir for 1.5 h and then ultrasonically disperse for 25 min to form an epoxy resin emulsion. Add the dried silver nanowires, coupling agent and defoamer into the epoxy resin emulsion, and stir at a stirring speed of 1500rpm for 25min to form a uniform epoxy resin-silver nanowire emulsion. The wall material prepolymerization solution (the ratio of urea to 37% formaldehyde solution is 1:1.5) was adjusted to pH 7.5~11.8 with NaOH solution in a flask, and stirred at 70°C for 3h. Add 130g of epoxy resin-nano-silver wire emulsion to 20g of the above-mentioned capsule wall material prepolymerization solution, adjust the pH value to 1~5, heat t...

Embodiment 3

[0050] (1) Preparation of self-healing microcapsules

[0051] According to the components specified in Example 3 in Table 1, the epoxy resin containing the diluent and the latent curing agent was mixed with the emulsifier, heated and stirred in a water bath at 70° C., and the stirring speed was 2000 rpm. Slowly add deionized water dropwise to the solution, stir for 2 hours and then ultrasonically disperse for 40 minutes to form an epoxy resin emulsion. Add the dried silver nanowires, coupling agent, and defoamer into the epoxy resin emulsion, and stir at a stirring speed of 2000 rpm for 25 minutes to form a uniform epoxy resin-silver nanowire emulsion. The prepolymerization solution of the capsule wall material (the ratio of styrene, divinylbenzene and benzoyl peroxide solution is 1:1~3) is adjusted in the flask to a pH value of 6~8. Add 140 g of epoxy resin-nano silver wire emulsion to 20 g of the above-mentioned capsule wall material pre-polymerization liquid, heat to 75° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com