Ultra-wide-span roller guide rail structure

A technology of roller guide rail and span, applied in the direction of bearings, linear motion bearings, bearing components, etc., can solve the problems of large support table, affecting the installation and use of equipment, etc., to improve the use capacity, ensure normal use, and reduce self-load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

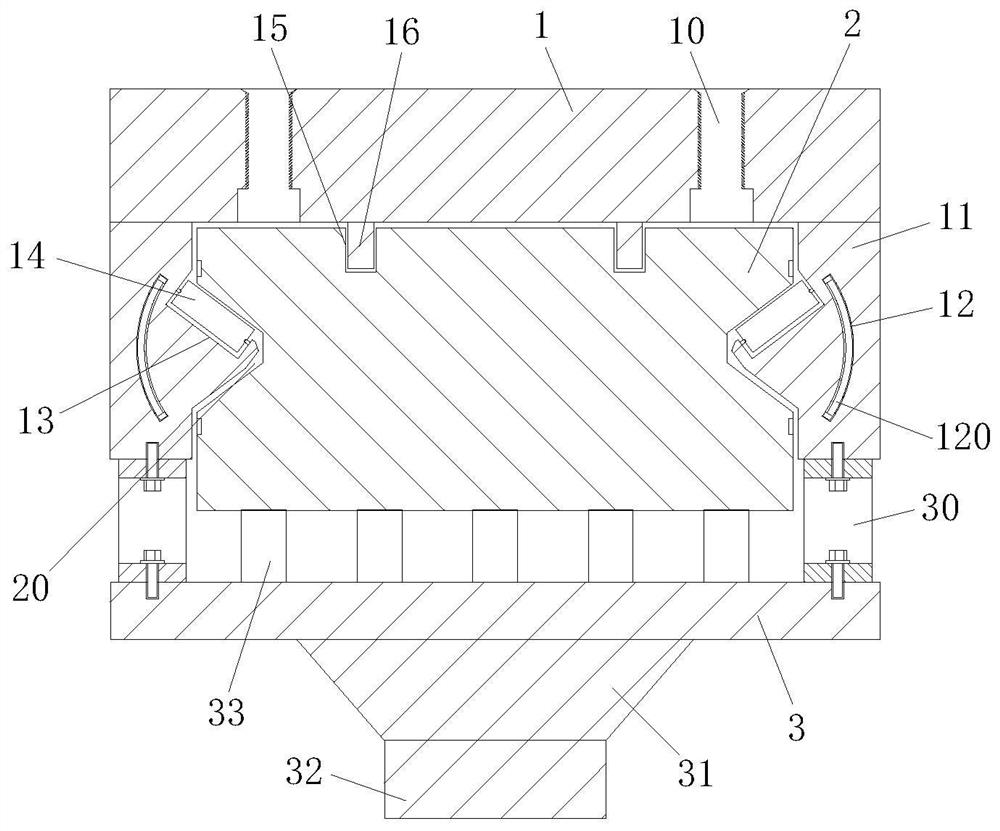

[0027] Example 1, please refer to Figure 1~3 , an ultra-wide-span roller guide rail structure, comprising a sliding body 1, a rail body 2 supporting the sliding body 1, and a fixing frame 3 stably supporting the rail body 2;

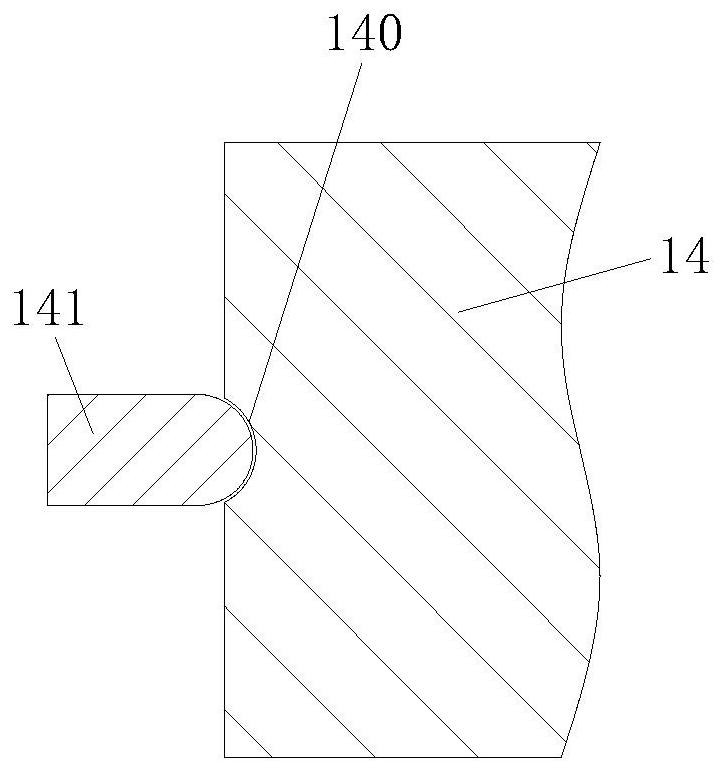

[0028] The sliding body 1 includes a rectangular parallelepiped fixed platform directly above the guide rail body 2, a side plate 11 and a sliding assembly. The side plate 11 is located on the left and right sides of the fixed platform and is integrally formed with the fixed platform. The top of the fixed platform is preset. There is a threaded mounting hole 10, and the upper bottom of the fixed platform is integrally formed with a fitting strip 16; the middle position of the side plate 11 is preset with a through groove 12; the sliding assembly includes a roller 14, and the inner position of the side plate 11 is A sinking groove 13 is preset, and the roller 14 is placed in the sinking groove 13;

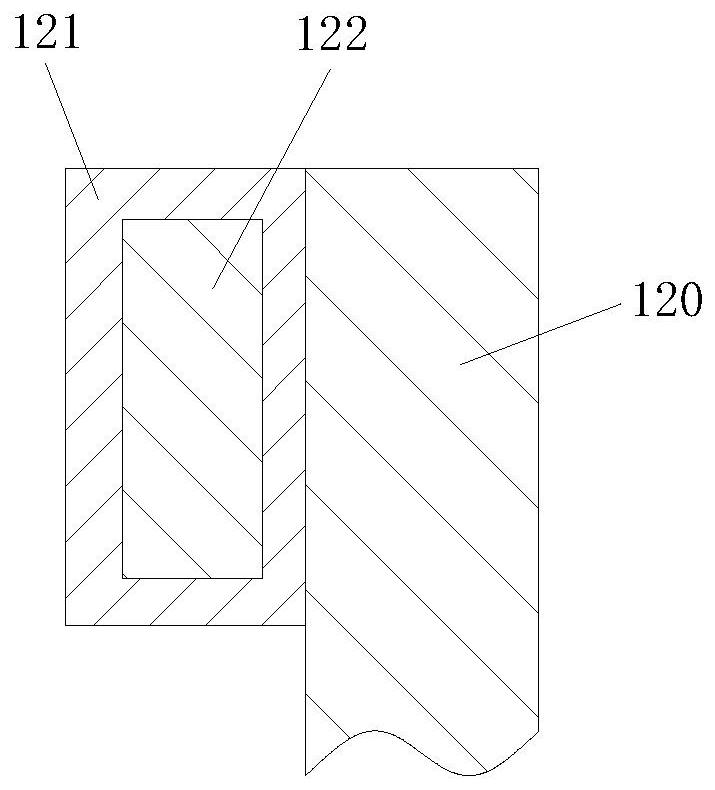

[0029] A dust-proof curtain 120 is worn in the through...

Embodiment 2

[0033] Example 2, please refer to Figure 1~5 , an ultra-wide-span roller guide rail structure, comprising a sliding body 1, a rail body 2 supporting the sliding body 1, and a fixing frame 3 stably supporting the rail body 2;

[0034] The sliding body 1 includes a rectangular parallelepiped fixed platform directly above the guide rail body 2, a side plate 11 and a sliding assembly. The side plate 11 is located on the left and right sides of the fixed platform and is integrally formed with the fixed platform. The top of the fixed platform is preset. There is a threaded mounting hole 10, and the upper bottom of the fixed platform is integrally formed with a fitting strip 16; the middle position of the side plate 11 is preset with a through groove 12; the sliding assembly includes a roller 14, and the inner position of the side plate 11 is A sinking groove 13 is preset, and the roller 14 is placed in the sinking groove 13;

[0035] A dust-proof curtain 120 is worn in the through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com