Automatic cutting device for non-woven fabric tube bank

An automatic cutting device and cutting device technology, applied in the field of machinery, can solve the problems of harmful gas smoke, short oxidation life of electric furnace wire, and affecting human health, etc., and achieve the effects of short response time, reduced manual cutting, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

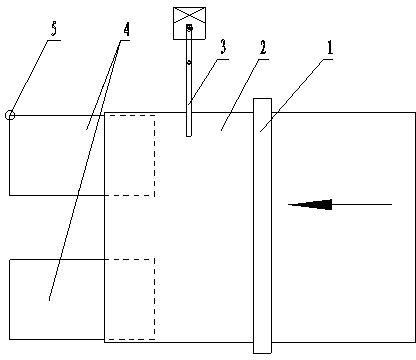

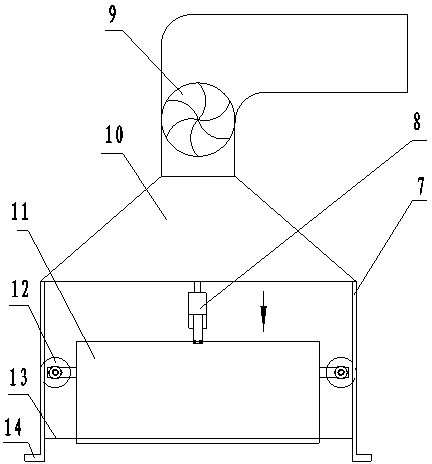

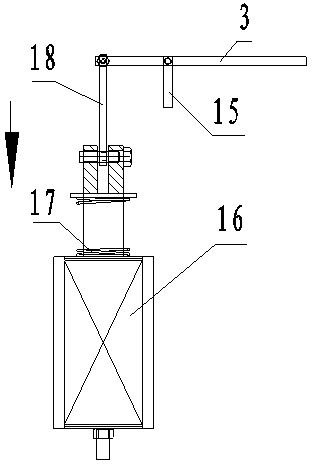

[0023] In the embodiments shown in 1 to 4, an automatic cutting device for non-woven fabric pipes includes a cutting device 1, a positioning cutting table 2, a pulling and telescopic device, and a pushing device. At the output end of the pipe of the molding machine, the cutting device 1 is composed of an electric heating cutter 11, a double-acting lifting cylinder 8, an induced draft fan 9, an air duct 10 and a cleaning plate 13. The cutting device 1 is installed on the bracket 14, and the bracket 14 is installed On the positioning cutting table 2, the guide wheel groove 7 is installed at the two ends of the support 14, the guide wheel 12 is installed at the two ends of the electrothermal cutting knife 11, and the guide wheel 12 is embedded in the guide wheel groove 7, and the guide wheel 12 is in the guide wheel groove 7 along the Reciprocating rotation, before work, the temperature of the electric cutting knife 11 is raised to 350°C, and within 15 seconds, the drawing telesco...

Embodiment 2

[0025] In the embodiments shown in 1 to 4, an automatic cutting device for non-woven fabric pipes includes a cutting device 1, a positioning cutting table 2, a pulling and telescopic device, and a pushing device. At the output end of the pipe of the molding machine, the cutting device 1 is composed of an electric heating cutter 11, a double-acting lifting cylinder 8, an induced draft fan 9, an air duct 10 and a cleaning plate 13. The cutting device 1 is installed on the bracket 14, and the bracket 14 is installed On the positioning cutting table 2, the guide wheel groove 7 is installed at the two ends of the support 14, the guide wheel 12 is installed at the two ends of the electrothermal cutting knife 11, and the guide wheel 12 is embedded in the guide wheel groove 7, and the guide wheel 12 is in the guide wheel groove 7 along the Reciprocating rotation, before work, first raise the temperature of the electric heating cutting knife 11 to 370 ° C, and use 16 seconds to draw the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com