Fully automatic tube bending and forming equipment

A fully automatic, body-folding technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of cutting labor costs and low processing efficiency, and achieve low processing costs, smooth bending process, and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

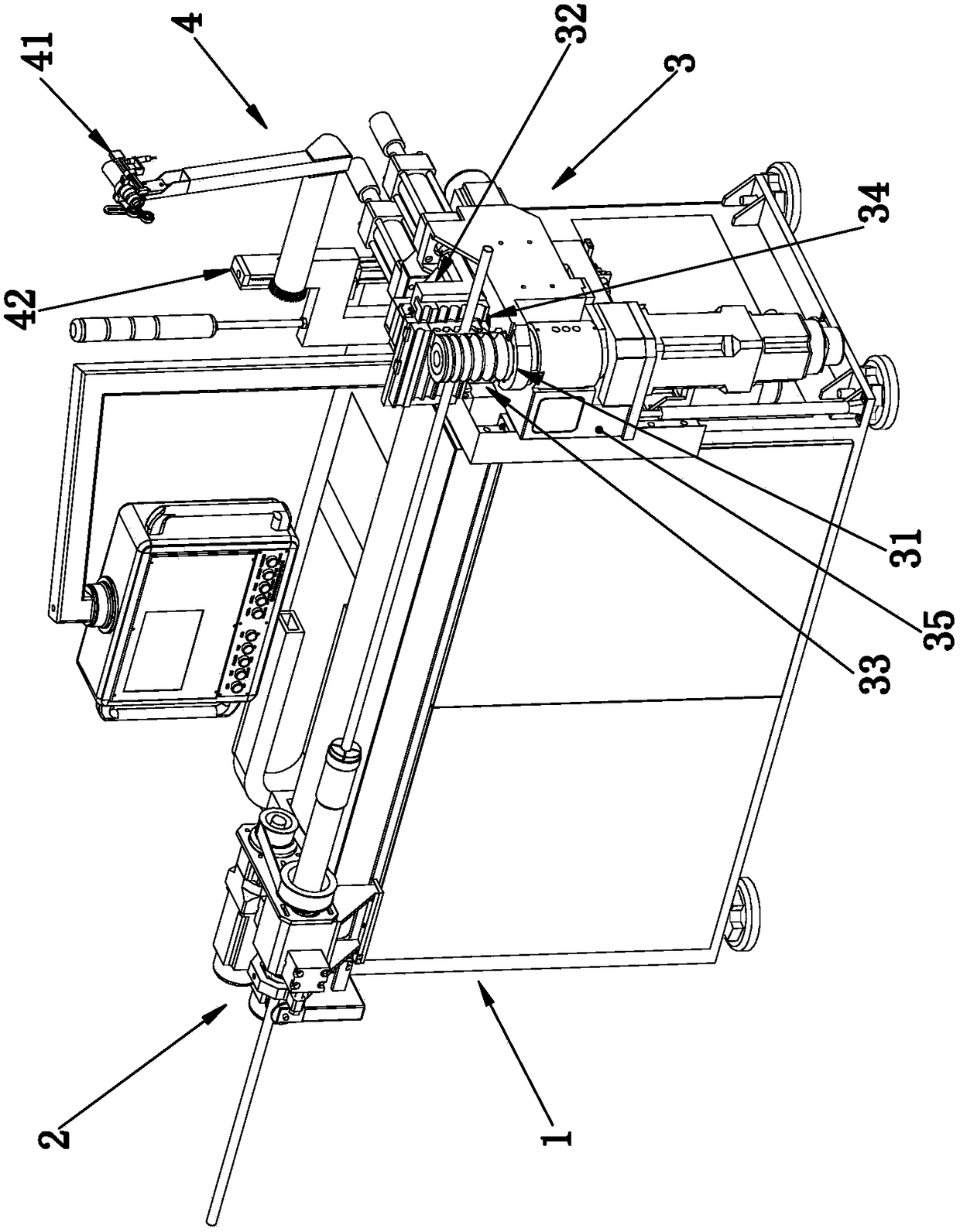

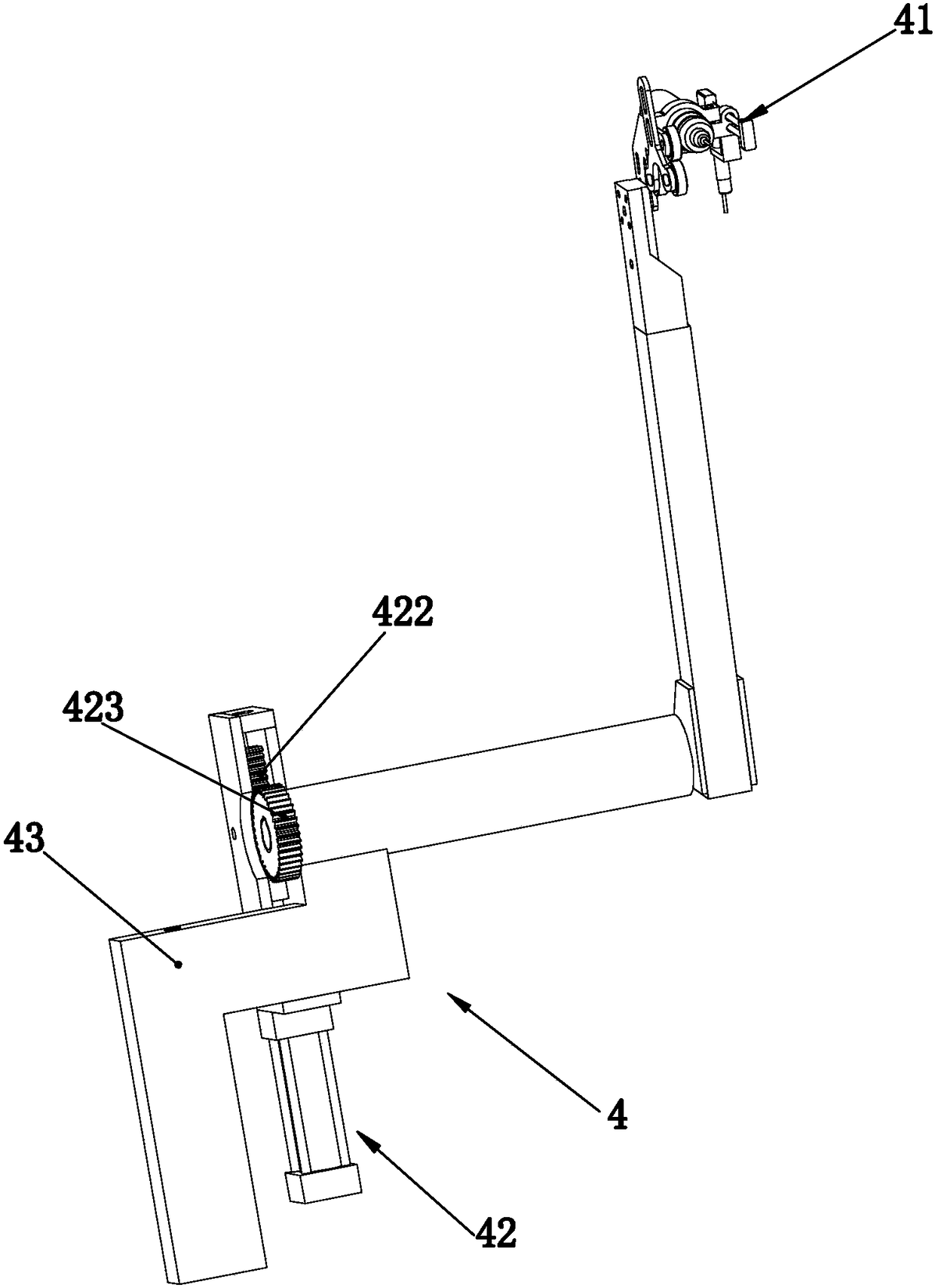

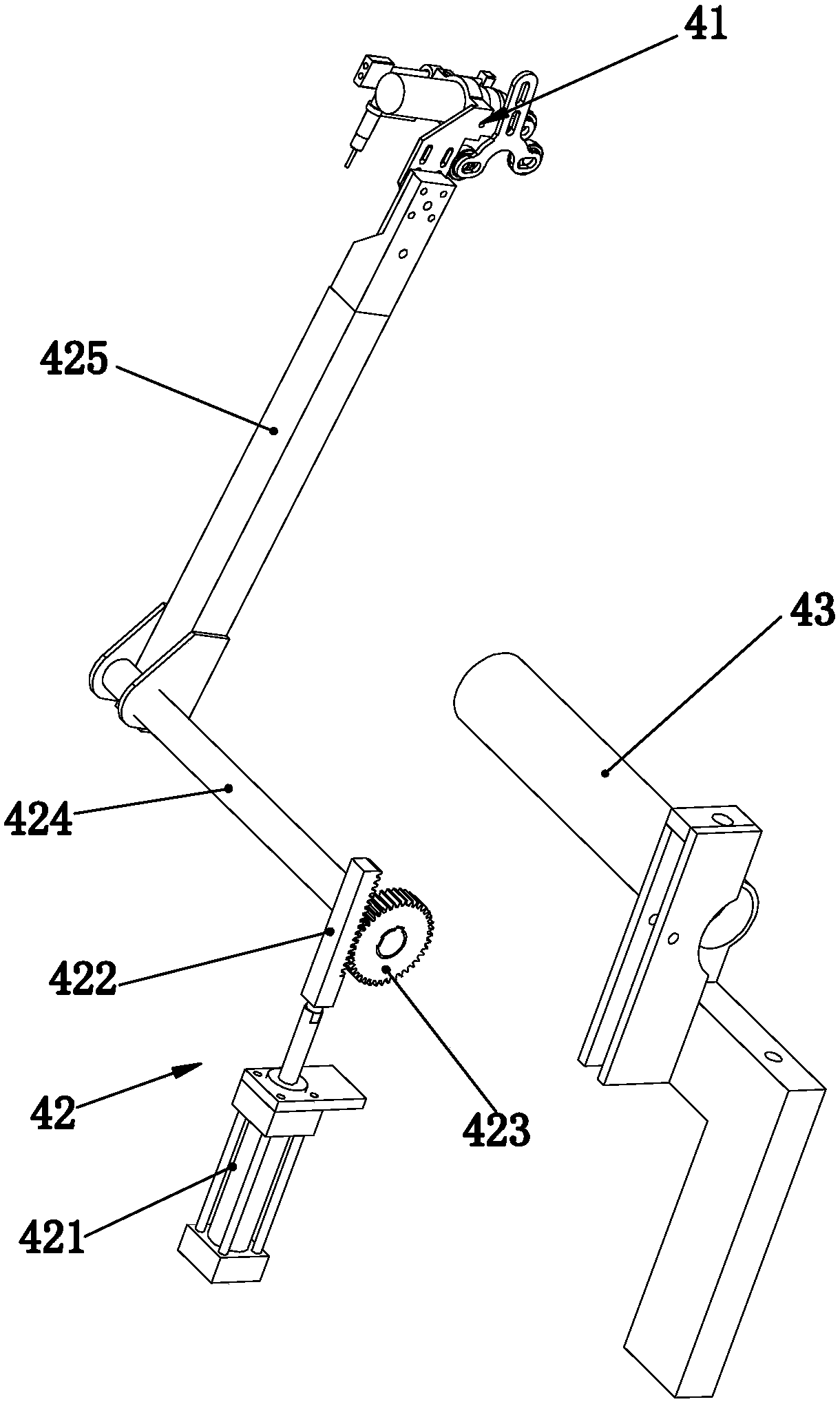

[0020] Such as figure 1 — Figure 6 A fully automatic pipe body bending forming equipment shown includes a body 1, a pipe body clamping and conveying device 2 arranged on the body 1, and a bending mold 3 connected with the pipe body clamping and conveying device 2, the bending mold 3. It includes a fixed mold 31 and a movable mold 32 that has a positioning bending space between the fixed mold 31 and can rotate along the fixed mold 31. The end of the bending mold 3 connected with the pipe clamping and conveying device 1 is the input station 33 , the other end is the output station 34, the body 1 is located at the output station 34 of the bending die 3 is provided with a forming pipe body cutting device 4, the forming pipe body cutting device 4 includes an output that can extend to the bending die 3 The cutting head 41 at the station 34 and the cutting device driving assembly 42 for driving the cutting head 41 . In the above scheme, by setting the forming tube body cutting dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com