Patents

Literature

281results about How to "Reduce agglomeration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

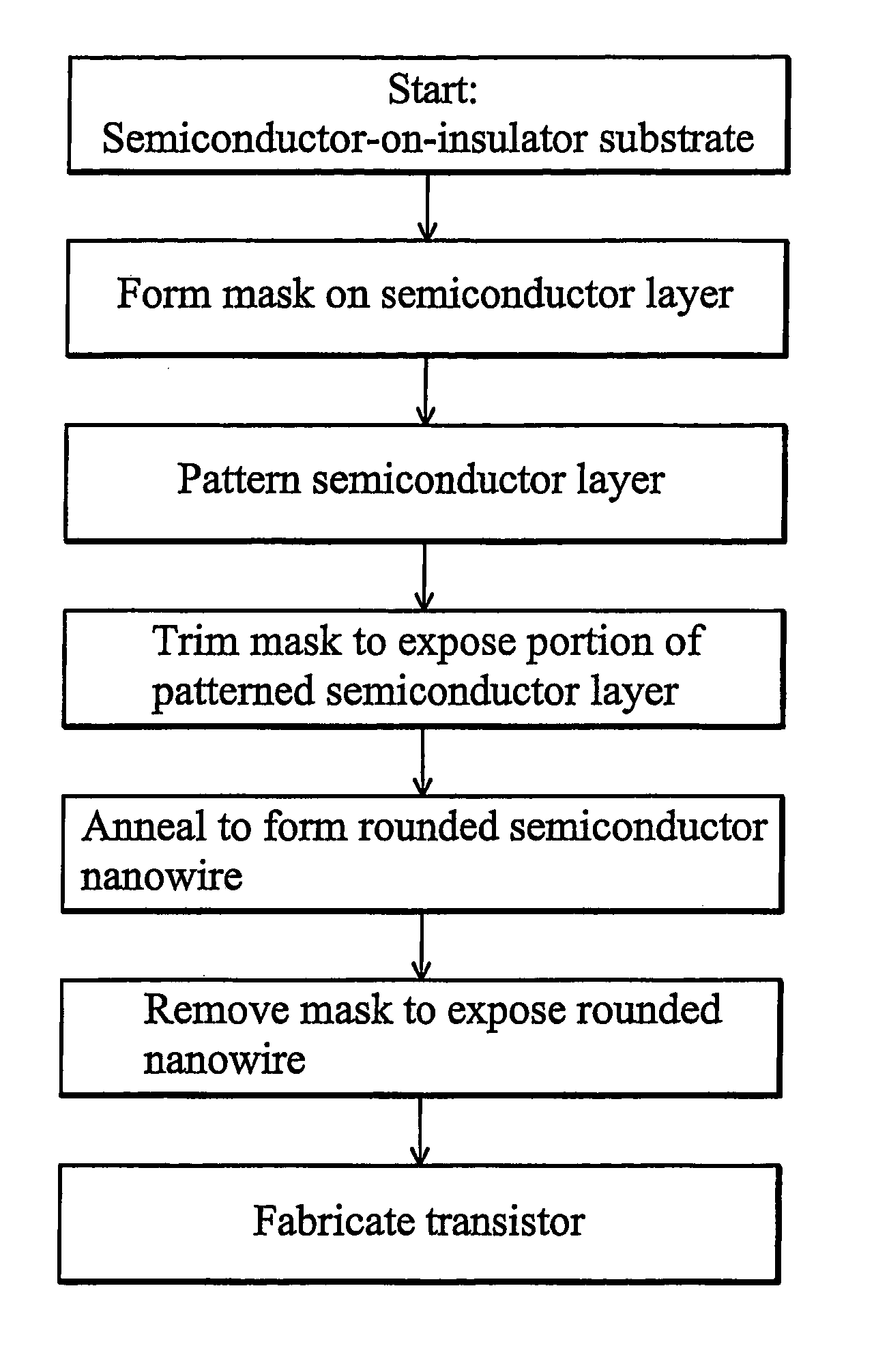

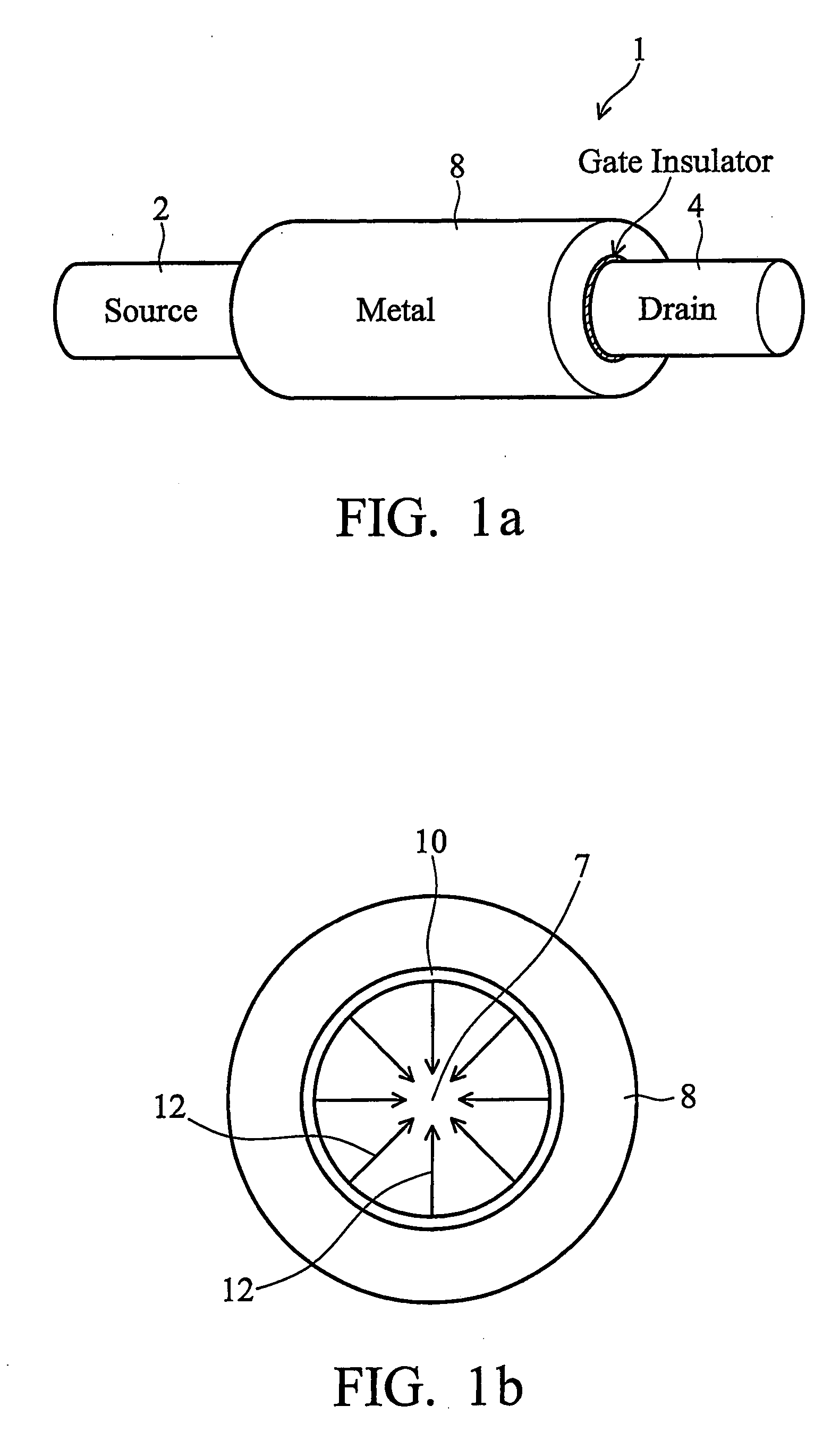

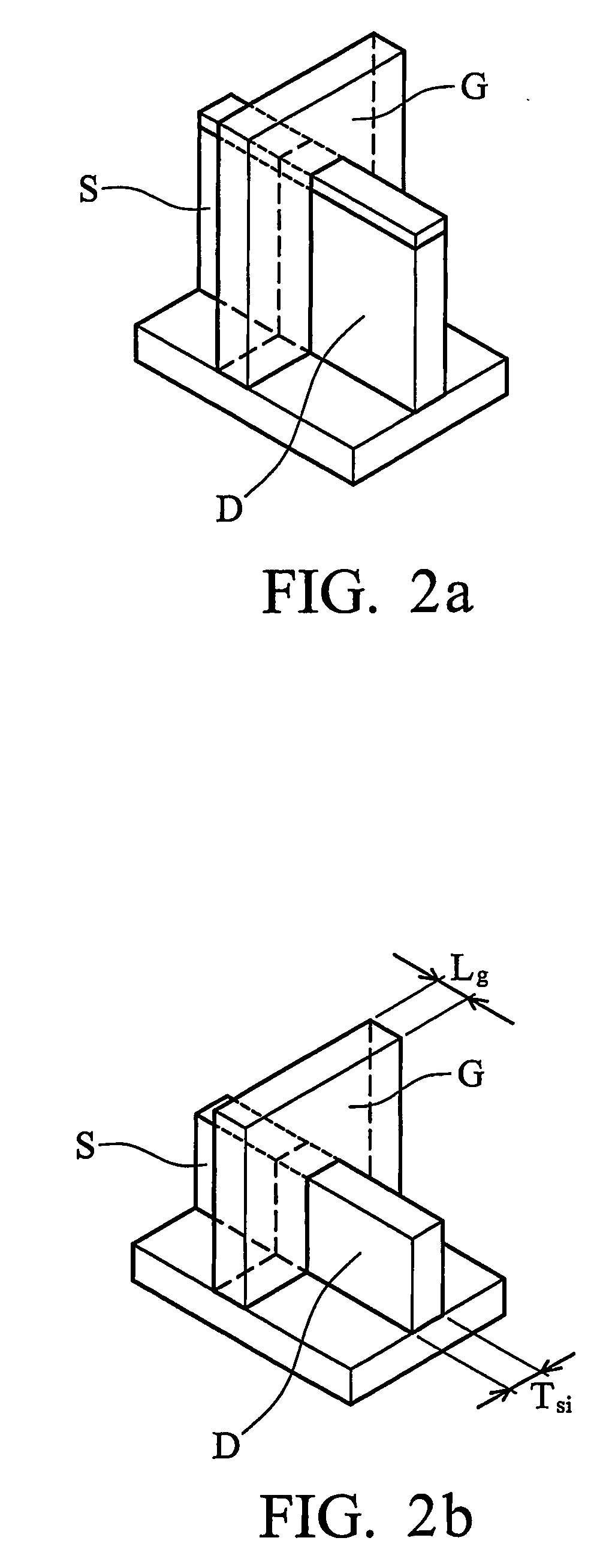

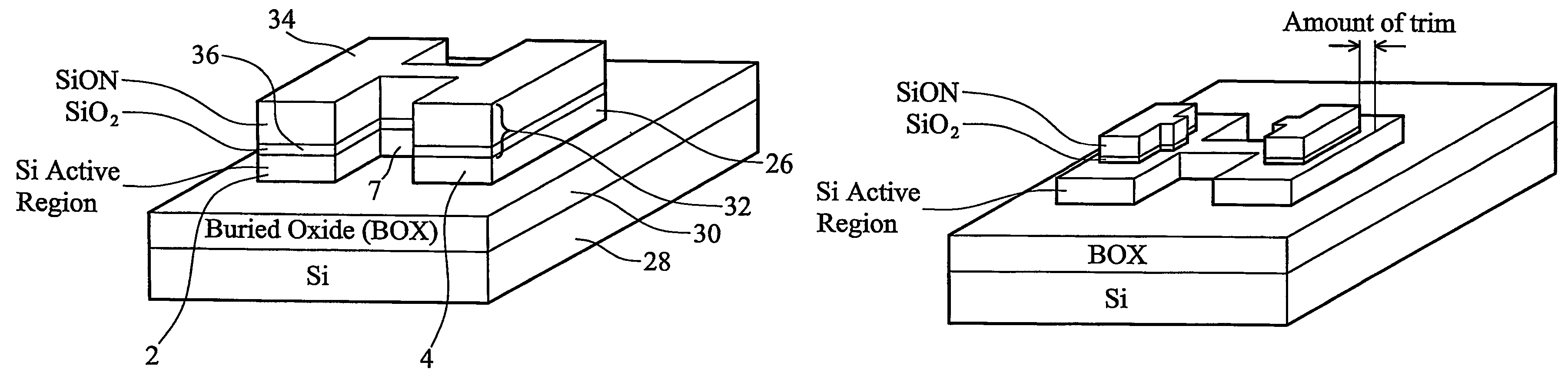

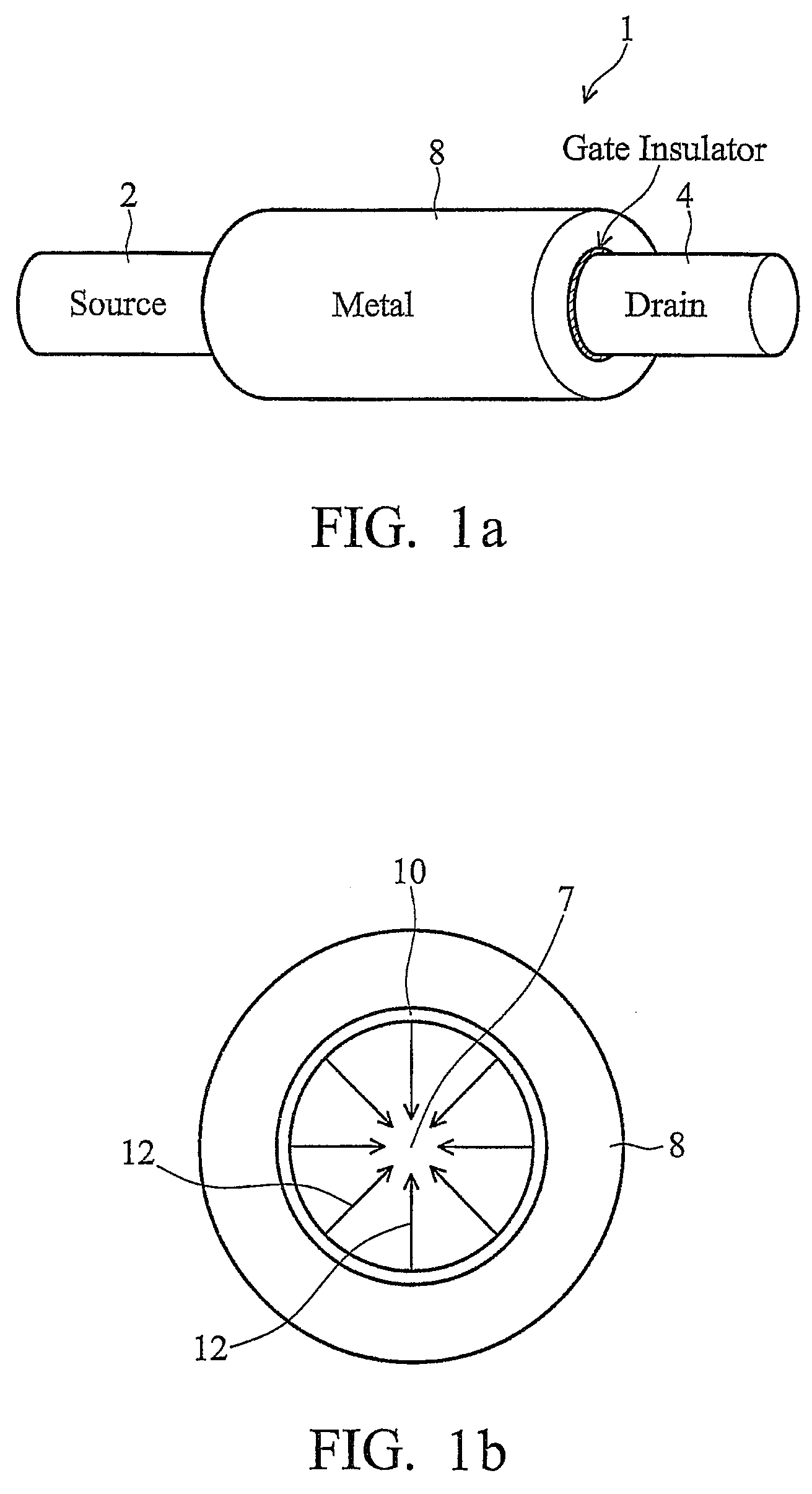

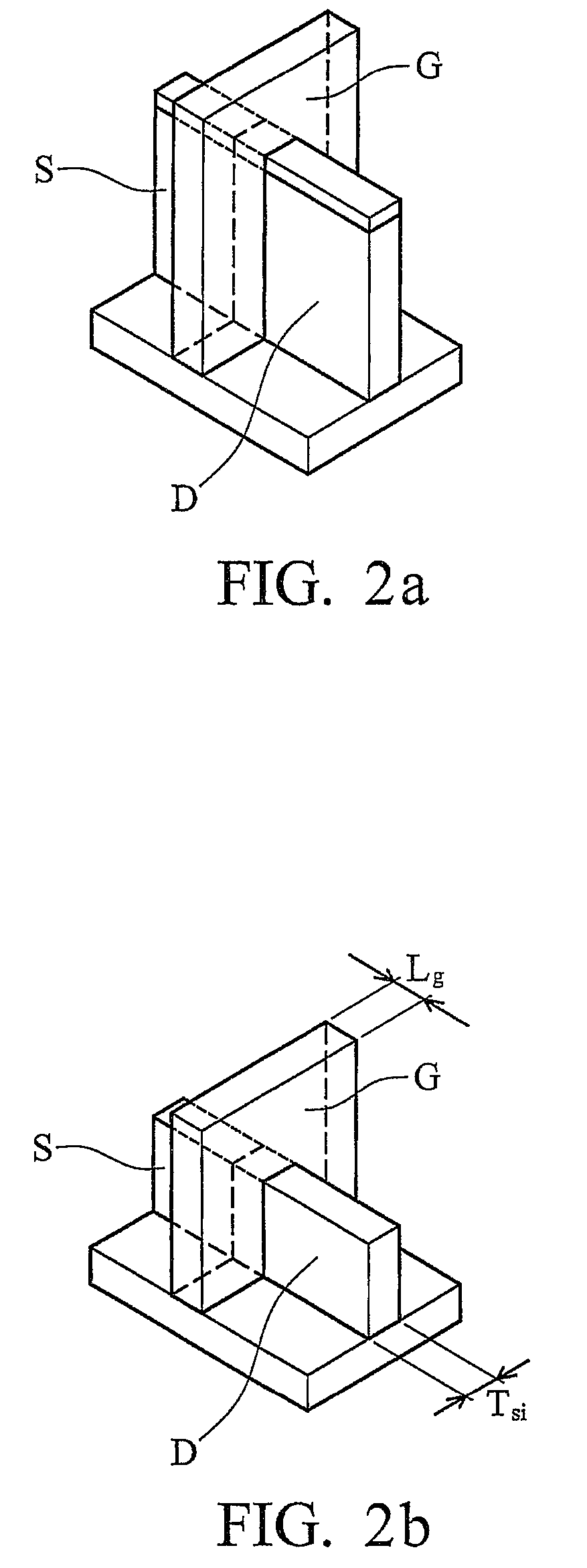

Semiconductor nano-wire devices and methods of fabrication

InactiveUS20050275010A1Rule out the possibilityReduce agglomerationTransistorNanoinformaticsDielectricNanowire

Nano-wires, preferably of less than 20 nm diameter, can be formed with minimized risk of narrowing and breaking that results from silicon atom migration during an annealing process step. This is accomplished by masking portion of the active layer where silicon atomer would otherwise agglomerate with a material such as silicon dioxide, silicon nitride, or other dielectric that eliminates or substantially reduces the silicon atom migration. Nano-wires, nanotubes, nano-rods, and other features can be formed and can optionally be incorporated into devices, such as by use as a channel region in a transistor device.

Owner:TAIWAN SEMICON MFG CO LTD

Semiconductor nano-wire devices and methods of fabrication

InactiveUS7452778B2Rule out the possibilityReduce agglomerationTransistorNanoinformaticsDielectricNanowire

Nano-wires, preferably of less than 20 nm diameter, can be formed with minimized risk of narrowing and breaking that results from silicon atom migration during an annealing process step. This is accomplished by masking portion of the active layer where silicon atomer would otherwise agglomerate with a material such as silicon dioxide, silicon nitride, or other dielectric that eliminates or substantially reduces the silicon atom migration. Nano-wires, nanotubes, nano-rods, and other features can be formed and can optionally be incorporated into devices, such as by use as a channel region in a transistor device.

Owner:TAIWAN SEMICON MFG CO LTD

Stabilized controlled release substrate having a coating derived from an aqueous dispersion of hydrophobic polymer

InactiveUS6316031B1Reduce reunionStable productionLiquid surface applicatorsGranular deliveryHydrophobic polymerDissolution

A stabilized solid controlled release dosage form having a coating derived from an aqueous dispersion of ethylcellulose is obtained by overcoating a substrate including a therapeutically active with an aqueous dispersion of ethylcellulose and then curing the coated substrate at a temperature and relative humidity elevated to a suitable level above ambient conditions until the coated dosage form attains a stabilized dissolution profile substantially unaffected by exposure to storage conditions of elevated temperature and / or elevated relative humidity.

Owner:PURDUE PHARMA LP

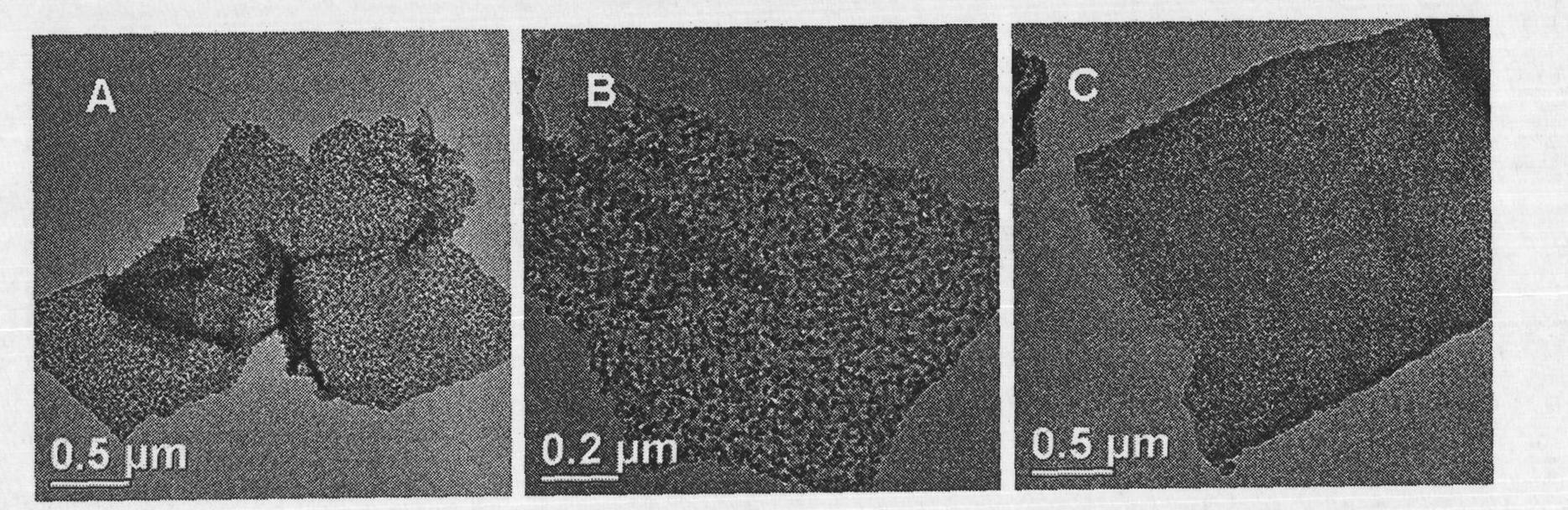

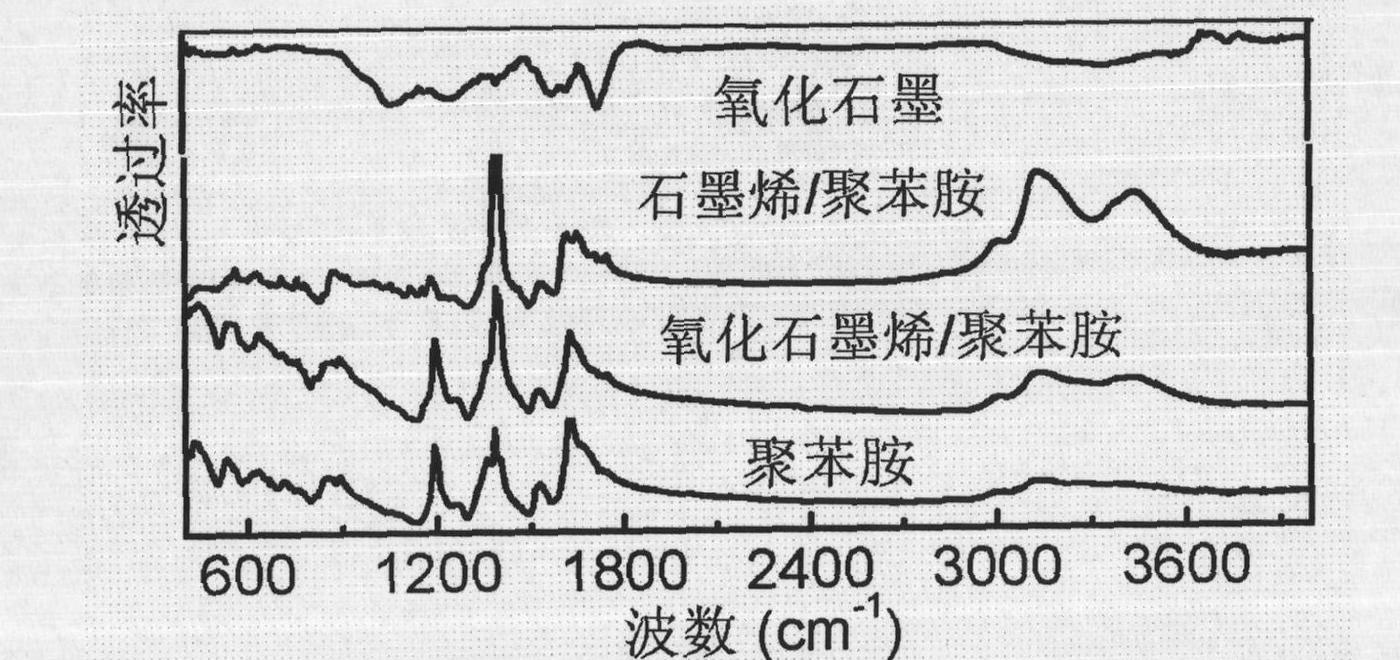

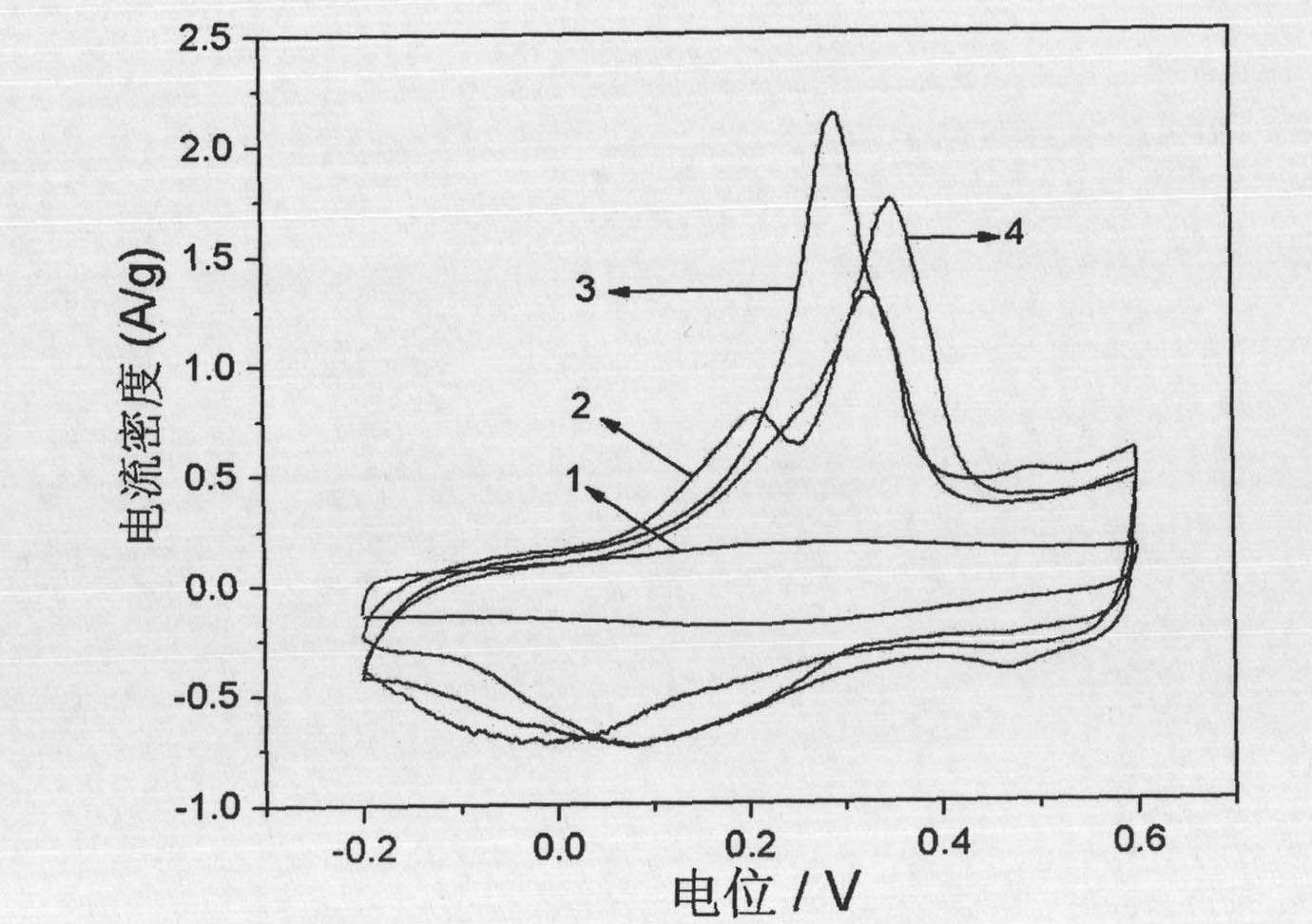

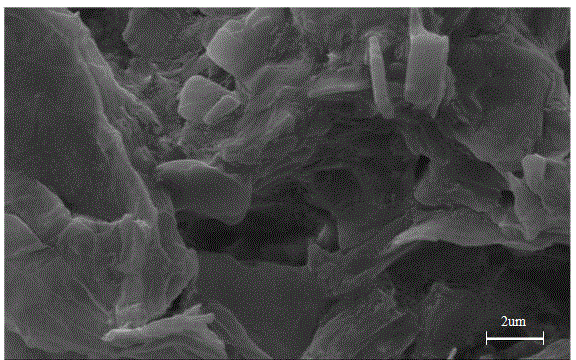

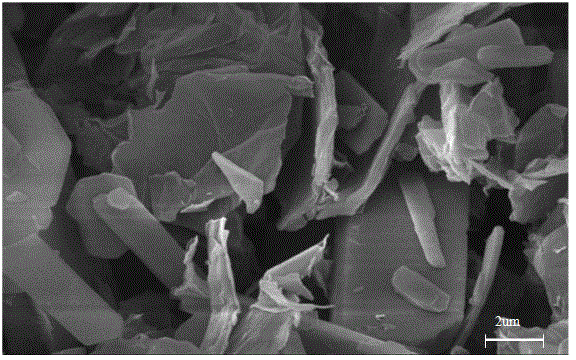

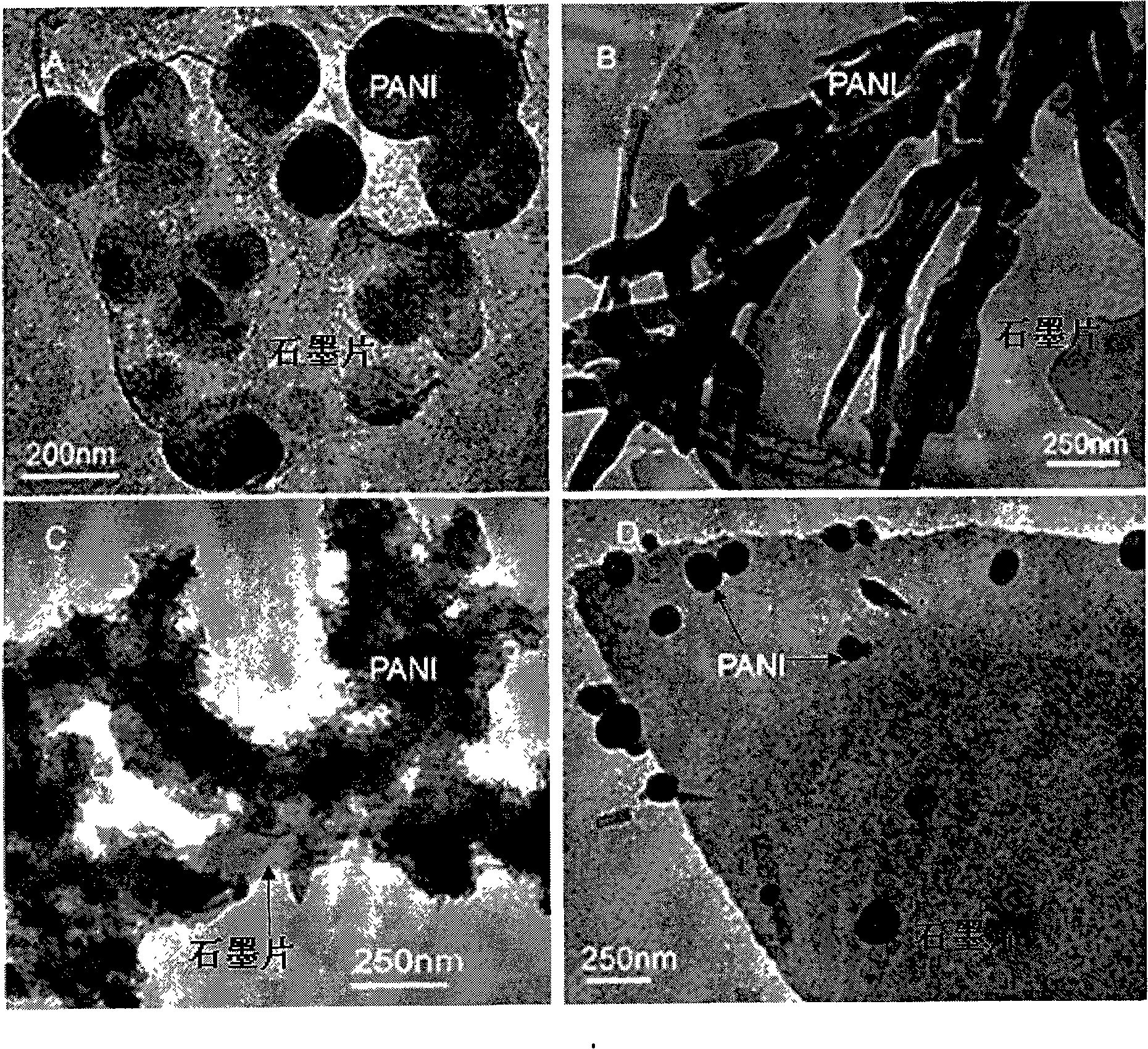

Graphene -organic acid doped polyaniline composite material and preparation method thereof

The invention discloses graphene-organic acid doped polyaniline composite material and a preparation method thereof. The preparation method includes the following steps: adding graphite oxide to dispersing agent for ultrasonic dispersion to form evenly dispersed graphene oxide liquid mixture; adding aniline monomer to the liquid mixture obtained in the first step for further dispersion under room temperature to form liquid mixture, and then blending for certain time; gradually dripping oxidizer and organic doping acid to the liquid mixture obtained in the second step, and blending for polymerization; centrifuging the liquid mixture obtained in the third step, and washing to get graphene oxide-polyaniline composite material; adding concentrated alkaline to the water suspension of the graphene oxide-polyaniline composite material, heating and blending for reaction; and centrifuging the mixture obtained in the fifth step and washing to get graphene-polyaniline composite material. The invention takes the advantage of the big specific surface area of graphene oxide and the capability of the graphene oxide for absorbing aniline on the surface thereof in on organic system to form sandwiched polyaniline / graphene oxide- polyaniline compound through polymerization.

Owner:NANJING UNIV OF SCI & TECH

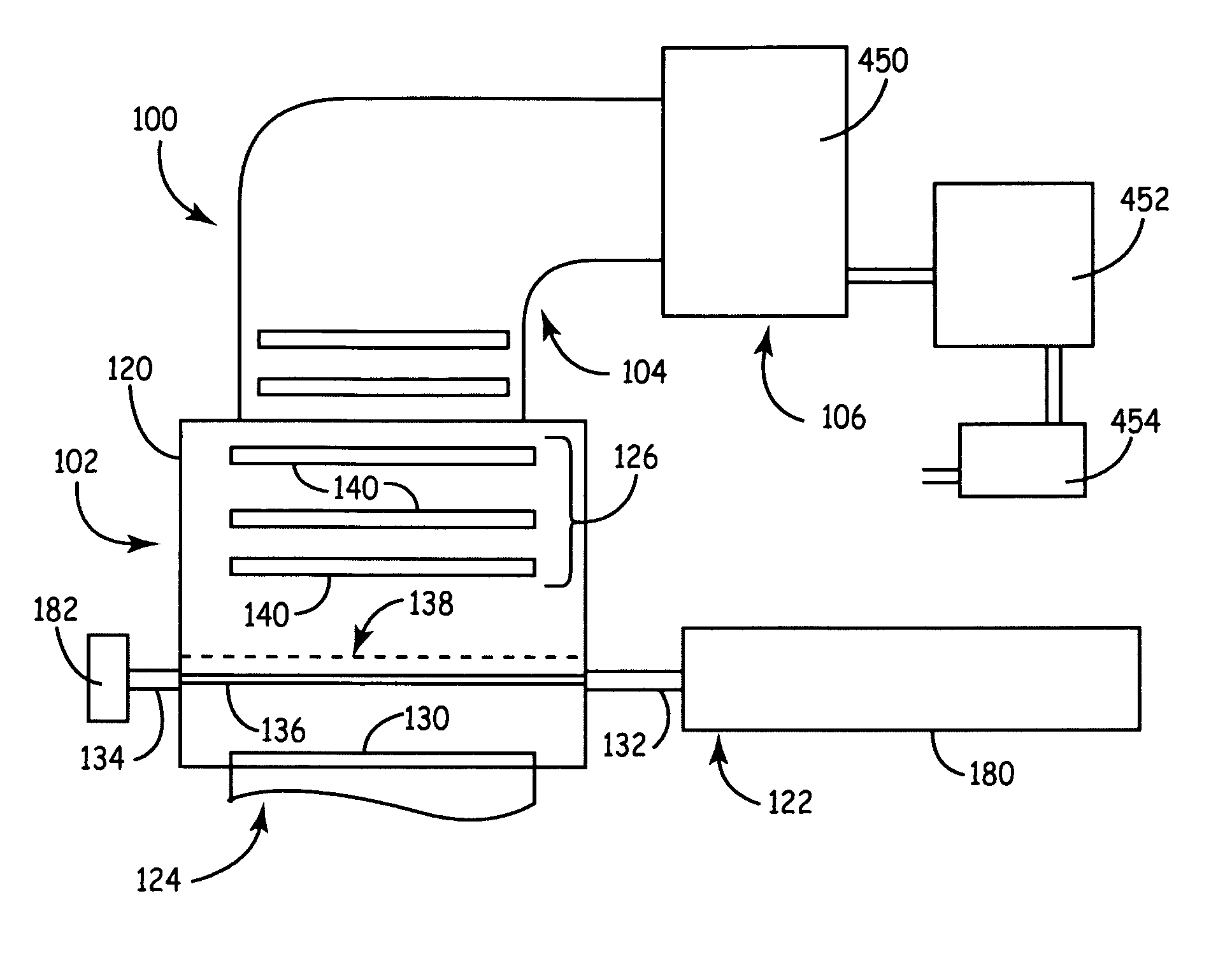

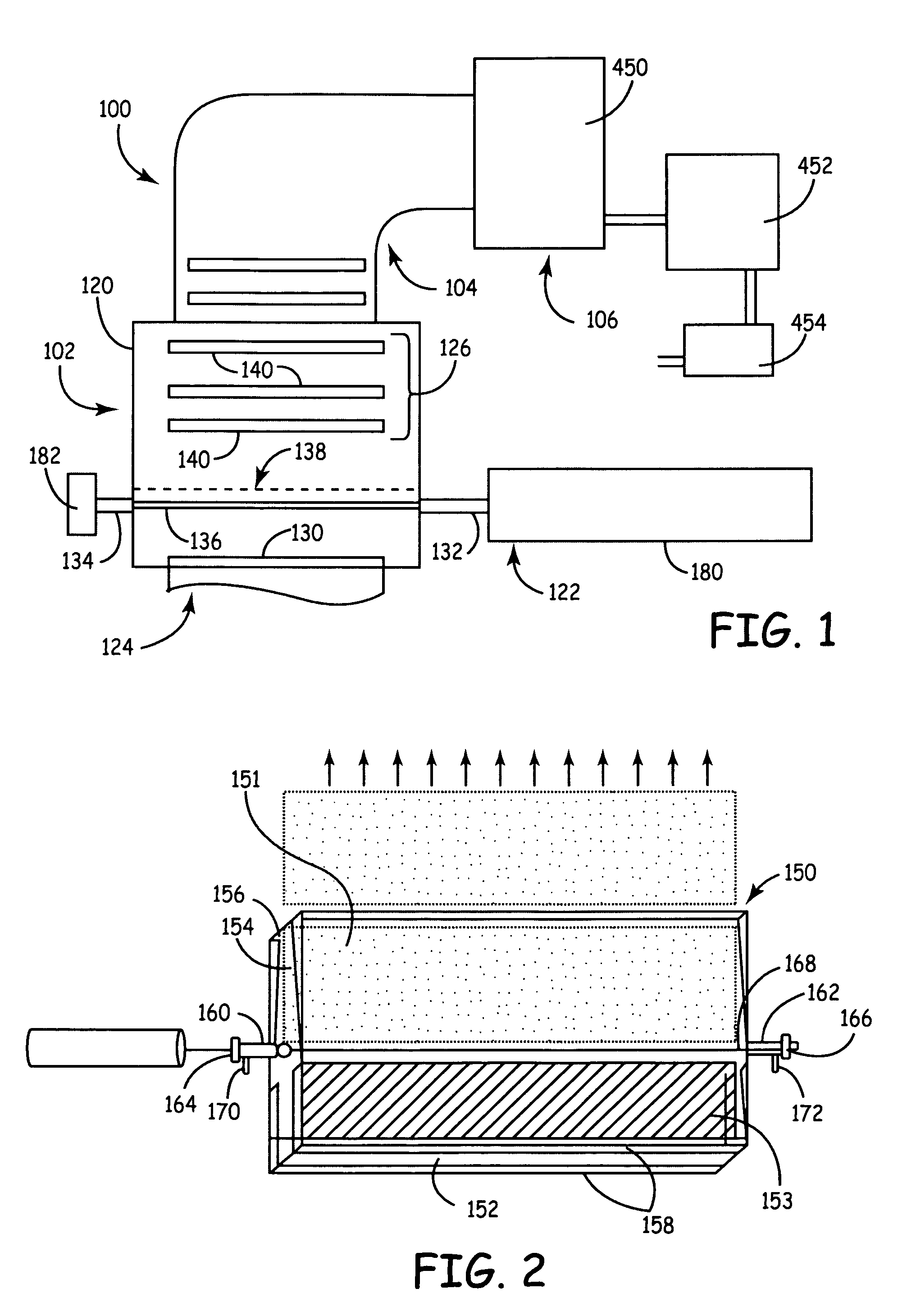

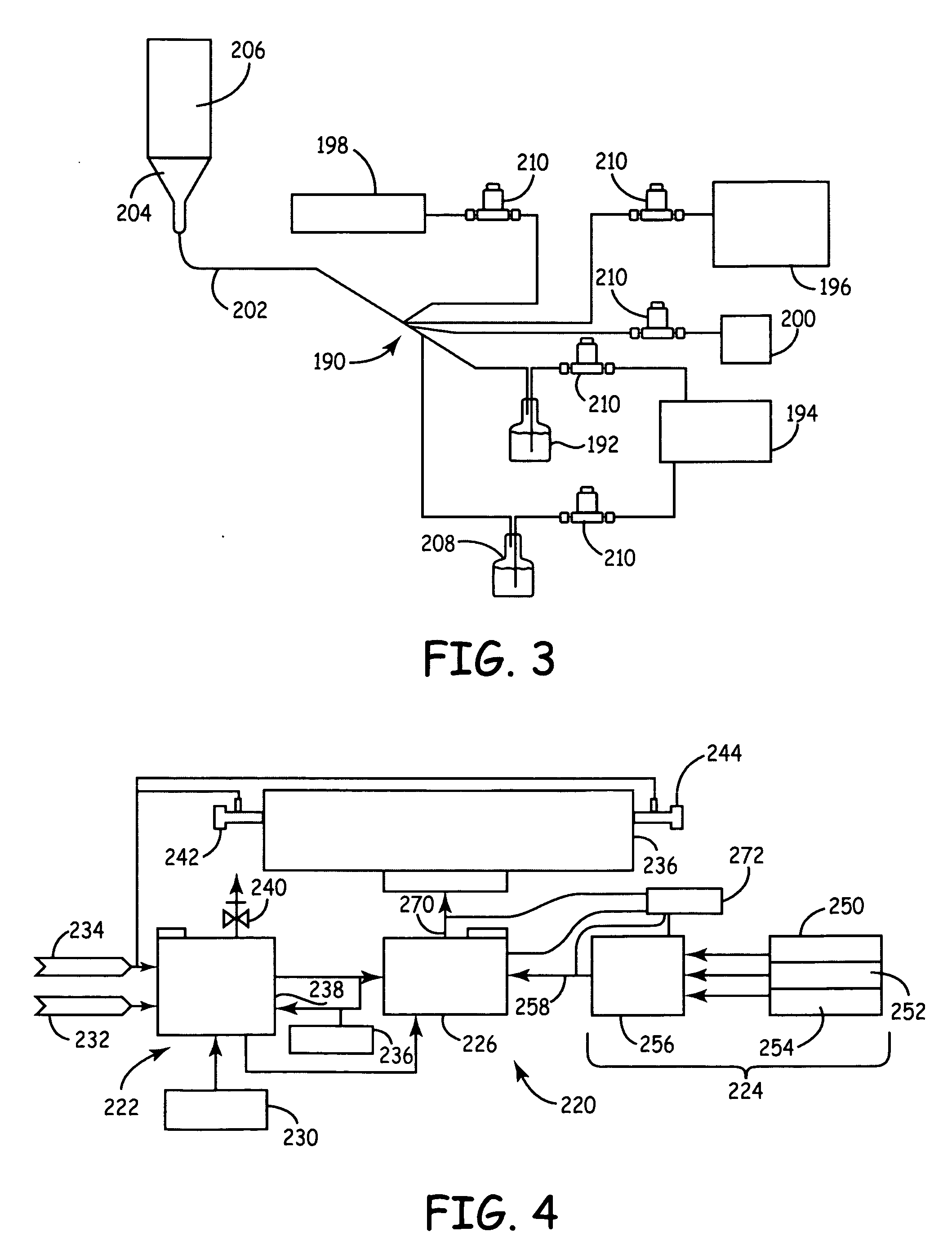

In-flight modification of inorganic particles within a reaction product flow

InactiveUS20070003694A1Reduce agglomerationMaterial granulation and coatingPretreated surfacesInorganic SynthesesRadiation

Methods involve in-flight processing of inorganic particles synthesized within the flow. Thus, the flow extends from an inlet connected to a reactant delivery system with inorganic particle precursors to a collector. The as formed inorganic particle can be modified with radiation and / or the application of a coating composition. Additional processing steps can be introduced as desired. Suitable apparatuses for in-flight processing can be based on addition of processing elements onto an inorganic synthesis reactor, such as a laser pyrolysis reactor.

Owner:NANOGRAM

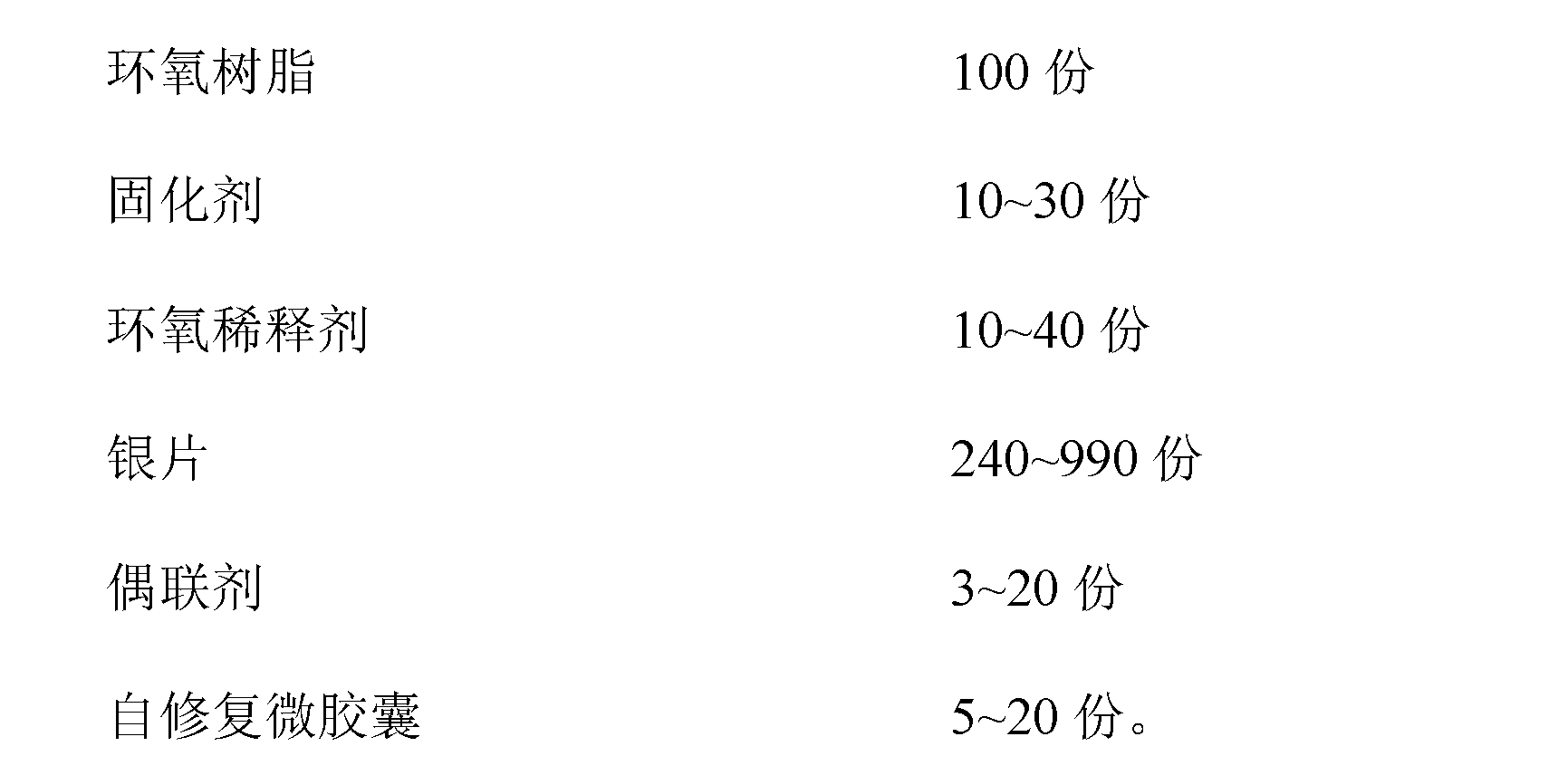

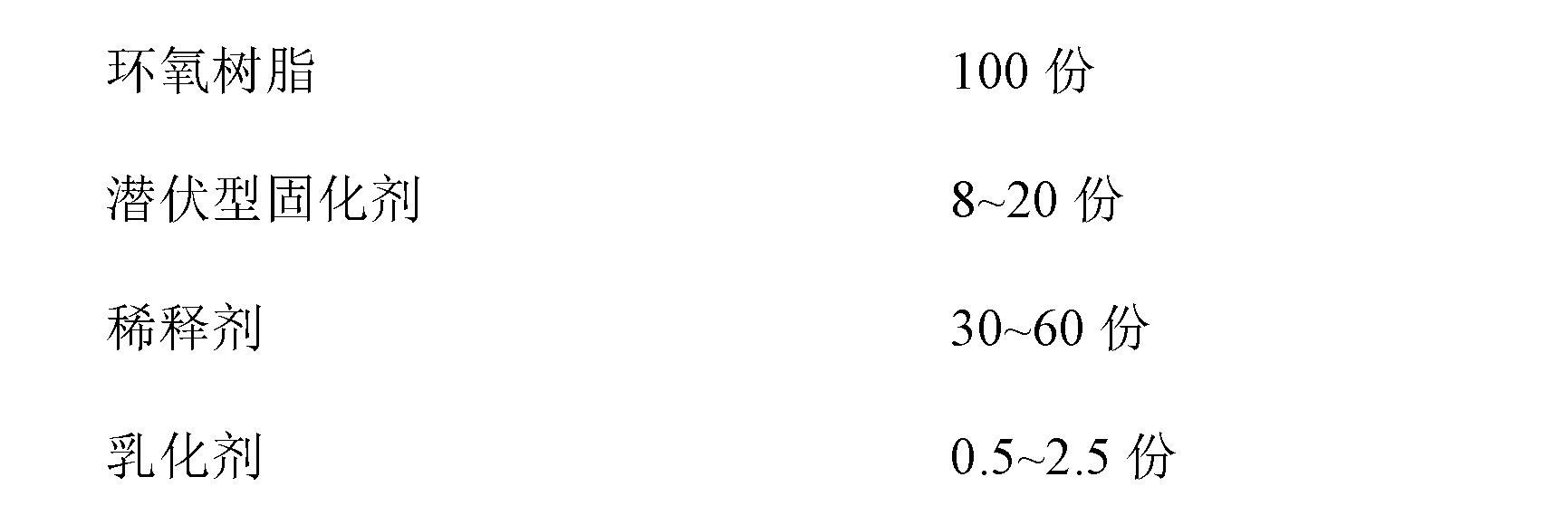

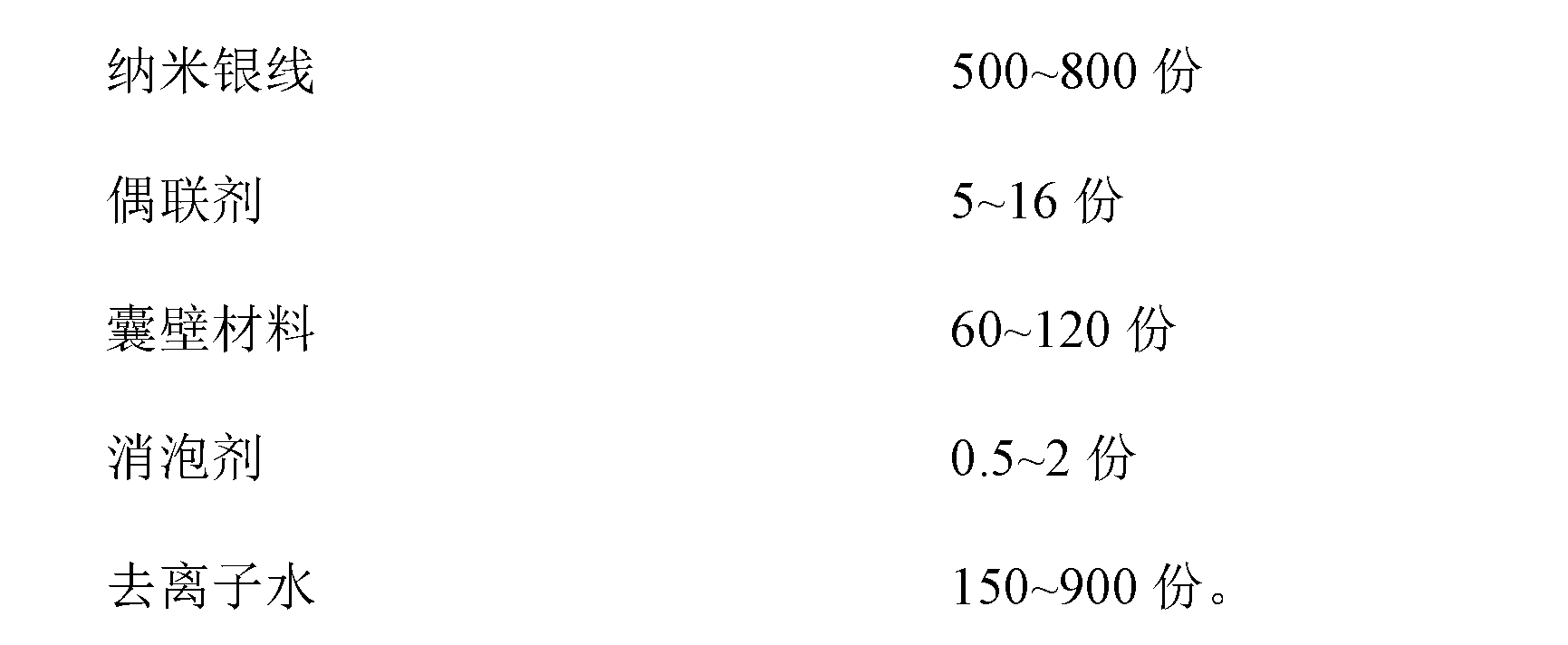

High temperature self-repairing conductive silver adhesive and preparation method thereof

ActiveCN103194164AGuaranteed long-term use effectEvenly dispersedEpoxy resin adhesivesMicroballoon preparationEpoxyAdhesive

The invention provides a high temperature self-repairing conductive silver adhesive. The high temperature self-repairing conductive silver adhesive is prepared from the following raw constituents by parts: 100 parts of epoxy resin, 10-30 parts of curing agent, 10-40 parts of epoxy diluent, 240-990 parts of silver pieces, 3-20 parts of coupling agent and 5-20 parts of self-repairing microcapsule; wherein the self-repairing microcapsule is composed of the following raw constituents by parts: 100 parts of epoxy resin, 8-20 parts of latent curing agent, 30-60 parts of diluents, 0.5-2.5 parts of emulsifying agent, 500-800 parts of nano silver wires, 5-16 parts of coupling agent, 60-120 parts of capsule wall material, 0.5-2 parts of antifoaming agent and 150-900 parts of deionized water. The invention also provides a preparation method of the high temperature self-repairing conductive silver adhesive. The high temperature self-repairing conductive silver adhesive has the positive effects that the repairing efficiency is high, the repairing effect is expanded on the basis of the original conductive network, crack-conductive network double repairing is realized, and the long-term using effect of the conductive adhesive is guaranteed, the cost is saved, and the reliability and service life of the conductive adhesive in high temperature working environment are improved.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

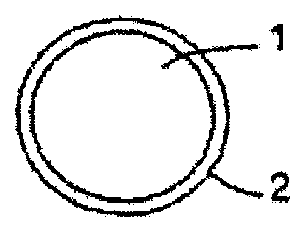

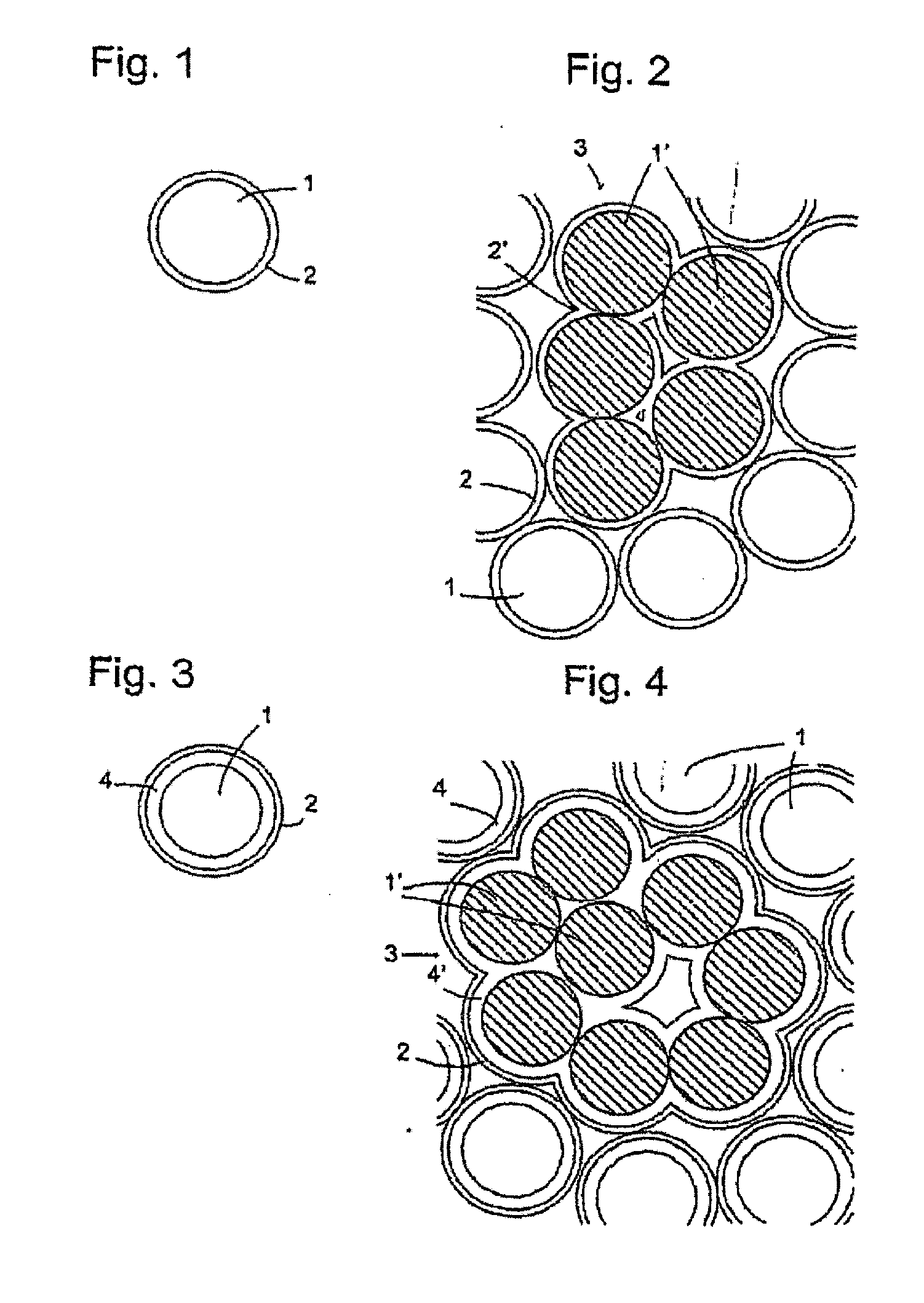

Granular material for 3d binder printing, production method and uses therefor

InactiveUS20050276976A1Extended service lifeFlat surfaceGranule coatingPretreated surfacesSurface layerMaterials science

The invention relates to a granular material for 3D binder printing, said granular material consisting of particles provided with an externally non-polar surface layer (2). The invention also relates to a method for producing a granular material for 3D binder printing, whereby a surface layer (2) having a non-polar outer side is applied to initial particles (1), and to a method for producing an object consisting of the inventive granular material, according to which a layer of the inventive granular material is applied to a base, and pre-determined regions (3) of said layer are moistened with a binding fluid, said binding fluid being selected from fluids in which a surface layer of the particles of the granular material is soluble. The invention further realties to objects consisting of interconnected particles of the inventive granular material. The invention enables a very precise printing process.

Owner:VOXELJET AG

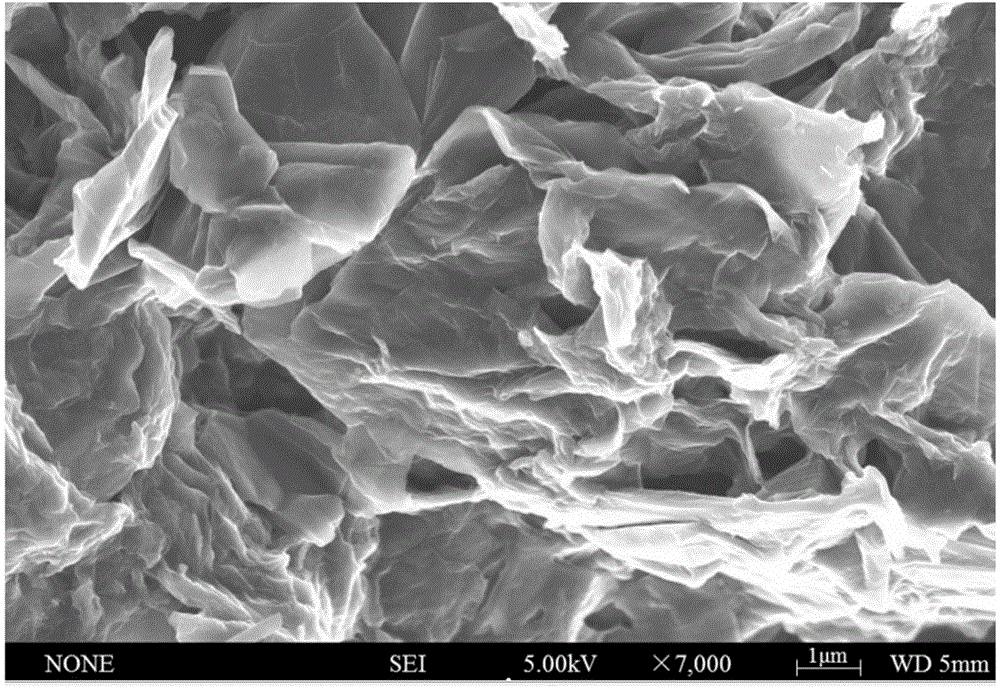

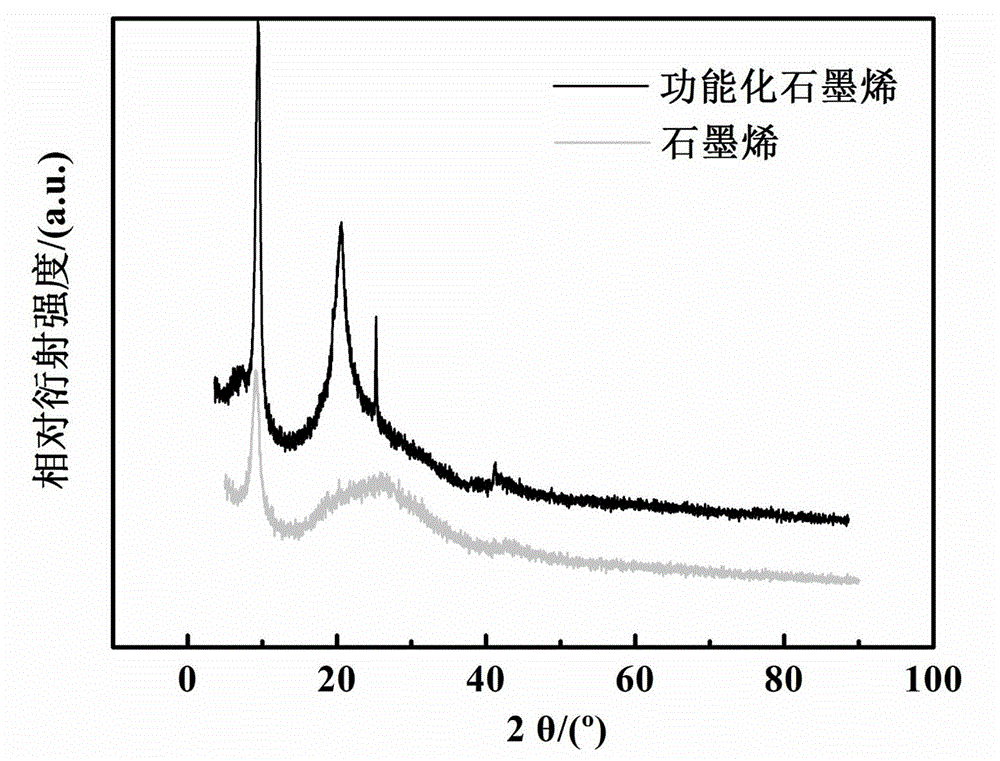

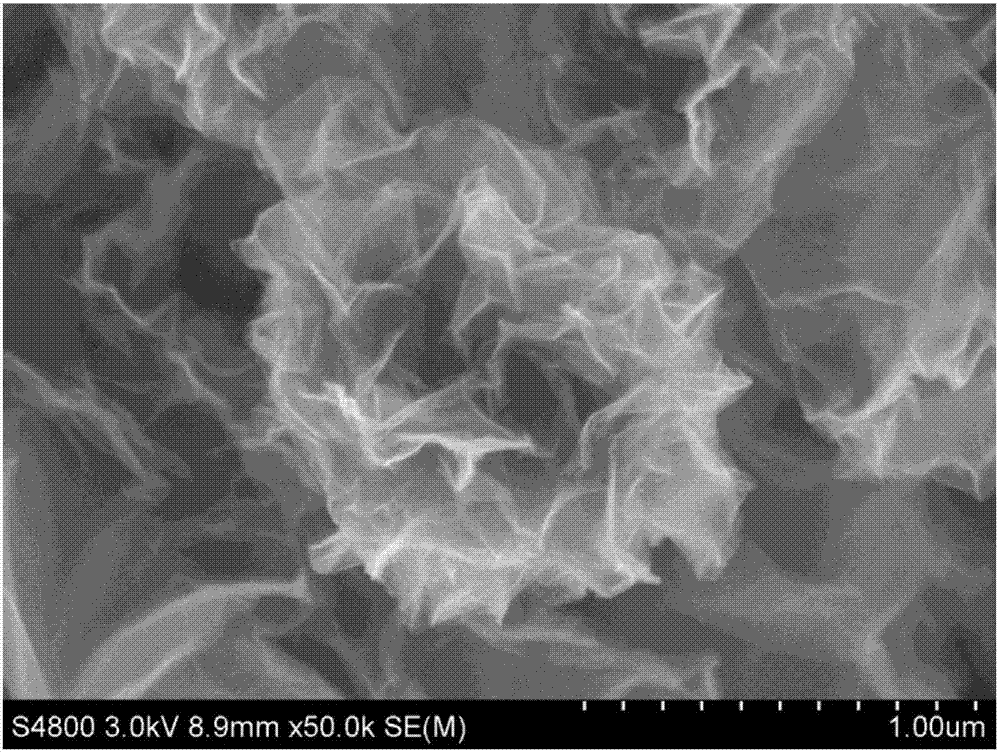

Functionalized graphene adsorbent and preparation method and application thereof

ActiveCN102974307AReduce agglomerationHigh specific surface areaOther chemical processesWater contaminantsEngineeringAmmonium bromide

The invention discloses a functionalized graphene adsorbent and a preparation method and application of the functionalized graphene adsorbent. The adsorbent is mainly composed of grapheme and cetyl trimethyl ammonium bromide. The cetyl trimethyl ammonium bromide inserts into the edge or surface layer of the layered grapheme and or embeds into the edge or surface layer of the layered grapheme through the function of non-covalent bond. The mass fraction of the cetyl trimethyl ammonium bromide in the adsorbent is 40%-50%. The invention discloses the preparation method of the functionalized graphene adsorbent. The method comprises the steps of dispersing the graphene oxide into the water, adding cetyl trimethyl ammonium bromide to the dispersed suspension liquid and stirring to make reaction, then adding suspension liquid to the heated reaction system and conducting suction filtration, washing and drying to the black cotton-shaped precipitate obtained by reduction. The functionalized graphene adsorbent can wipe out the chrome in the waste. The adsorbent is added into the chromate waste water, control the temperature of the waste, then after the full adsorption and complete oscillatory removal of the chromate is completed. The functionalized graphene adsorbent and a preparation method and application of the functionalized graphene adsorbent has the advantages of being simple, high efficient, green, economical and environmental and the like.

Owner:湖南红普创新科技发展有限公司

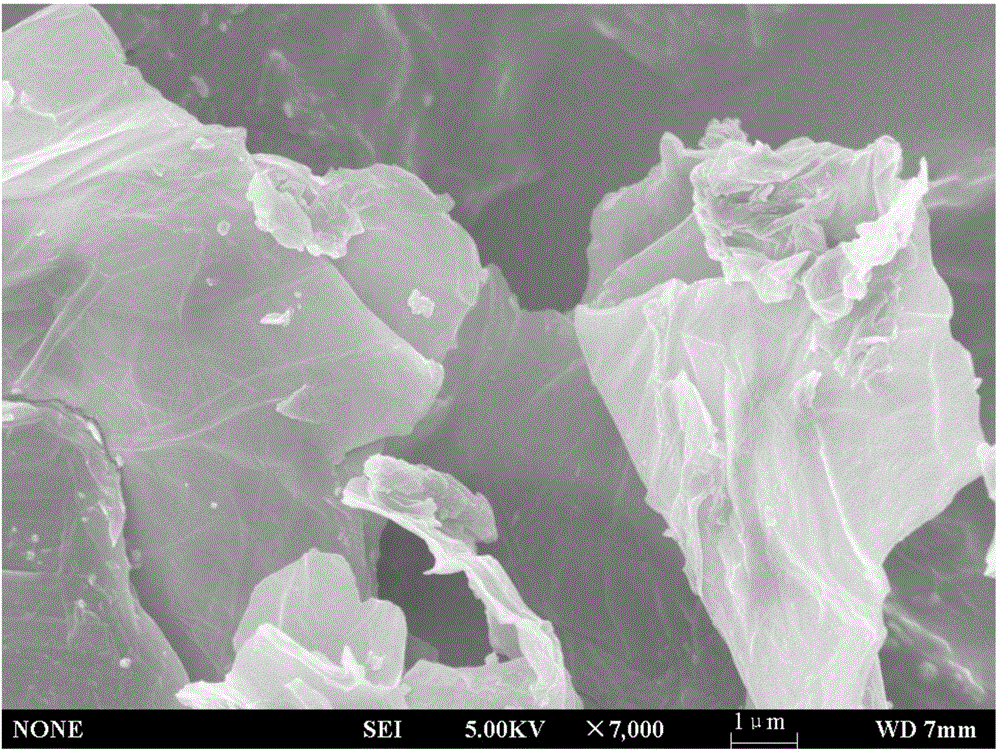

Compound grapheme absorption agent, method for preparing compound grapheme absorption agent and application of compound grapheme absorption agent

InactiveCN103480333AReduce reunionHigh specific surface areaOther chemical processesWater/sewage treatment by sorptionCvd grapheneGraphite oxide

The invention discloses a compound grapheme absorption agent which comprises grapheme, nanometer zero-valent iron and cetyl trimethyl ammonium bromide. The invention further discloses a method for preparing the compound grapheme absorption agent. The method for preparing the compound grapheme absorption agent includes the following steps that firstly, oxidized grapheme is dispersed in water with ultrasonic waves and oxidized grapheme suspension liquid is obtained; secondly, the nanometer zero-valent iron and the cetyl trimethyl ammonium bromide are added into the oxidized grapheme suspension liquid obtained in the first step, fully stirred and fully reacted and a reaction solution is obtained; thirdly, the reaction solution obtained in the second step is added with reductive agents and fully reacted and black flocks are obtained; fourthly, the black flocks obtained in the third step are filtered, washed and dried to obtain the compound grapheme absorption agent. The compound grapheme absorption agent is efficient, green, economic, friendly to environment, and suitable for large-scale production. The preparing method is simple and conditions are easy to control.

Owner:SOUTH CHINA UNIV OF TECH

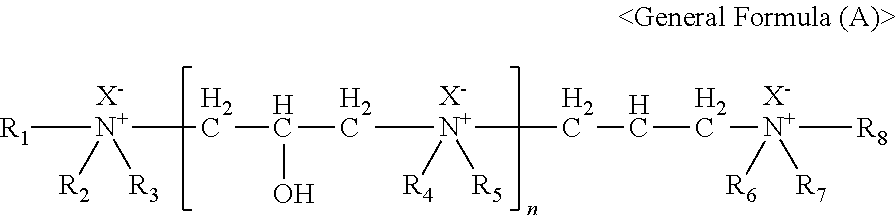

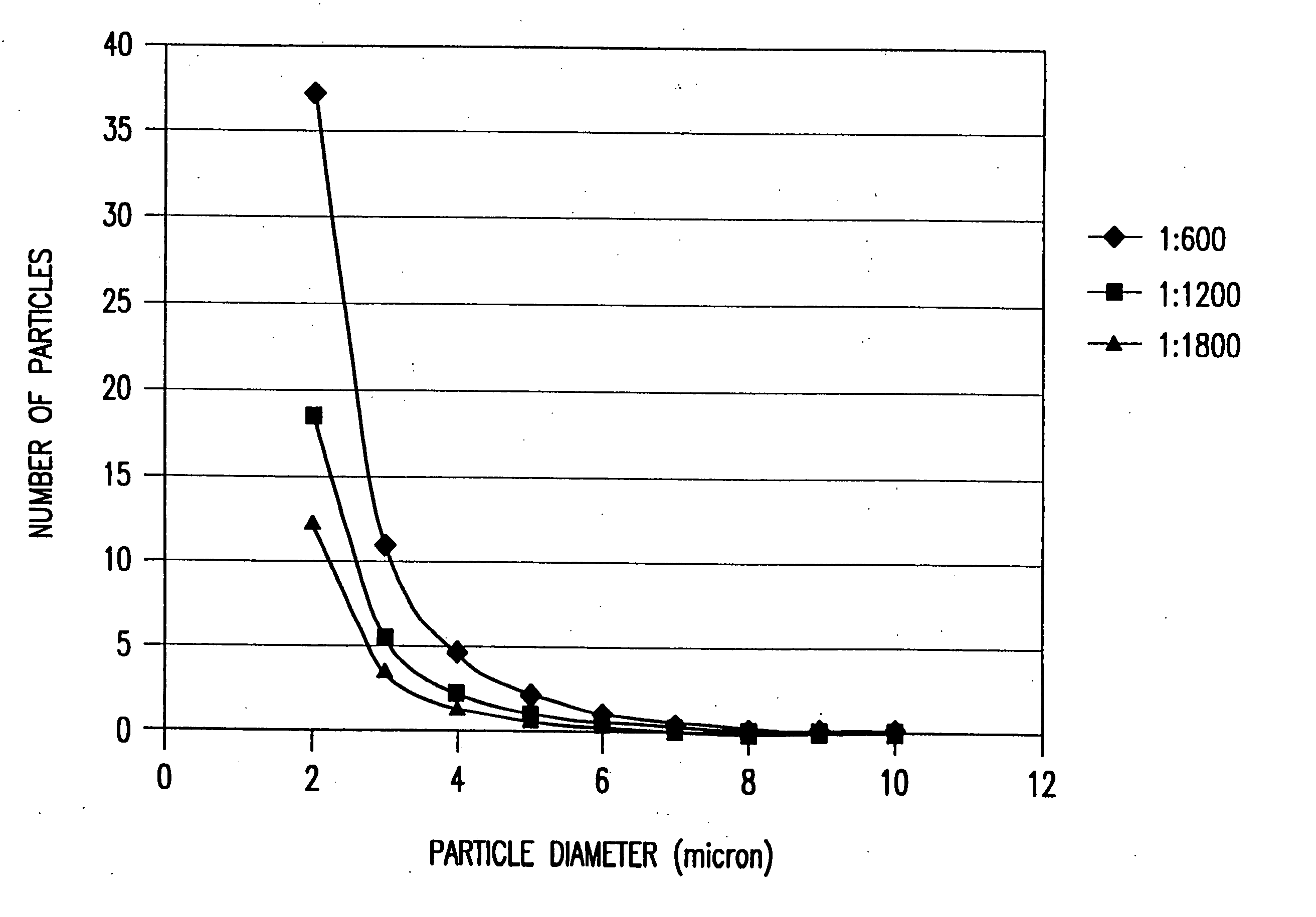

Pigmented inks and dispersants used therewith

Pigmented inks are disclosed comprising an aqueous medium, a pigment, a dispersant, and a humectant. Inks are disclosed where the humectant is a sulfonated polyethylene oxide which provides long decap times and fast drying of the printed image. Inks are further disclosed where the dispersant is an alkyl(sulfophenoxy)benzenesulfonic acid or its salt. Such dispersants reduce the agglomeration of pigment particles and reduce or eliminate the deposition of foreign substances on heater elements during the jetting process. A variety of pigments, dispersants, humectants, and aqueous media can be used. Combinations of a sulfonated polyethylene oxide humectant and an alkyl(sulfophenoxy)benzenesulfonic acid (salt) dispersant provide inks with good stability, few kogation problems, long decap times and relatively fast drying times.

Owner:3M INNOVATIVE PROPERTIES CO

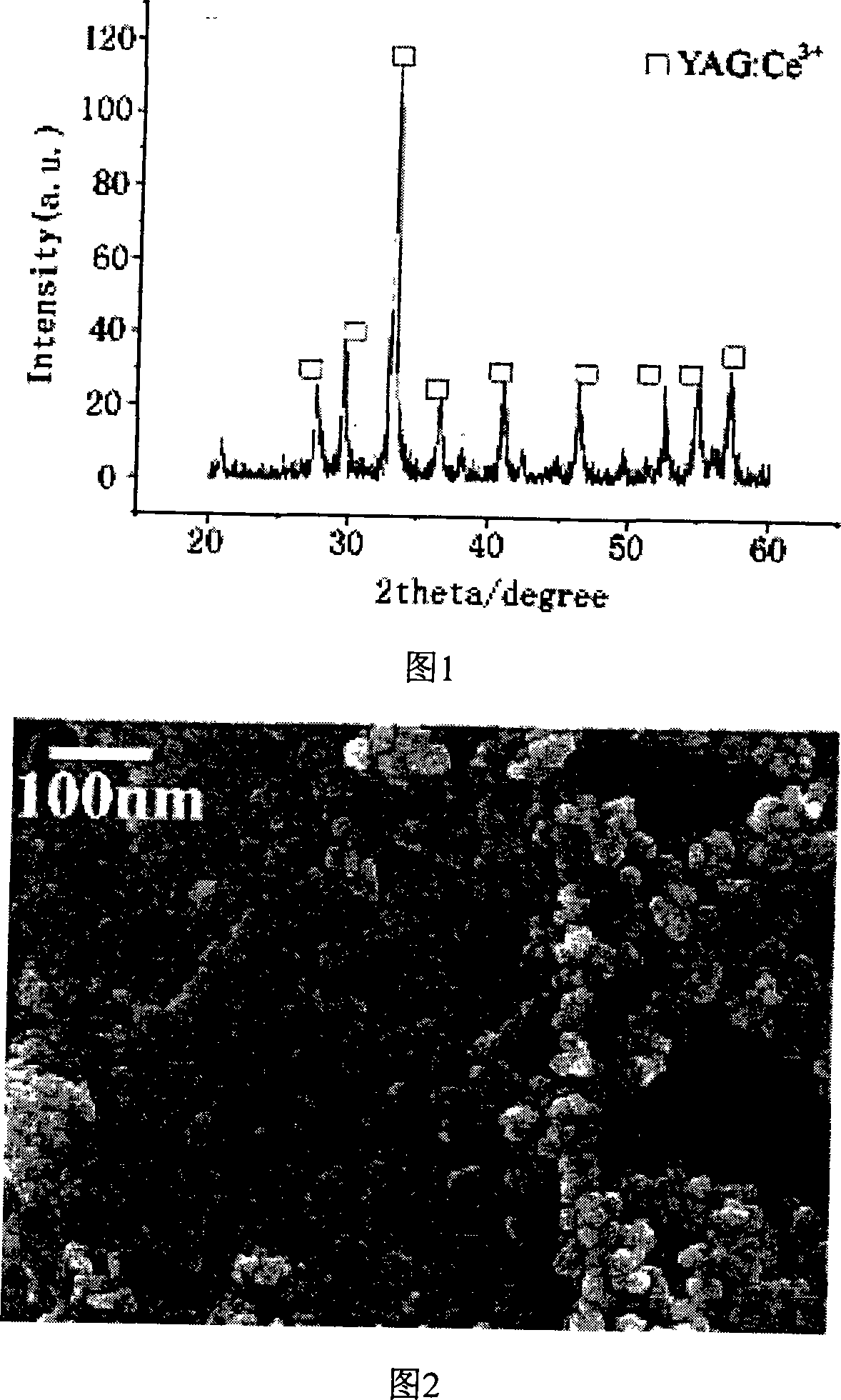

Method for preparing YAG nano powder

InactiveCN101249978ASimple requirementsWell mixedRare earth metal compoundsPolymer sciencePolymer network

Disclosed is a process for preparing YAG nano-powder, which belongs to the inorganic materials and the preparation field. The invention utilizes acrylamide as monomer, employs N, N'-methylene diacrylamide as polymer network agent, utilizes Al(NO3)3Y(NO3)3, Ce(NO3)3*6H2O as raw materials, employs citric acid as regulator, and uses a polymer network gel method and an active carbon adsorption process to prepare the nano-powder of Y3Al5O12(YAG):Ce3+. The method is characterized in that requirements to raw materials are simple and inorganic saline solution can be utilized as the raw materials, the component of the obtained micro powder is mixed evenly, most importantly, the polymer network formed in the gel process and the active carbon decomposed under nitriding atmosphere reduce the contact opportunity of precursor grains, thereby agglomeration is reduced, the nano-powder which is small in grain size and uniform in dispersion can be obtained, thereby largely reducing preparation temperature of materials, and calcination temperature is only 800 DEG C.

Owner:SHANGHAI INST OF TECH

Functional diatomite putty powder and preparation method thereof

InactiveCN105949863AImprove efficiencyShorten the timeFilling pastesInorganic pigmentsMaterials science

The invention relates to putty powder, in particular to functional diatomite putty powder and a preparation method thereof, wherein the putty powder includes in percent by weight: 10-50% of high-temperature activated diatomite, 5-30% of an inorganic binder, 30-70% of an inorganic filler, 0.01-2% of a functional aid, 0.1-5% of an inorganic pigment, 0.5-5% of an organic binder, and 0.5-5% of an organic aid. The functional diatomite putty powder meets the related standard requirements of putty powder and diatomite, and has qualified constructability and functionality, namely having standard-meeting properties such as humidity regulation, formaldehyde clarifying performance, long duration of formaldehyde purifying performance, mold-proof performance, and mold durability.

Owner:CENT SOUTH UNIV +1

Modified graphene adsorbent as well as preparation method and application thereof

ActiveCN103949218AReduce agglomerationHigh specific surface areaOther chemical processesMultistage water/sewage treatmentPolyacrylamideAluminium

The invention discloses a modified graphene adsorbent as well as a preparation method and application thereof. The preparation method of the modified graphene adsorbent comprises the following steps: carrying out ultrasonic dispersion on oxidized graphene, adding hydroxyl aluminum and a surfactant, stirring fully, then adding a reducing agent, fully reacting so as to obtain a black flocculent precipitate, carrying out suction filtration on black flocculent precipitate, washing and drying, thereby obtaining the modified graphene adsorbent, wherein the surfactant comprises more than one of polyacrylamide, cetyl trimethyl ammonium bromide or sodium dodecyl benzene sulfonate. The modified graphene adsorbent has the characteristics of being simple, easily available, high in adsorption amount, high in removing rate and the like, and can be used for treating wastewater, especially acid dye wastewater; adopted raw materials are low in price and available; the preparation method is simple, is free from pollution, is low in cost, and is easy for industrialization.

Owner:SOUTH CHINA UNIV OF TECH

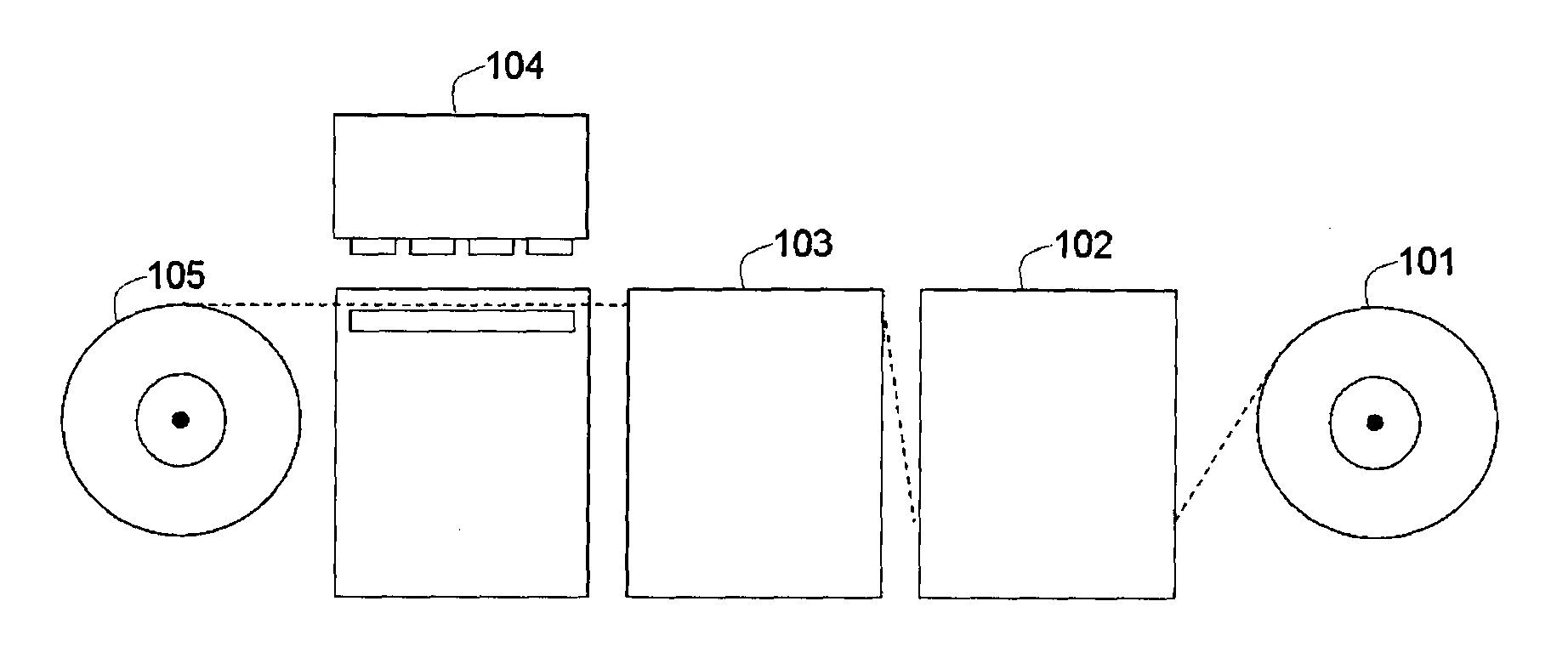

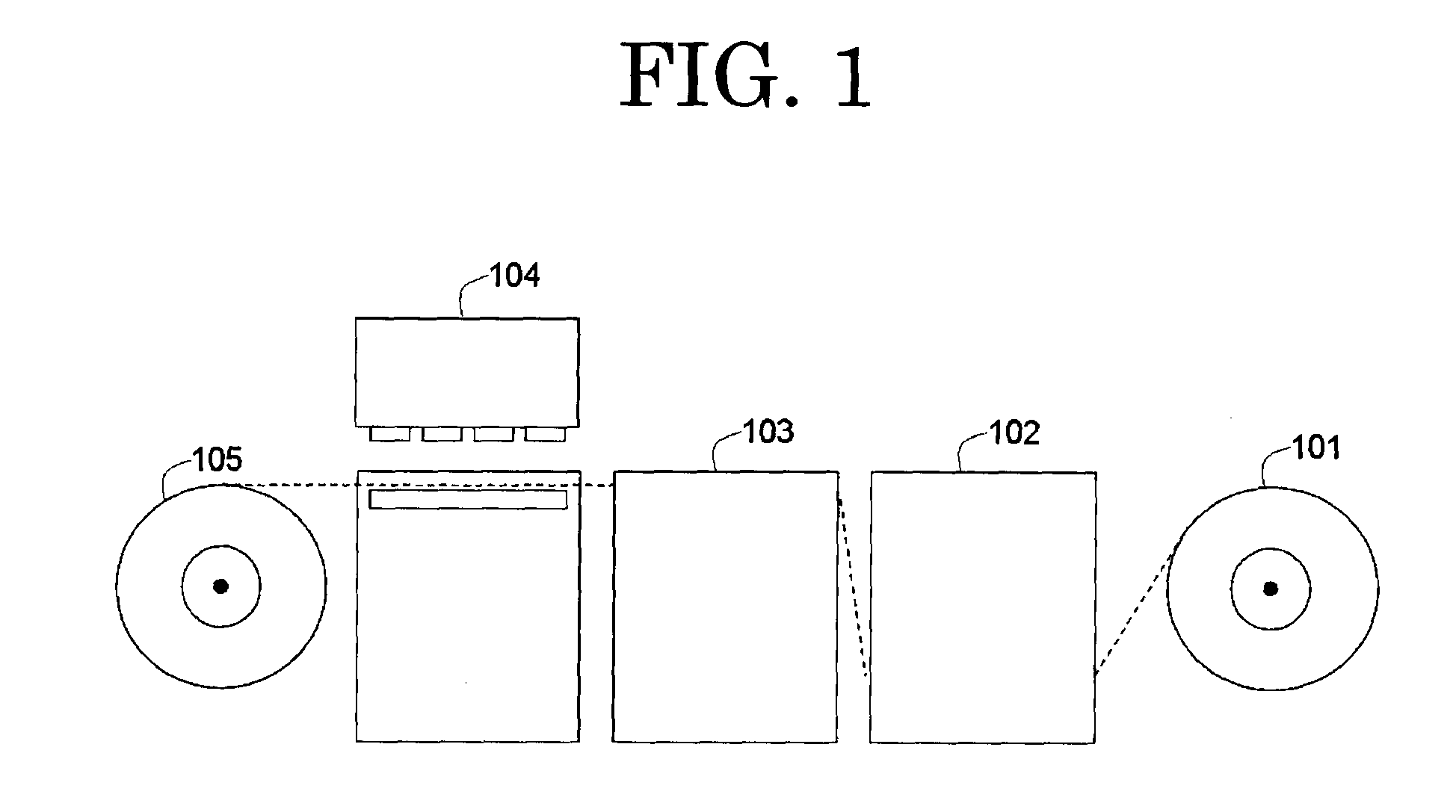

Image forming method, image forming apparatus, and recorded matter

ActiveUS20150283828A1Improve image qualityReduce agglomerationLayered productsDuplicating/marking methodsWater basedPolymer science

To provide an image forming method, including: a pre-treatment liquid application step for applying a pre-treatment liquid on a recording medium including a substrate and a coating layer at least on one surface of the substrate, wherein the pre-treatment liquid is applied on a surface of the recording layer with the coating layer! a drying step for drying the recording medium on which the pre-treatment liquid has been applied; and an image forming step for forming an image on the recording medium after drying by discharging a water-based ink by inkjet method, wherein the pre-treatment liquid includes a water-soluble cationic polymer, an ammonium salt of an organic acid and water, and wherein the water-based ink includes water and negatively charged colored particles including a colorant.

Owner:RICOH KK

Sterol Ester Powder

InactiveUS20080187643A1Good solubilization effectReduce aggregationMilk preparationGranular deliveryDairy foodsSterol ester

Compositions in powder form of sterols or stanol esters, and milk powder and / or proteins are disclosed. A process of making the compositions is also disclosed. The suitability of incorporation of the compositions in powder form in food products, for example beverages and milk products, is also disclosed.

Owner:COGNIS IP MANAGEMENT GMBH

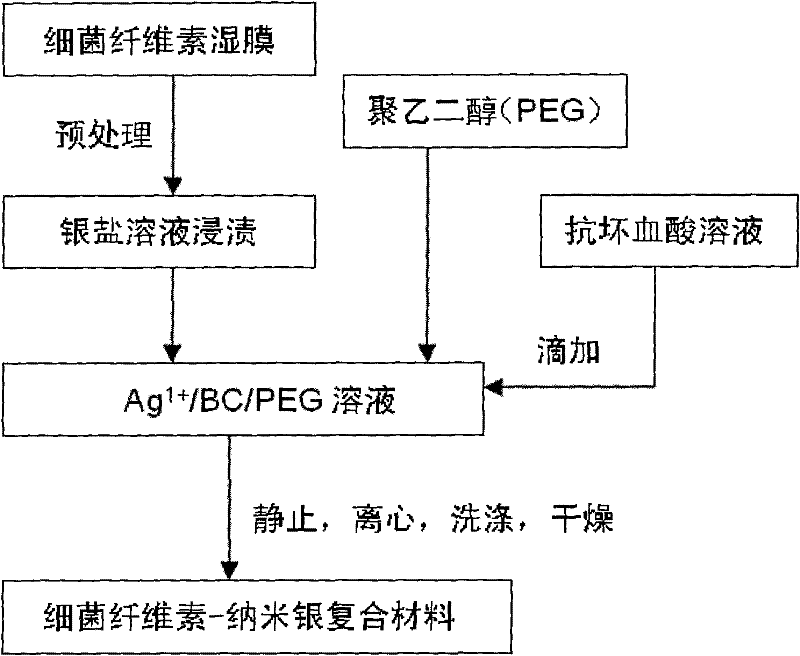

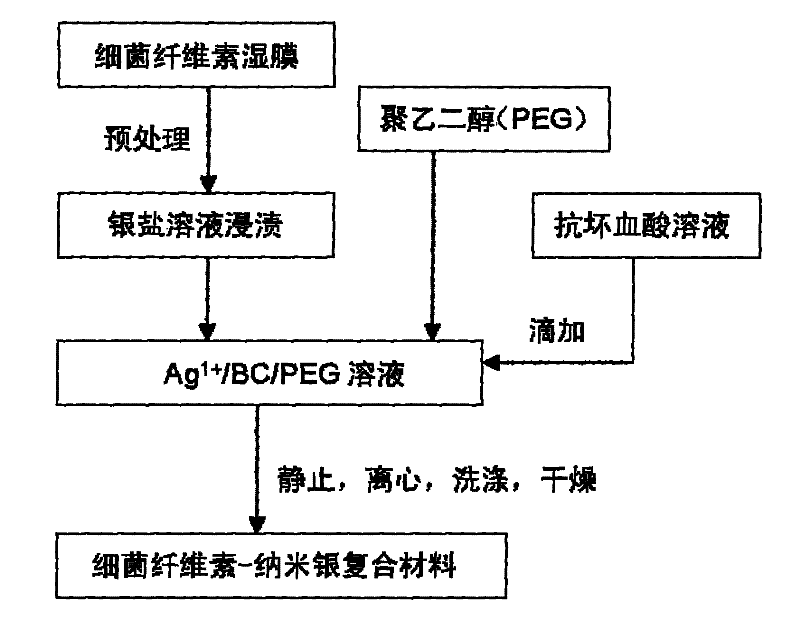

Preparation method of bacterial cellulose-nano silver composite material

ActiveCN102212806AReduce agglomerationSmall particle sizeLiquid/solution decomposition chemical coatingPolyethylene glycolSalt solution

The invention discloses a preparation method of a bacterial cellulose-nano silver composite material. The composite material is prepared by the following steps: pretreating a bacterial cellulose wet film; impregnating in a silver salt solution; transferring the bacterial cellulose with adsorbed silver ions into a polyethylene glycol solution; dropwisely adding an ascorbic acid solution into the mixed system; and carrying out centrifugal separation, washing, and drying to obtain the bacterial cellulose-nano silver composite material. By using the method for reducing silver ions through ascorbic acid under the protection of polyethylene glycol, the invention takes advantages of the stabilizing effect of the polyethylene glycol, the mild reaction conditions and nontoxicity of the ascorbic acid and the like, thus forming a nano composite system having the characteristics of small particle diameter and uniform distribution. The bacterial cellulose-nano silver composite material can be usedin the fields such as medical antiseptic dressings and the like.

Owner:NANJING UNIV OF SCI & TECH

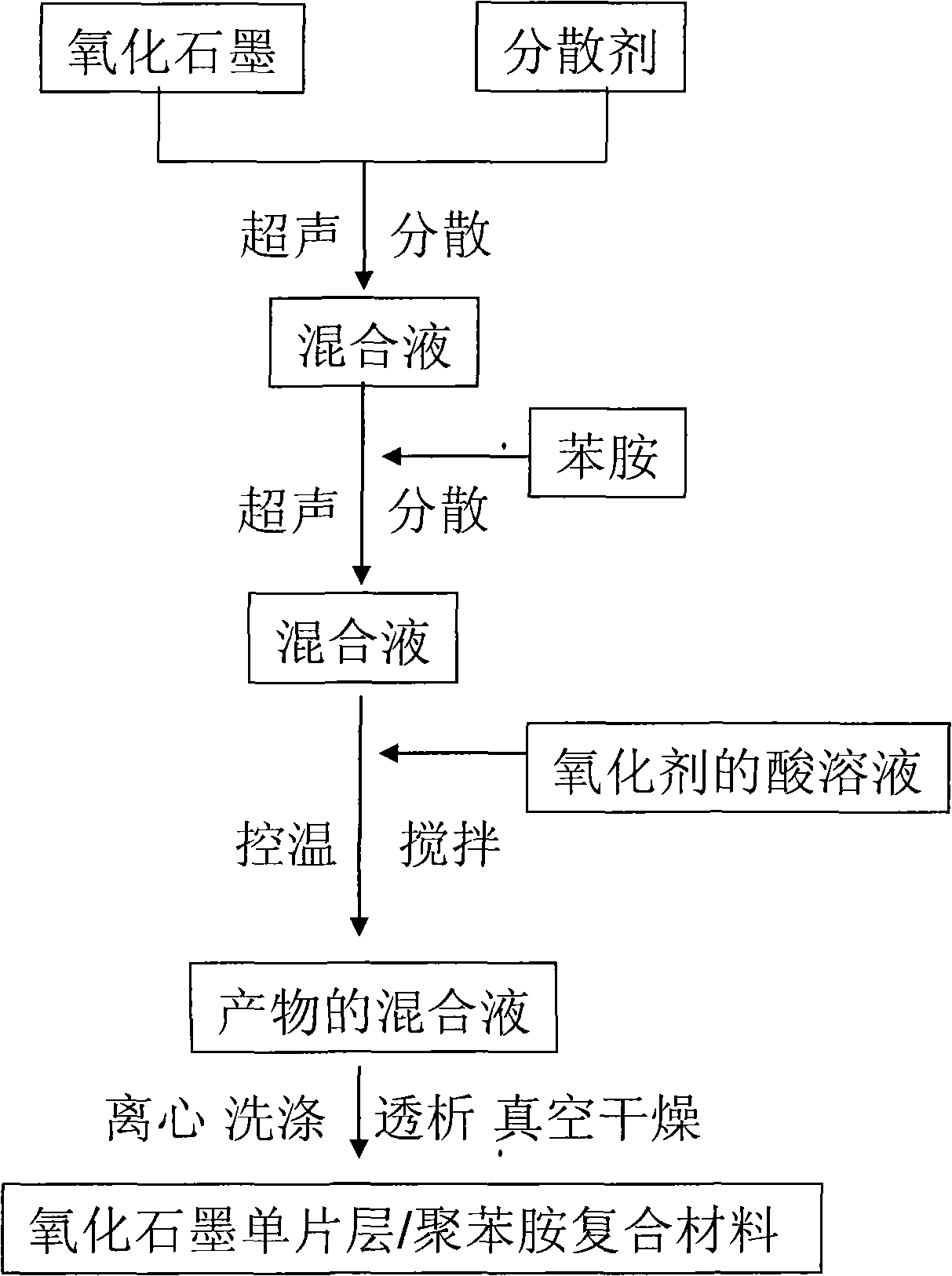

Oxidized graphite flake layer/polyaniline composite material and method for preparing the same

The invention relates to oxidized graphite sheet layer / polyaniline composite material and a preparation method thereof. The composite material is prepared by the following steps: the oxidized graphite is added into a dispersant for ultrasonic dispersion so as to form homodispersed single-sheet layer oxidized graphite mixed liquor; at the room temperature, aniline is added into the mixed liquor obtained in the first step drop by drop, and the ultrasonic dispersion is carried out to form the mixed liquor; a solution obtained by adding an oxidant into doping acid is dropwise added into the mixed liquor obtained in the second step for stirring and polymerization; the mixed liquor obtained in the third step is centrifugated, washed and dried in vacuum so as to obtain the oxidized graphite sheet layer / polyaniline composite material. The invention takes full advantages of big specific area of the oxidized graphite and surface oxygroup group to form binding sites and is organically combined with polyaniline skeleton by the chemical doping function of carboxylic acid group on the single-sheet layer of the oxidized graphite so as to form oxidized graphite / polyaniline complex; the operation process of preparing the product is simple, the production period thereof is short, the yield is high and the requirements on devices are low.

Owner:NANJING UNIV OF SCI & TECH

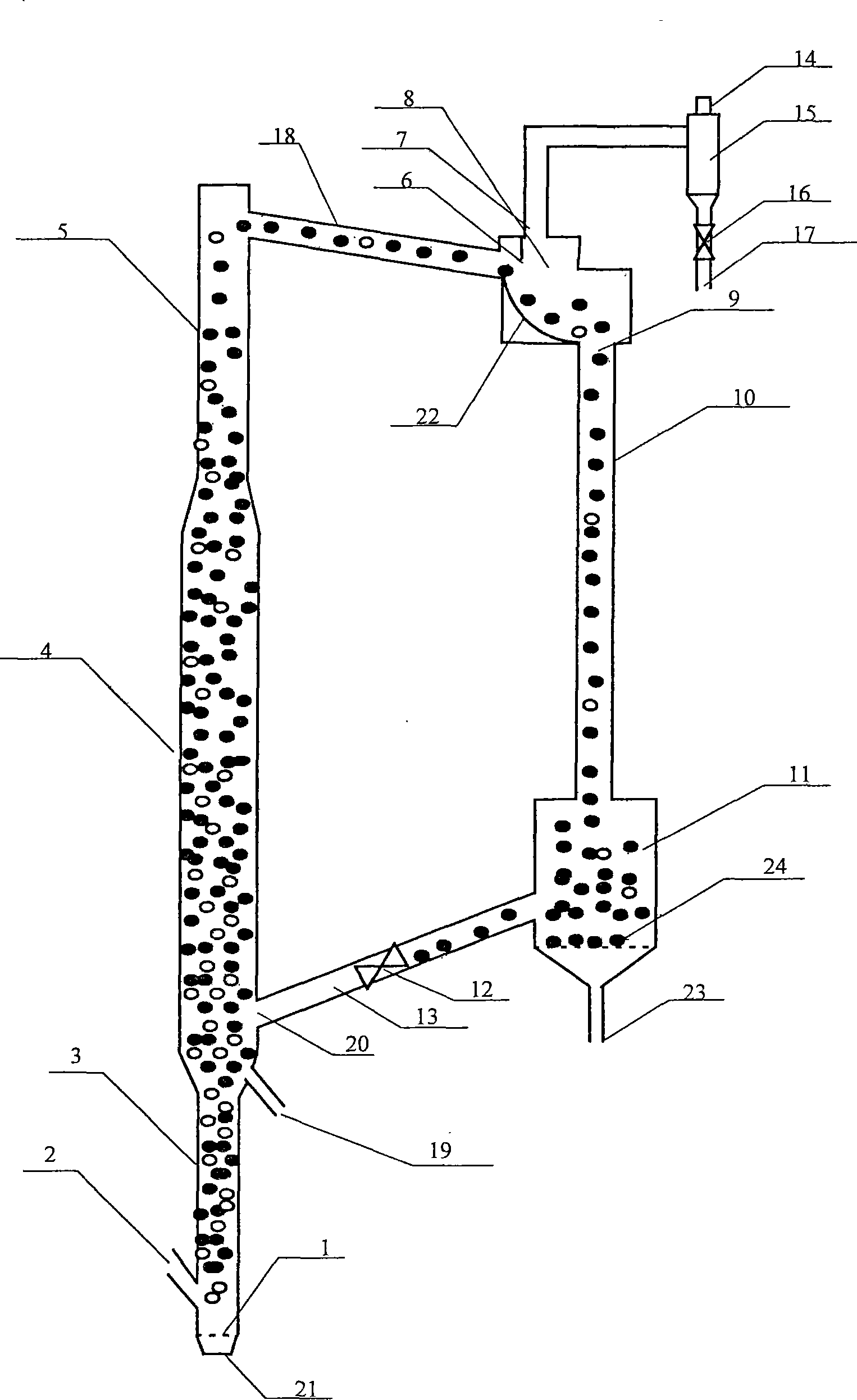

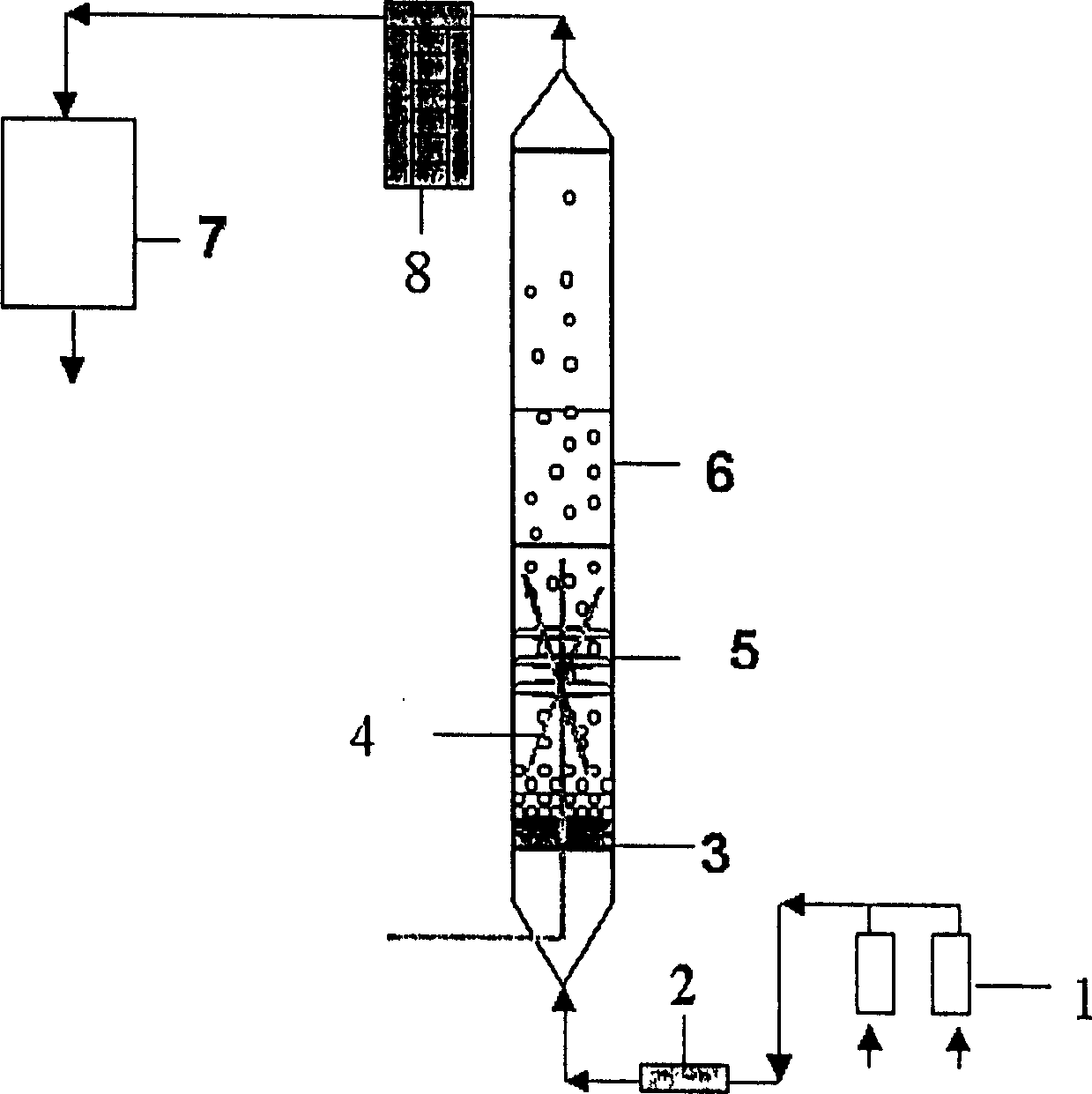

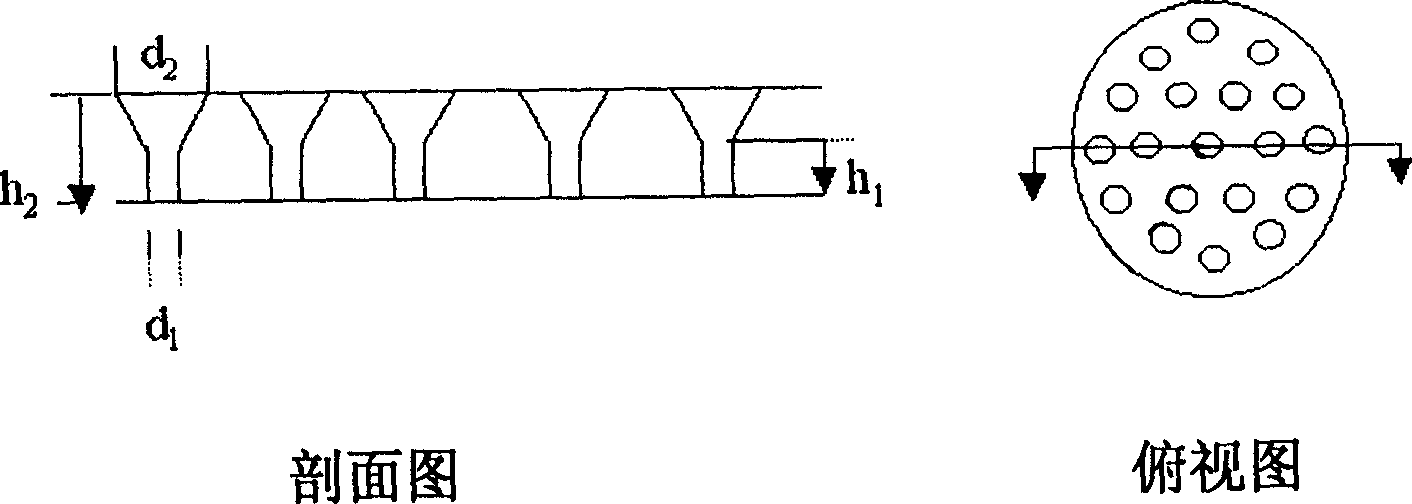

Method for preparing titanic chloride by half cycle fluidization

InactiveCN101475210AReduce agglomerationSolve the conundrum problemFluidised-bed furnacesTitanium halidesNitrogenLower grade

The invention discloses a method for preparing titanium tetrachloride through semi-circulating fluidization, which relates to a method for preparing the titanium tetrachloride. The method takes low-grade high titanium slag and coke as solid raw materials, takes chloride and nitrogen as gas raw materials, and utilizes a semi-circulating fluidized bed to obtain a finished product through a chlorination reaction, cooling and gas-solid separation. The method avoids the agglomeration and adhesion of the particles by circulating coke particles with smaller viscosity and suspending high titanium slag particles with larger viscosity in a fluidized bed reactor, can fully utilize low-grade high titanium slag resource, and has the characteristics of high production efficiency, good product quality, simple and convenient operation, suitability for industrial mass production and the like. The method can be widely applied to the preparation of the titanium tetrachloride by utilizing titanium ore, and is particularly suitable to utilize the low-grade high titanium slag to prepare the titanium tetrachloride.

Owner:CHONGQING UNIV

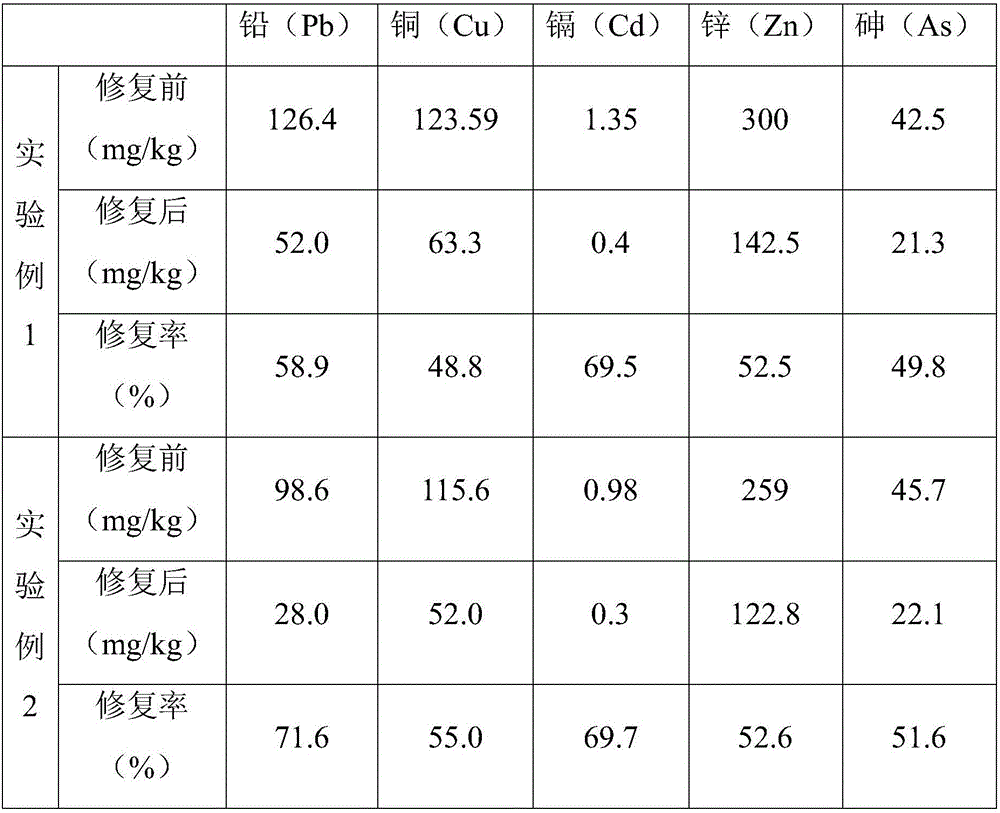

Repair agent for treating compound pollution of heavy metal in soil and preparation method of repair agent

InactiveCN106800939AIncrease surface areaReduce agglomerationAgriculture tools and machinesOther chemical processesSoil heavy metalsAgricultural residue

The invention discloses a repair agent for treating compound pollution of a heavy metal in soil and a preparation method of the repair agent. The repair agent is prepared from the following components in parts by weight: 6-8 parts of modified nano-carbon black, 2-5 parts of sodium bentonite-loaded nano zero-valent iron, 1-2 parts of phosphate mineral and 5-10 parts of decomposed forestry and agricultural residues. The preparation method comprises the steps of (1) crushing the phosphate mineral and the decomposed forestry and agricultural residues into powder of which the particle size is 100-200 meshes separately and drying for later use; and (2) mixing the modified nano-carbon black, the phosphate mineral, the sodium bentonite-loaded nano zero-valent iron and the decomposed forestry and agricultural residues according to the formula, and stirring in a closed container to prepare the repair agent for treating compound pollution of the heavy metal in the soil.

Owner:四川省有色冶金研究院有限公司

Method for coating small particles

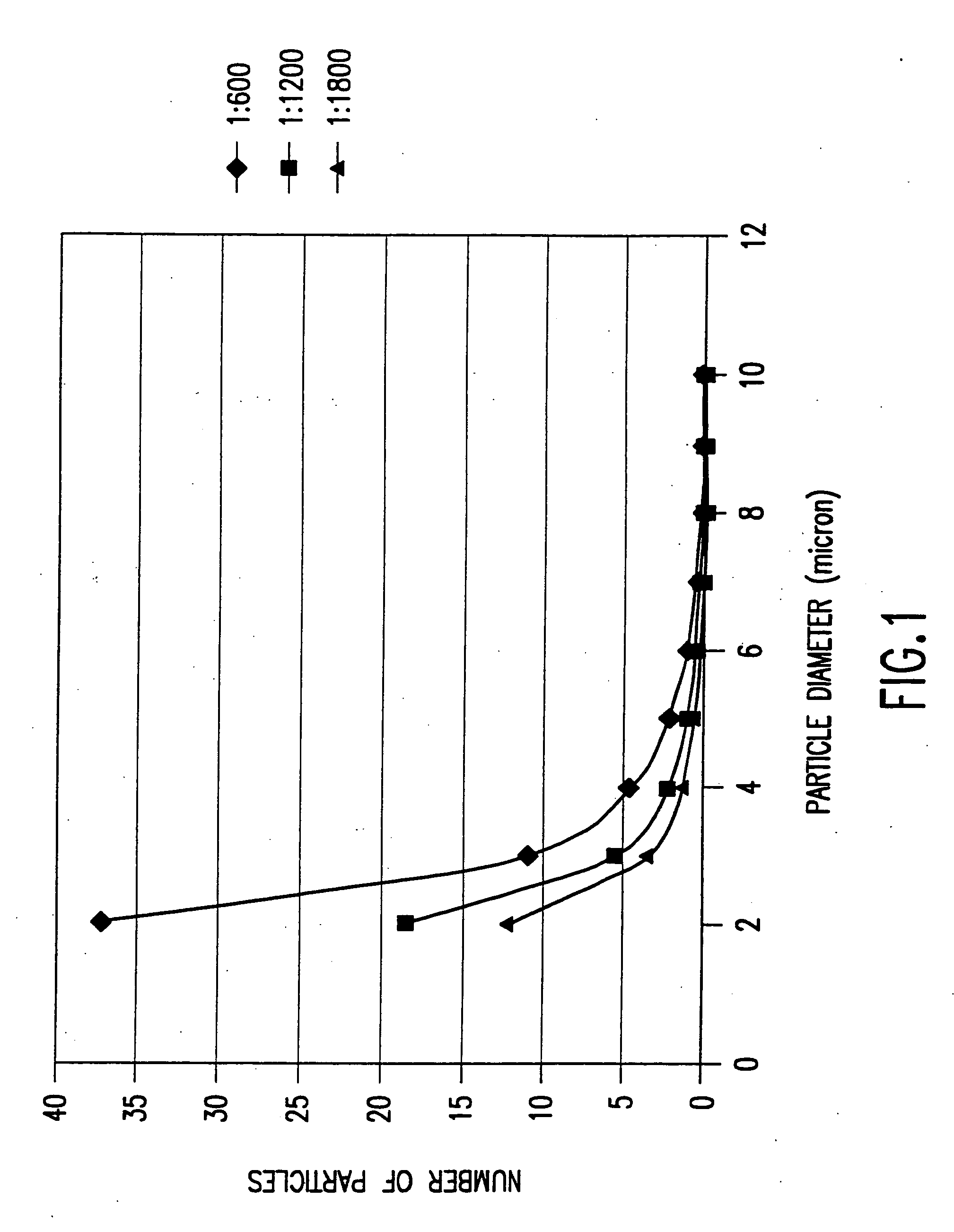

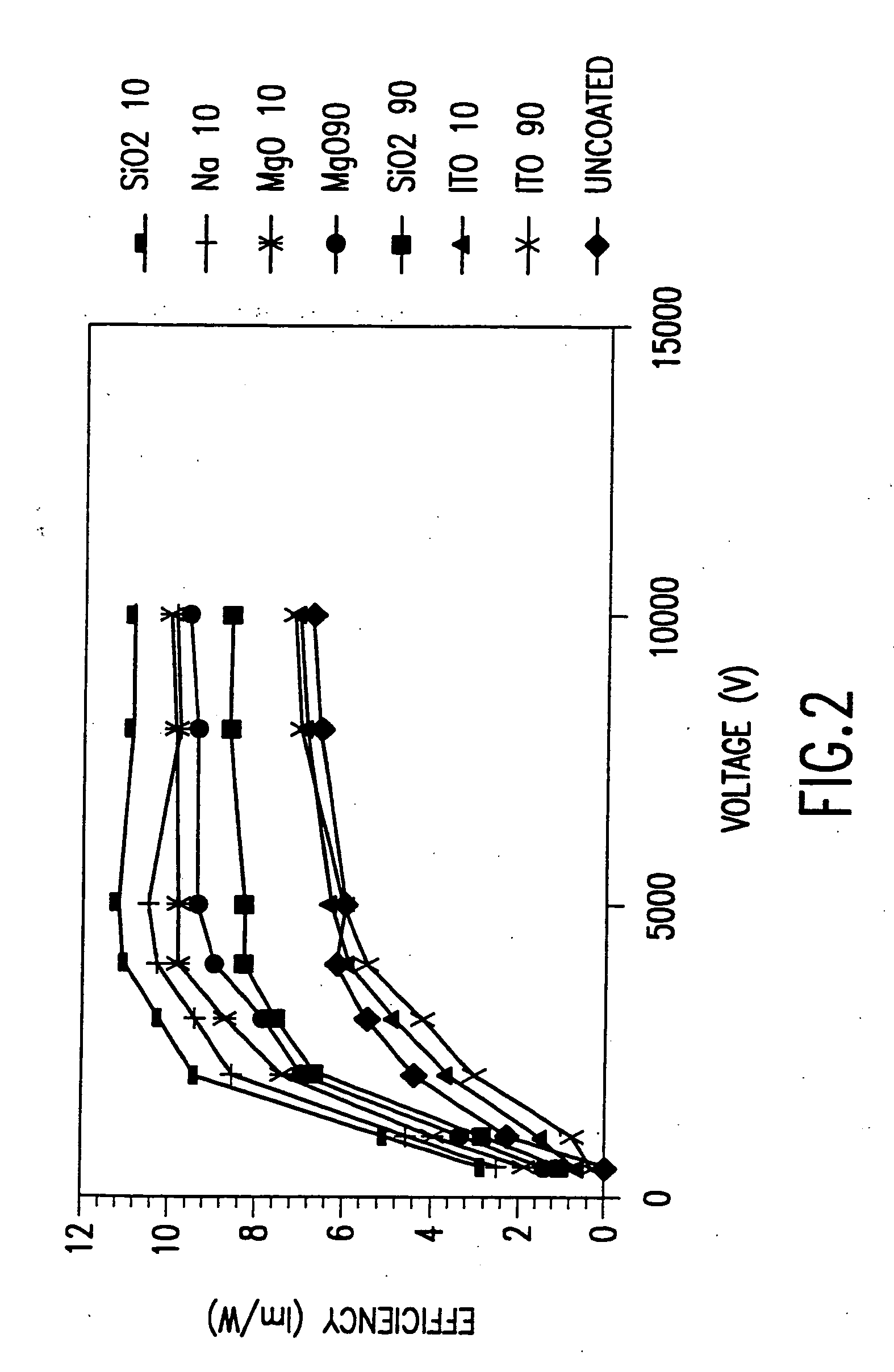

InactiveUS20060024436A1Good coating uniformityReduce agglomerationLiquid surface applicatorsGranule coatingSolventSmall particle

The coating method includes the steps of dissolving coating precursor(s) in a solvent to form a precursor solution: adding with mixing a miscible diluent to the precursor solution to form a coating solution; admixing solid particles to the coating solution to form a coating slurry, with the particles surrounded with the coating solution; spraying the coating slurry to form droplets containing at least one particle; passing the droplets through a drying zone where the droplets are dried and form dry particles coated with a coating material formed from the coating precursor(s); heat-treating the coating material on the particles emanating from the drying zone to remove volatile matter on the coating material, to improve integrity of the coating material and / or to effect another objective; and collecting dry coated particles.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

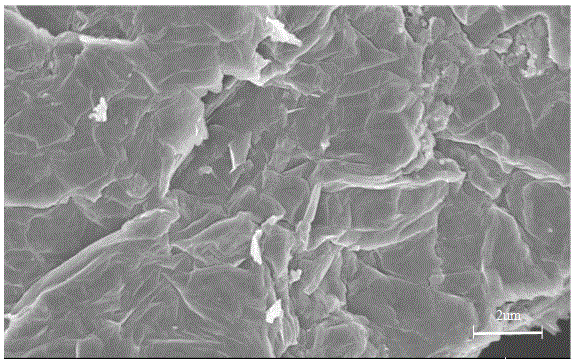

Preparation method of graphene heat conducting film

ActiveCN105964522AGood orientationReduce agglomerationPretreated surfacesCoatingsFiberPolymer science

The invention provides a preparation method of a graphene heat conducting film and belongs to the technical field of graphene materials. The problems that according to the conventional preparation method of the graphene heat conducting film, the technology is complicated and obtained graphene is low in orientation degree, poor in heat conducting property and low in tensile strength are solved. The method comprises: first soaking graphite in an acid-blended solution, and then adding an intercalator and stirring the mixture so as to obtain a mixed solution; then, adding an organic reagent into the mixed solution for reaction so as to obtain graphene aqueous dispersion; adding natural plant macrofibers or polymer macrofibers into the graphene aqueous dispersion, and carrying out ultrasonic processing so as to obtain fiber and graphene mixed dispersion; and finally arranging the fiber and graphene mixed dispersion on a substrate, and processing a film obtained after drying at a temperature of 500-900 DEG C for 15-30 minutes so as to obtain the graphene heat conducting film. The graphene heat conducting film prepared by the method has high orientation degree. The heat conducting coefficient can reach 1000-1500W / mK, and the mechanical tensile strength can reach 30-70MPa.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

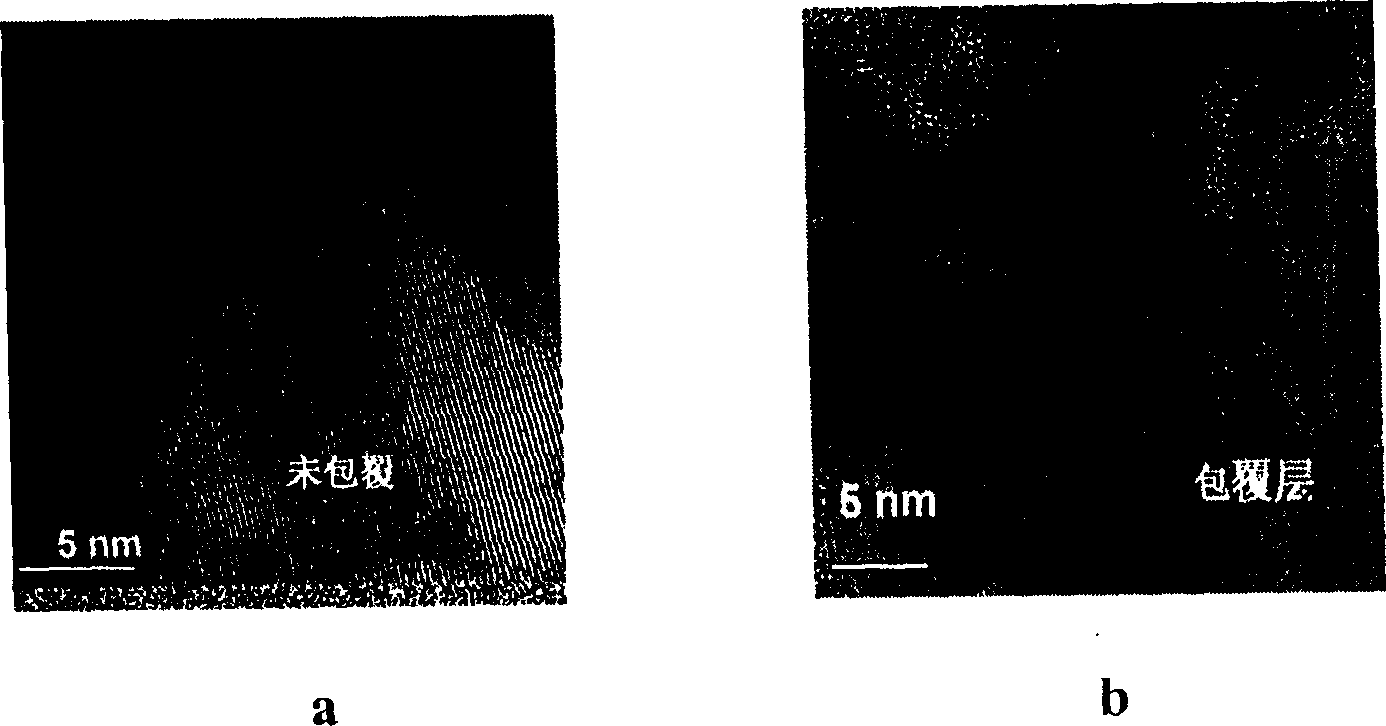

Nano particle surface physicochemical structure cutting and coating method

InactiveCN1488462AEasily brokenPromote infiltrationVacuum evaporation coatingSputtering coatingChemical structureSurface roughness

The invention is a cutting and coating method for surface physical and chemical structure of nano particles. Through confecting the radio frequency plasma to control pulse ratio, time, power, and furthermore control the kind, content, sediment layer thickness the coarse rate of packing film of functional group, it can cut and coat the special monomer molecular functional group film on the surface of the nano particles, and adjusts the thickness, surface coarse rate and so on, gets the coating film with special physical and chemical structure, changes the physical and chemical structure of nano particles.

Owner:DONGHUA UNIV

Liquid-based cell preservation solution

InactiveCN105409925ABrightly dyedLess inflammatory cellsDead animal preservationPotassiumCervical mucus

The present invention relates to pathological examination, especially to a liquid-based cell preservation solution used in pathologically examining cells such as human cervical mucus, sputum, urine, thoracic liquid, and tracheal mucus. The liquid-based cell preservation solution is characterized by being prepared from alcohols, a sodium phosphate buffer solution, disodium ethylenediamine tetraacetate, 0.08-0.12% sodium chloride, potassium chloride, formaldehyde, dithiothreitol, calcium acetate, magnesium acetate and the like. The cell preservation solution cannot only maintain the cell structure stability and reduce the agglomerated precipitation of the cell mucus and the cell breakage loss, but also enables the cells easily to be stained, improves the clarity of the cell sheets, and facilitates smooth performance of the examination work. Moreover, the cell preservation solution is low in cost and easy to promote and use.

Owner:孝感宏翔生物医械技术有限公司

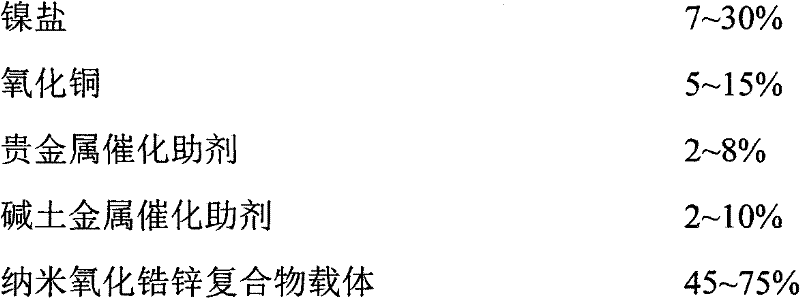

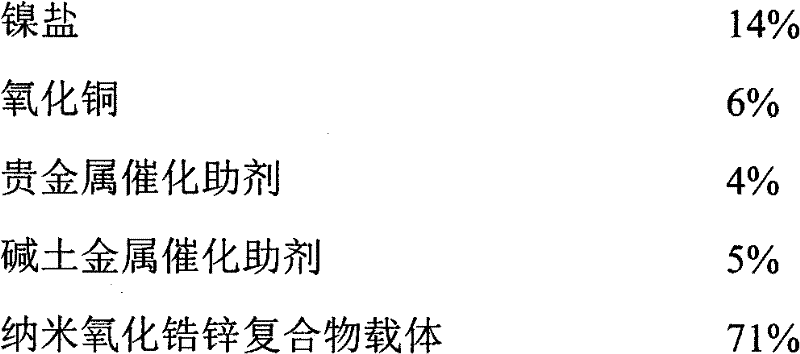

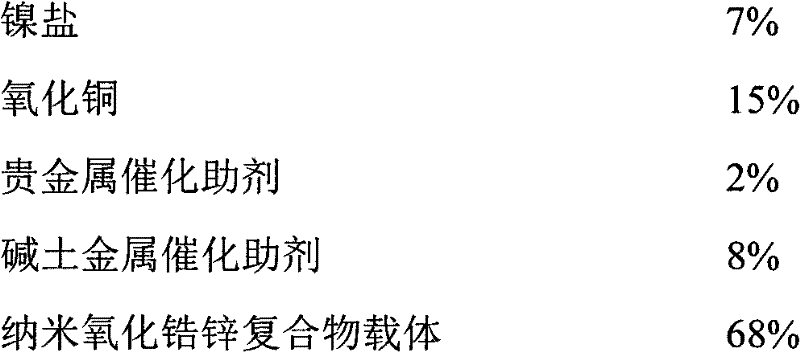

Catalyst for hydrogen production through catalytic cracking of methane and its preparation method

InactiveCN102489311AHigh activityImprove stabilityCatalyst carriersHydrogenAlkaneAlkaline earth metal

Belonging to the technical field of catalysts for hydrogen production through catalytic cracking of methane, the invention relates to a catalyst for hydrogen production through catalytic cracking of methane and its preparation method. The catalyst in the invention is composed of a nickel salt, copper oxide, a precious metal catalytic promoter, an alkaline earth metal catalytic promoter, and a nanometer ZrO-ZnO composite carrier. The method in the invention comprises: taking the nickel salt, the copper oxide, the precious metal catalytic promoter, the alkaline earth metal catalytic promoter, azirconium salt, a zinc salt, and an alkaline precipitating agent as raw materials, first preparing a nanometer ZrO-ZnO composite carrier, then implementing the simple processes of mixing, ultrasonic dispersion, roasting, and moulding, thus obtaining a product. The method in the invention has the advantages of simple process, mild reaction condition, energy saving, sufficient material and liquid utilization, and no discharge of ''three wastes''. The product prepared by the method of the invention has the characteristics of high activity, good dispersibility, and strong temperature resistance, etc. The catalyst prepared by the method provided in the invention can be widely applied in catalytic cracking of methane, ethane and other low carbon alkanes, and is especially suitable for catalyticcracking of methane in a fluidized bed for hydrogen production.

Owner:CHONGQING UNIV

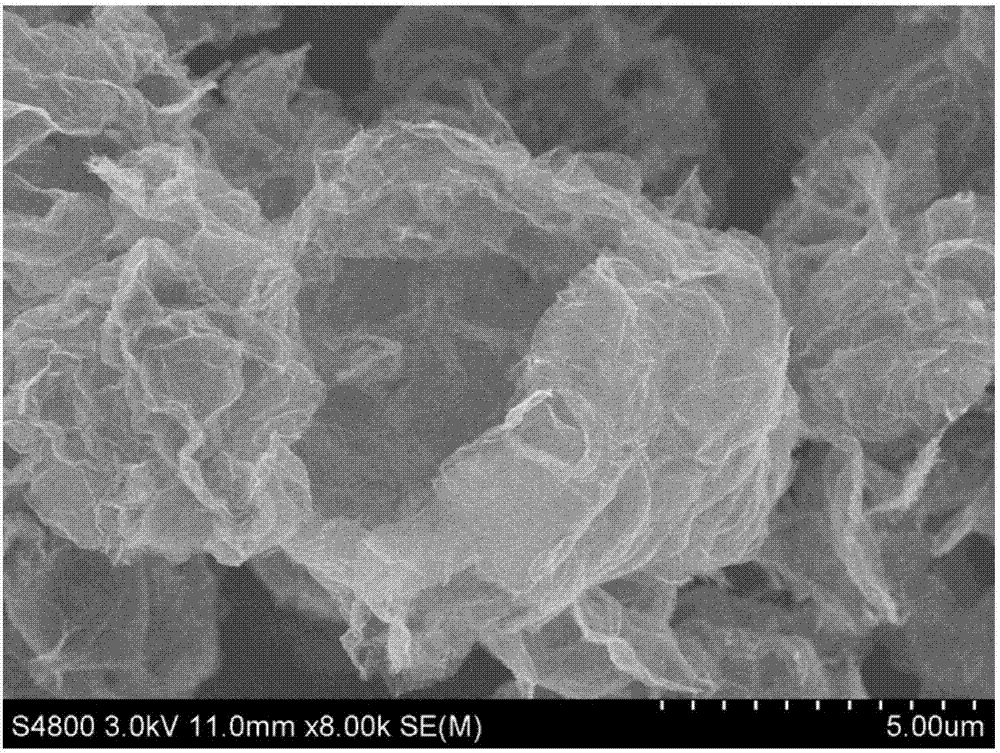

Graphene-based waterborne acrylic paint and preparation method thereof

ActiveCN106987188ASimple structureCompact structureAntifouling/underwater paintsPaints with biocidesEmulsionAcrylic resin

The invention discloses a graphene-based waterborne acrylic paint and a preparation method thereof. The paint is prepared by mixing the following raw materials in parts by weight: 100 parts of an acrylic resin emulsion, 0.1-1 part of spitball graphene microspheres, 30-60 parts of an inorganic filler, 9-12 parts of an assistant and 10-20 parts of water. The spitball graphene microspheres with good mechanical property and elasticity can be obtained through spray drying and two-step method reduction. The spitball graphene microspheres are capable of effectively absorbing shock after being added to the paint, so that the abrasive resistance of a coating is improved and the chemical corrosion resistance can be improved. The spitball graphene microspheres have a unique microstructure, so that graphene can be effectively prevented from being stacked, the phenomena of aggregation and precipitation of the graphene in the paint are avoided and the overall stability of the paint is greatly improved.

Owner:HANGZHOU GAOXI TECH CO LTD

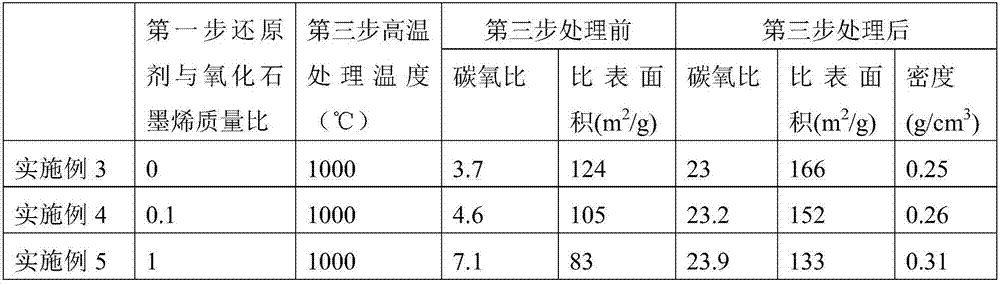

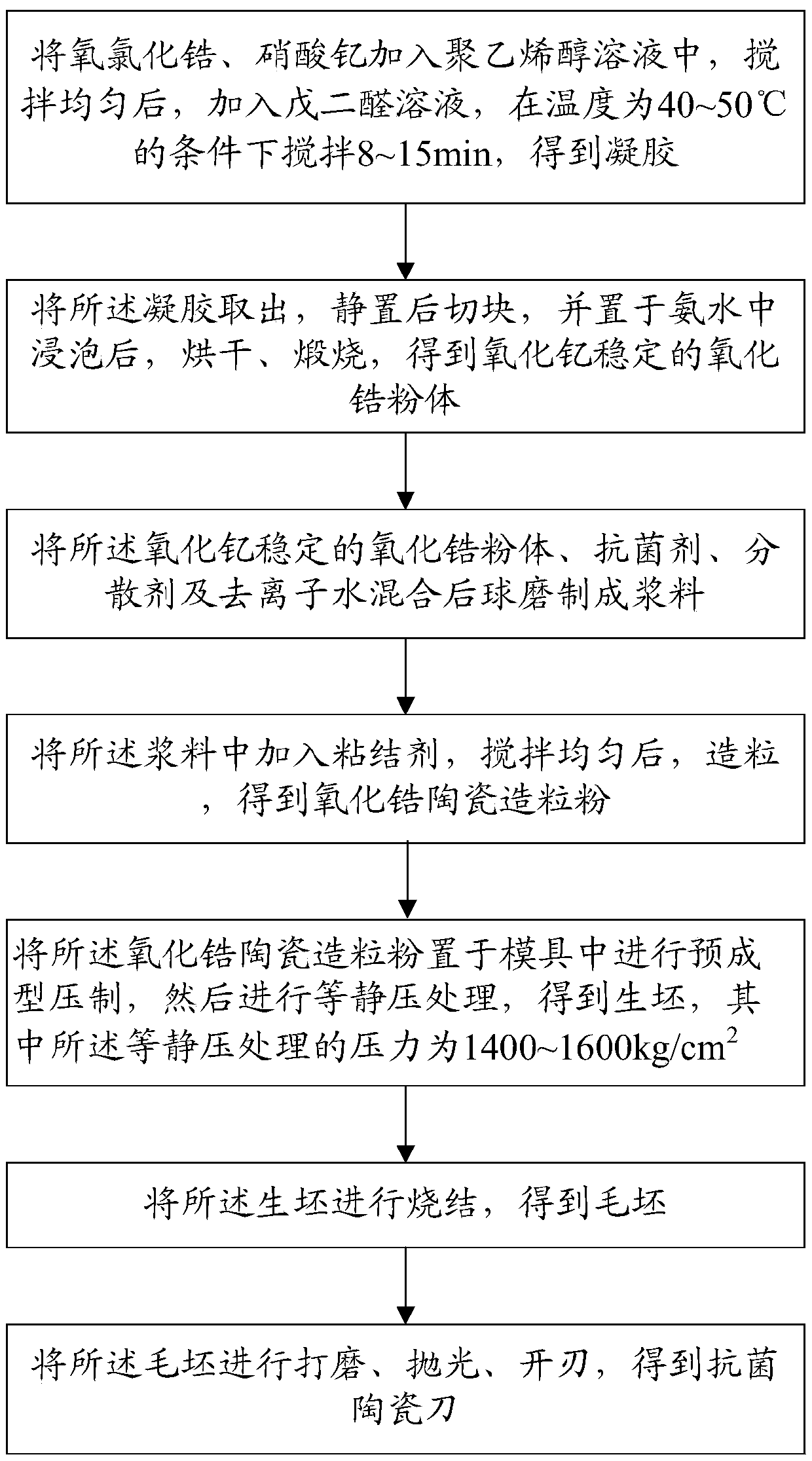

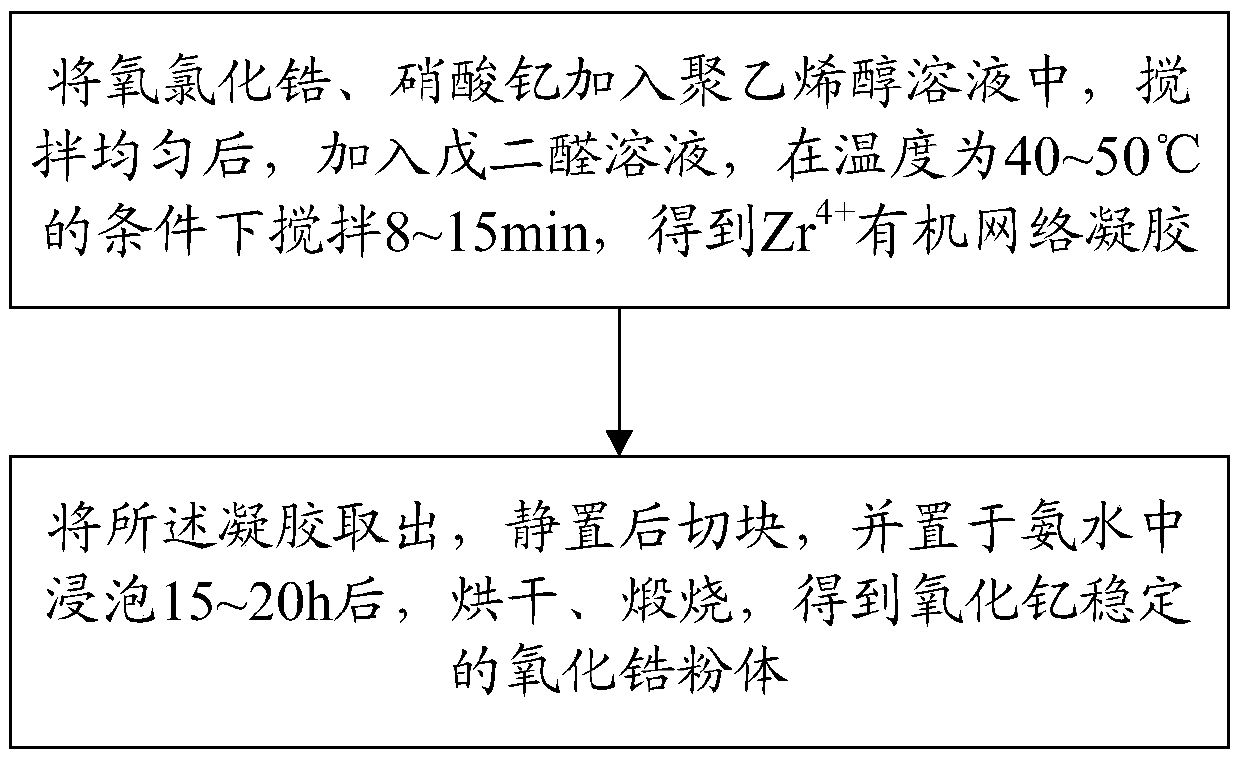

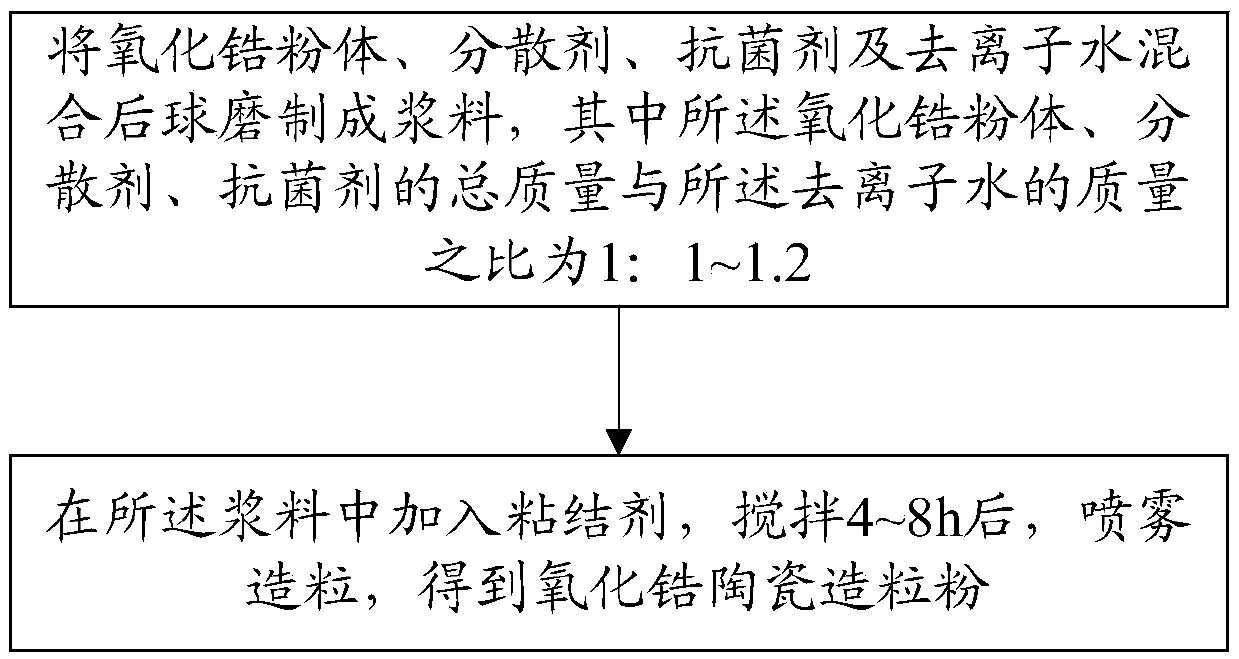

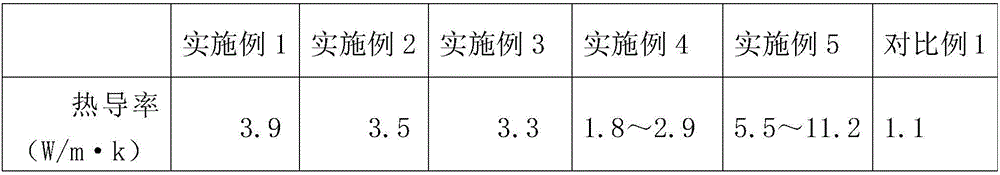

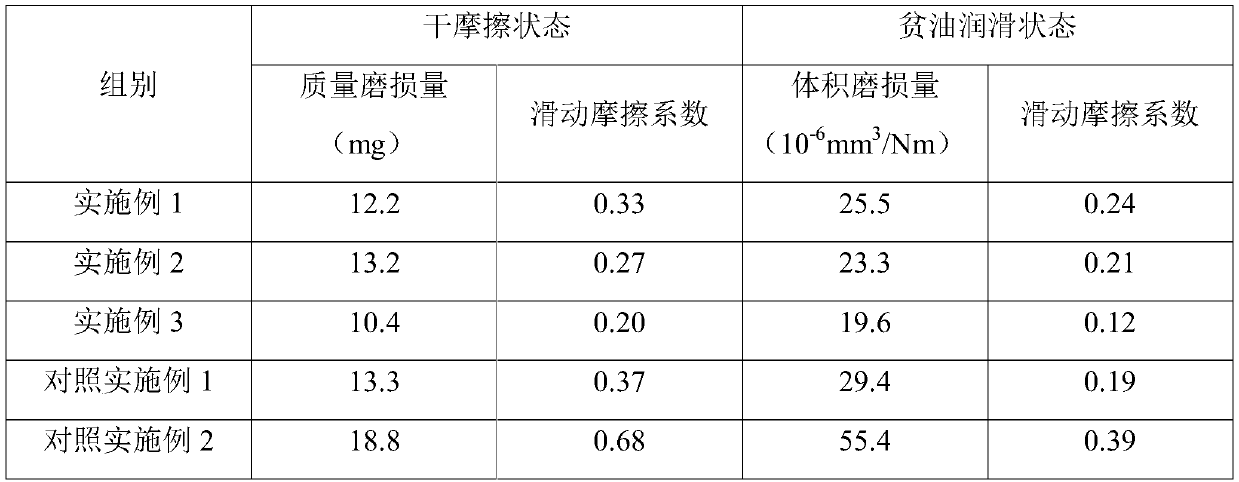

Preparation method for yttria-stabilized zirconia powder

The invention relates to a preparation method for yttria-stabilized zirconia powder. The method comprises the steps that zirconium oxychloride and yttrium nitrate are added into a polyvinyl alcohol solution, the mixture is stirred to be uniform, then a glutaraldehyde solution is added, and the mixture is stirred for 8-15 min at the temperature of 40-50 DEG C to obtain gel, wherein the molar ratio of zirconium oxychloride to yttrium nitrate is 97 to 3; the gel is taken out for standing before being cut into blocks, placed in ammonium hydroxide to be soaked for 15-20 hours and then dried and calcined to obtain the yttria-stabilized zirconia powder. Through the preparation method for the yttria-stabilized zirconia powder, formed zirconia crystal nuclei grow in a cross-linking network provided by polyvinyl alcohol gel liquid; due to limitation of the three-dimensional network, zirconia particles can be prevented from colliding with one another and gathering, agglomeration is reduced, and the yttria-stabilized zirconia powder with a small particle size and good uniformity can be obtained conveniently.

Owner:DONGGUAN XINBO STRUCTURAL CERAMICS CO LTD

Graphene polymer composite heat-conduction plastic and preparation method

The invention discloses a graphene polymer composite heat-conduction plastic and a preparation method. The graphene polymer composite heat-conduction plastic comprises the following components in parts by weight: 100 parts of polymer matrix resin, 2-10 parts of modified graphene, 0.1-1 part of an antioxidant. The preparation method of the graphene polymer composite heat-conduction plastic comprises the following steps: step 1, preparing modified graphene; and step 2, preparing the graphene polymer composite heat-conduction plastic. Dispersity of the graphene in a resin matrix is improved, graphene agglomeration is reduced, the high-heat-conductivity heat-conduction plastic can be obtained when the content of the graphene is low, high heat conductivity can be achieved by the small content of the graphene only, influence to basic mechanical property and processing property of the material is low, and the technical requirement on modern electronic packaging can be met well.

Owner:金华碳力新材料科技有限公司

Preparation method of magnolia fruit extract and application thereof in cigarette

ActiveCN102793264AReduce agglomerationImprove clusteringTobacco treatmentEssential-oils/perfumesSmokeBiotechnology

The invention relates to a preparation method of a magnolia fruit extract, which is characterized in that the magnolia fruits as raw material are processed to the magnolia fruit extract by the steps of baking, pulverizing, solvent extraction and concentration. The magnolia fruit extract is added into tobacco shreds, so as to greatly reduce undesired gases in the smoke, reduce irritation of the smoke, improve the concentration and agglomeration of the smoke, improve the smoking property and enhance elegant flavor of the smoke. The preparation method is advantageous in developing the new use of magnolia fruits by use of the common solvents and methods and providing a new natural tobacco flavor.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Aluminum-based material and preparation method thereof

InactiveCN109706350AHigh hardnessImprove wear resistanceFoundry mouldsMetallic material coating processesWear resistantAlloy substrate

The invention discloses an aluminum-based material. Aluminum nitride, zirconium oxide and tantalum oxide particles are uniformly distributed in an aluminum alloy substrate, MoS2, Al2O3 and SiC are distributed on part of a surface layer of the aluminum alloy substrate, the hardness of aluminum nitride, zirconium oxide and tantalum oxide is high, the hardness and wear-resisting performance of the substrate are significantly improved, and fluorinated graphite powder can improve the anti-friction property. The surface of the substrate is coated with a Mn-Cr coating in a fusion mode to effectivelyimprove the wear-resisting performance and corrosion resistance of the alloy surface. The dispersion strengthening of strengthening phases of Si, Cu, Cr, Ni, Hf, Fe, Ag, Ca, Li, Ba and other elementsin the alloy improves the mechanical properties of the material. A preparation method enables mixed powder to be located in the center of a master alloy solution during casting through a method by adhering the mixed powder to a pure aluminum metal wire, the rapid diffusion and homogenization of micro powder particles is facilitated, the production efficiency is improved, wear-resistant materials are locally added by friction stir machining, and the material utilization ratio is improved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

High-dispersity nano-zirconia particles and method for preparing transparent dispersoid of high-dispersity nano-zirconia particles

InactiveCN108529674AReduce agglomerationGood modification effectMaterial nanotechnologyZirconium oxidesDispersityPolymer science

The invention discloses high-dispersity nano-zirconia particles and a method for preparing transparent dispersoid of the high-dispersity nano-zirconia particles. The solid content of transparent nano-zirconia liquid phase dispersoid ranges from 1 wt% to 80 wt%, zirconia crystals are small in grain size and even in distribution, the one-dimensional size ranges from 1 nanometer to 10 nanometers, andthe average grain size is 3 nanometers. According to the preparation method, the nano-zirconia particles are prepared through a method for pyrolyzing inorganic zirconium salt in a supergravity environment, the aggregation performance is greatly reduced as the supergravity level is improved, and then the transparent zirconia liquid phase dispersoid is directly obtained after washing and modifyingare carried out; the problem that nano-zirconia particles are easy to aggregate, poor in dispersity and poor in composite optical performance can be solved, and therefore the product has higher application performance and a wider application range.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com