Method for preparing YAG nano powder

A technology of nano-powder and preparation steps, which is applied in the field of inorganic materials and its preparation, which can solve the problems of harsh synthesis conditions, serious agglomeration, and long synthesis cycle, and achieve the effects of lowering the preparation temperature, reducing the chance of contact, and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Raw material Y 3+ Nitrate aqueous solution (0.3mol / L) 45ml and Al 3+ Nitrate aqueous solution (0.3mol / L) 75ml, cerium nitrate 0.1383g, citric acid 13.7290g, acrylamide monomer 21.3285g, N, N'-methylenebisacrylamide network agent 11.5431g, a little After heating to dissolve and cooling, 0.0119 g of an ammonium persulfate initiator was added. Polymerize at 80°C to obtain a gel, and continue to heat up to 95°C until it is completely dried into a powder to obtain a precursor.

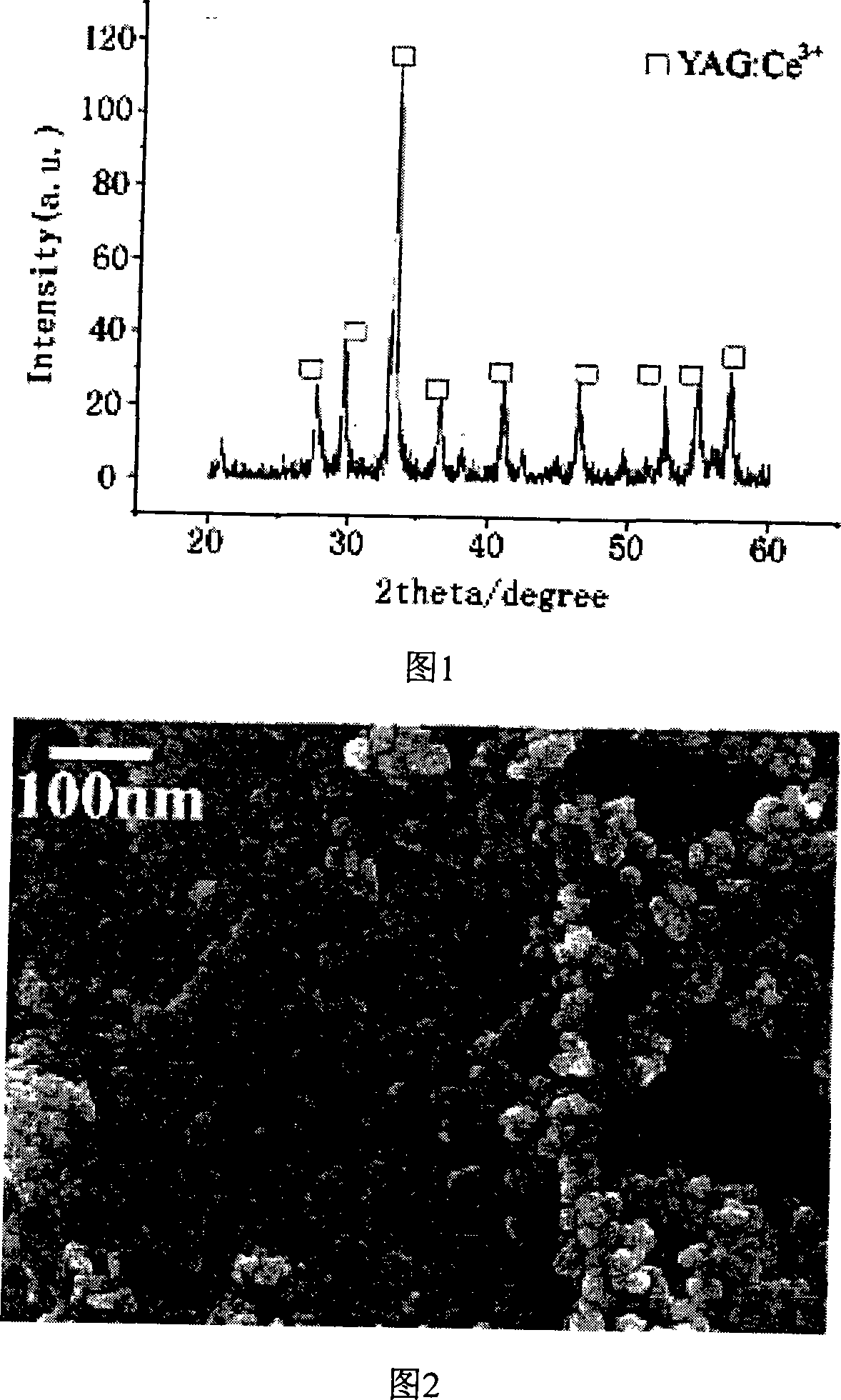

[0012] Carbonize the precursor at 700°C under a nitrogen atmosphere to obtain a black solid (heat up for 135 minutes, hold for 120 minutes, cool down for 120 minutes), and then carry out calcination and decarburization at 800°C with oxygen (heat up for 60 minutes, hold for 60 minutes, cool down for 120 minutes) , to obtain a white powder, XRD spectrum and SEM photo results show that the obtained uniformly dispersed nano-YAG:Ce 3+ Powder.

Embodiment 2

[0014] Raw material Y 3+ Nitrate aqueous solution (0.05mol / L) 45ml and Al 3+ Nitrate aqueous solution (0.05mol / L) 75ml, cerium nitrate 0.06839g, citric acid 6.8558g, acrylamide monomer 10.6641g, N, N'-methylenebisacrylamide network agent 5.7676g, a little Heat to dissolve and cool, and then add 0.0001 g of ammonium persulfate initiator. Polymerize at 80°C to obtain a gel, and continue to heat up to 95°C until it is dried into a powder to obtain a precursor.

[0015] Carbonize the precursor at 700°C under a nitrogen atmosphere to obtain a black solid (heat up for 135 minutes, hold for 120 minutes, cool down for 120 minutes), and then carry out calcination and decarburization at 800°C with oxygen (heat up for 60 minutes, hold for 60 minutes, cool down for 120 minutes) , to obtain a white powder, the XRD spectrum and SEM photo results are the same as in Example 1.

Embodiment 3

[0017] Raw material Y 3+ Nitrate aqueous solution (1mol / L) 45ml and Al 3+ Nitrate aqueous solution (1mol / L) 75ml, add cerium nitrate 0.4610g, citric acid 45.7633g, acrylamide monomer 71.0950g, N, N'-methylenebisacrylamide network agent 38.4770g to the raw material solution, heat slightly After dissolving and cooling, 0.0396 g of an ammonium persulfate initiator was added. Polymerize at 80°C to obtain a gel, and continue to heat up to 95°C until it is completely dried into a powder to obtain a precursor.

[0018] Carbonize the precursor at 700°C under a nitrogen atmosphere to obtain a black solid (heat up for 135 minutes, hold for 120 minutes, cool down for 120 minutes), and then carry out calcination and decarburization at 800°C with oxygen (heat up for 60 minutes, hold for 60 minutes, cool down for 120 minutes) , to obtain a white powder, the XRD spectrum and SEM photo results are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com