Functionalized graphene adsorbent and preparation method and application thereof

An adsorbent and graphene technology, which is applied in the field of nanomaterials and environmental science, can solve the problems of restricting the application of pollutant removal, reducing the specific surface area of graphene, and less application of graphene materials, so as to improve dispersibility and hydrophilicity, The effect of low cost of treatment process and easy control of conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

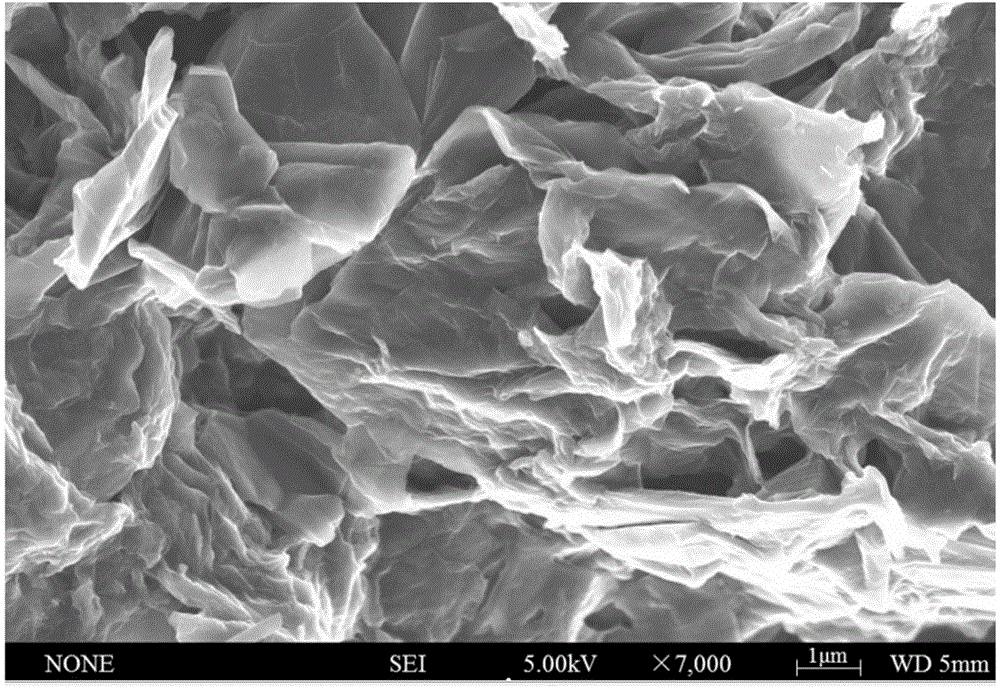

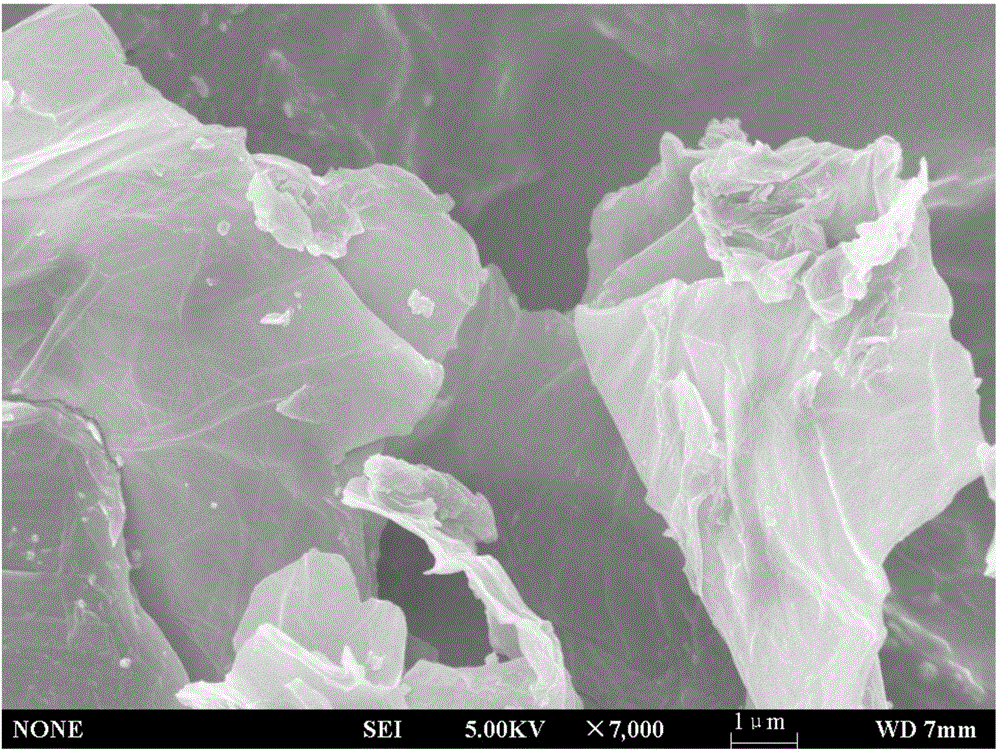

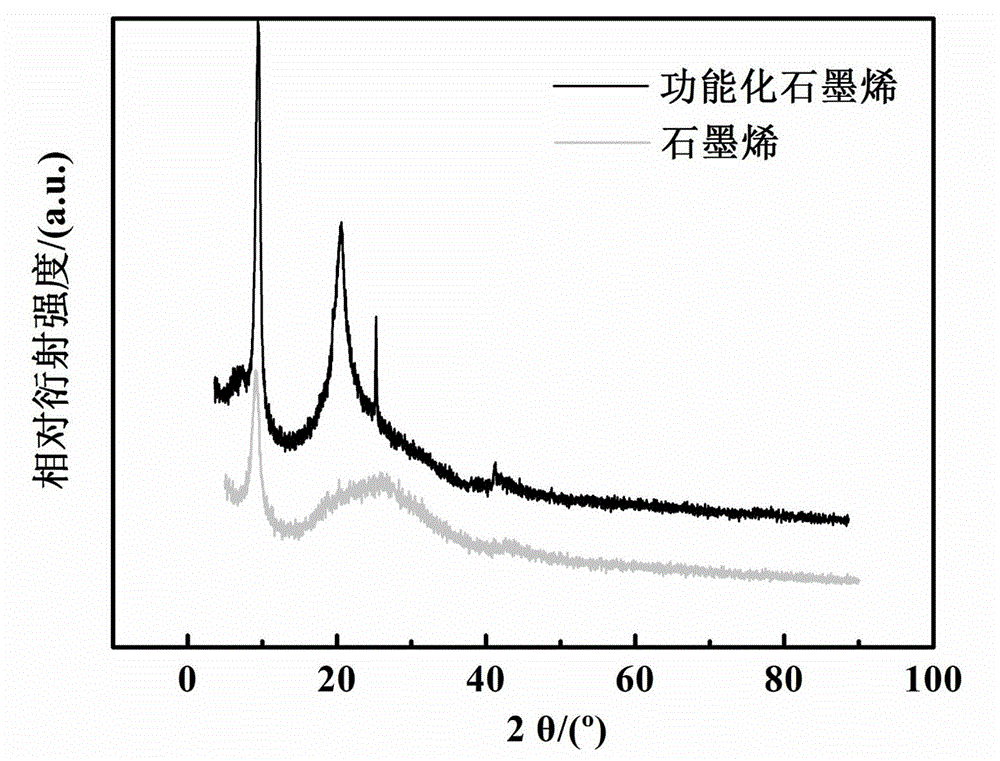

[0036] a kind of like figure 2 Shown functionalized graphene adsorbent of the present invention, this functionalized graphene adsorbent is mainly made up of graphene and cetyltrimethylammonium bromide, and this cetyltrimethylammonium bromide passes non- The covalent bond is inserted and / or embedded in the edge or surface of the layered graphene, and the mass fraction of cetyltrimethylammonium bromide in the functionalized graphene adsorbent is 45%.

[0037] The preparation method of the functionalized graphene adsorbent of the present embodiment comprises the following steps.

[0038] 1. Use the modified Hummers method to synthesize graphene oxide. The specific steps are as follows: slowly add 10g of graphite and 5g of sodium nitrate into a flask containing 230ml of concentrated sulfuric acid, and stir in an ice-water mixture. After 30min, slowly add 30g of high manganese During the stirring process, control the reaction temperature to always be less than 15°C and keep it fo...

Embodiment 2

[0045] Utilize the functionalized graphene adsorbent obtained in embodiment 1 to remove chromium in waste water, concrete steps include:

[0046] (1) The functionalized graphene adsorbent of the above-mentioned embodiment 1 is divided into 9 groups, and then added to the chromium-containing wastewater whose initial concentration of chromium is 50ppm, and the consumption of the adsorbent is 0.4g / L;

[0047] (2) Perform oscillation reaction on the above-mentioned groups of wastewater. The pH values of each group of wastewater are 1, 2, 3, 4, 5, 6, 8, 10 and 12 respectively, and the reaction temperature of each group of wastewater is 30°C. The reaction speed is 130rpm, and the shaking reaction time is 40min;

[0048] (3) Use a 0.22 μm filter membrane to filter each group of wastewater after the oscillation reaction to complete the removal of chromium in the wastewater.

[0049] Measure the residual amount of heavy metal chromium in each group of wastewater samples of this embo...

Embodiment 3

[0051] Utilize the functionalized graphene adsorbent obtained in embodiment 1 to remove chromium in waste water, concrete steps include:

[0052] (1) The above functionalized graphene adsorbents were divided into 10 groups, and then added to chromium-containing wastewater with an initial concentration of chromium of 50ppm, and the amount of adsorbents was 0.4g / L;

[0053] (2) Perform oscillation reaction on the above-mentioned groups of wastewater. The pH value of each group of wastewater is controlled at 2, the temperature is 30°C, the rotation speed of the oscillation reaction is 130rpm, and the oscillation reaction time is 1min, 3min, 5min, 10min, respectively. 20min, 30min, 40min, 60min, 90min and 120min;

[0054] (3) Use a 0.22 μm filter membrane to filter each group of wastewater after the oscillation reaction to complete the removal of chromium in the wastewater.

[0055] Determination of the residual amount of heavy metal chromium in each group of wastewater samples, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com