Graphene polymer composite heat-conduction plastic and preparation method

A technology of olefinic polymers and thermally conductive plastics, applied in the field of graphite polymer composite thermally conductive plastics and its preparation, can solve the problems of high price of thermally conductive plastics, expensive graphene, and difficulty in wide-scale application, and achieve basic mechanical properties and processing properties Small impact, good initial thermal conductivity, and the effect of reducing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

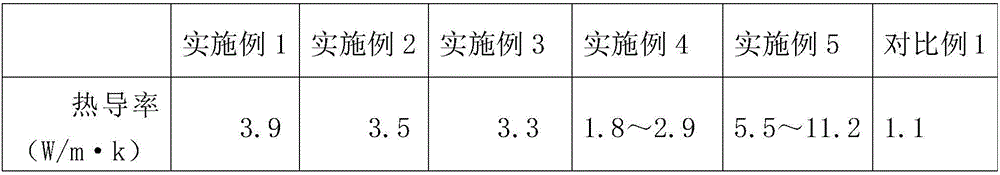

Examples

Embodiment 1

[0022] A graphene polymer composite thermally conductive plastic, in parts by weight, said polygraphene polymer composite thermally conductive plastic comprises 100 parts of polymer matrix resin, 2.5 parts of modified graphene, 0.3 parts of antioxidant, and 0.3 parts of additives. The polymer matrix resin is nylon 6 (PA6), the antioxidant is 0.15 parts of antioxidant 1010, and 0.15 parts of antioxidant 168. The auxiliary agent is ethylene bis stearamide, and the modified graphene is styrene maleic anhydride binary copolymer grafted modified multilayer graphene, and the styrene unit and maleic anhydride in the styrene maleic anhydride binary copolymer The weight ratio of the units is 1:2.

[0023] A method for preparing a graphene polymer composite thermally conductive plastic, comprising the steps of:

[0024] Step 1: prepare modified graphene;

[0025] Step 2: Preparation of graphene-polymer composite heat-conducting plastics: Weigh 100 parts of polymer matrix resin, 2.5 pa...

Embodiment 2

[0030] A graphene polymer composite heat-conducting plastic. In parts by weight, the polygraphene polymer composite heat-conducting plastic includes 100 parts of polymer matrix resin, 3 parts of modified graphene, 0.4 parts of antioxidant, and 0.3 parts of auxiliary agent. The polymer matrix resin is nylon 12 (PA12). The antioxidant is 0.2 part of antioxidant 1076 and 0.2 part of antioxidant 626. The additive is silicone powder. The modified graphene is a styrene-maleic anhydride binary copolymer grafted modified multi-layer graphene, and the weight ratio of the styrene unit to the maleic anhydride unit in the binary copolymer is 1:2.

[0031] A method for preparing a graphene polymer composite thermally conductive plastic, comprising the steps of:

[0032] Step 1: prepare modified graphene;

[0033] Step 2: Preparation of graphene polymer composite heat-conducting plastic: weigh 100 parts of polymer matrix resin, 3 parts of modified graphene, 0.4 parts of antioxidant, and ...

Embodiment 3

[0038] A graphene polymer composite thermally conductive plastic, in parts by weight, said polygraphene polymer composite thermally conductive plastic comprises 100 parts of polymer matrix resin, 3 parts of modified graphene, 0.4 part of antioxidant, and 0.5 part of auxiliary agent. The polymer matrix resin is polybutylene terephthalate PBT. The antioxidant is 0.2 part of antioxidant 1010 and 0.2 part of antioxidant 168. The auxiliary agent is ethylene bis stearamide. The modified graphene is a styrene maleic anhydride binary copolymer grafted modified multilayer graphene, and the weight ratio of styrene and maleic anhydride units in the binary copolymer is 1:2.

[0039] A method for preparing a graphene polymer composite thermally conductive plastic, comprising the steps of:

[0040] Step 1: prepare modified graphene;

[0041] Step 2: Preparation of graphene-polymer composite heat-conducting plastic: Weigh 100 parts of polymer matrix resin, 3 parts of modified graphene, 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com