Aluminum-based material and preparation method thereof

An aluminum-based material and matrix technology, applied in the field of aluminum alloy materials, can solve the problems of inability to concentrate wear resistance, inability to isolate corrosion factors, and increase material costs, so as to improve hardness and wear resistance, and achieve significant wear resistance. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

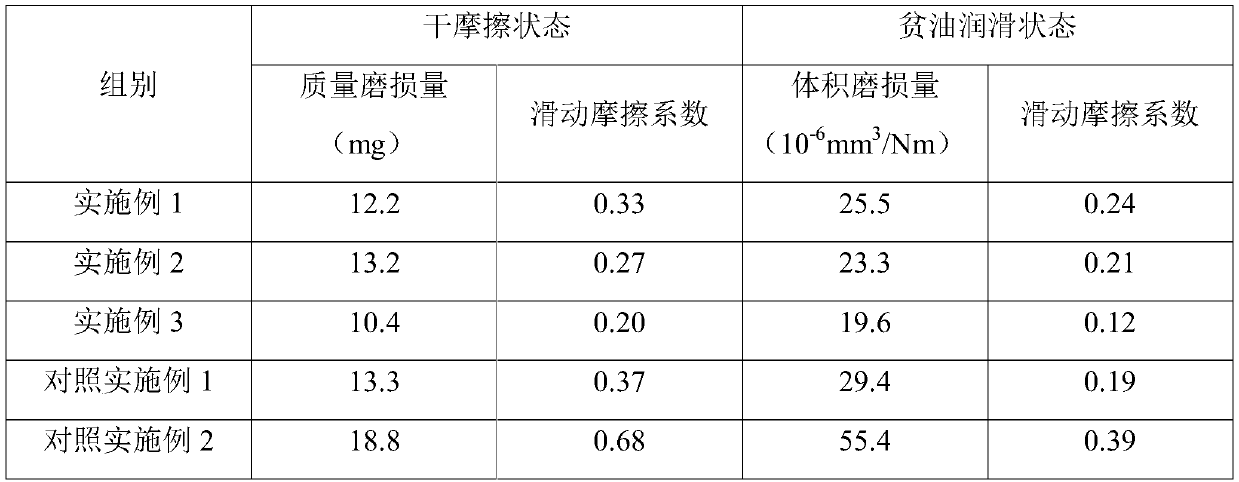

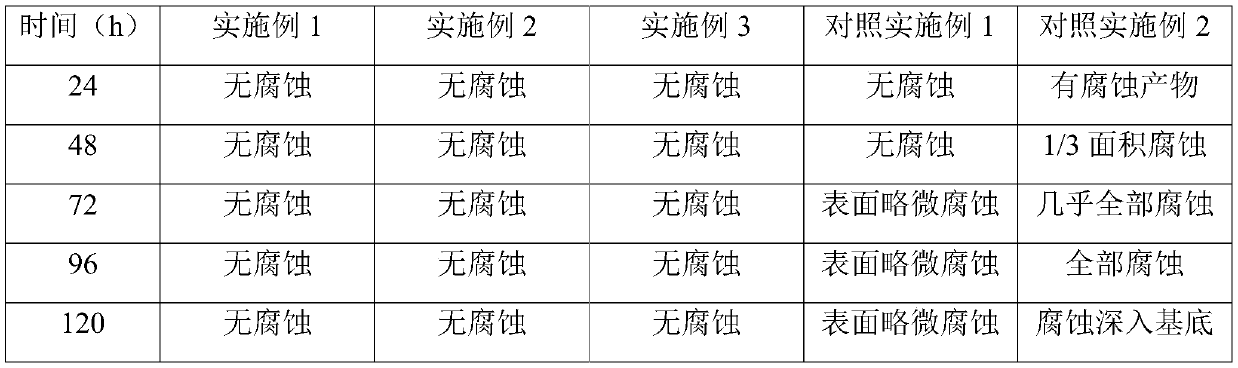

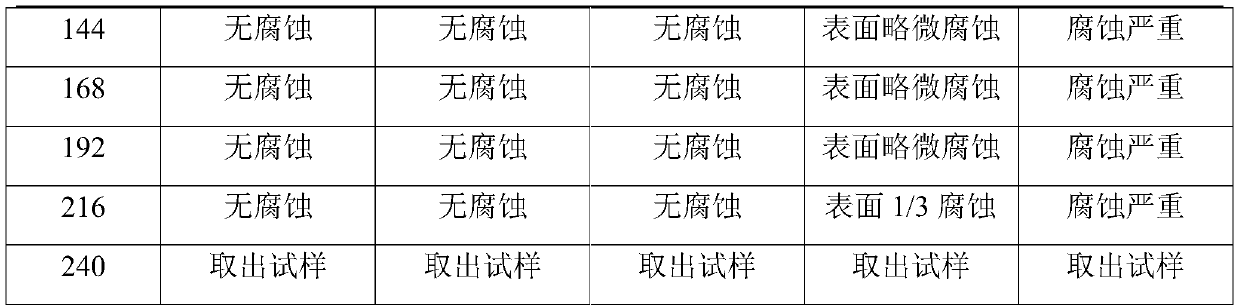

Examples

Embodiment 1

[0033] Embodiment 1: Aluminum-based materials are prepared as follows:

[0034] 1. Preparation of raw materials:

[0035] The relative weight ratio of aluminum nitride, zirconia, tantalum oxide, and graphite fluoride is 1.2:1:1:0.06; Ag, Ca, Li, Hf, Cr, Si, Fe, Cu, Ba, and Al in the raw materials are all simple substances , the purity is greater than 99.9%; Ni is added in the form of aluminum-nickel alloy, wherein the weight percentage of Ni is 15%, and the rest is aluminum;

[0036] Mn-Al alloy and Cr 2 o 3 The weight ratio of the Mn-Al alloy is 3:1, the content of Mn in the Mn-Al alloy is 33.5wt%, and the rest is aluminum.

[0037] MoS 2 、Al 2 o 3 , The average particle size of SiC mixed particles is 10-15μm, MoS 2 :Al 2 o 3 : The mass ratio of SiC is 1:3:4.

[0038] Second, the preparation of aluminum-based materials:

[0039] (1) Preparation of aluminum alloy matrix: Weigh raw materials according to the following weight percentages: 0.003% Ag, 0.09% Ca, 0.2% Li,...

Embodiment 2

[0050] Embodiment 2: Aluminum-based materials are prepared as follows:

[0051] 1. Preparation of raw materials:

[0052] The relative weight ratio of aluminum nitride, zirconia, tantalum oxide, and graphite fluoride is 1.5:1:1:0.06; Ag, Ca, Li, Hf, Cr, Si, Fe, Cu, Ba, and Al in the raw materials are all Simple substance, the purity is greater than 99.9%; Ni is added in the form of aluminum-nickel alloy, wherein the weight percentage of Ni is 15%, and the rest is aluminum;

[0053] Mn-Al alloy and Cr 2 o 3 The weight ratio of the Mn-Al alloy is 10:1, the content of Mn in the Mn-Al alloy is 55.6wt%, and the rest is aluminum.

[0054] MoS 2 、Al 2 o 3 , The average particle size of SiC mixed particles is 15μm, MoS 2 :Al 2 o 3 : The mass ratio of SiC is 1:5:4.

[0055] Second, the preparation of aluminum-based materials:

[0056] (1) Preparation of aluminum alloy matrix: Weigh raw materials according to the following weight percentages: 0.008% Ag, 0.13% Ca, 0.7% Li, 6% ...

Embodiment 3

[0067] Embodiment 3: Aluminum-based materials are prepared as follows:

[0068] 1. Preparation of raw materials:

[0069] The relative weight ratio of aluminum nitride, zirconia, tantalum oxide, and graphite fluoride is 1.35:1:1:0.06; Ag, Ca, Li, Hf, Cr, Si, Fe, Cu, Ba, and Al in the raw materials are all Simple substance, the purity is greater than 99.9%; Ni is added in the form of aluminum-nickel alloy, wherein the weight percentage of Ni is 15%, and the rest is aluminum;

[0070] Mn-Al alloy and Cr 2 o 3 The weight ratio of the Mn-Al alloy is 6:1, the content of Mn in the Mn-Al alloy is 43.6wt%, and the rest is aluminum.

[0071] MoS 2 、Al 2 o 3 , The average particle size of SiC mixed particles is 13μm, MoS 2 :Al 2 o 3 : The mass ratio of SiC is 1:4:4.

[0072] Second, the preparation of aluminum-based materials:

[0073] (1) Preparation of aluminum alloy matrix: Weigh raw materials according to the following weight percentages: 0.0055% Ag, 0.011% Ca, 0.5% Li, 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com