High-dispersity nano-zirconia particles and method for preparing transparent dispersoid of high-dispersity nano-zirconia particles

A technology of nano-zirconia and zirconia, applied in zirconia, nanotechnology, nanotechnology, etc., can solve the problems of easy agglomeration of nano-zirconia particles, poor optical properties of composite materials, and reduced agglomeration, and achieve wide dispersion And compatibility, good transparency, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) Weigh 5 grams of basic zirconium carbonate, 1 gram of sodium hydroxide and 400 milliliters of deionized water, and stir to form a slurry;

[0042]2) Put the slurry into the internal circulation supergravity reactor, control the temperature to 80° C., the rotational speed to 500 rpm, and the reaction time to 8 hours.

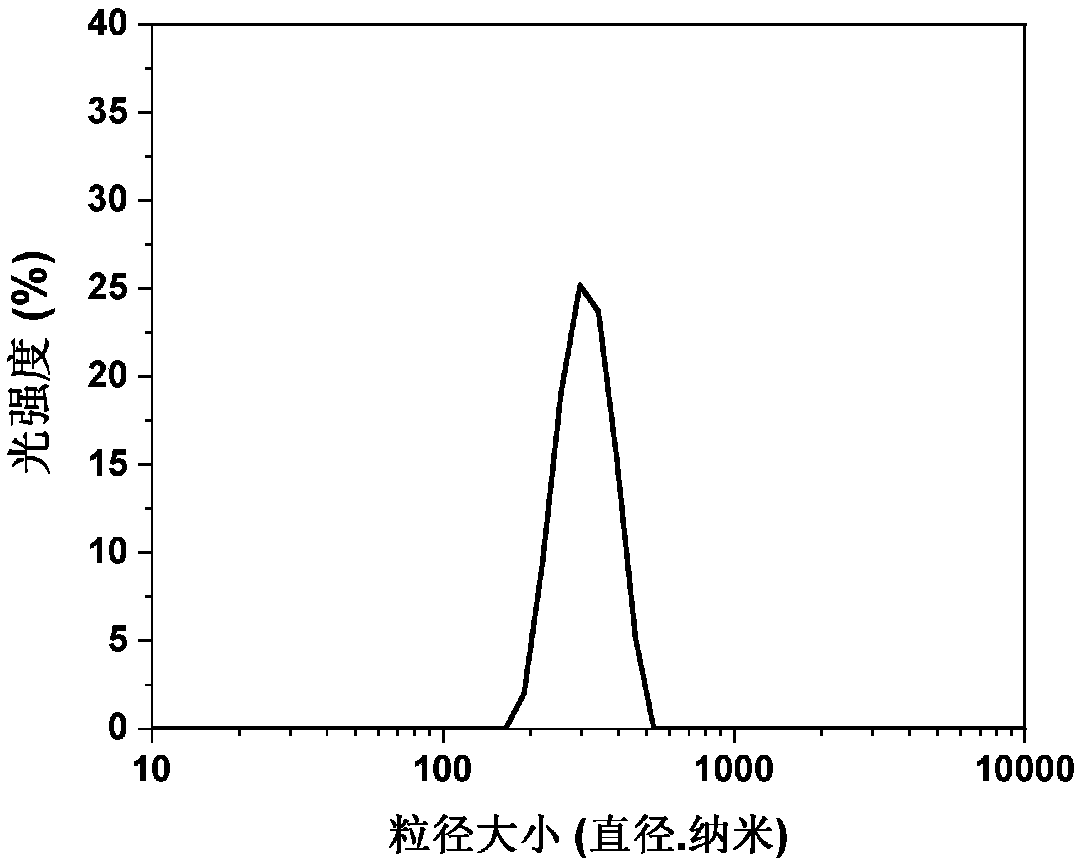

[0043] 3) After the reaction is completed, take the discharge liquid from the discharge port, wash the precipitate with 1 liter of clear water, take 0.1 g of the washed precipitate and put it in 10 ml of deionized water to form the aqueous phase dispersion, wherein the particle size of the nanoparticles under the electron microscope is 5 nanometers . Dynamic light scattering laser particle size analysis The average particle size of nanoparticles is 313.5 nm.

Embodiment 2

[0045] 1) Weigh 5 grams of basic zirconium carbonate, 1 gram of sodium hydroxide and 400 milliliters of deionized water, and stir to form a slurry;

[0046] 2) Put the slurry into the internal circulation supergravity reactor, control the temperature to 80°C, the rotational speed to 1000 rpm, and the reaction time to 8 hours.

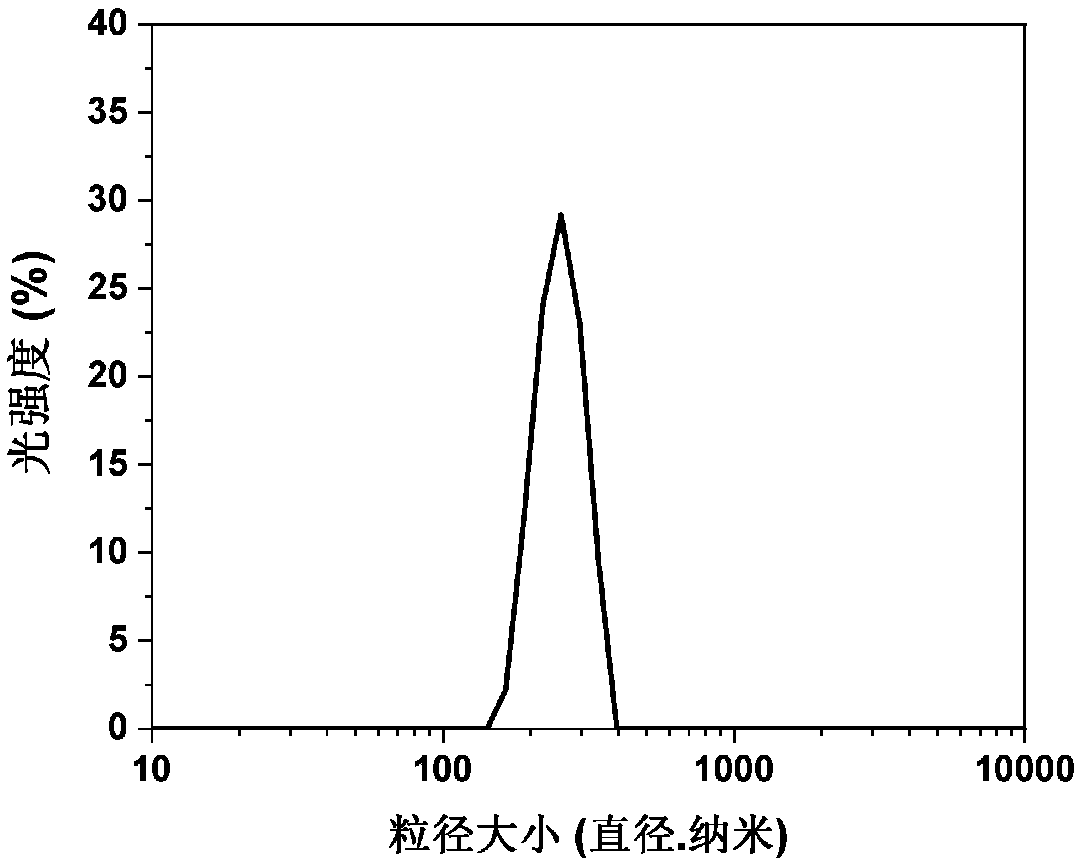

[0047] 3) After the reaction is completed, take the discharge liquid from the discharge port, wash the precipitate with 1 liter of water, take 0.1 g of the washed precipitate and put it in 10 ml of deionized water to be the aqueous phase dispersion, wherein the particle size of the nanoparticles under the electron microscope is 4 nanometers . Dynamic light scattering laser particle size analysis The average particle size of nanoparticles is 254.6 nm.

Embodiment 3

[0049] 1) Weigh 50 grams of basic zirconium carbonate, 75 grams of sodium hydroxide and 2500 milliliters of deionized water, and stir to form a slurry;

[0050] 2) Put the slurry into the internal circulation supergravity reactor, control the temperature at 80° C., the rotational speed at 1500 rpm, and the reaction time at 8 hours.

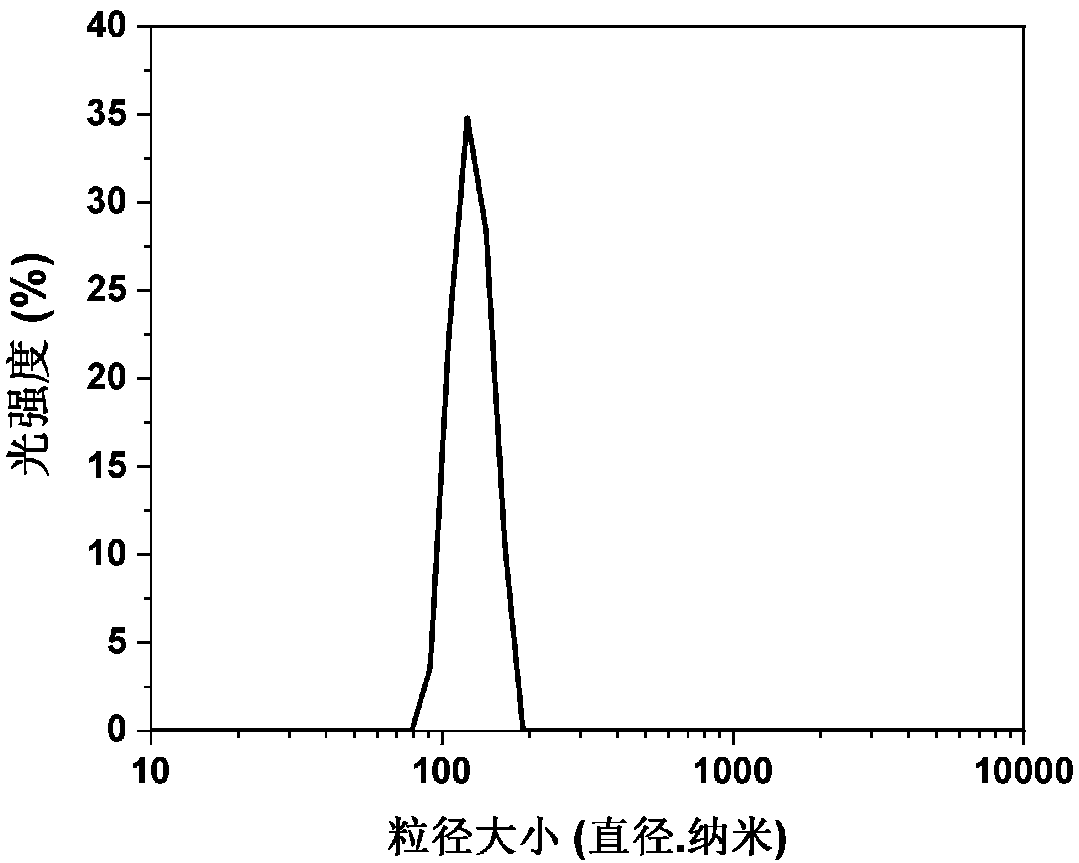

[0051] 3) After the reaction is completed, take the discharge liquid from the discharge port, wash the precipitate with 1 liter of clear water, take 0.1 g of the washed precipitate and put it in 10 ml of deionized water to form the aqueous dispersion, wherein the particle size of the nanoparticles under the electron microscope is 3 nanometers . Dynamic light scattering laser particle size analysis The average particle size of nanoparticles is 127.5 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com