Graphene -organic acid doped polyaniline composite material and preparation method thereof

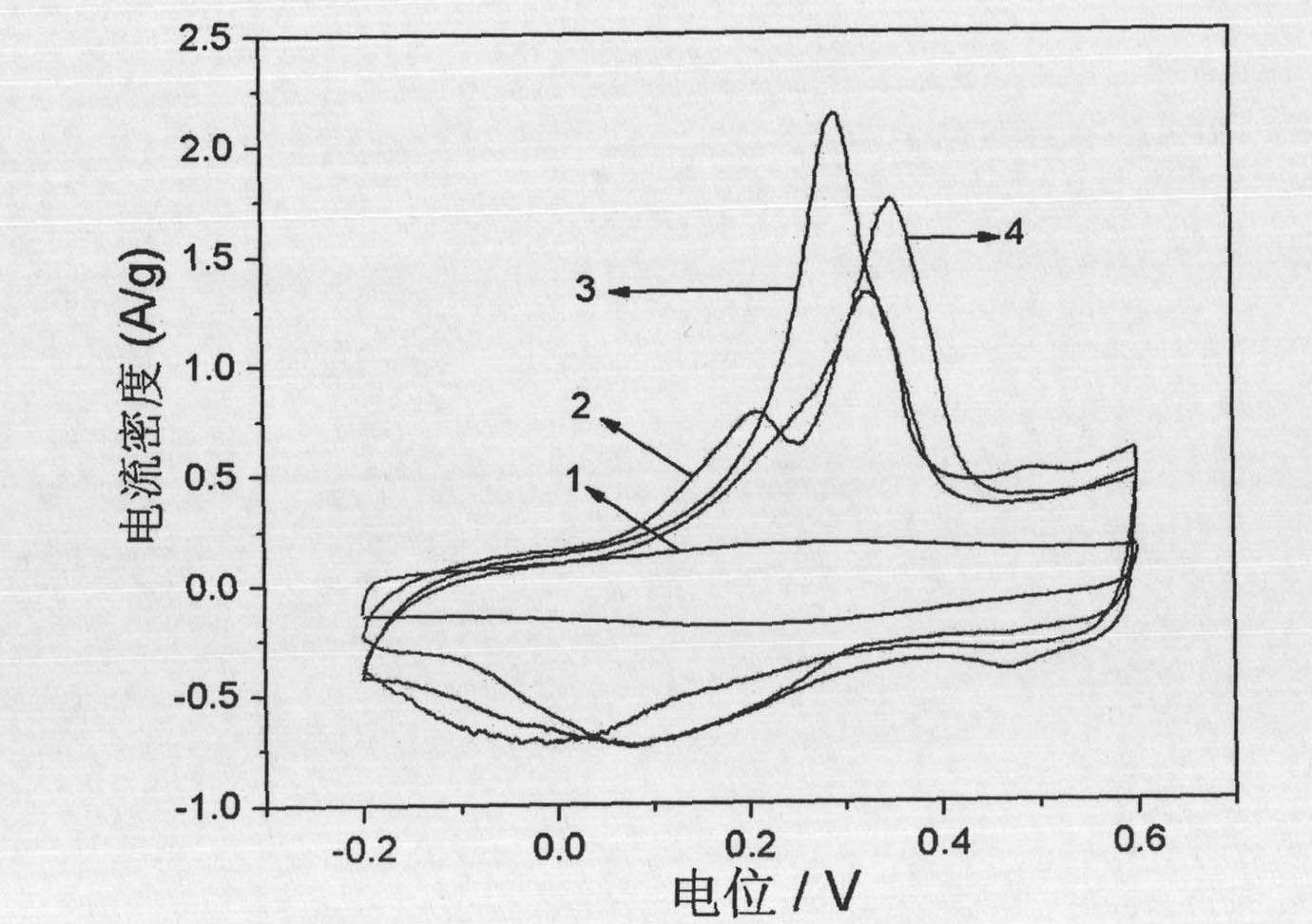

A composite material and graphene technology, which is applied in the field of organic and inorganic conductive composite materials, can solve the problems of affecting material properties and uneven composite materials, and achieve the effects of low equipment requirements, improved electrochemical performance, and short production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

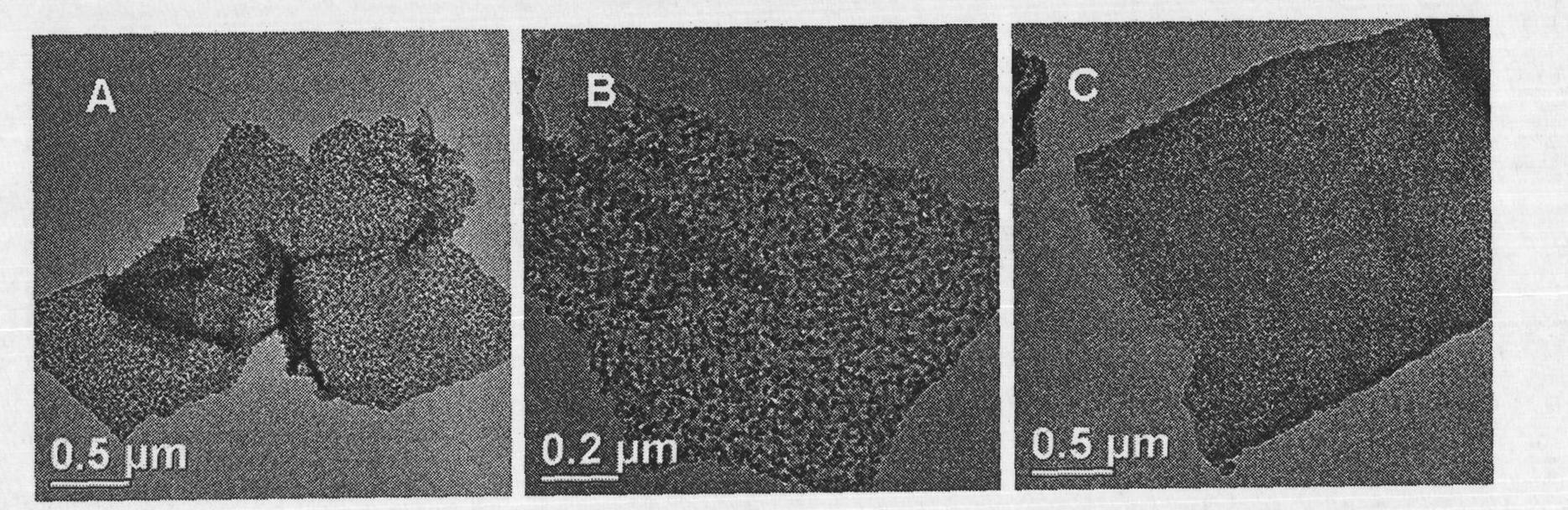

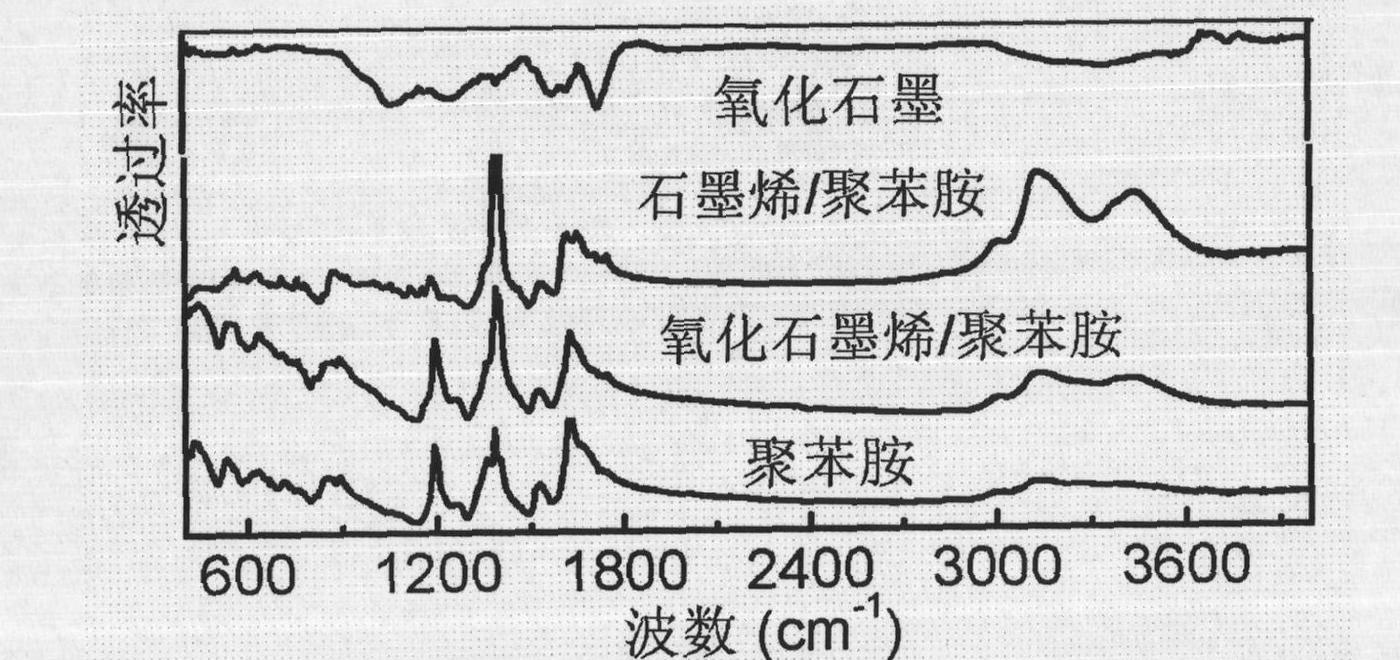

[0016] Graphene-organic acid doped polyaniline composite material of the present invention and preparation method thereof, the steps are as follows:

[0017] In the first step, graphite oxide is added to the dispersant for ultrasonic dispersion to form a uniformly dispersed graphene oxide mixture;

[0018] In the second step, at room temperature, add aniline monomer to the mixed solution obtained in the first step, continue ultrasonic dispersion to form a mixed solution, and then stir for a certain period of time;

[0019] In the third step, the solution of the dispersant of the oxidizing agent and the organic doping acid is added dropwise to the mixed solution obtained in the second step, and the polymerization is stirred;

[0020] The fourth step is to centrifuge and wash the mixed solution obtained in the third step to obtain a graphene oxide-polyaniline composite material;

[0021] Step 5, adding concentrated alkali to the aqueous suspension of the above product, heating ...

Embodiment 1

[0026] The preparation method of graphene-organic acid doped polyaniline composite material of the present invention, the steps are as follows:

[0027] In the first step, add 5mg of graphite oxide to 40mL of ethylene glycol and ultrasonically disperse to form a uniformly dispersed graphene oxide mixture, ultrasonically for 20-120min;

[0028] In the second step, 0.46 mL of aniline monomer is added to the product of the second step, dispersed by ultrasonication for 10-60 minutes to form a mixed solution, and then stirred for 30-120 minutes.

[0029] In the third step, 10 mL of an ethylene glycol solution of 1.141 g of ammonium persulfate and 2.32 g of camphorsulfonic acid was added dropwise to the system obtained in the second step at 0°C, and the stirring was continued for 1 h.

[0030] In the fourth step, the mixed solution obtained in the third step is centrifuged, and washed repeatedly with ethanol and water to obtain a graphene oxide-polyaniline composite material.

[00...

Embodiment 2

[0041] The preparation method of graphene-organic acid doped polyaniline composite material of the present invention, the steps are as follows:

[0042] In the first step, add 1.1mg of graphite oxide to 50mL of ethanol and ultrasonically disperse to form a uniformly dispersed graphene oxide mixture, ultrasonically for 20-120min;

[0043] In the second step, 1.1 mL of aniline monomer is added to the product of the second step, dispersed by ultrasonication for 10-60 minutes to form a mixed solution, and then stirred for 30-120 minutes.

[0044] In the third step, 10 mL of an ethanol solution of 1.37 g of ammonium persulfate and 2.78 g of camphorsulfonic acid was added dropwise to the system obtained in the second step at 10° C., and the stirring was continued for 15 min.

[0045] The fourth step is the same as step four in Example 1.

[0046] Step 5: Add NaOH to the 50 mL aqueous suspension of the above product to make the concentration 8 mol / L, heat and stir at 80°C for 1 h; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com