Oxidized graphite flake layer/polyaniline composite material and method for preparing the same

A composite material and graphite sheet technology, which is applied in the field of graphite oxide sheet/polyaniline composite material and its preparation, can solve the performance gap of graphite oxide/polystyrene composite material, the comprehensive performance of the composite material is not high, and the weak bonding interface low cost, high yield, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

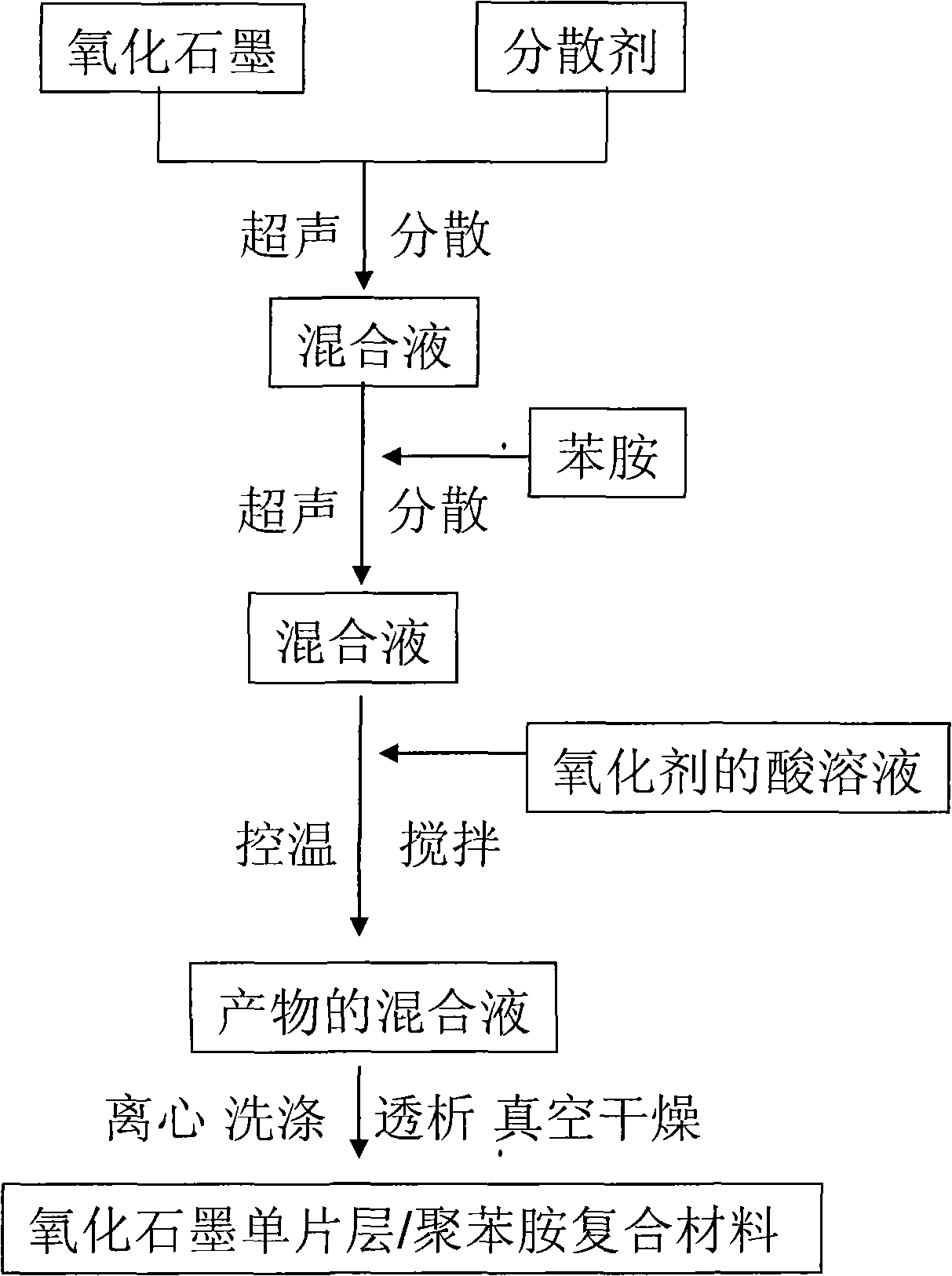

[0026] Embodiment 1: the method for preparing graphite oxide flake / polyaniline composite material of the present invention comprises the following steps:

[0027] The first step is the preparation of graphite oxide flakes. Add 10g of phosphorus pentoxide and 10g of potassium persulfate into 30mL of concentrated sulfuric acid at 80°C and stir for 30 minutes, take it out, react at room temperature for 6 hours, filter the product, wash to neutral and dry at room temperature to constant weight. Add the above product into 460mL of concentrated sulfuric acid at 0°C, stir and slowly add potassium permanganate, while controlling the temperature of the system not to exceed 15°C, stir evenly and raise the temperature to 35±3°C, continue stirring for a certain period of time, and then pour into the system Slowly add 1L of deionized water, control the temperature not to exceed 100°C, and continue stirring for 15min. Add 2.8L of deionized water and 50mL of 30% hydrogen peroxide. After sti...

Embodiment 2

[0033] Embodiment 2: the method for preparing graphite oxide flake / polyaniline composite material of the present invention comprises the following steps:

[0034] The first step is the same as Step 1 in Example 1.

[0035] In the second step, add 1mg of graphite oxide into 50mL of water or ethanol, and sonicate for 20-120min.

[0036] In the third step, the aniline monomer is added dropwise to the product of the second step, and ultrasonically dispersed for 10-60 minutes to form a mixed solution of 0.2 mol / L aniline.

[0037] In the fourth step, add 10 mL of 0.1 mol / L sulfuric acid solution of 0.05 mol / L ammonium persulfate dropwise to the system obtained in the third step at 0-5°C, and continue stirring for 2 hours, then raise the temperature to room temperature, and continue stirring for 6 hours .

[0038] The fifth step is the same as step five in Example 1.

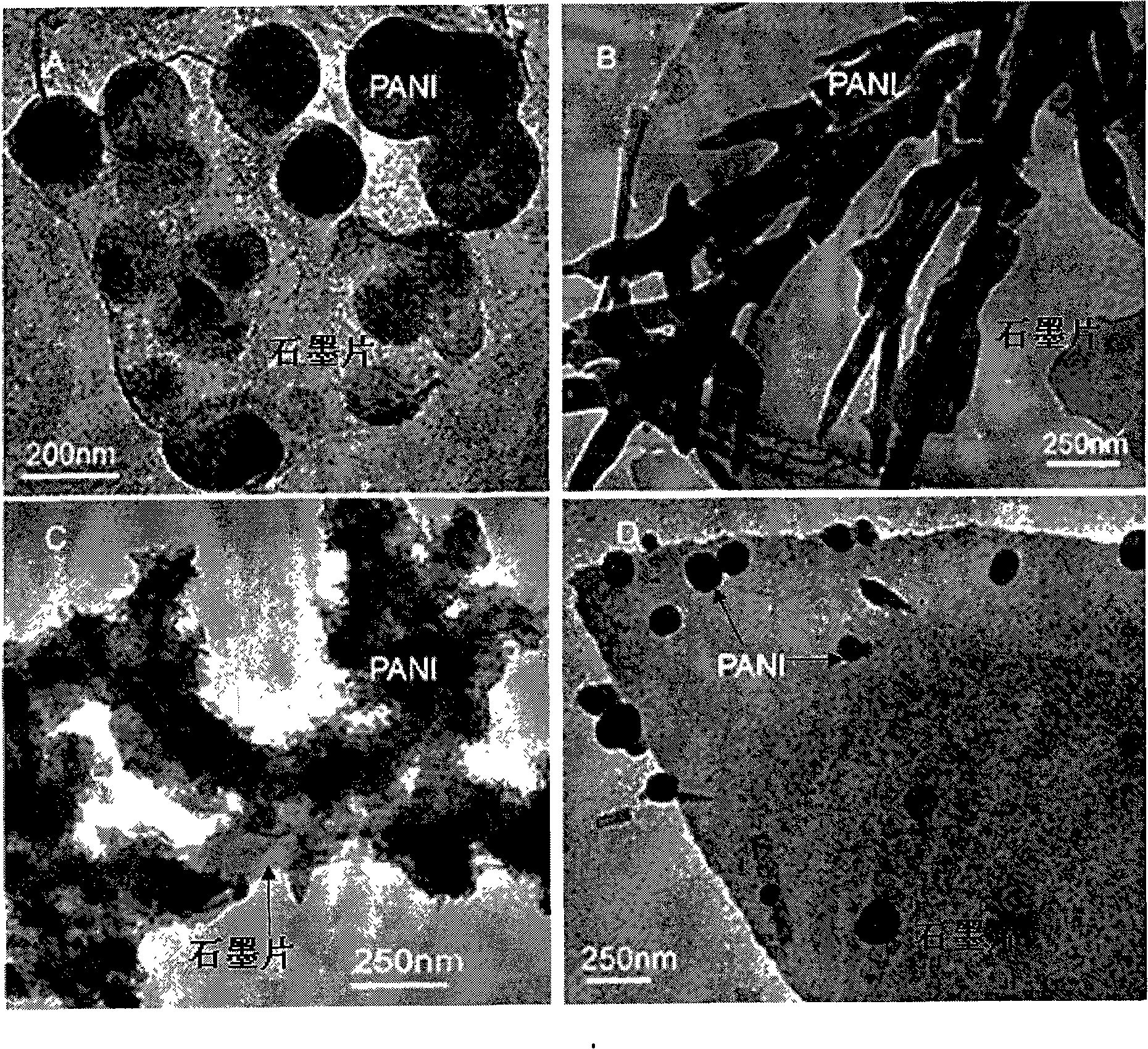

[0039] The transmission electron microscope image of the obtained composite material is shown in figure 2 (B),...

Embodiment 3

[0040] Embodiment 3: the method for preparing graphite oxide flake / polyaniline composite material of the present invention comprises the following steps:

[0041] The first step is the same as Step 1 in Example 1.

[0042] In the second step, add 1 mg of graphite oxide into 100 mL of water or ethanol, and sonicate for 20 to 120 min.

[0043]In the third step, the aniline monomer is added dropwise to the product of the second step, and ultrasonically dispersed for 10-60 minutes to form a mixed solution of 0.1 mol / L aniline.

[0044] In the fourth step, add 0.15mol / L FeCl dropwise to the system obtained in the third step at 0-5°C 3 Add 10 mL of 0.6 mol / L p-toluenesulfonic acid solution, and continue to stir for 4 h, warm up to room temperature, and continue to stir for 2 h.

[0045] The fifth step is the same as step five in Example 1.

[0046] The transmission electron microscope image of the obtained composite material is shown in figure 2 (C), as shown in the figure, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com