Patents

Literature

375results about "Titanium halides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

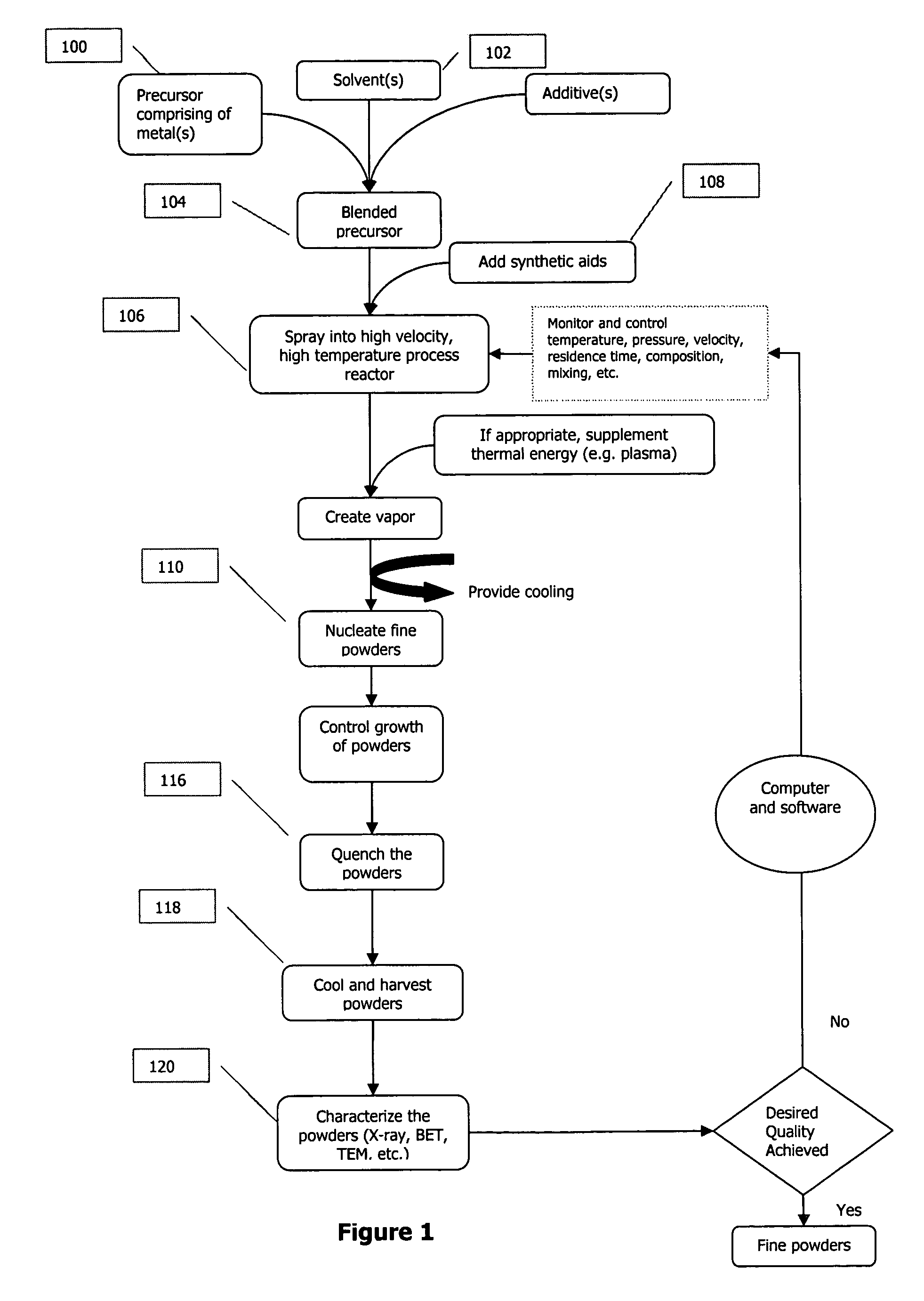

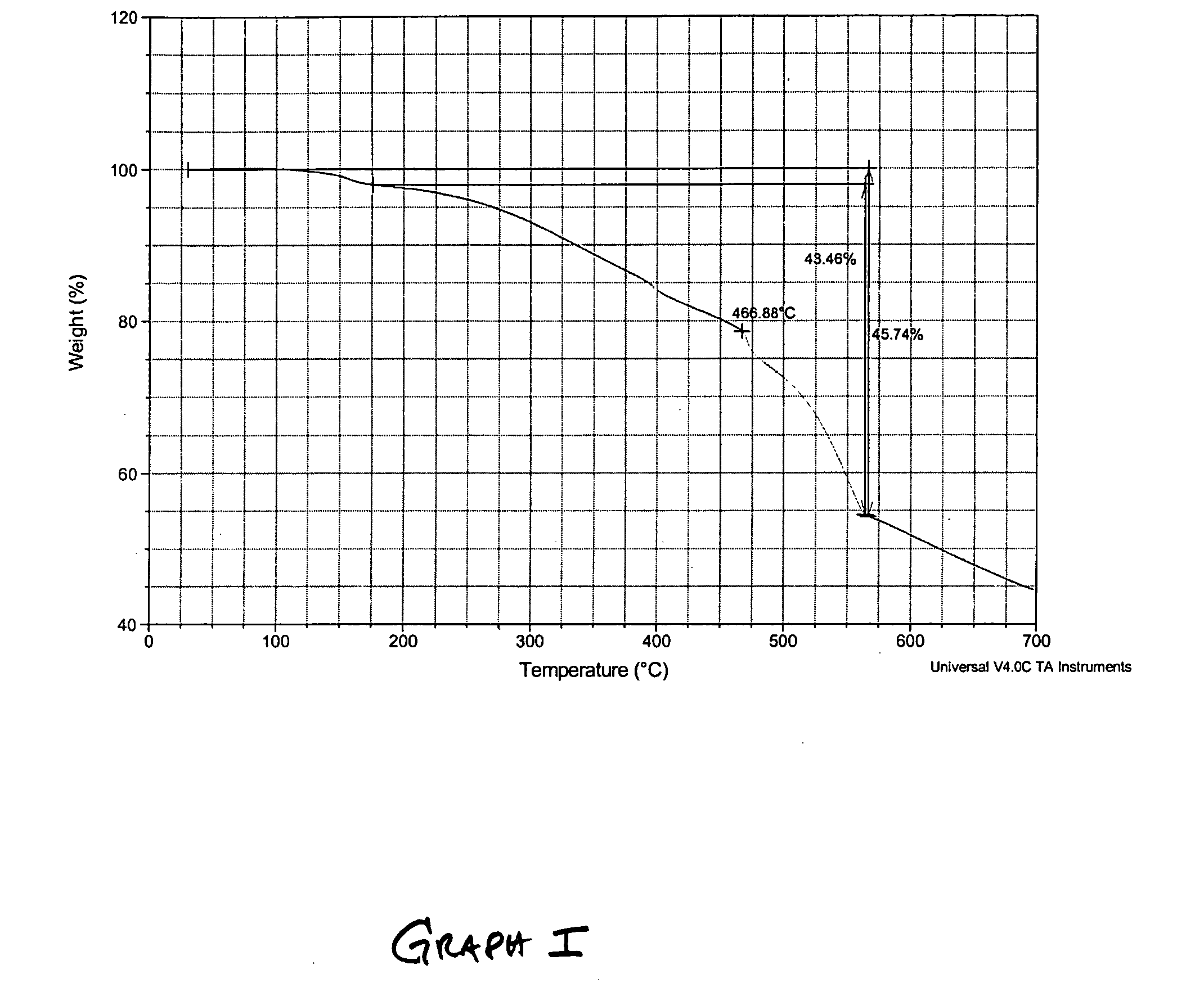

Titanium comprising nanoparticles and related nanotechnology

ActiveUS7232556B2Increase volumeLow cost productionNitrogen compoundsGermanium dioxideNanoparticleTitanium metal

Owner:PPG IND OHIO INC

Titanium comprising nanoparticles and related nanotechnology

ActiveUS20050191492A1Increase volumeLow cost productionNitrogen compoundsGermanium dioxideNanoparticleTitanium metal

Owner:PPG IND OHIO INC

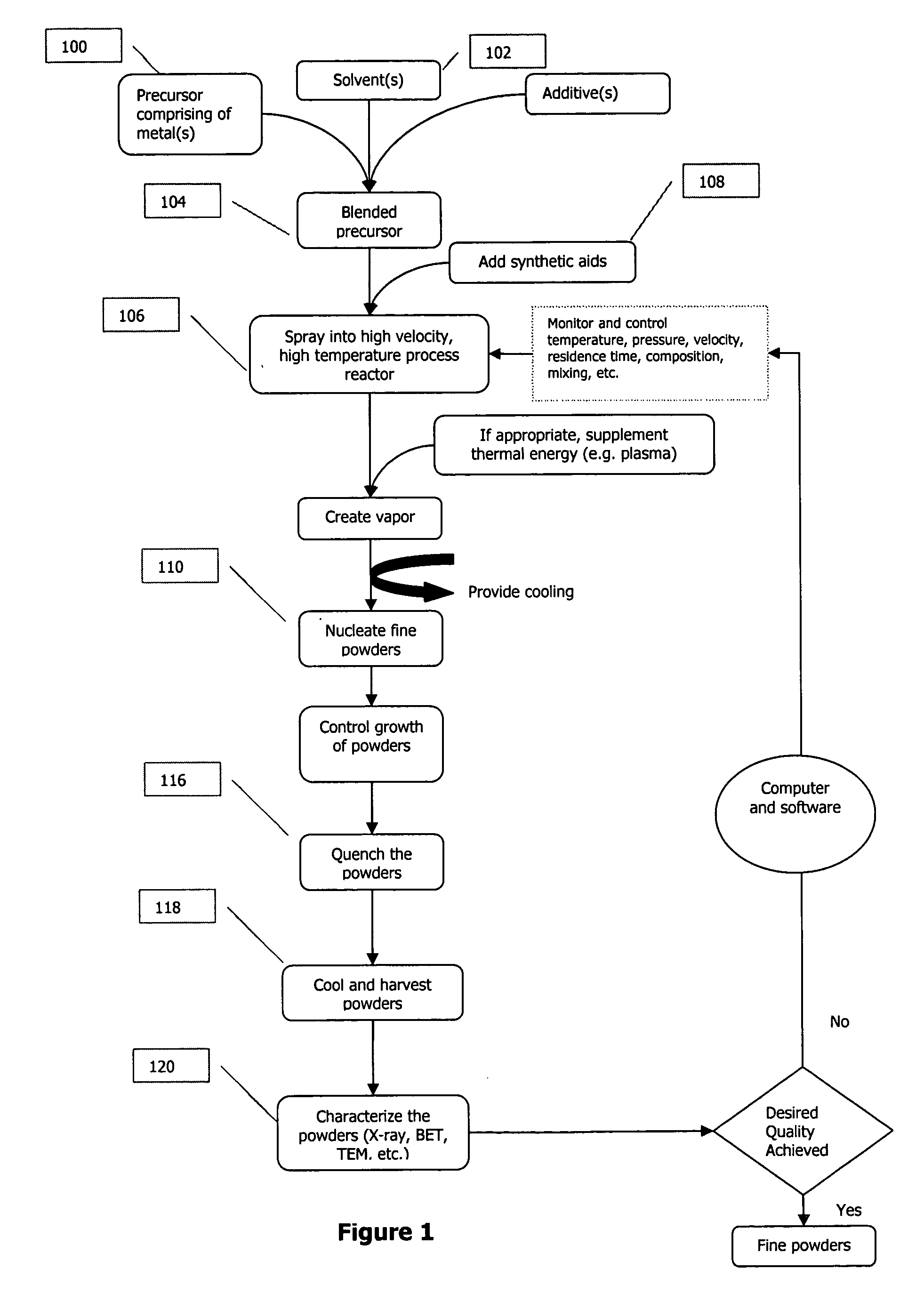

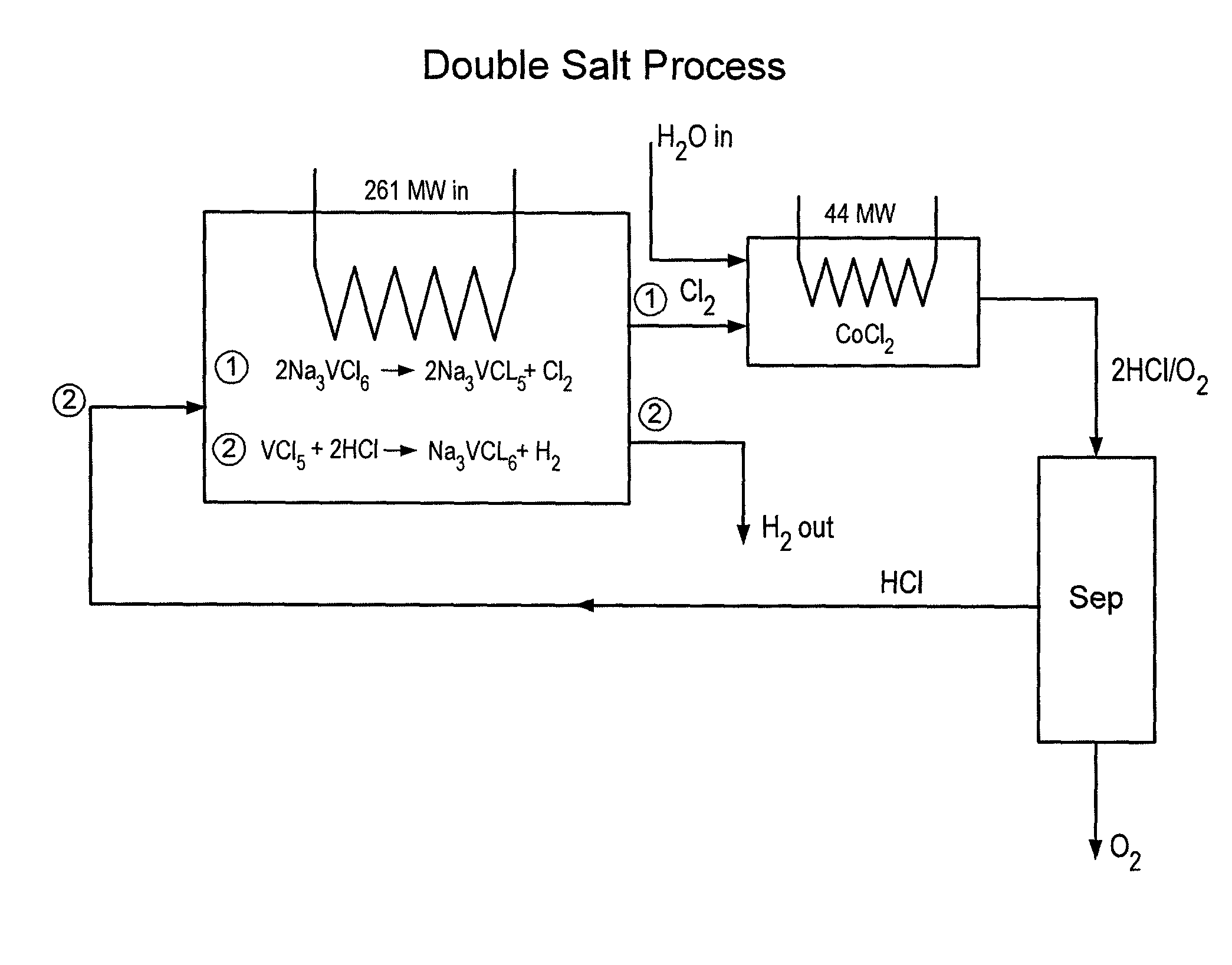

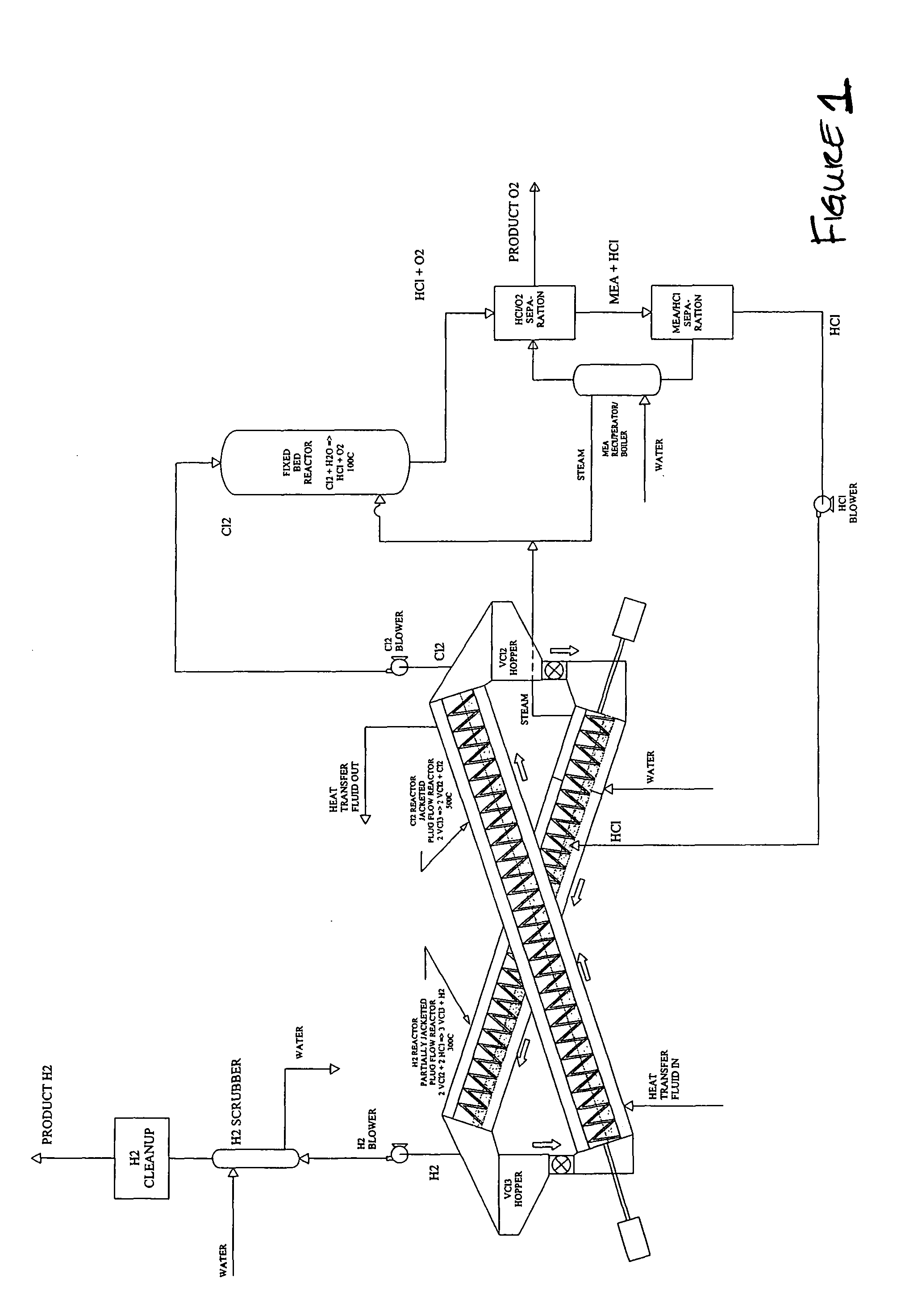

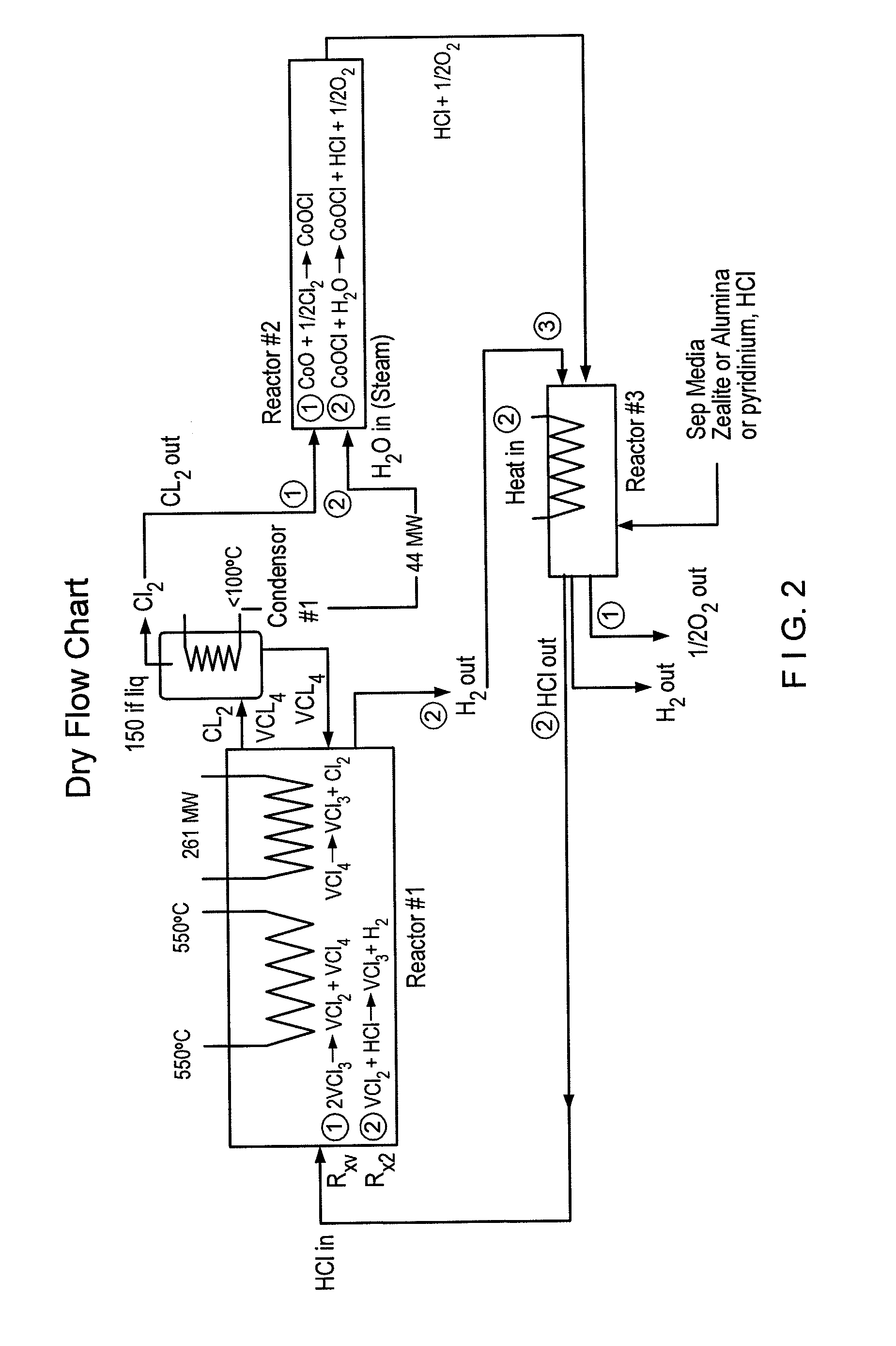

Thermochemical hydrogen produced from a vanadium decomposition cycle

InactiveUS20050013771A1Improve reliabilityHydrogen separation using liquid contactEnergy inputHydrogenDecomposition

A thermochemical water-splitting process all reactions of which operate at relatively low temperatures and high efficiencies, and in which relatively inexpensive materials and processing methods are made possible. This invention involves the decomposition of a metal halide compound, i.e., one which is capable of being reduced from a higher oxidation state to lower oxidation state, e.g. vanadium chloride III→vanadium dichloride. The process is cyclic and regenerative, and the only net inputs are water and heat; and the only net outputs are hydrogen and oxygen. The process makes it possible to utilize a wide variety of available heat, including solar, sources for the energy input.

Owner:AMENDOLA STEVEN

Process for increasing the yield in the manufacture of titanium dioxide by the chloride process

InactiveUS6399033B1Reduce coke contentReduced silica contentZirconium compoundsTitanium dioxideSingle stageFluidized bed

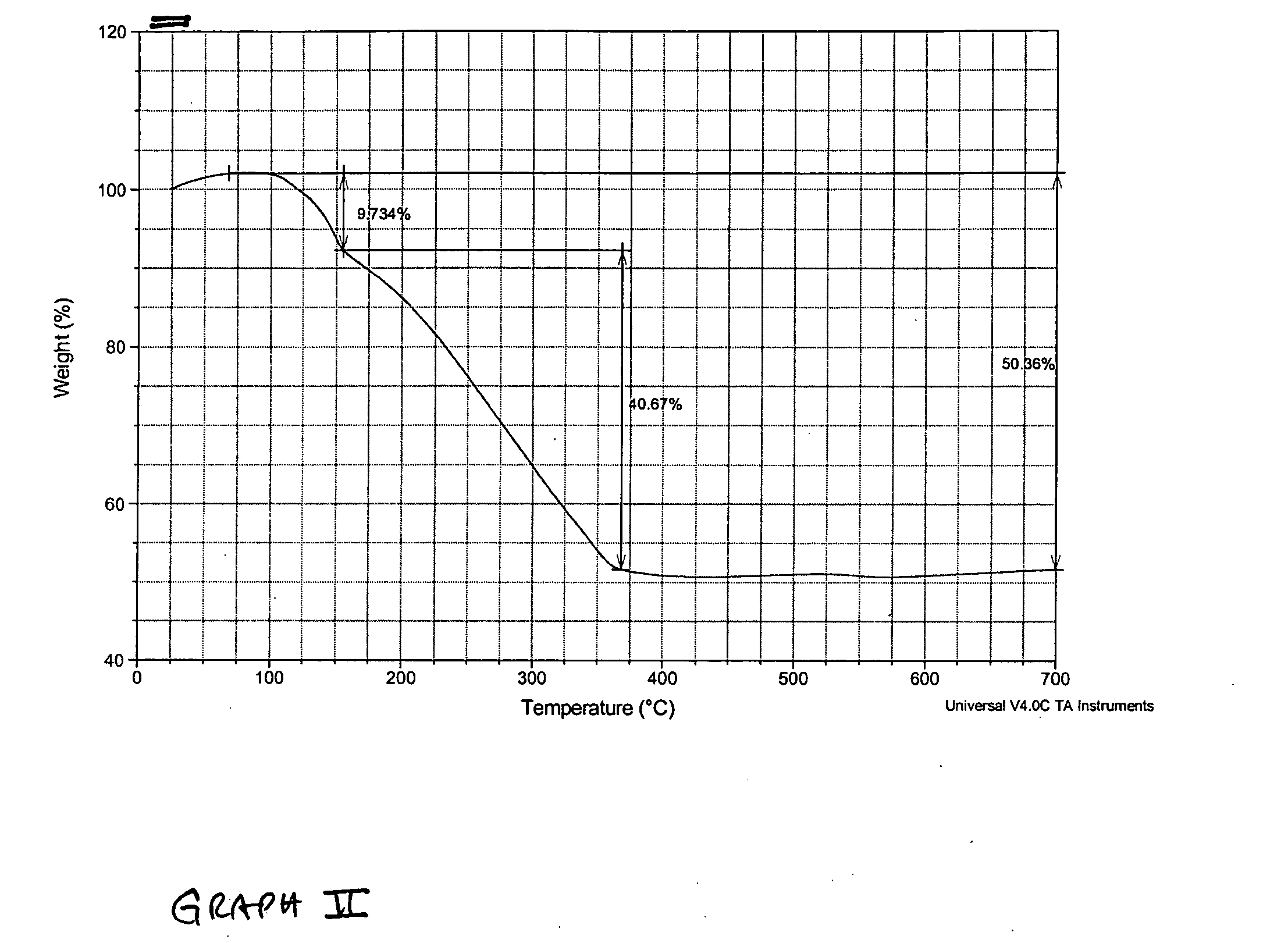

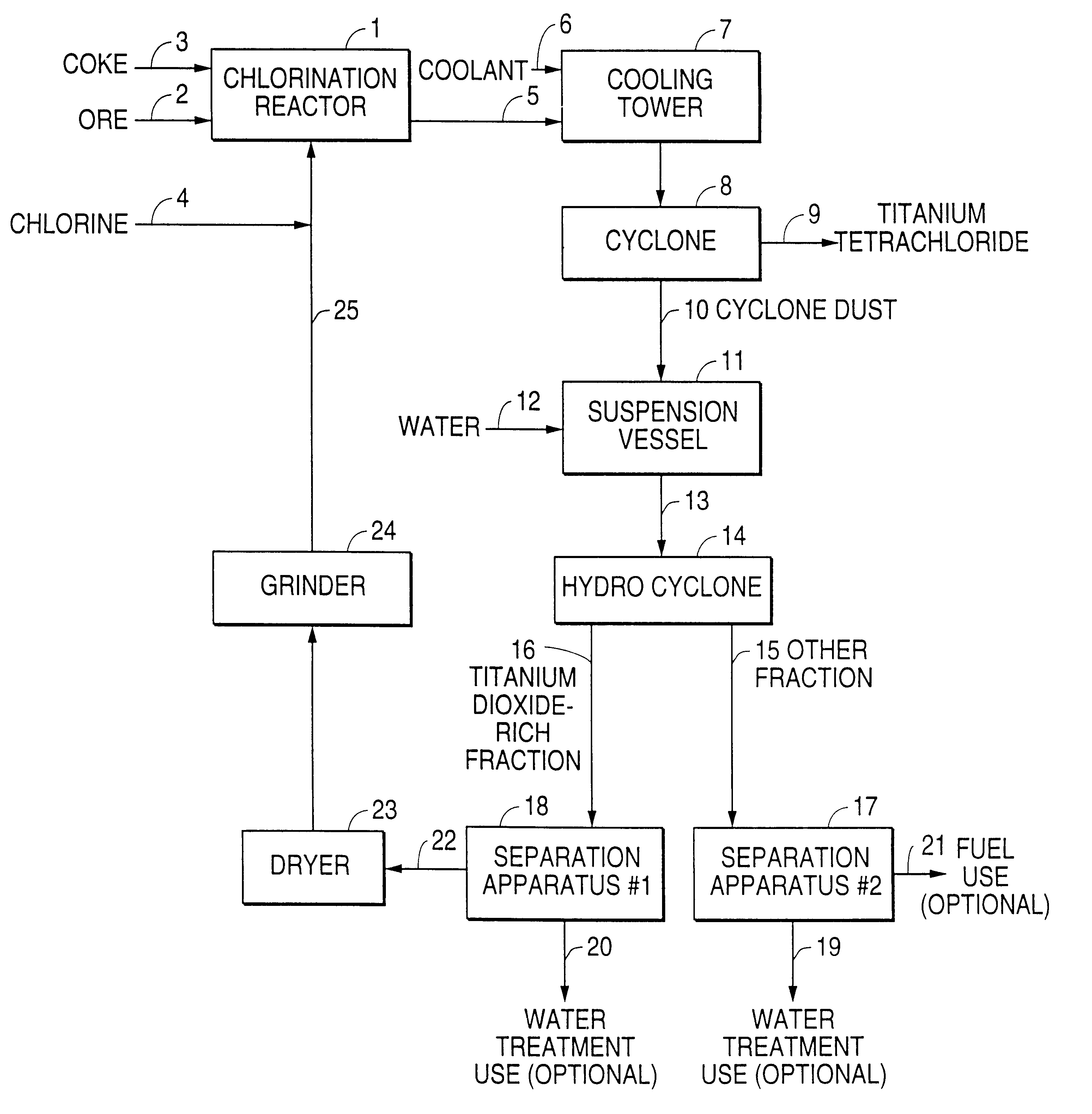

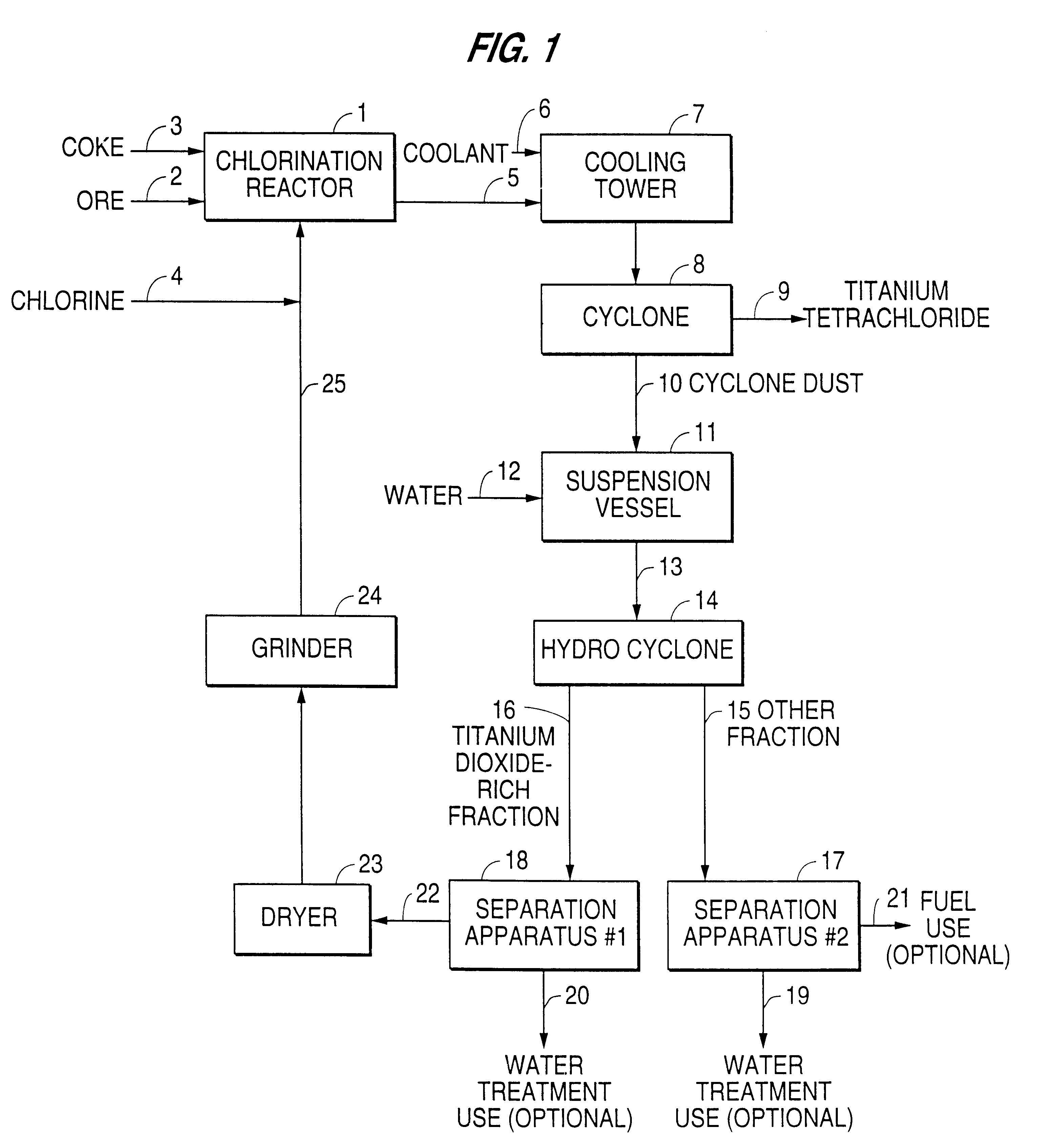

An improvement to the chloride process of making titanium dioxide. By recycling some of the cyclone dust, the yield in the chlorination of titanium-containing raw materials can be increased. In order to prevent silica accumulation in the fluidized bed, the cyclone dust is divided into two fractions. An economic solution is described of a single-stage separation of the cyclone dust in a hydrocyclone, the majority of the titanium dioxide occurring in the hydrocyclone underflow, although the separation is not sharp. By grinding and drying the solids from the hydrocyclone underflow, the titanium dioxide particles returned to the lower region of the fluidized-bed reactor are rapidly chlorinated, while the quartz and coke particles are rapidly discharged again from the fluid bed, so that no silica contamination occurs.

Owner:KRONOS INCORPORATED

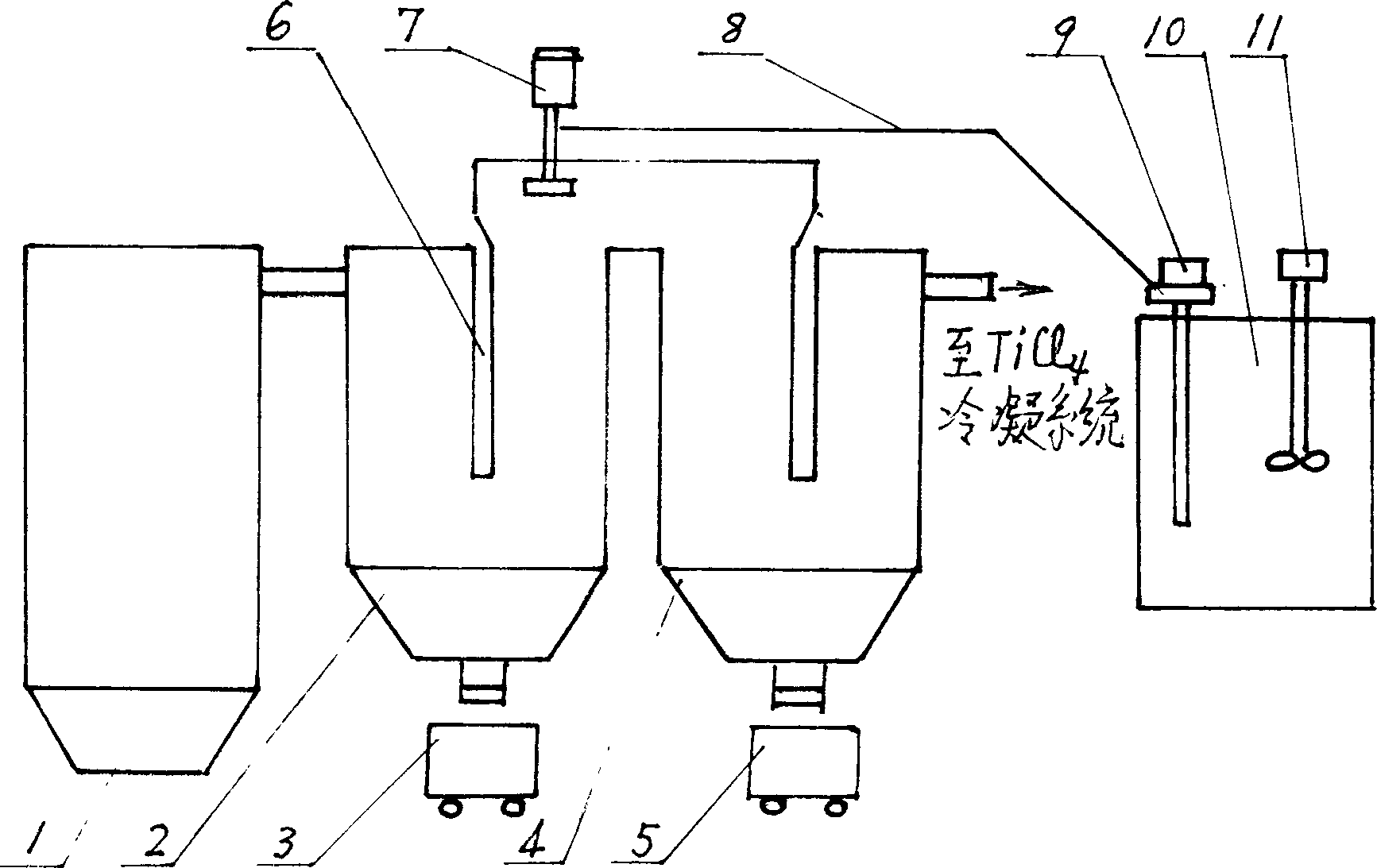

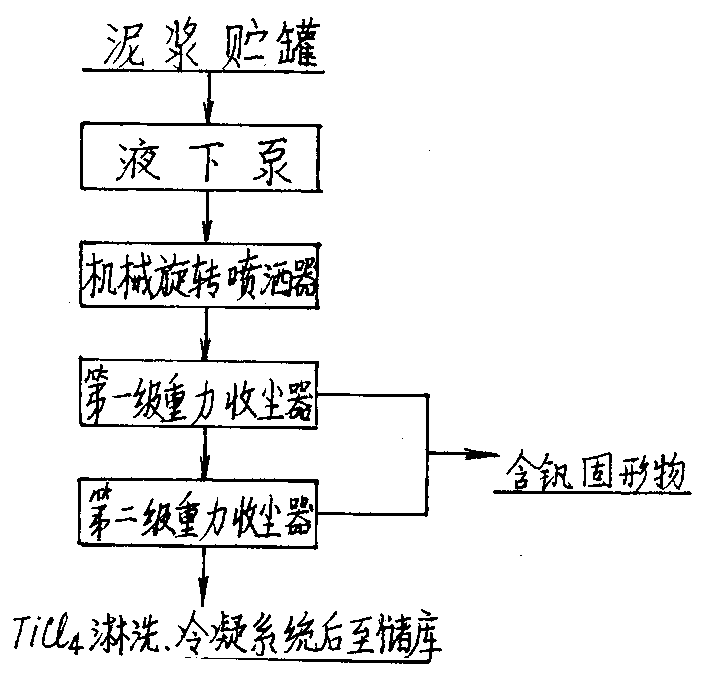

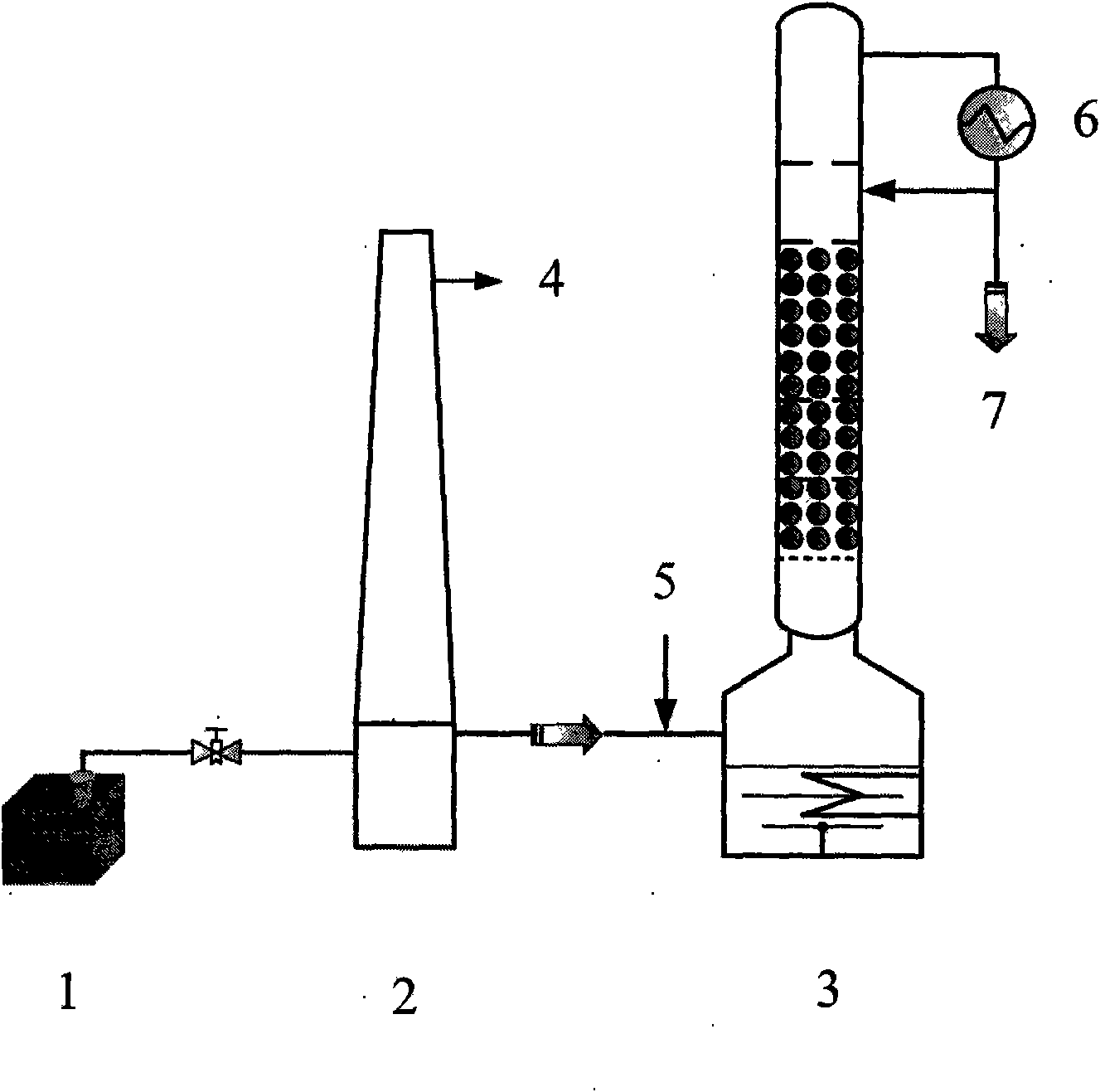

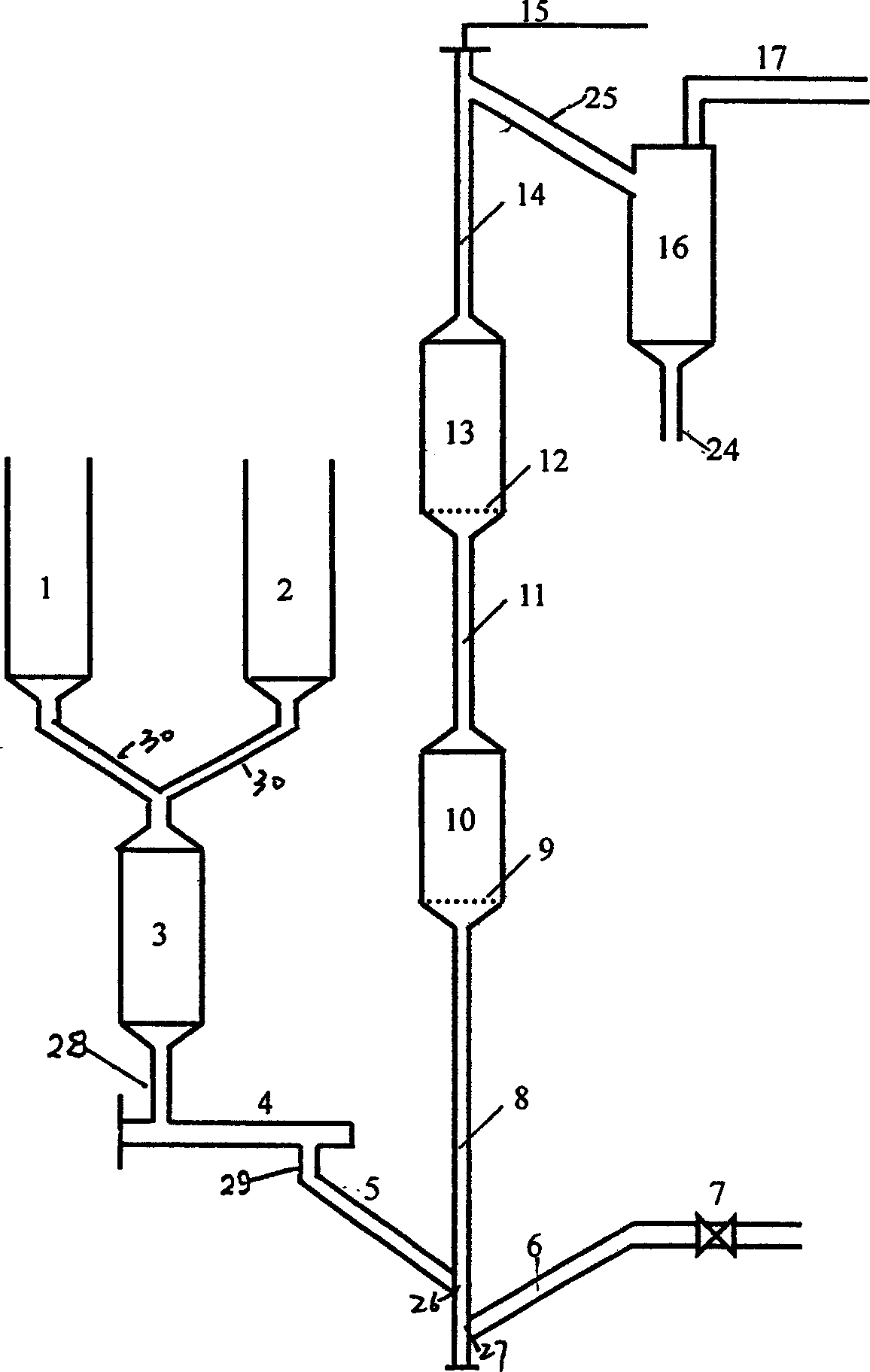

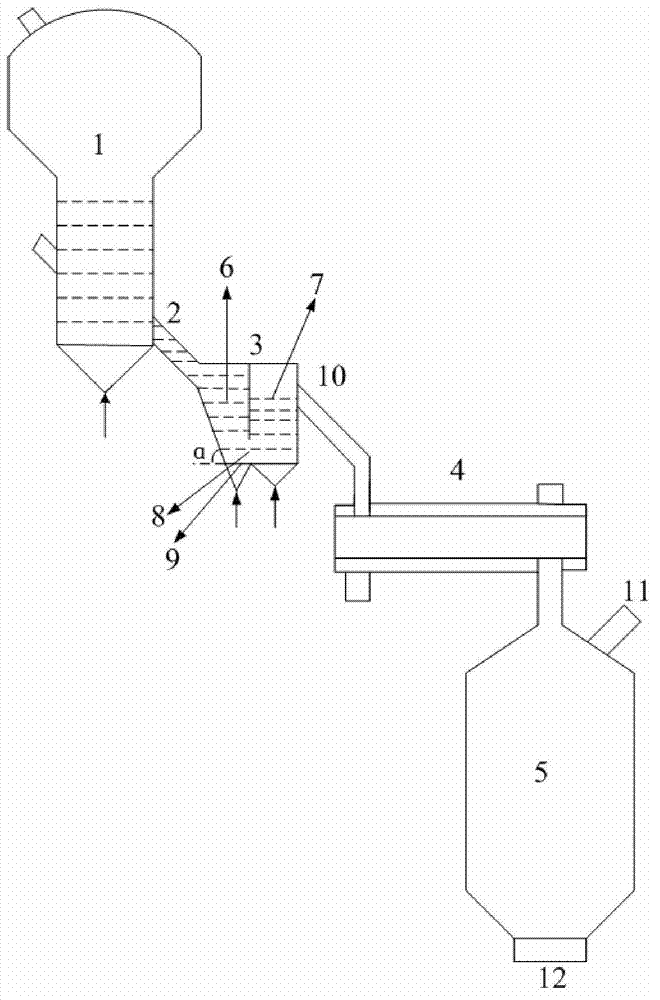

Technique and method for treating titanium tetrachloride slurry containing vanadium

InactiveCN1415547ASave moneySave energySludge treatmentTitanium halidesThermal energyCollection system

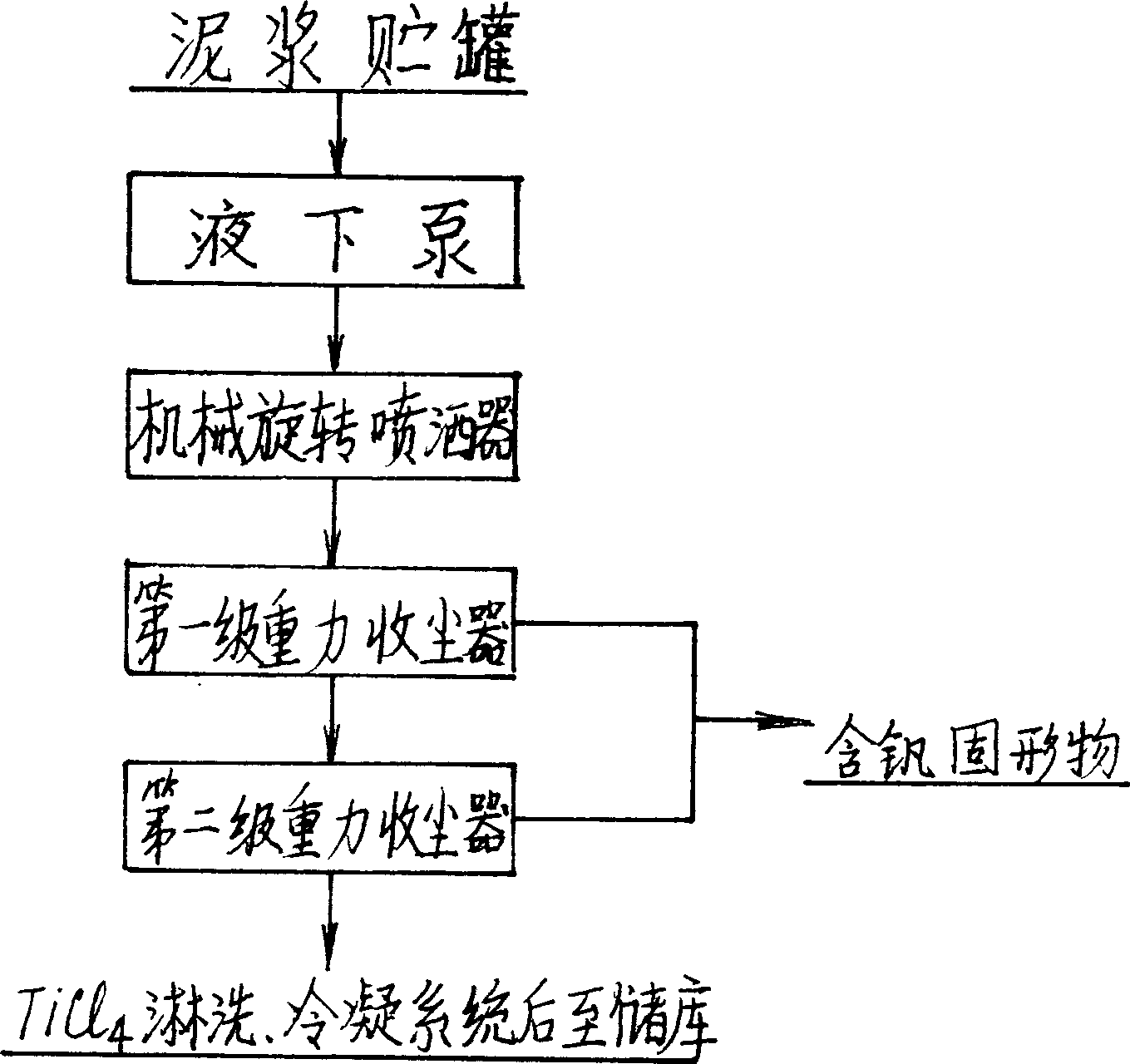

A process for treating the sludge containing CCl4 and V to recover TiCl4 includes such steps as pumping said sludge from sludge tank to the stage-1 gravitational dust collector in chlorinating system, countercurrent heat exchange between the sludge sprayed from top and the high-temp gas mixture from chlorinating furnace to gasifying the atomized TiCl4 drops, introducing the gas mixture to stage-2 dust collector, depositing the most of V-contained solid into ash collector while further separating, and condensing the purified TiCl4 gas for collecting it in original system. Its advantages are high recovery rate of TiCl4 and no pollution.

Owner:中信钛业股份有限公司

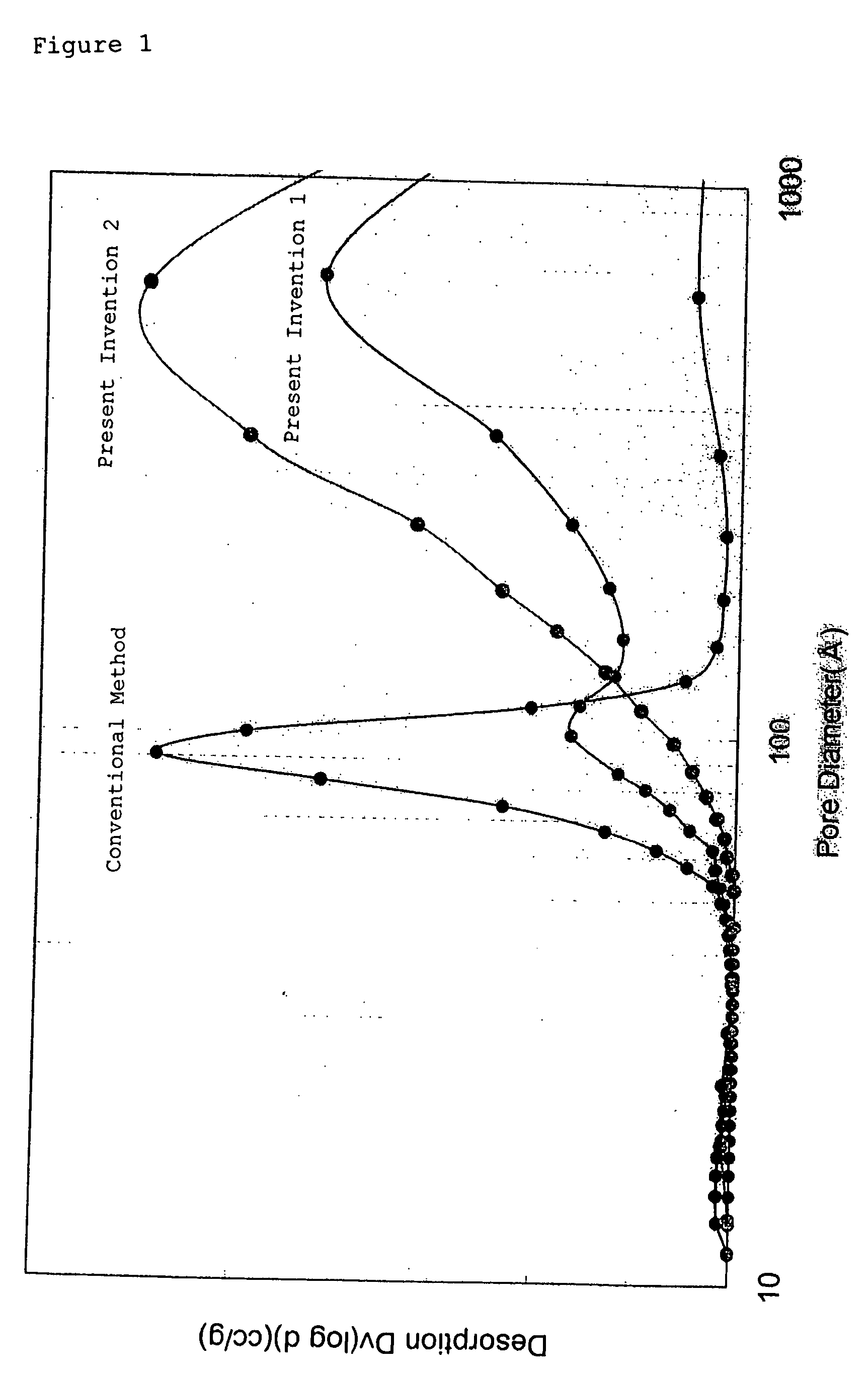

Zirconia porous body and manufacturing method thereof

ActiveUS20060018822A1Dispersed particle separationCatalyst activation/preparationPore distributionEngineering

A zirconia porous body with excellent stability of heat resistance is manufactured. This relates to a zirconia porous body having peaks at pore diameters of 8 to 20 nm and 30 to 100 nm in a pore distribution based on the BJH method, with a total pore volume of 0.4 cc / g or more, and to a zirconia porous body having a peak at a pore diameters of 20 to 110 nm in a pore distribution based on the BJH method, with a total pore volume of 0.4 cc / g or more.

Owner:DAIICHI KIGENSO KAGAKU KOGYO CO LTD

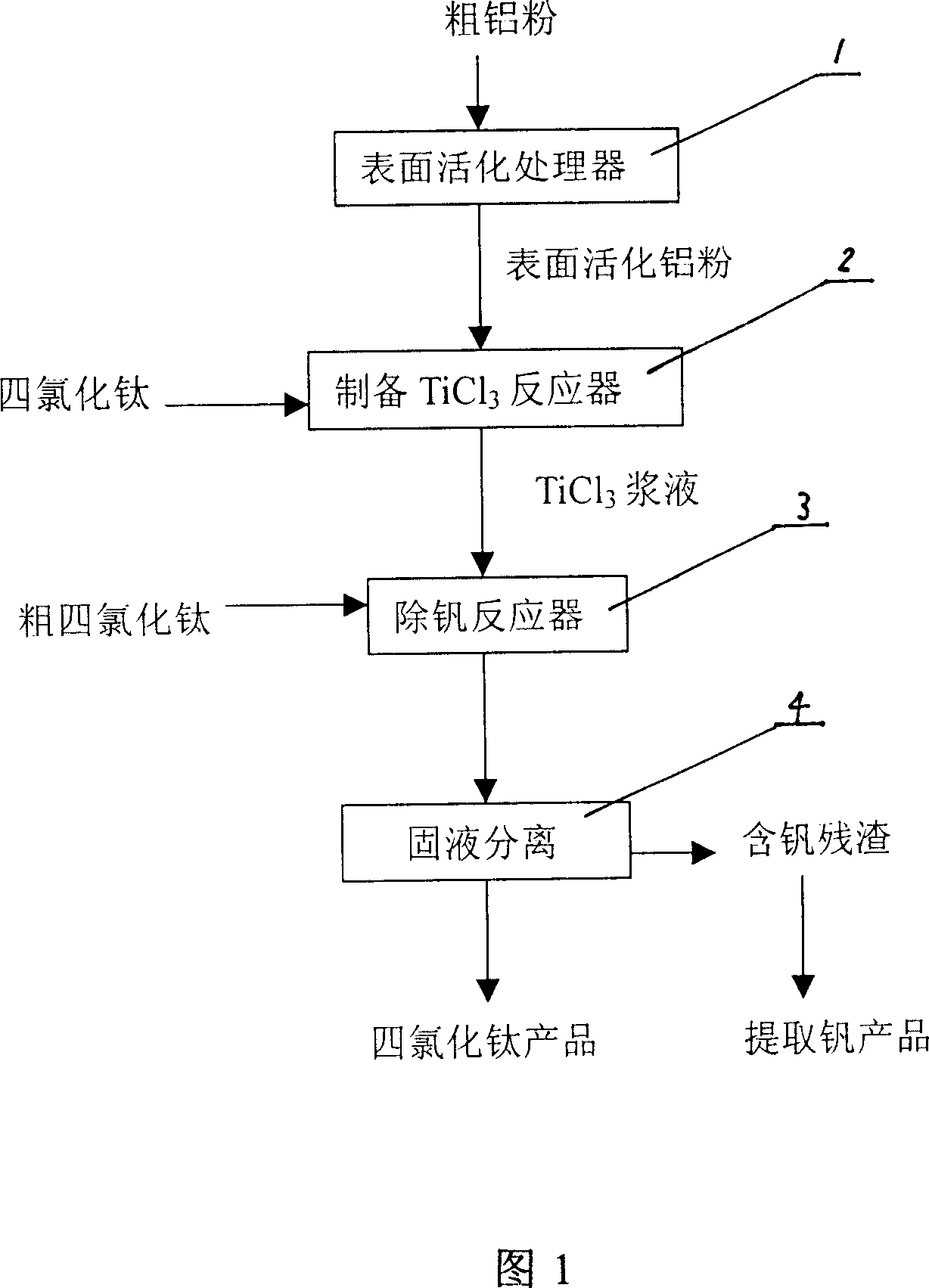

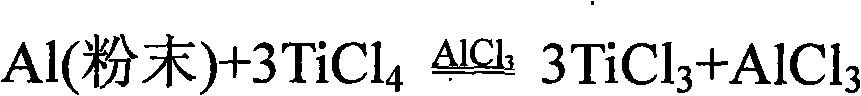

Method for removing vanadium in titanium tetrachloride

InactiveCN101054201ASimple processSimple waste treatmentTitanium halidesTetrachlorideBiological activation

The invention relates to a method for removing vanadium impurity from titanic tetrachloride. The invention prepares titanium trichloride serum by the reaction between the cost aluminum powders with the average grain size no bigger than 150mum after surface activation treatment. TiCl3 in the serum reduces VOCl3 in the titanic tetrachloride to be VOCl2 deposit so as to remove the vanadium. And the titanic tetrachloride after removing the vanadium contains no more than 0.0007% vanadium. The process of vanadium removal can be implemented together with rectification process in order to realize continuous operation. The invention has the advantages of simple in process, low in cost, safe in operation, high in product quality and recovery rate and simple in treating the ''three-waste'' pollution.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

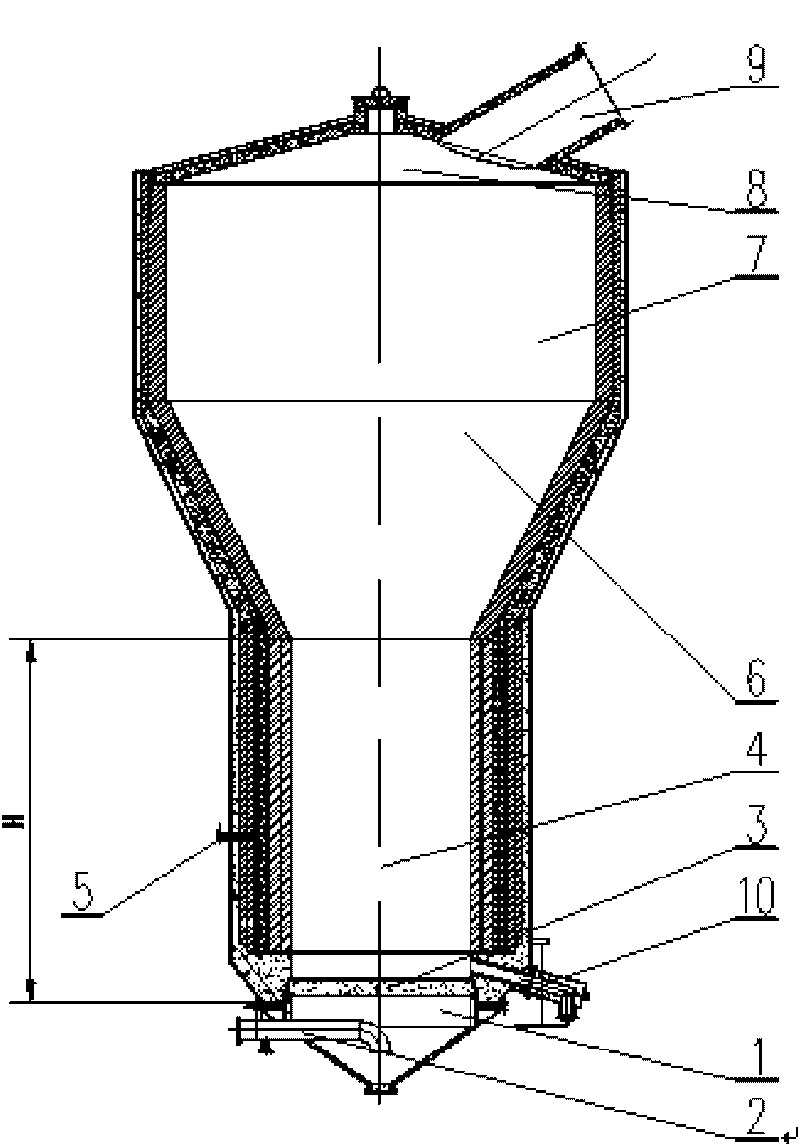

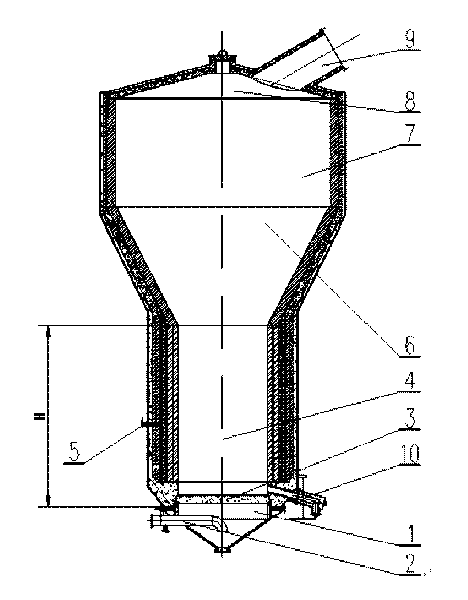

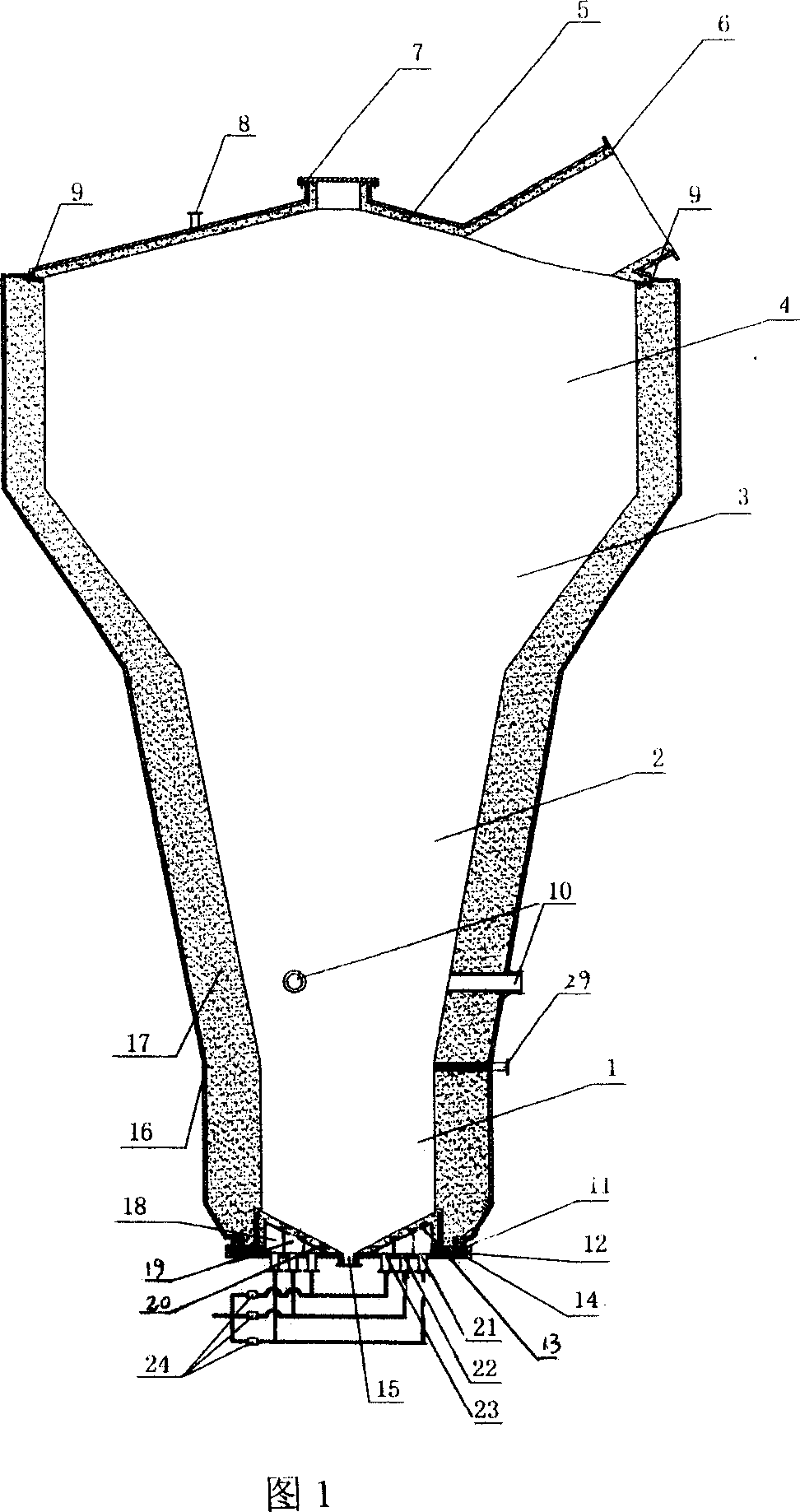

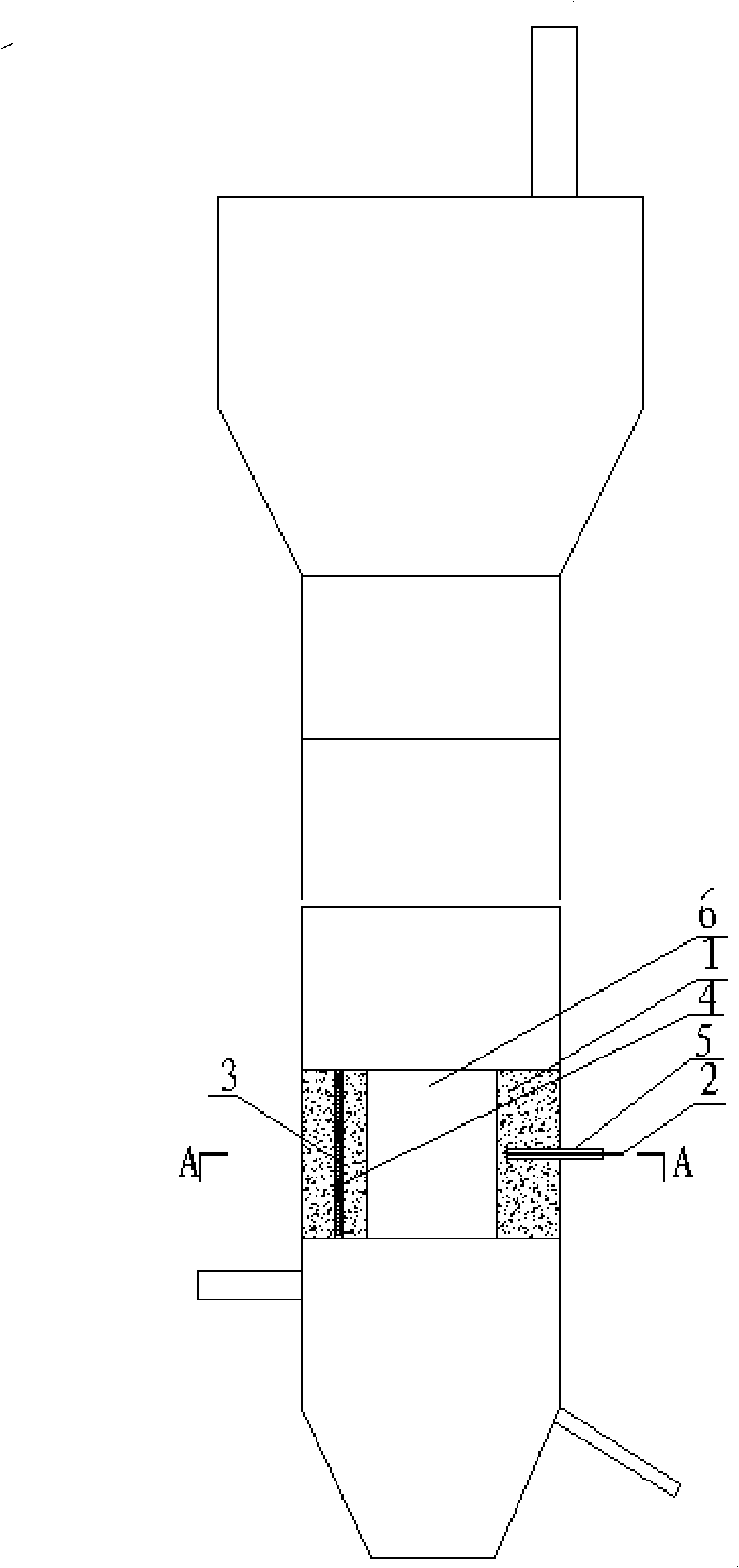

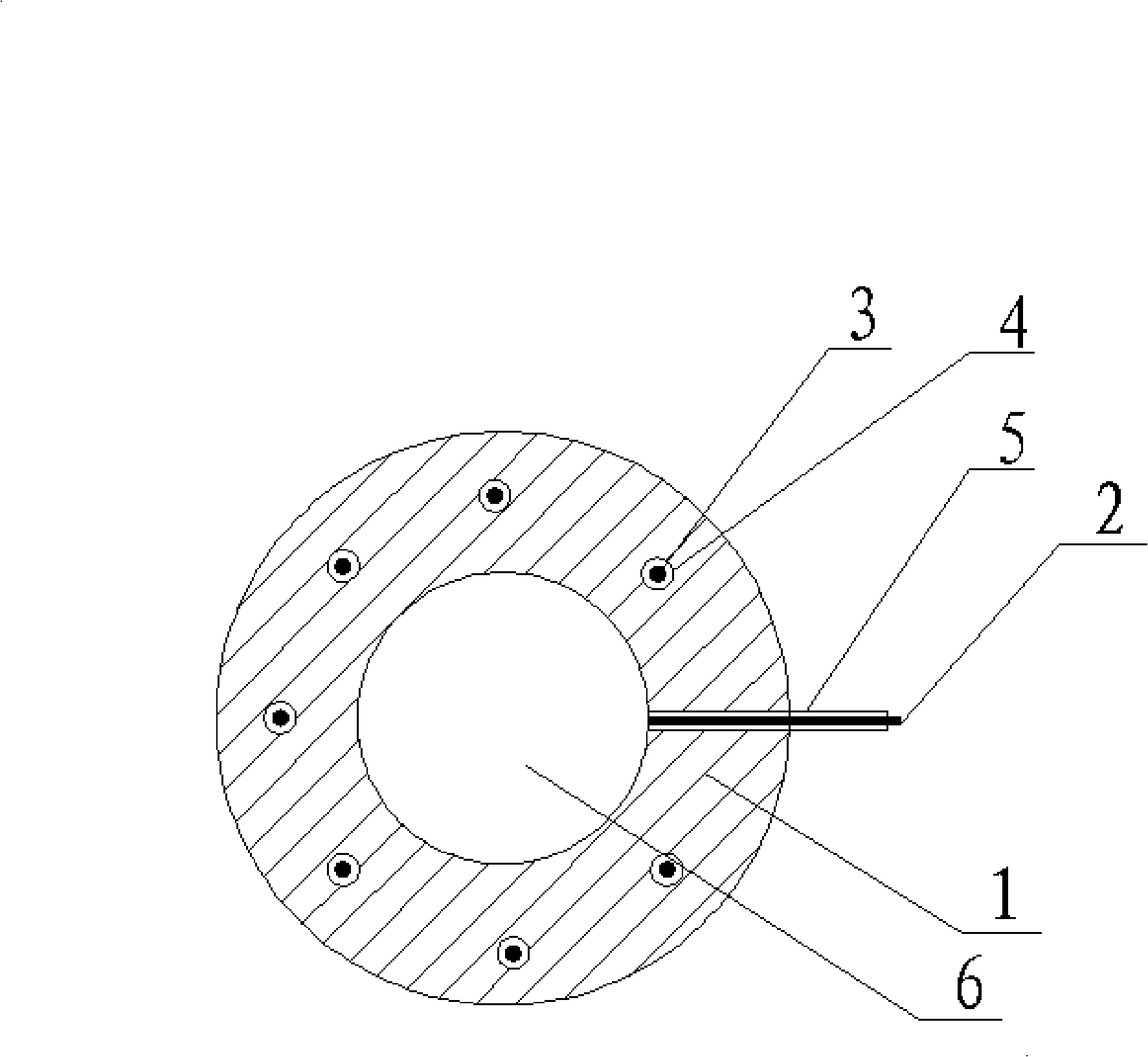

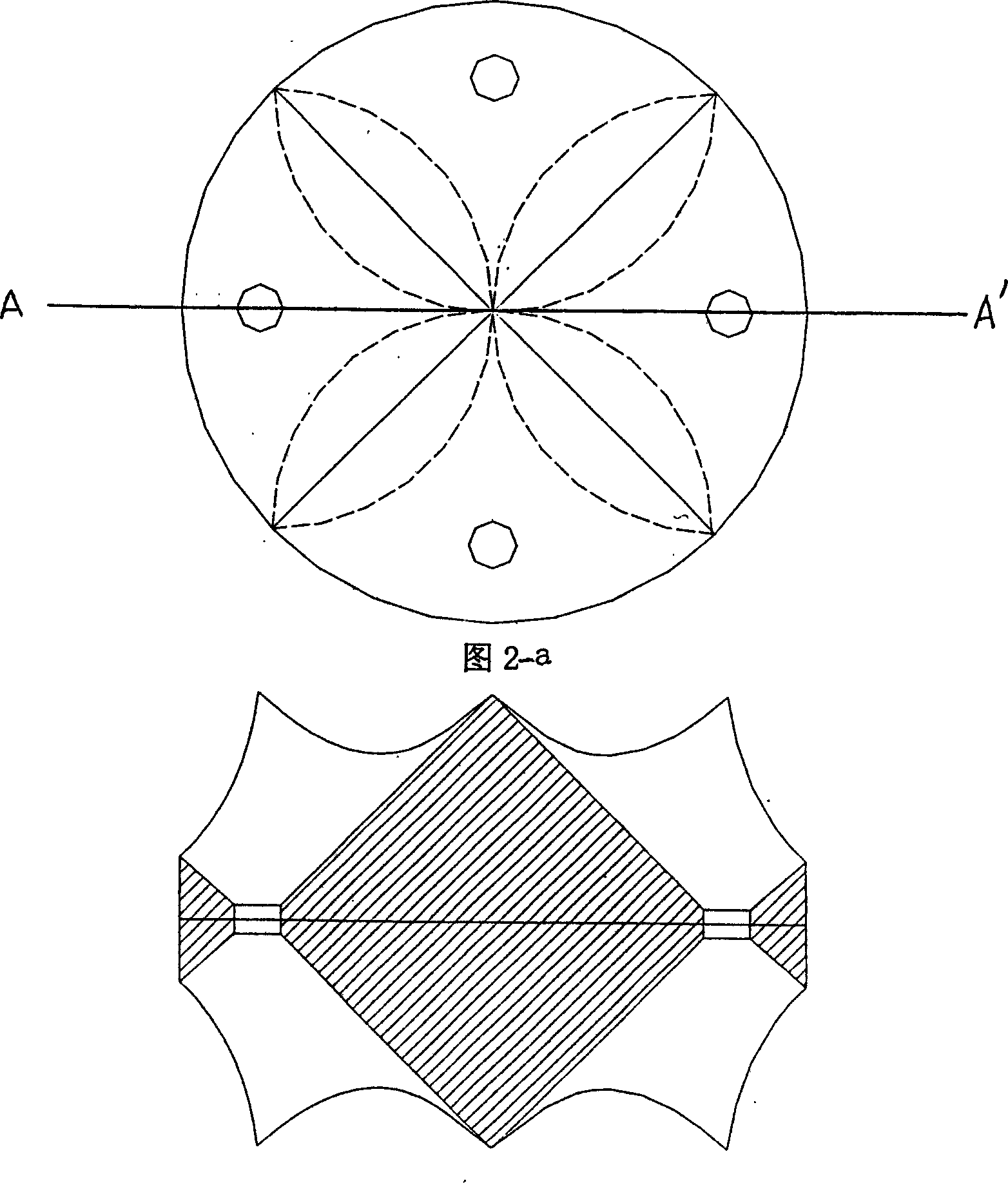

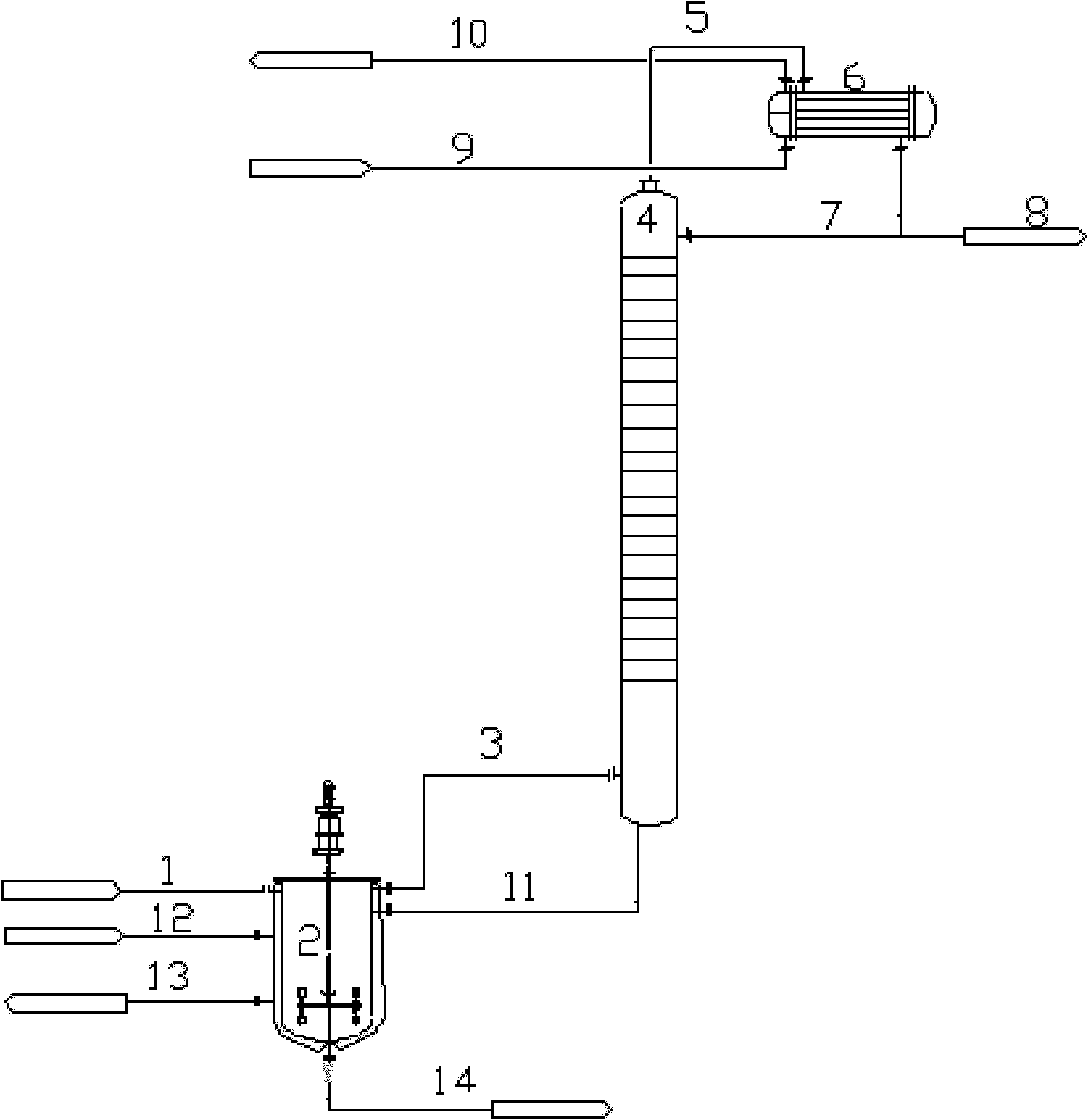

Boiling chlorination furnace for preparing titanium tetrachloride by using natural rutile

The invention discloses a boiling chlorination furnace for preparing titanium tetrachloride by using natural rutile. The boiling chlorination furnace comprises a boiling section (4). The boiling section (4) is connected with an expanded section (7) through a transitional section (6). A slag discharge port (10) and a hearth sealing cover (1) are arranged at the lower end of the boiling section (4). A chlorine inletting pipe (2) is inserted into the hearth sealing cover (1). A chorine distribution plate (3) is arranged between the hearth sealing cover (1) and the slag discharge port (10). A feeding pipe (5) is arranged on one side of the boiling section (4). A furnace top cover (8) is arranged at the upper end of the expanded section (7). A gas outlet (9) is arranged on the furnace top cover (8). The invention has the advantages that the normal operation of the boiling chlorination furnace is guaranteed, and the investment and the maintenance expense of the boiling chlorination furnace are saved. Moreover, since the chlorine distribution plate is placed at the bottom of the boiling section, the elasticity of the boiling chlorination furnace is good, the operation and the control are easy, the sieve openings are not blocked and the chlorine is evenly distributed.

Owner:GUIYANG AL-MG DESIGN & RES INST

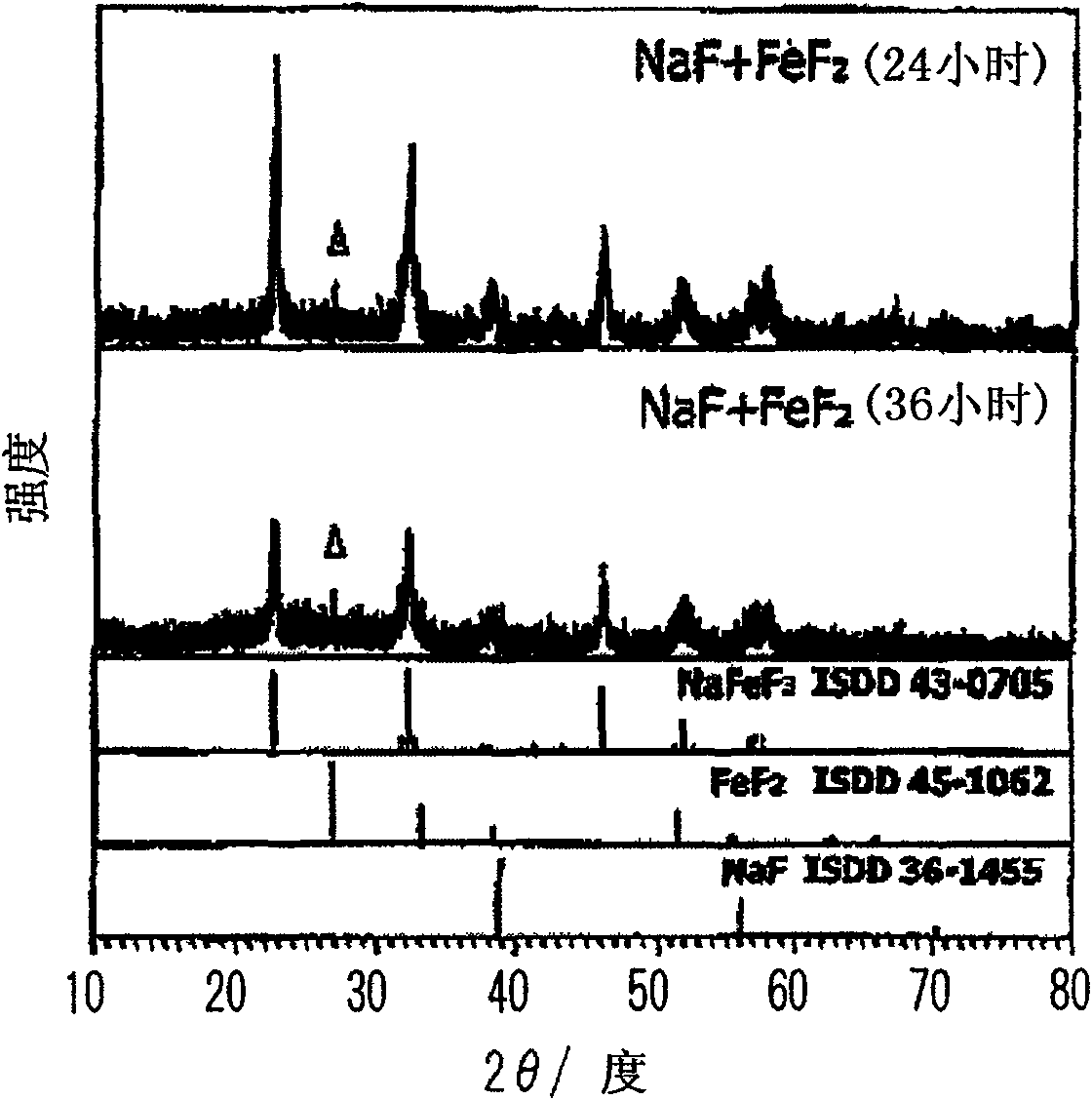

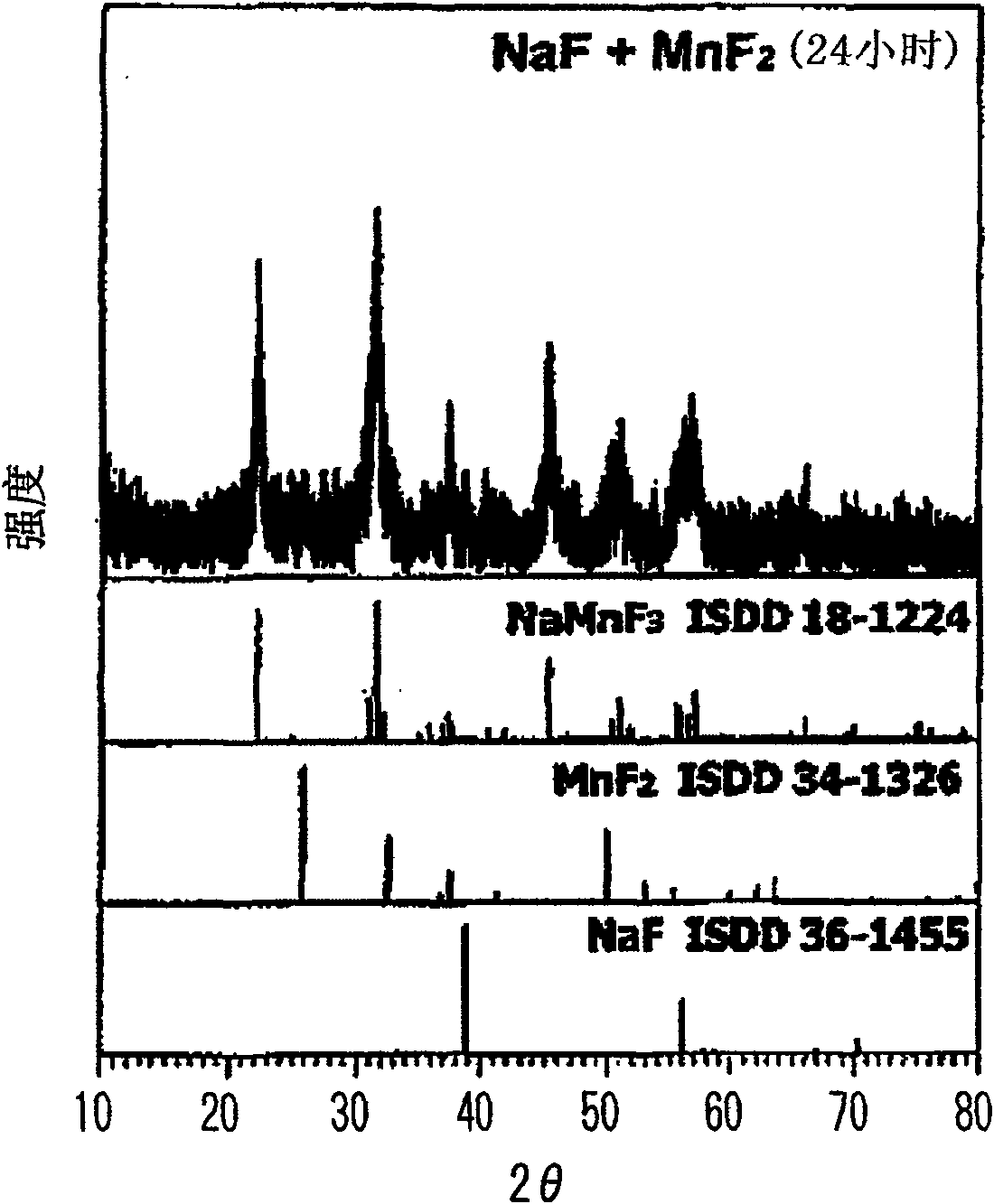

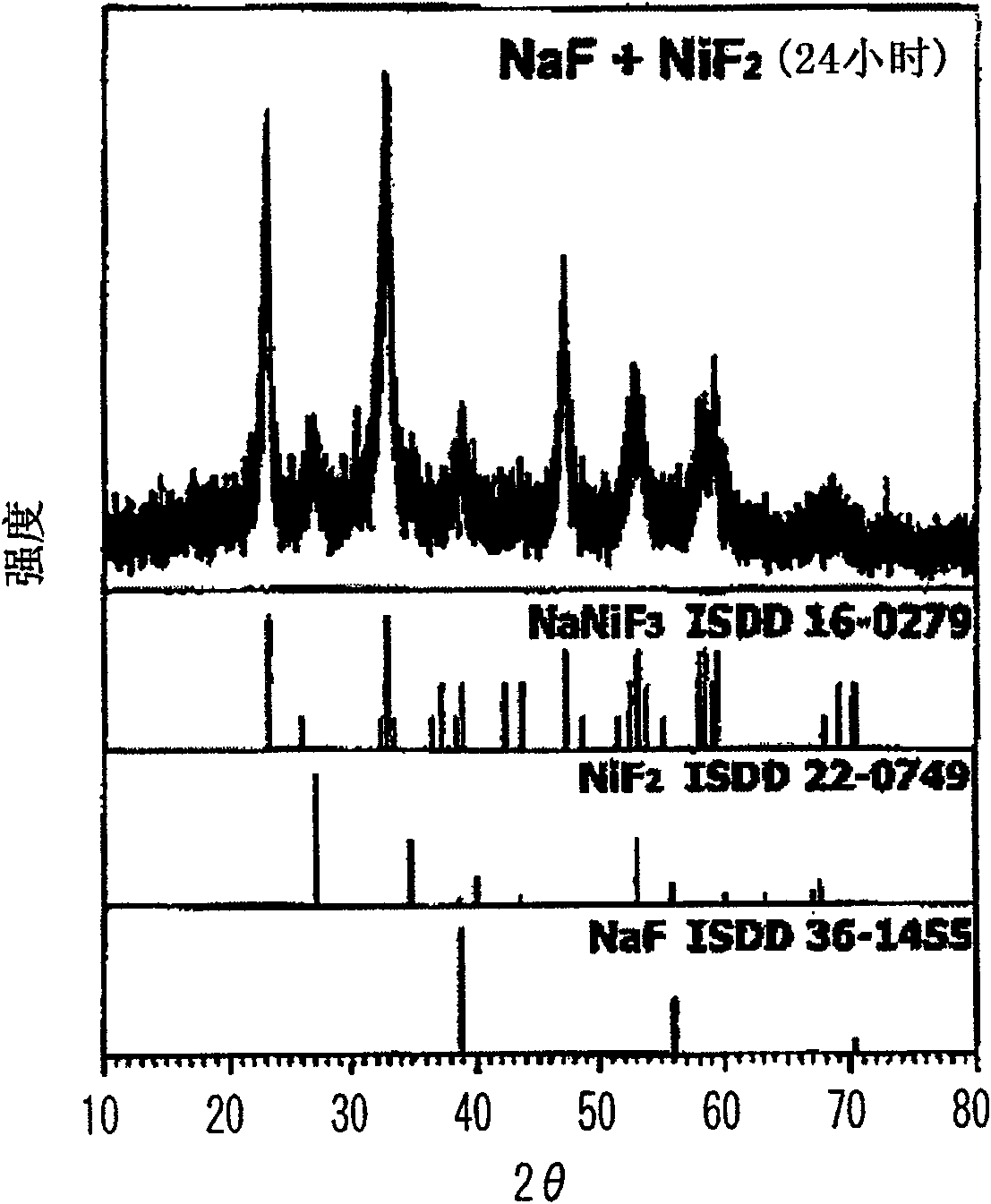

Cathode active material for nonaqueous electrolyte secondary battery and method of producing cathode active material for nonaqueous electrolyte secondary battery

To prepare a fluorinated cathode active material having a guest cation comprising sodium or lithium included therein in a nonaqueous electrolyte secondary battery, an alkali metal fluoride represented by the formula AF and a transition metal fluoride represented by the formula M'F2 are treated by chemical milling to thereby give a fluoride AM'F3. A satellite ball mill is preferably employed in the chemical milling treatment.

Owner:MITSUBISHI HEAVY IND LTD +1

Method of refining titanium tetrachloride by using aluminium powder and vash oil mixture

InactiveCN101549885AEfficient removalImprove refining efficiencyTitanium halidesTitanium chloridePhysical chemistry

Method of refining titanium tetrachloride by using aluminium powder and vash oil mixture. The method is refining of coarse titanium tetrachloride containing high content of vanadium impurities. Mixing aluminium powder, vash oil and a few AlCl[3] in certain percentage and adding into bottom of fractionating tower containing coarse titanium tetrachloride. Heating the bottom of fractionating tower at a temperature of 139 DEG and regulating reflux ratio of the tower, this moment the aluminium powder and mineral oil deoxidizing the VOCl[3] into lower valency indissoluble precipitate VOCl[2] and being removed, and the TiCl[4] and some low boiling point chemical compounds volatilizing into a reflux unit, extracting cuts of 136-137 DEG boiling point, then condensing to get fine titanium tetrachloride. The vanadium-removed fine titanium tetrachloride contains vanadium content of V%<=0.0007%. The vanadium removing process and the fractionating process are all proceeded in the fractionating tower that saves device. The invention reduces a large amount of residue and sewage discharge, and consumes less materials relative to technics of using aluminium powder and mineral oil to remove vanadium alone, the invention provides high refining efficiency, simple operation and continuous, and has economic and environmental benefit of energy-saving and emission-reduction.

Owner:PEKING UNIV

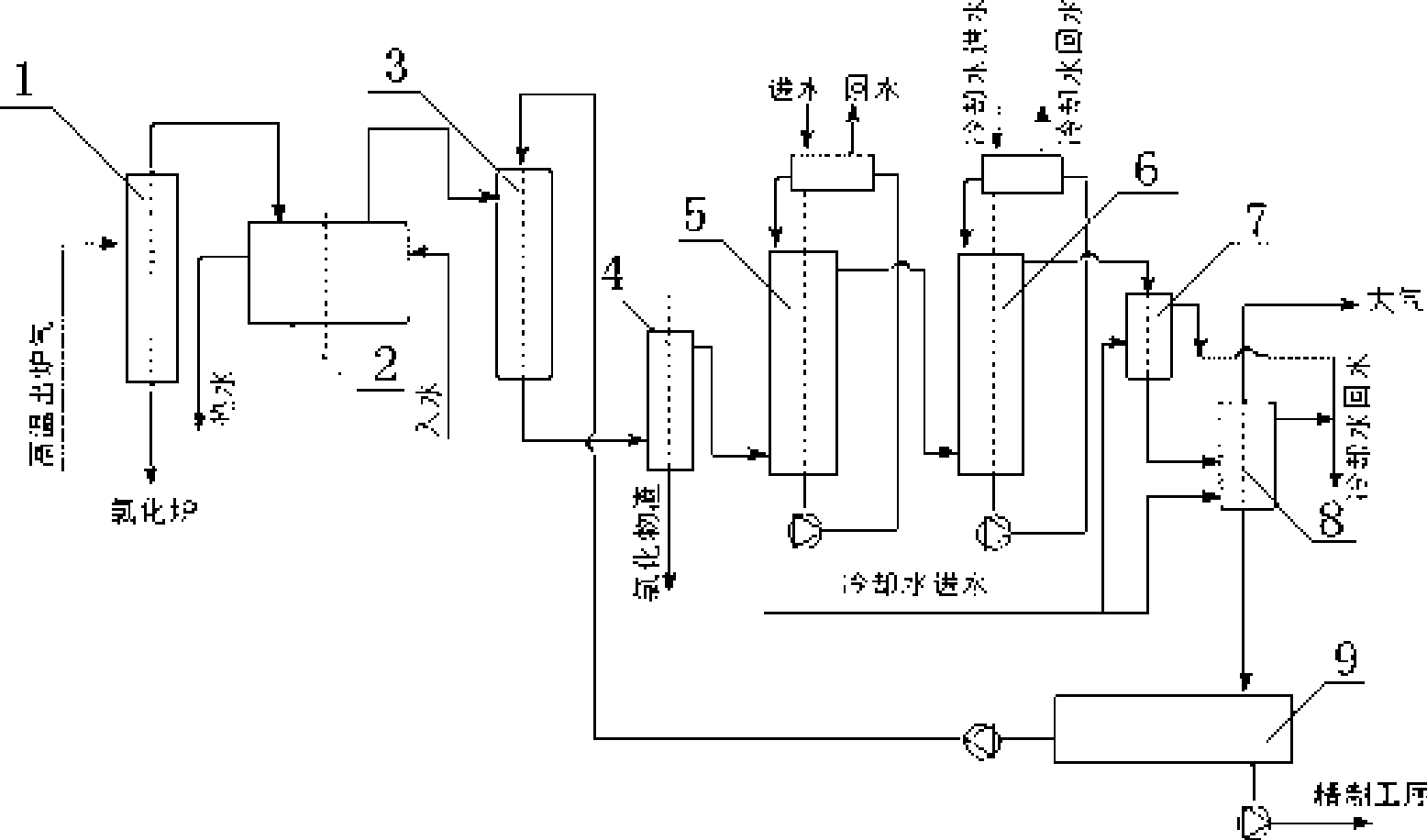

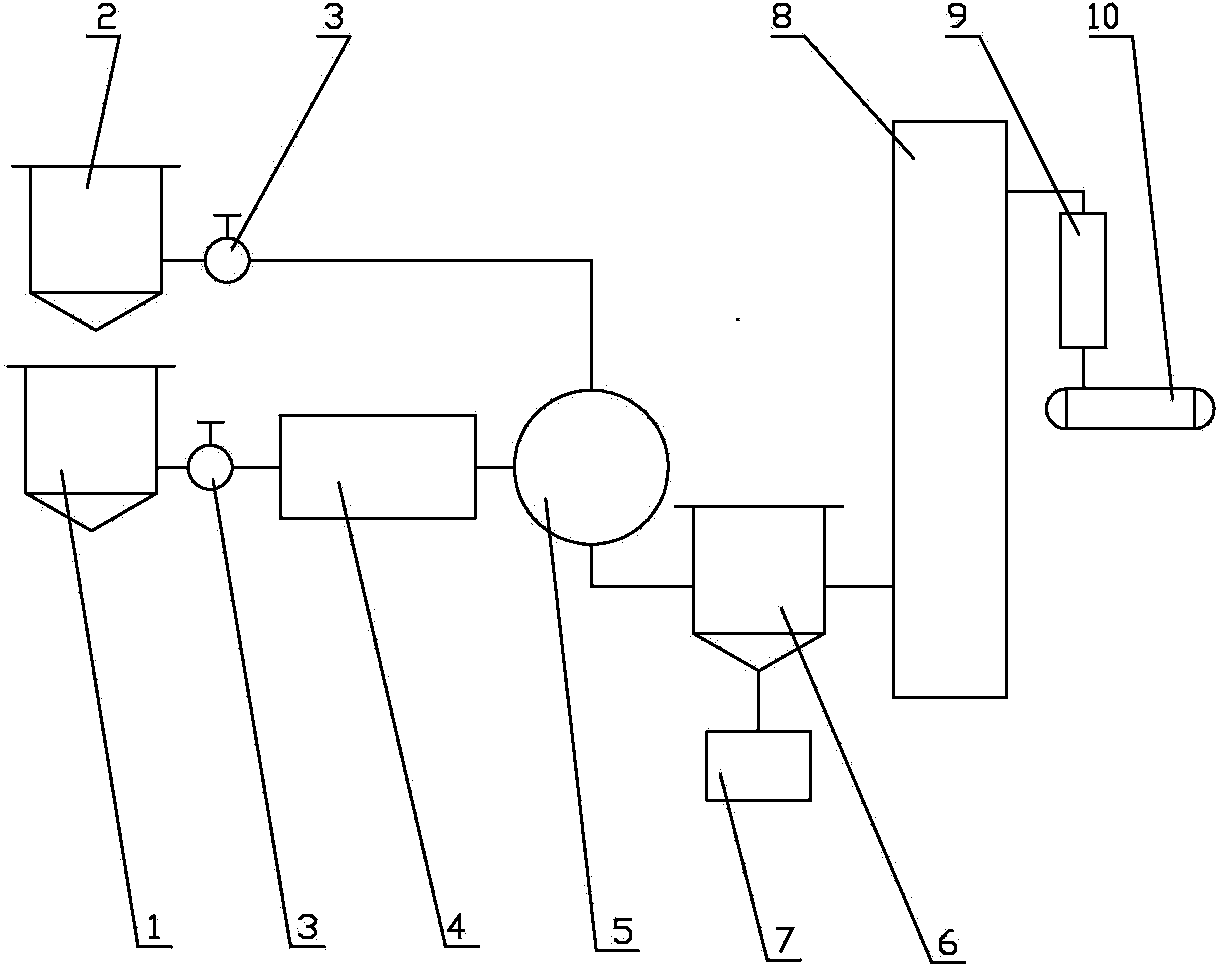

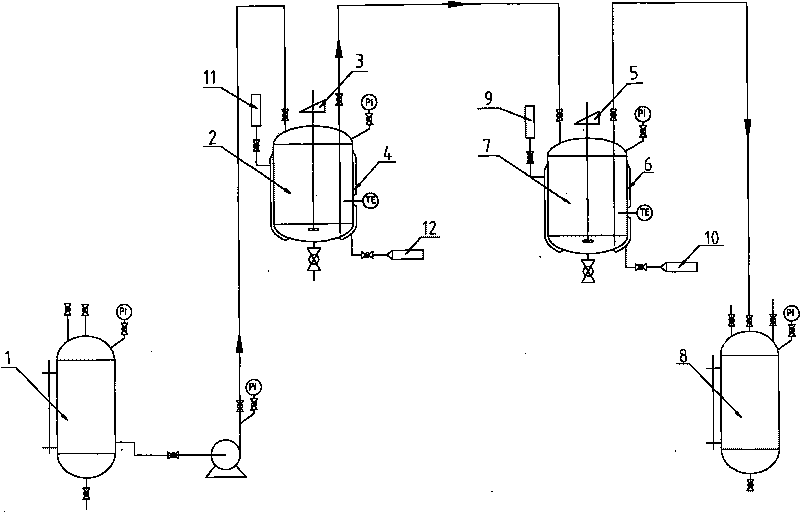

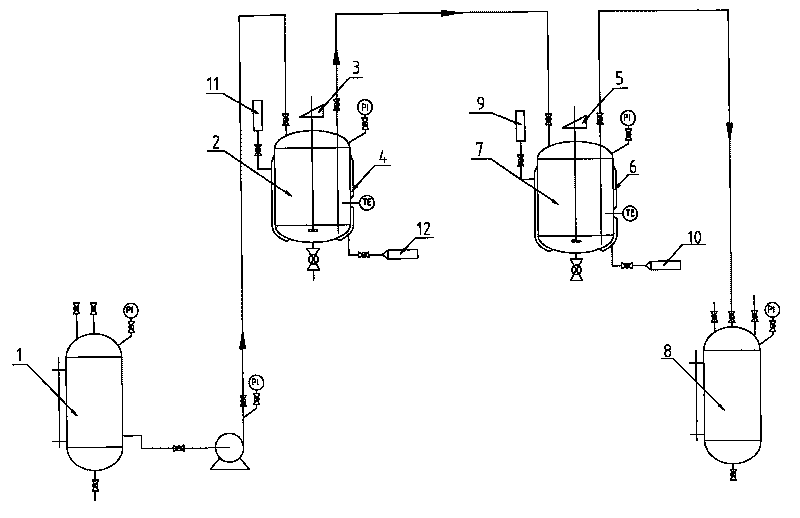

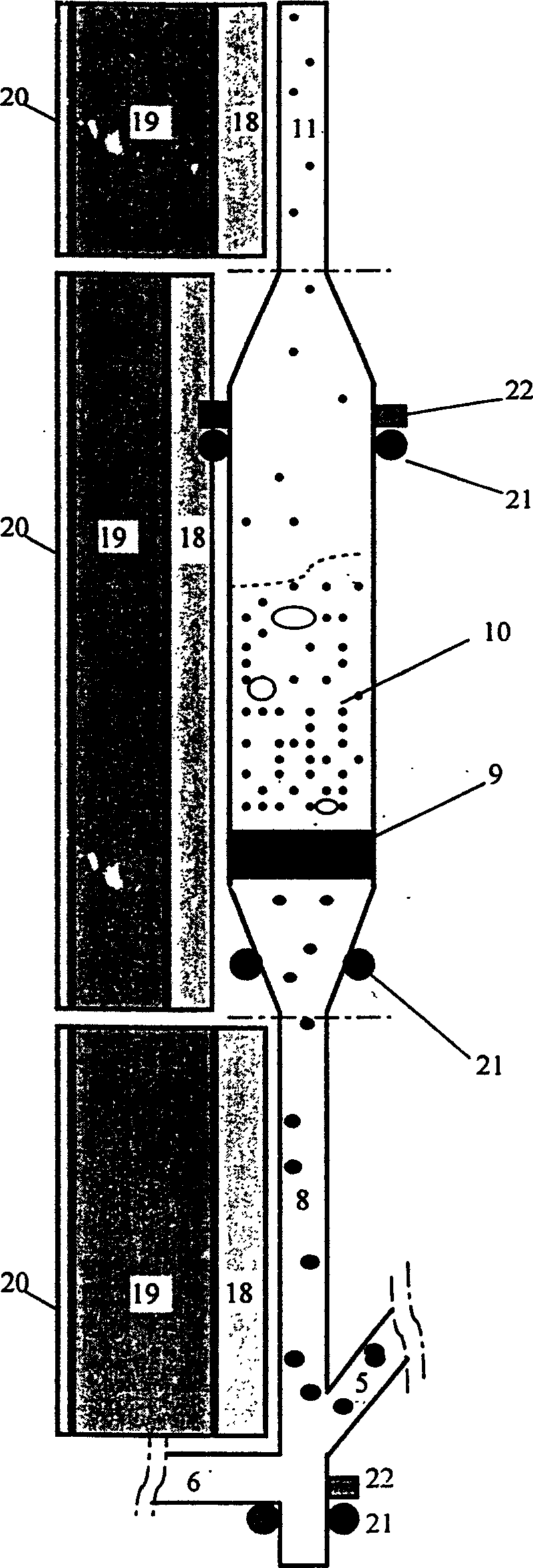

Technique for cooling titanic chloride burner gas

ActiveCN101462766AHigh yieldEmission reductionChemical industryDispersed particle separationEcological environmentAtmospheric air

The invention provides a process for cooling titanium tetrachloride furnace gas, which comprises the following steps: furnace gas discharged sequentially enters a cyclone dust extractor (1) for dust removal, a first cooler (2) for cooling, a spray condensing tower (3) for cooling, a bag filter (4) for filtering, a front leaching tower (5), a rear leaching tower (6), a second cooler (7) for further condensation and a cooling drum (8); waste gases discharged from the cooling drum enter a tail gas washing system and are discharged into the air after meeting discharge standards; and liquid enters a coarse titanium tetrachloride tank (9). The process reasonably uses the heat of the high-temperature titanium tetrachloride furnace gas, improves the recovery rate of TiCl4, reduces the discharge of harmful gases in the tail gas, contributes to environment production, and meets the requirements for establishing an industrial structure which is energy and resource-saving and ecological environment-friendly.

Owner:GUIYANG AL-MG DESIGN & RES INST

Method for preparing TiCl4 from titanium-containing furnace slag

ActiveCN101418383AChlorination is not easyDoes not destroy the fluidized stateTitanium halidesProcess efficiency improvementSlagReducer

The invention discloses a method for preparing TiCl4 through titanium-contained slag. The TiO2 content in the slag is 30 to 45 percent. The method is characterized in that the titanium-contained slag is directly reduced at a high temperature; and the reduced slag is used to prepare the TiCl4 through low-temperature boiling chlorination. According to the method, the titanium-contained slag, a reducer and a binding agent are mixed evenly and are used to make pellets; the pellets are reduced at the high temperature; the reduced pellets are crushed after being cooled down; and then the TiCl4 is obtained through the low-temperature boiling chlorination. The method has the advantages of low reducing temperature, short technical process, high total titanium recovery rate, and the like.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +3

Hybrid Catalyst for Olefin Metathesis

InactiveUS20120289617A1Easy to separateHigh selectivityCation exchanger materialsLithium organic compoundsOrganic chemistryOlefin metathesis

Owner:SAUDI ARABIAN OIL CO

Refining method of titanium tetrachloride

The invention provides a refining method of titanium tetrachloride. The refining method comprises the following steps: feeding crude TiCl4 into a heat exchanger from an overhead tank; preparing a mixed organic solution from paroline, saturated fatty acid, p-phenylenediamine and 2,2,4-trimethyl-1,2-dihydroquinoline polymer and feeding the mixed organic solution into a mixer; adding the crude TiCl4 in a semi-finished product tank into a float valve tower from the middle upper part of the tower, heating the float valve tower to the range of 60-100 DEG C so that the high-boiling-point titanium tetrachloride moves downwards to go into a second distillation kettle from the bottom of the float valve tower, and then carrying out next step of refining vanadium removal treatment. The refining method of the titanium tetrachloride has the advantages that the adopted organic matters are cheap and wide in source, a rectification tower has a self-cleaning function so that a copper wire in the tower can be reused, and the byproducts generated such as compounds containing vanadium and silicon are recycled by use of a recovery tank and clean production is realized. The refining method of the titanium tetrachloride succeeds in improving the shortcomings of vanadium removal by use of organic matters at present, and has excellent economic benefit and social benefit.

Owner:仙桃市中星电子材料有限公司

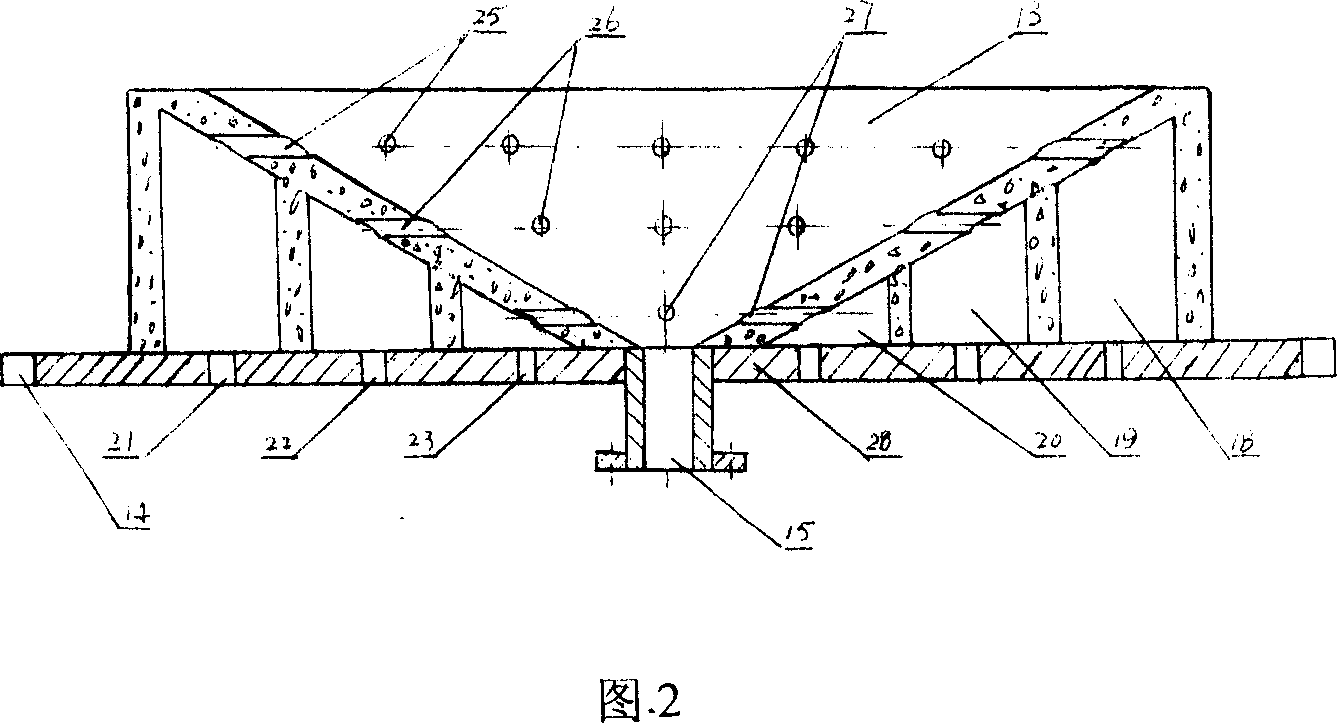

Multi-laminar flow cribriform-plate-free boiling chloridization furnace

InactiveCN1919442AOvercoming the disadvantages of easy blockagePromote sportsTitanium halidesChemical/physical processesCribriform plateCribriform plate fracture

The invention discloses a furnace with four segments, which is characterized by the following: the flannel (11) on the bottom of first furnace segment connects base flannel (14) with furnace base (13) through bolt, the second furnace segment (2) is conical, the third furnace segment is conical, the forth furnace segment (4) is column, the furnace base (13) is integral three-layer chlorine reserving structure, whose bottom board steel board (28) possesses cone chlorine reserving chamber of fireproof concrete, the chlorine inlet and outlet are opened on the chlorine reserving chamber, which is distributed at ring shape, the chlorine inlet connects chlorine pipe with each chlorine pipe allocating chlorine flow self-adjusting tool (24), the discharge hole (15) is set on the center of furnace base (13).

Owner:ZUNYI TITANIUM

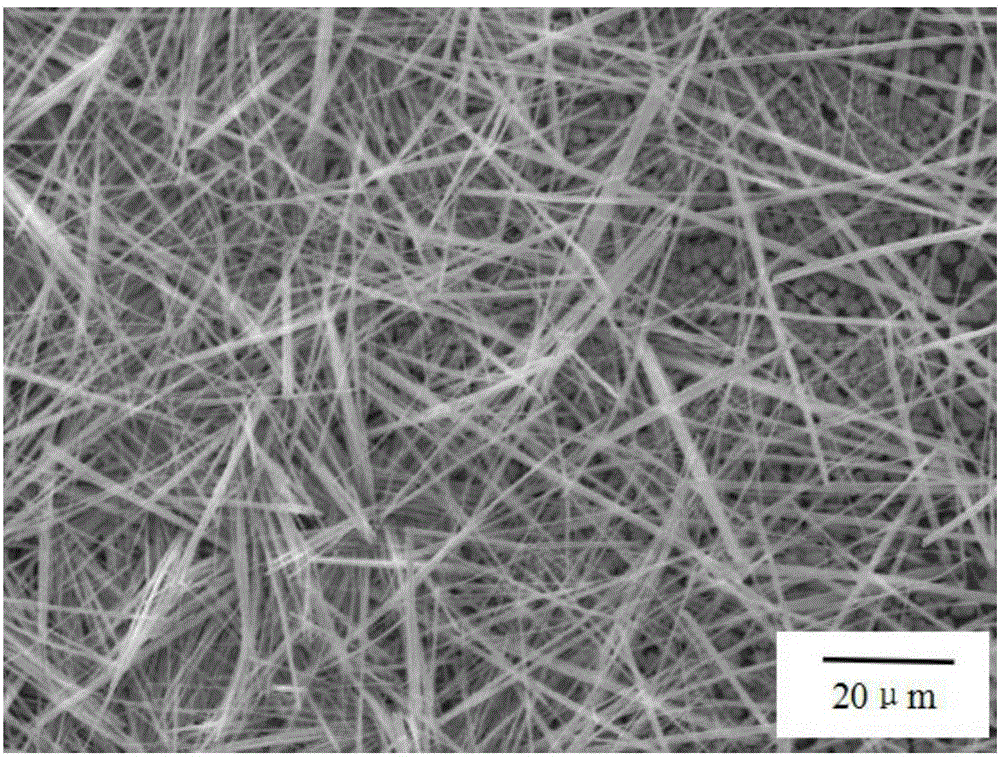

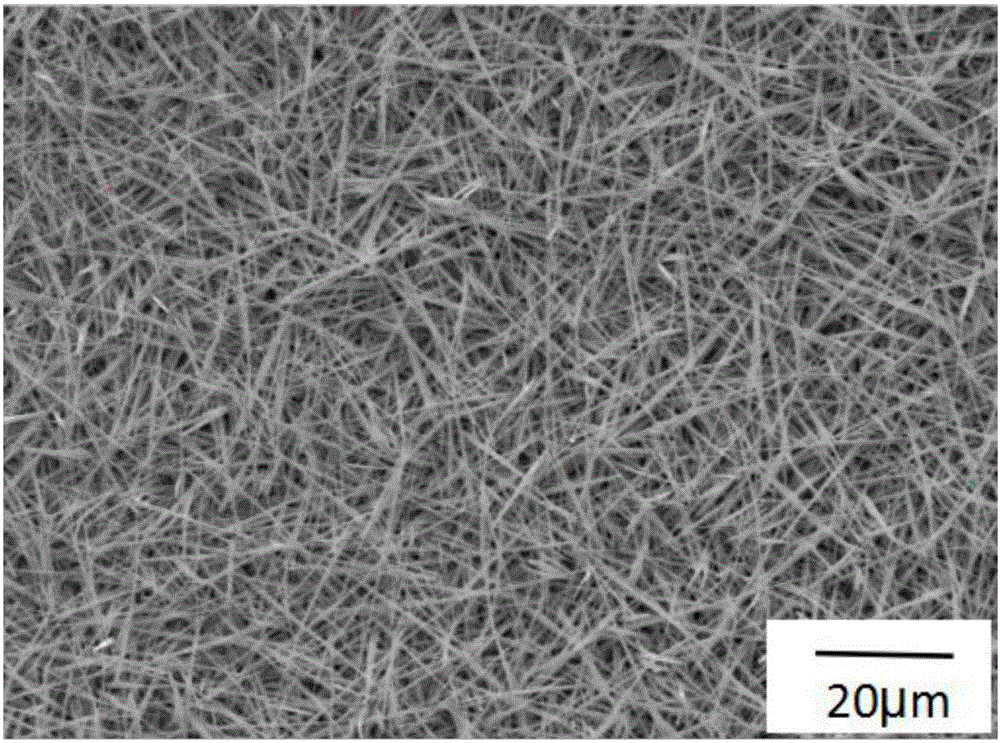

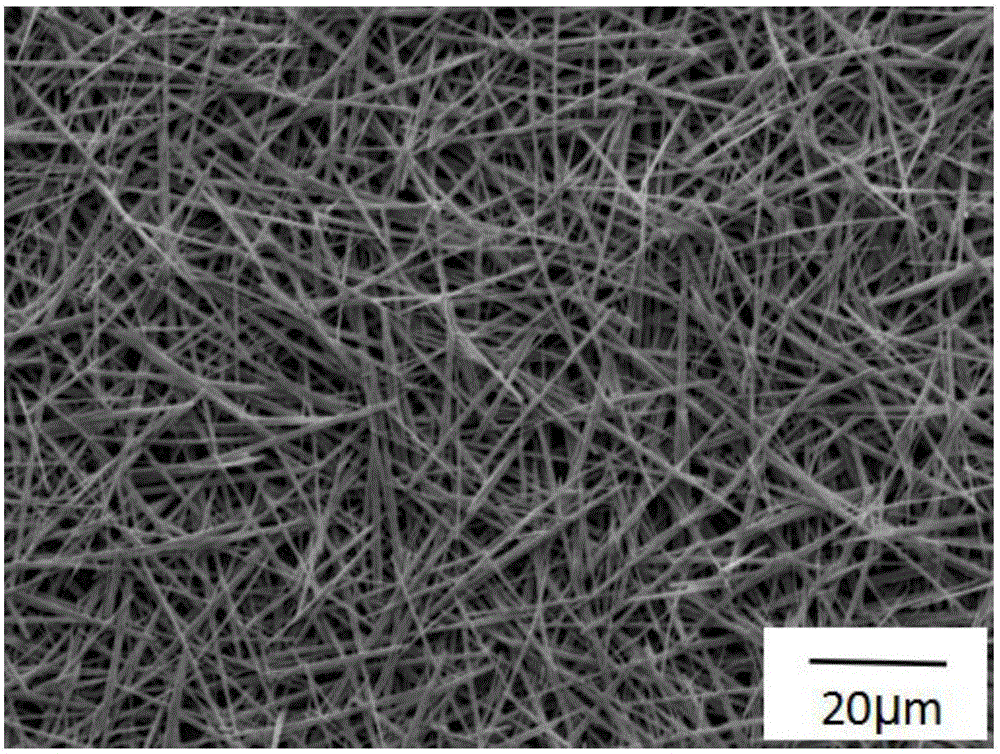

Method for using recrystallization method to prepare lead-halide perovskite nanowire

The invention discloses a method for using a recrystallization method to prepare a lead-halide perovskite nanowire. The method comprises the step of dropwise adding a poor solvent and a polar aprotic solvent in a spin coating process of preparation of APbI3 perovskite through a one-step method to prepare the lead-halide perovskite nanowire. The preparing method has the advantages that the operation is simple and convenient, and the reaction time can be saved. One-dimensional perovskite nanocrystalline film prepared through the one-step method is uniform in length and good in coverage degree, and can be used as a candidate material for an optical detector and a laser device. Compared with pure perovskite, the perovskite nanowire has a better optical conduction capability, and can be used in devices like an optical conductor and the laser device.

Owner:NANJING UNIV OF SCI & TECH

Method for reclaiming and purifying titanium tetrachloride for preparing olefin polymerization catalysts

InactiveCN101717113ASimplify the impurity removal and purification processReduce manufacturing costTitanium halidesOlefin polymerizationAlkene

The invention relates to a method for reclaiming and purifying titanium tetrachloride for preparing olefin polymerization catalysts. The adopted technical scheme comprises the following steps of: adding a titanium tetrachloride mother solution produced in the preparation process of the olefin polymerization catalysts to an intermediate storage tank I; introducing circulating water with the temperature of 10 DEG C to 30 DEG C to a water jacket for stirring, wherein the stirring rotation speed is 100 to 300 rpm; transferring pretreated titanium tetrachloride mother solution to a cryogenic kettle; introducing refrigerant medium with the temperature of 5 DEG C below zero to 35 DEG C below zero to a refrigerant jacket; gradually reducing the temperature of the titanium tetrachloride mother solution to be between 0 DEG C and 25 DEG C below zero; controlling the stirring rotation speed to be 10 to 150 rpm; carrying out cold separation and settlement for 2 to 12 hours under stirring; and separating a supernatant and crystallinesubstance in the titanium tetrachloride mother solution, and transferring the supernatant to an intermediate storage tank II through a pipeline. The invention has simple process, low energy consumption and high recovery ratio, and is environment friendly.

Owner:LIAONING DINGJIDE PETROCHEM

Boiling chlorination furnace with temperature-controlling device and temperature-controlling method thereof

InactiveCN101264927AEasy to manufactureLow costFluidised-bed furnacesTitanium halidesTemperature controlSlag

The invention discloses a chloride boiling furnace with a heating device and a corresponding temperature control method, comprising a heating device and a temperature measuring device, which is characterized in that: the chloride boiling furnace facilitates to control environmental temperature of the chlorination reaction; the heating device is arranged on the wall of the chloride boiling furnace and adopts the resistance wire which is even distributed in the wall of the furnace; the temperature measuring device adopts a thermocouple which is protected by bushing. When using the chloride boiling furnace, the temperature control method is that: the adding material is heated by heating device to reaction temperature firstly; different adding material temperatures are adopted according to the different chloride materials which is high-titanic slag or titanium carbide; and then the normal temperature of the chloride boiling furnace in running is controlled through monitoring the thermocouple and making-breaking the resistance wire. The chloride boiling furnace has the advantages of simple and easy practice, convenient manufacture, low cost, being able to control the temperature in the furnace conveniently and accurately, being suitable for controlling the running temperature in small chloride boiling furnace particularly and applying in the preparing of the titanium tetrachloride field mostly.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

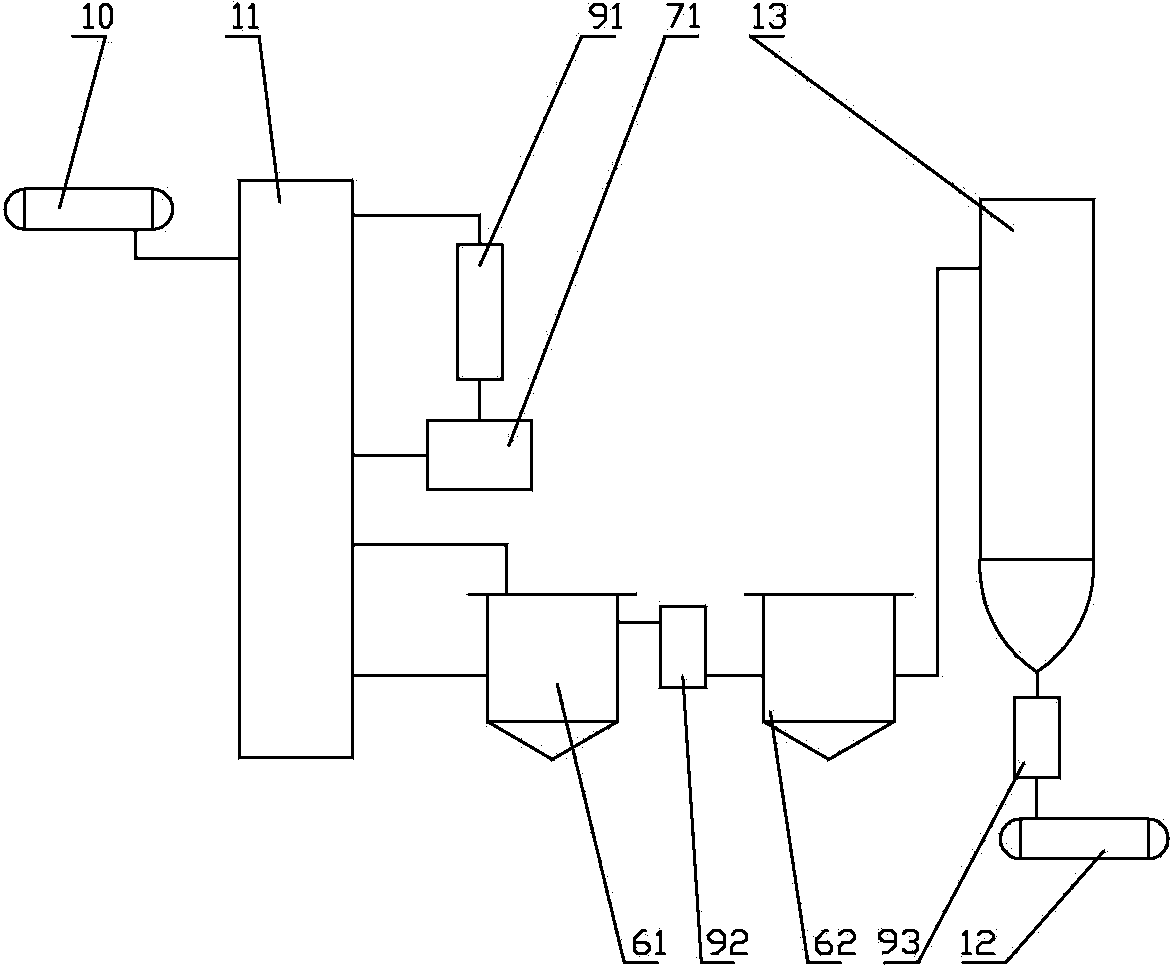

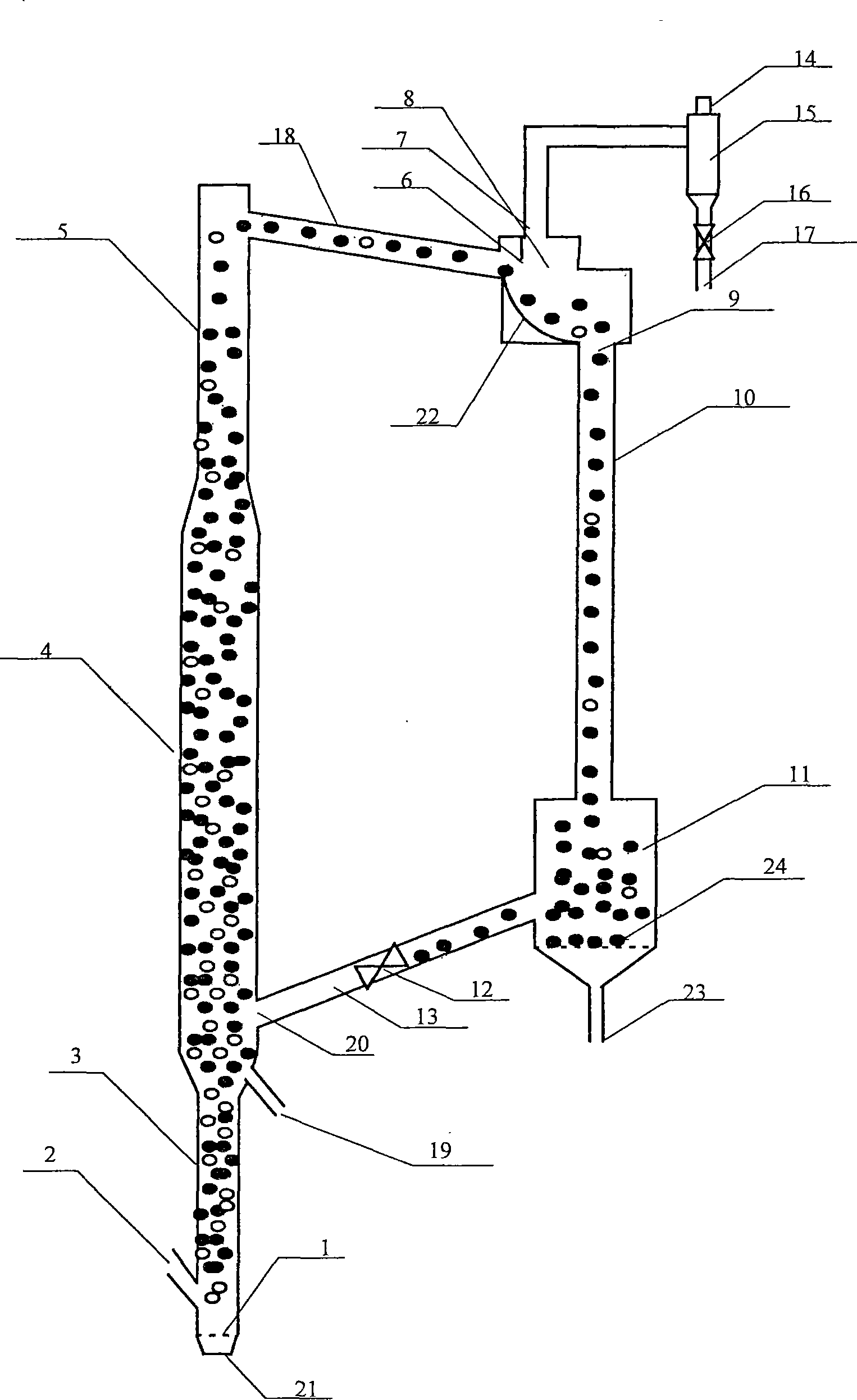

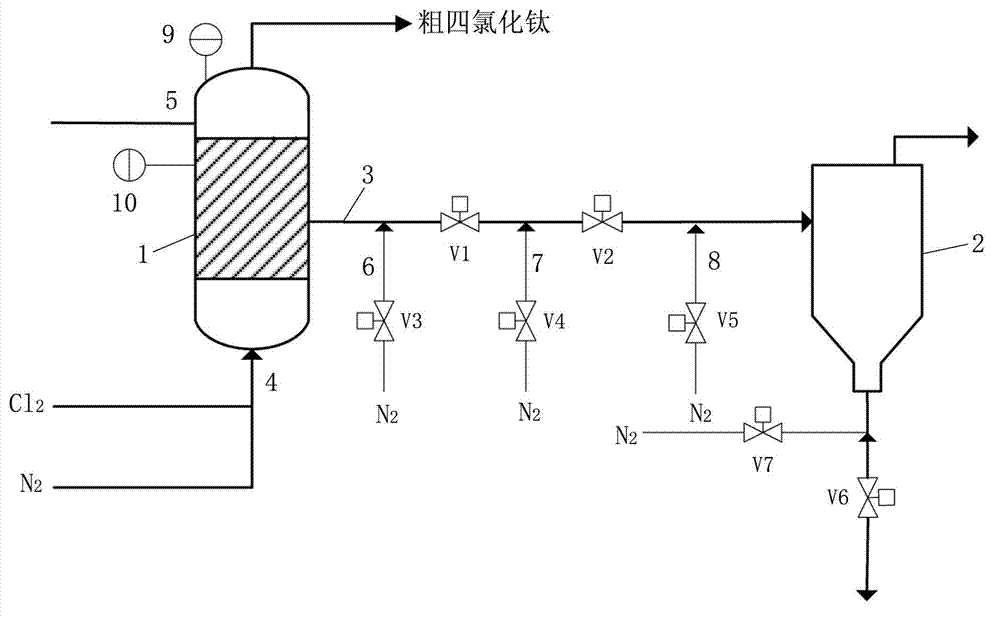

Method for preparing titanic chloride by half cycle fluidization

InactiveCN101475210AReduce agglomerationSolve the conundrum problemFluidised-bed furnacesTitanium halidesNitrogenLower grade

The invention discloses a method for preparing titanium tetrachloride through semi-circulating fluidization, which relates to a method for preparing the titanium tetrachloride. The method takes low-grade high titanium slag and coke as solid raw materials, takes chloride and nitrogen as gas raw materials, and utilizes a semi-circulating fluidized bed to obtain a finished product through a chlorination reaction, cooling and gas-solid separation. The method avoids the agglomeration and adhesion of the particles by circulating coke particles with smaller viscosity and suspending high titanium slag particles with larger viscosity in a fluidized bed reactor, can fully utilize low-grade high titanium slag resource, and has the characteristics of high production efficiency, good product quality, simple and convenient operation, suitability for industrial mass production and the like. The method can be widely applied to the preparation of the titanium tetrachloride by utilizing titanium ore, and is particularly suitable to utilize the low-grade high titanium slag to prepare the titanium tetrachloride.

Owner:CHONGQING UNIV

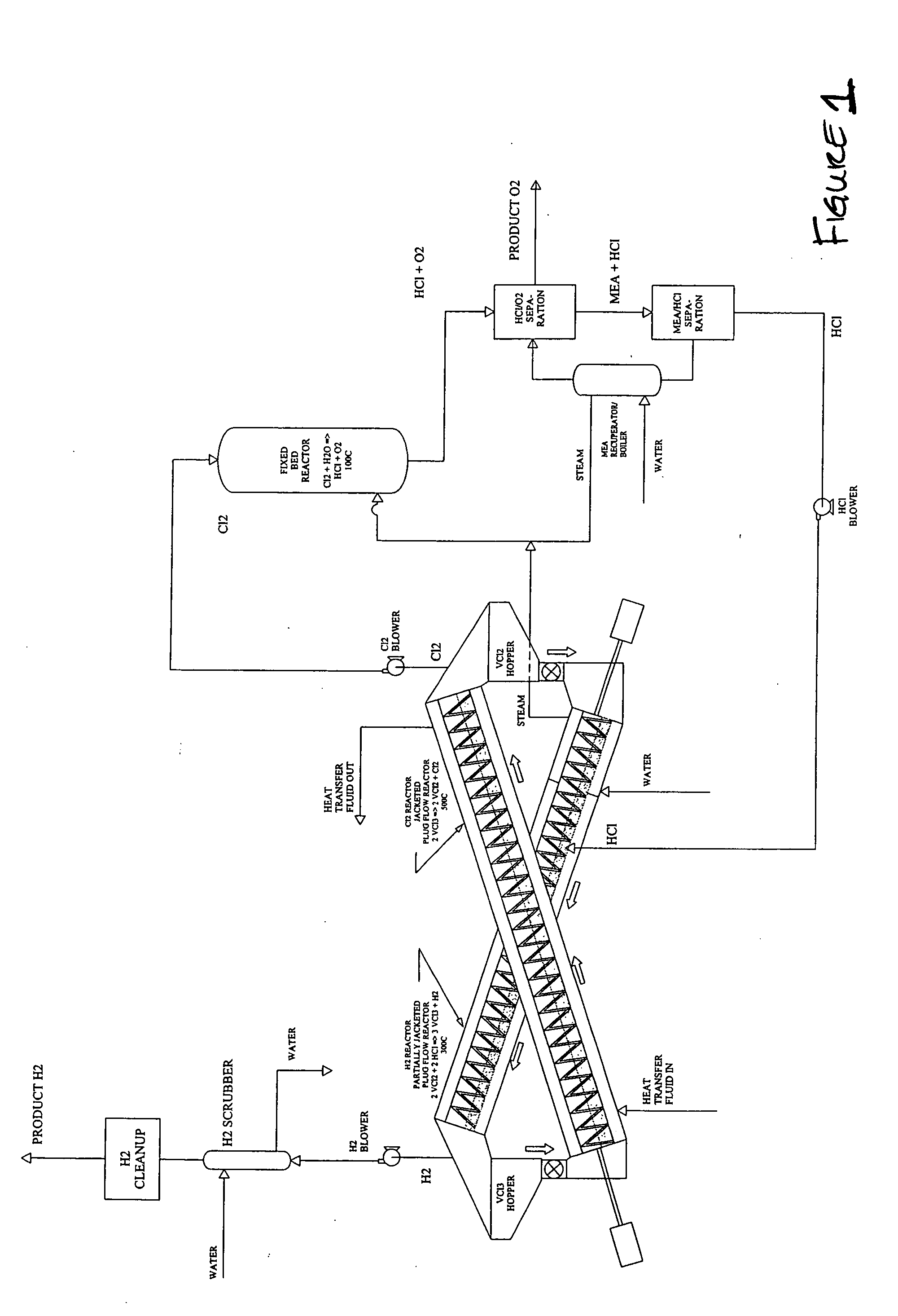

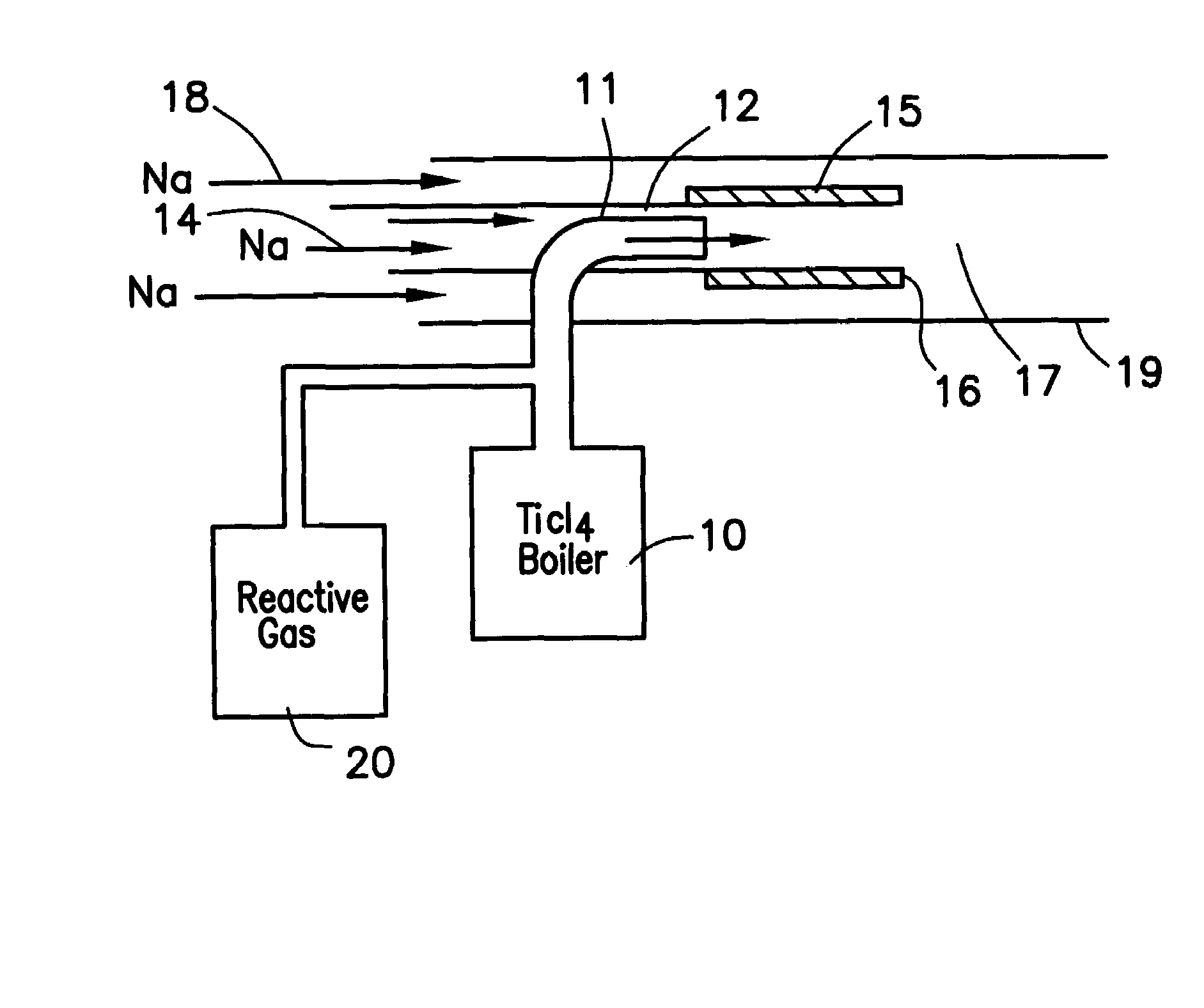

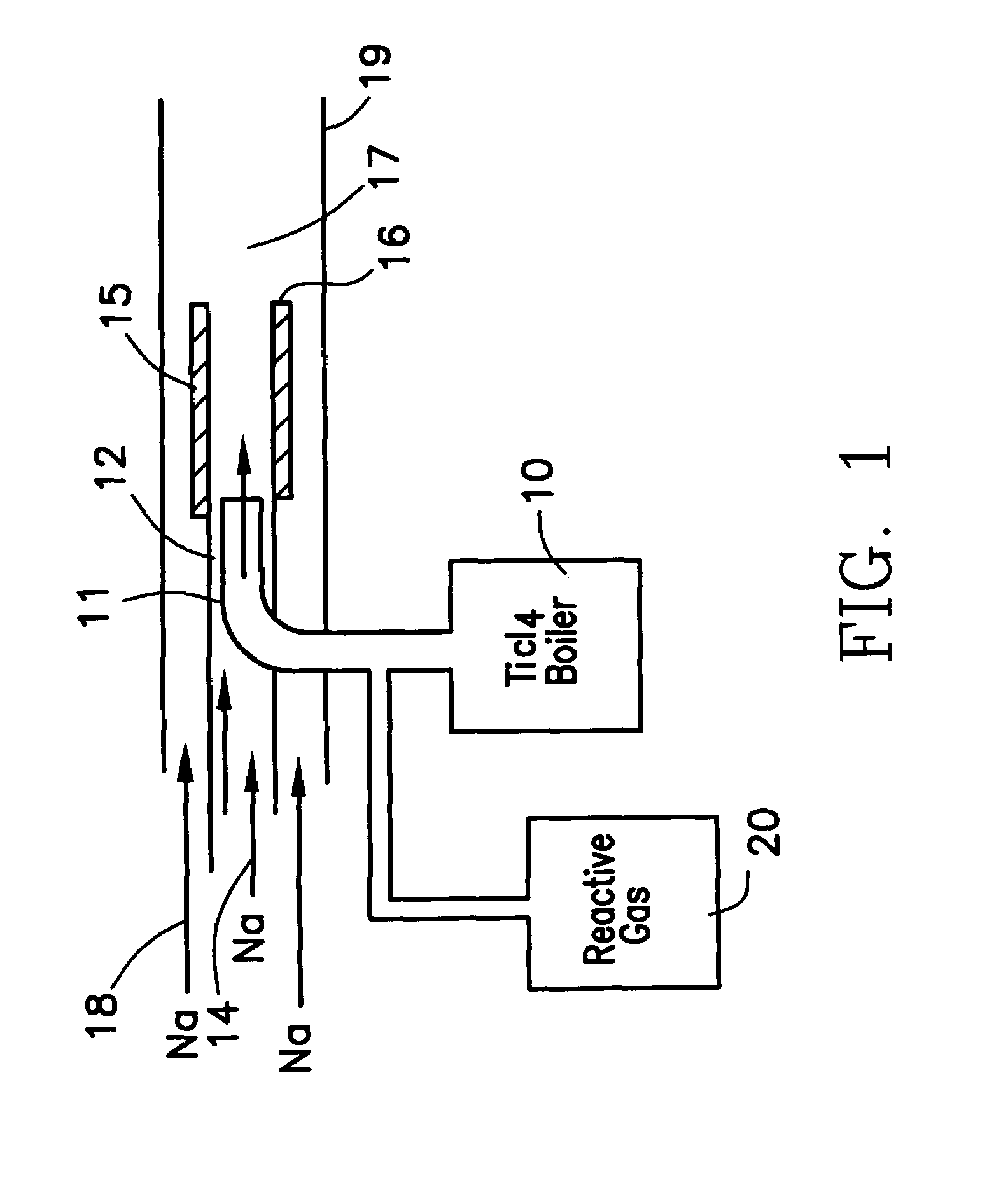

Method and apparatus for controlling the size of powder produced by the Armstrong process

InactiveUS7351272B2Material nanotechnologyNitrogen-metal/silicon/boron binary compoundsLiquid stateReaction zone

A method of controlling the size and morphology of powder made by the subsurface injection of a halide vapor into a liquid metal is disclosed. A reaction zone is established and the temperature thereof or the time the powder remains therein is controlled to change powder characteristics.

Owner:CRISTAL US INC

Zirconia-based mixed oxide and production process thereof

ActiveUS7781365B2Improve heat resistanceReduce probabilityOxygen/ozone/oxide/hydroxideHeterogenous catalyst chemical elementsMischmetalMixed oxide

The present invention provides a zirconia-based mixed oxide which, together with improving the heat resistance of specific surface area at a high temperature (1000° C. for 3 hours), has a ceria reduction rate of 80% or more, or in other words, improves the heat resistance of specific surface area and the reduction rate of ceria. The zirconia-based mixed oxide has zirconia for the main component thereof and contains 5% or more of ceria and 1 to 30% of a rare earth metal oxide other than ceria, wherein the specific surface area after heat treating for 3 hours at 1000° C. is 50 m2 / g or more, the reduction rate of the ceria contained in the mixed oxide is 80% or more, and preferably the specific surface area after heat treating for 3 hours at 1100° C. is 20 m2 / g or more.

Owner:DAIICHI KIGENSO KAGAKU KOGYO CO LTD

Apparatus and method of preparing titanium tetrachloride for chlorination of titanium-containing mineral

InactiveCN1454849AReduce pollutionEliminates the risk of stickingTitanium halidesChemical/physical processesFluidized bedEngineering

The present invention relates to an equipment for preparing titanium tetrachloride by chlorination of titanium-containing mineral and its method. The upper hole of sealed storage tank is communicated with lower hole of preparation storage tank by pipe, the lower hole of the sealed storage tank is communicated with feeding hole of screw feeder the outlet of which is connected on the feeding hole of rapid reaction fluidized bed by a pipe, said rapid reaction fluidized bed has a gas inlet communicated with a gas pipe. Said fluidized bed is communicated with a condenser, which a gas-solid cyclone separator is connected, its upper portion has a product outlet and its lower portion has a waste material outlet. Said method includes: chlorination reaction, fluidized bed reaction, cooling and gas-solid separation.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

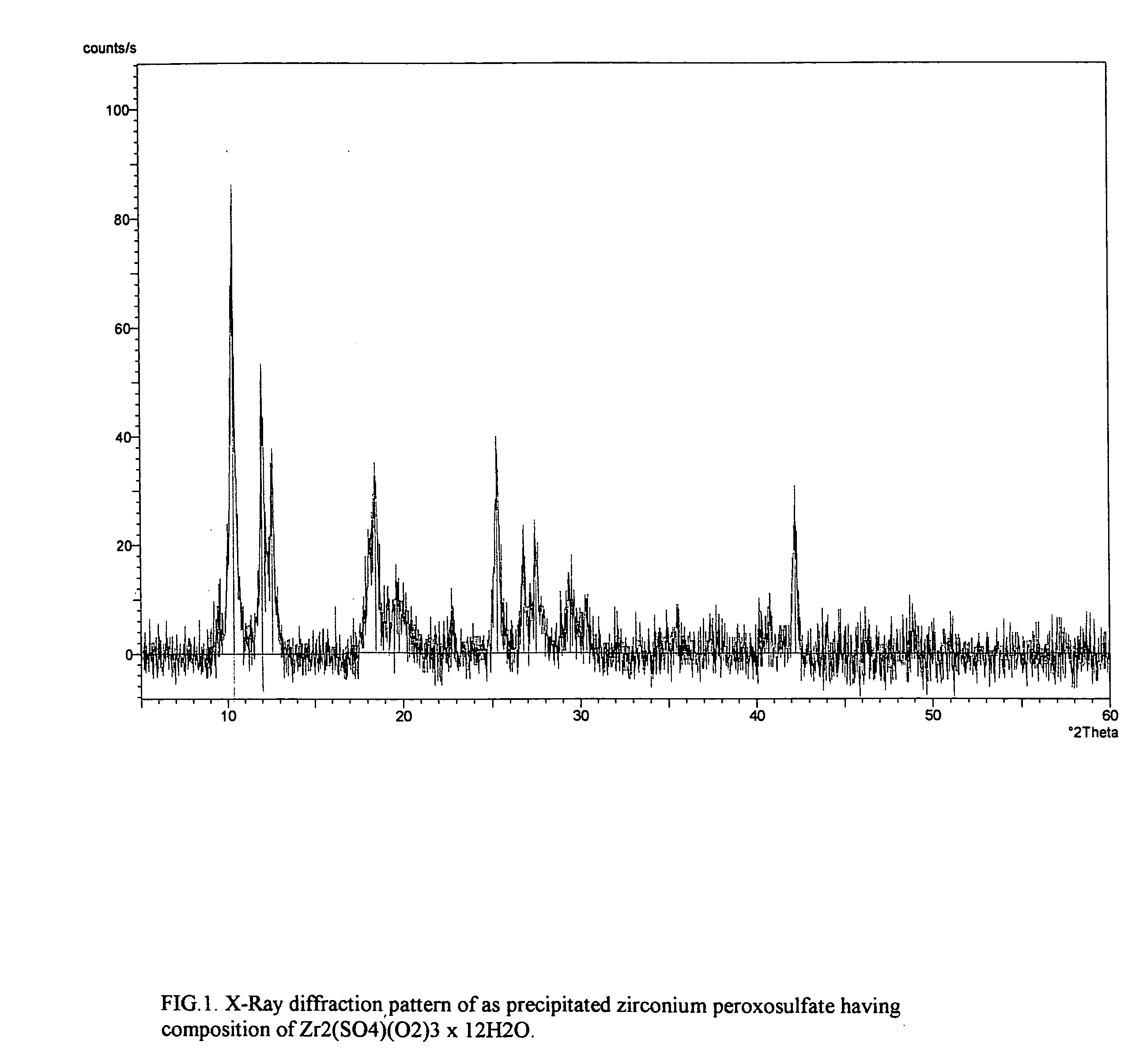

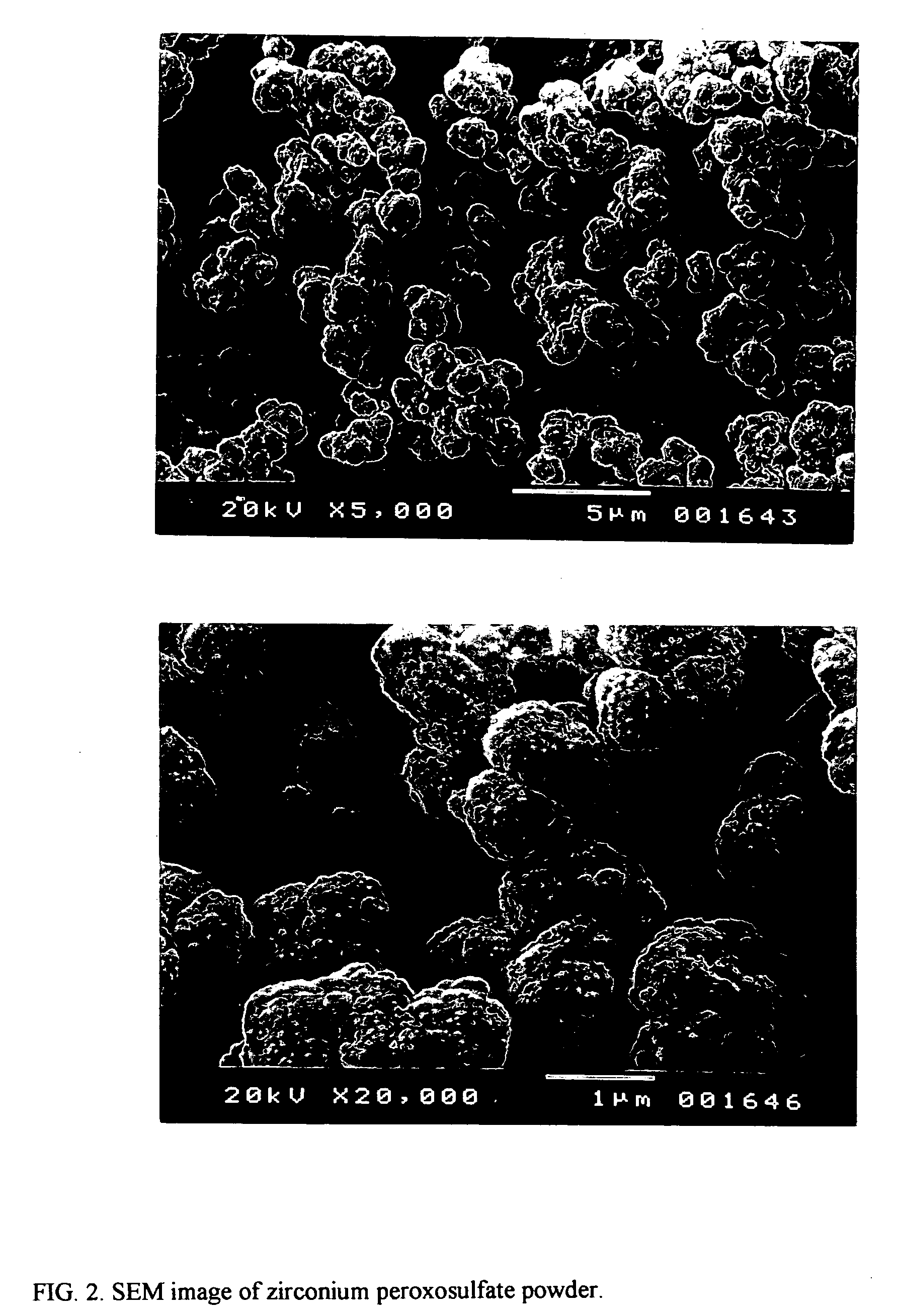

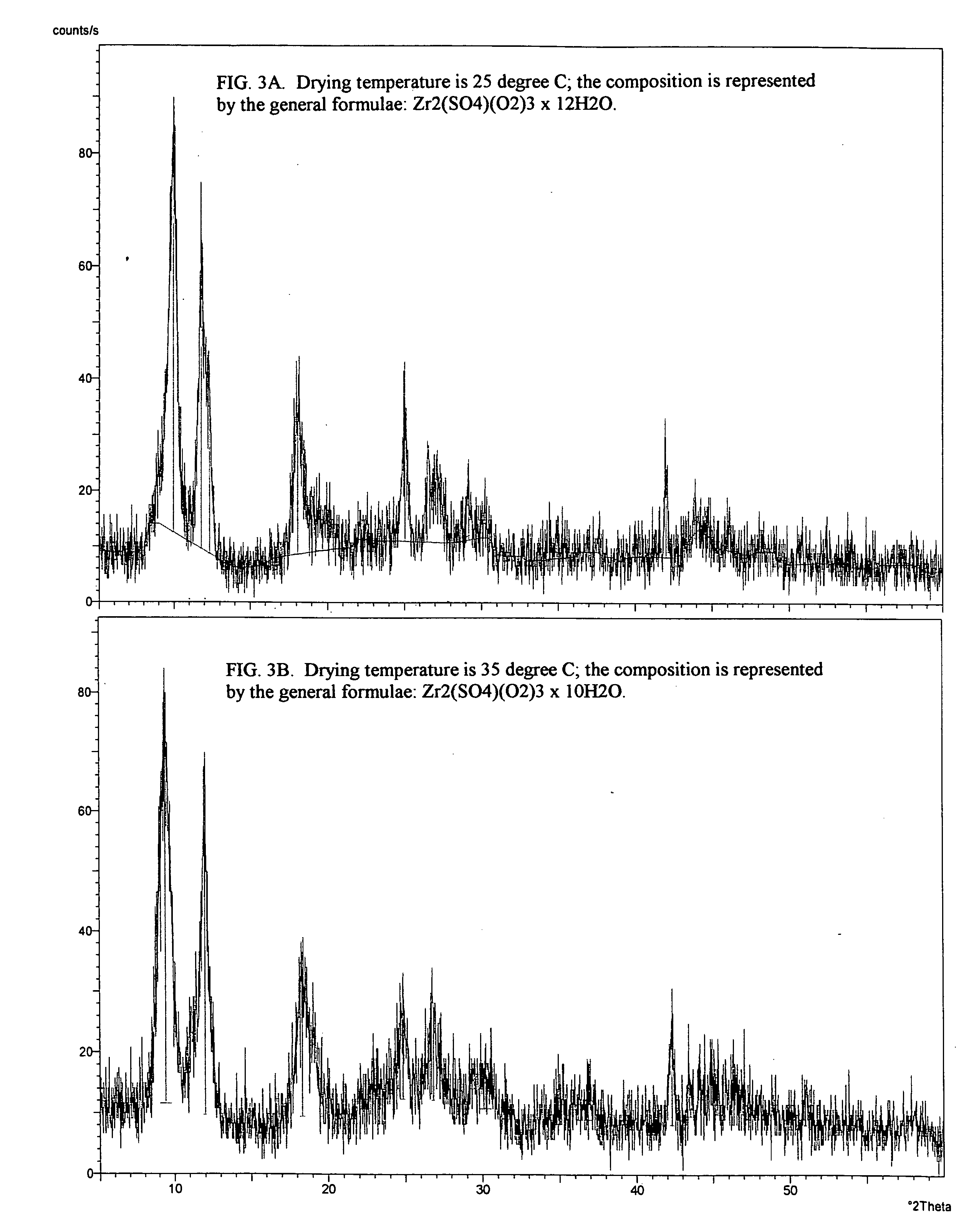

Process for the isolation and purification of zirconium peroxosulfate and uses thereof

InactiveUS20050180911A1High degreeShort processing timePeroxyhydrates/peroxyacidsSulfate preparationPurification methodsZirconium compounds

Provided is a process for isolating zirconium peroxosulfate and its use, either as is or to prepare high purity zirconium compounds including powders of zirconium dioxide and stabilized zirconia. The process is based on precipitating a peroxide compound from an acidic peroxide solution of zirconium and provides a simple, economical method for producing the zirconium peroxosulfate powder and its derivatives with degree of zirconium recovery more than 99%. This process further provides an effective method for the separation and purification of zirconium from a variety of elements and / or naturally occurring ores.

Owner:BELOV VLADIMIR +1

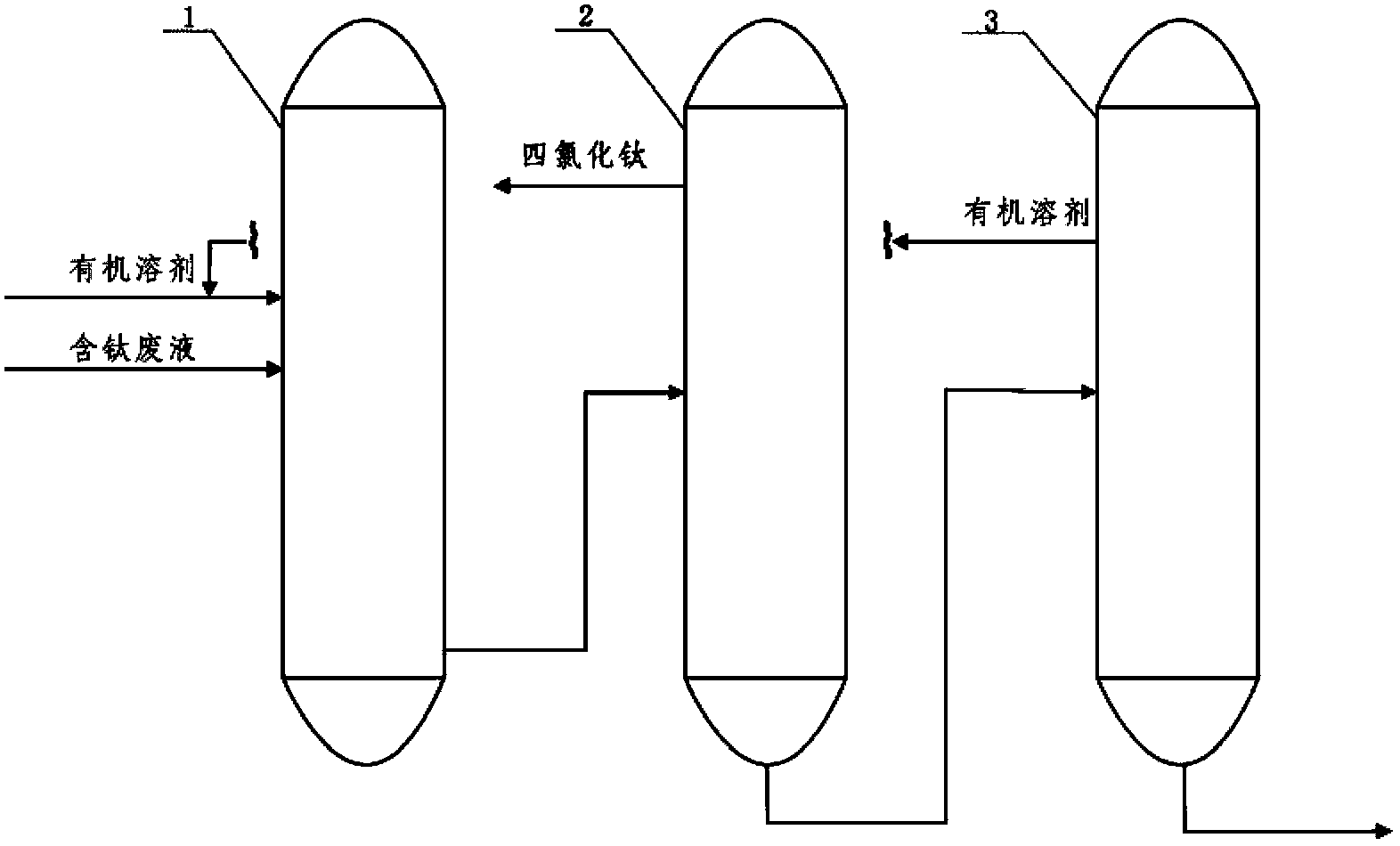

Recovery processing method of titanium-containing waste liquid

ActiveCN103420437ASolve the problem of high viscosity and poor fluidityPrevent scalingWater/sewage treatment by heatingTitanium halidesLiquid wasteOrganic solvent

The invention discloses a recovery processing method of titanium containing waste liquid. The method comprises following steps: (1) adding an organic solvent into titanium-containing waste liquid, and fully mixing with the titanium-containing waste liquid; (2) distilling the obtained mixture in a distillation device, and separating titanium tetrachloride from the top of the distillation device; (3) adding an alkali solution in the residual mixed solution in the distillation device, and then carrying out a hydrolysis treatment to recycle the organic solvent. The recovery processing method avoids the scaling and obstruction tendencies in the conventional distillation process, and is capable of increasing recovery rate of titanium tetrachloride in the titanium-containing waste liquid. The recovery rate of titanium tetrachloride rises by 97% or more by adopting the recovery processing method. Furthermore, after the distillation treatment the distilled residual liquid contains little titanium tetrachloride, thus the waste liquid is easy to process, and the processing cost is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing titanium tetrachloride in large-sized high temperature boiling chlorination furnace

InactiveCN103395830AIncrease profitIncreased Chlorine CapacityTitanium halidesDifferential pressureAtmospheric pressure

The invention provides a method for producing titanium tetrachloride in a large-sized high temperature boiling chlorination furnace. The diameter of the chlorination furnace is more than 4,000 millimeters. The method comprises the following steps of: mixing 75-80 parts by weight of high titanium slag and 20-25 parts by weight of carbon reducer uniformly to form a mixture, and spraying the mixture into the chlorination furnace from a feeding hole to produce chlorination reaction with chlorine introduced from an air inlet; in the chlorination reaction process, controlling the pressure difference between the gas pressure in the dilute phase zone of the chlorination furnace and the atmospheric pressure at 0.08-0.10MPa, controlling the material height of the solid material in the furnace at 2.8-3.2 meters, controlling the material temperature at 900-1,050 DEG C, and discharging slag and spraying a fresh mixture to ensure that the weight sum of the high titanium slag and the carbon reducer accounts for more than 50 percent of the weight of the solid material in the furnace. By adopting the method, the chlorination technical level (comprising improvement on the chlorination rate of titanium, the utilization rate of chlorine, the productivity of the chlorination furnace and the like) of the large-sized chlorination furnace can be improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

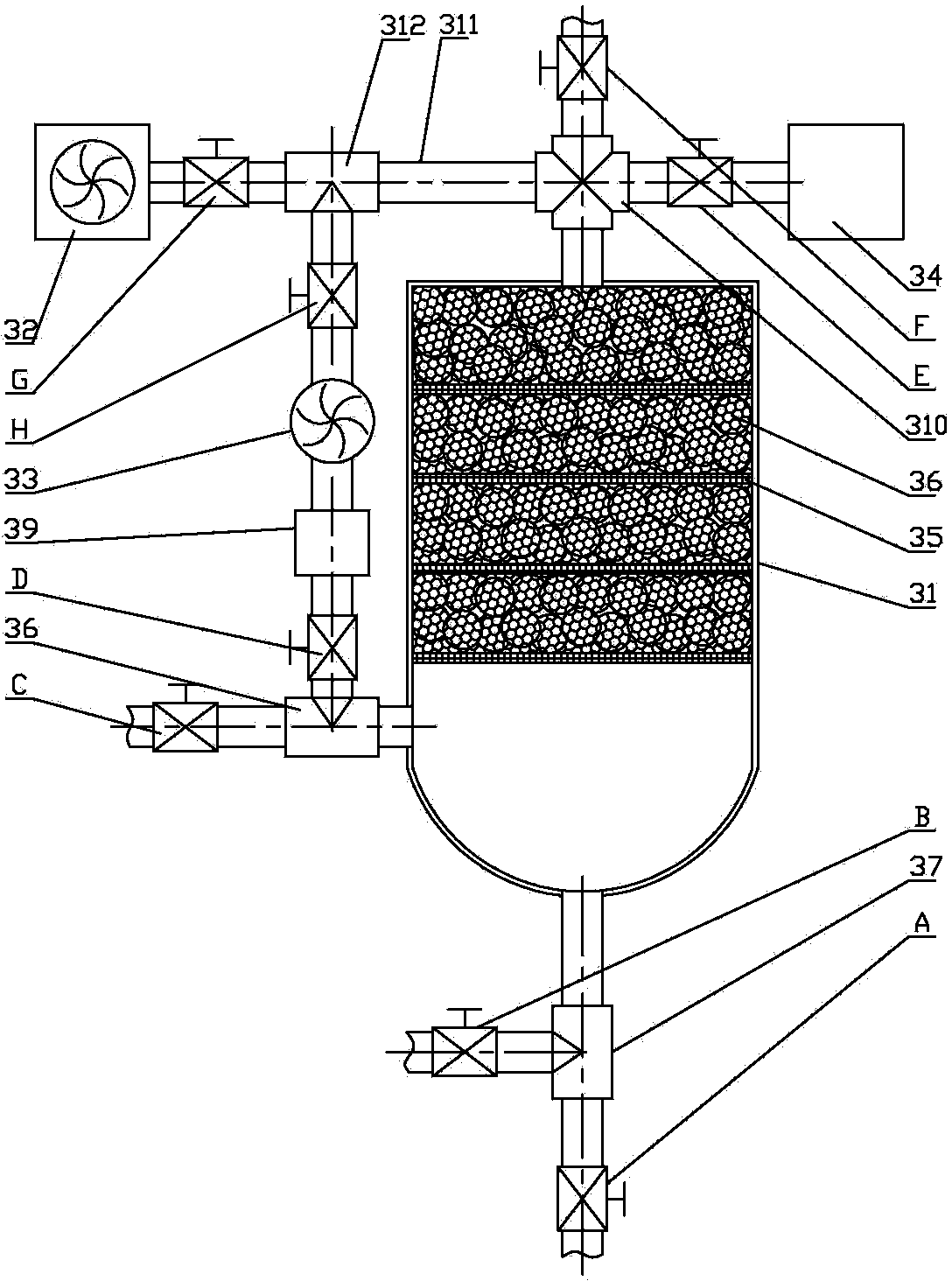

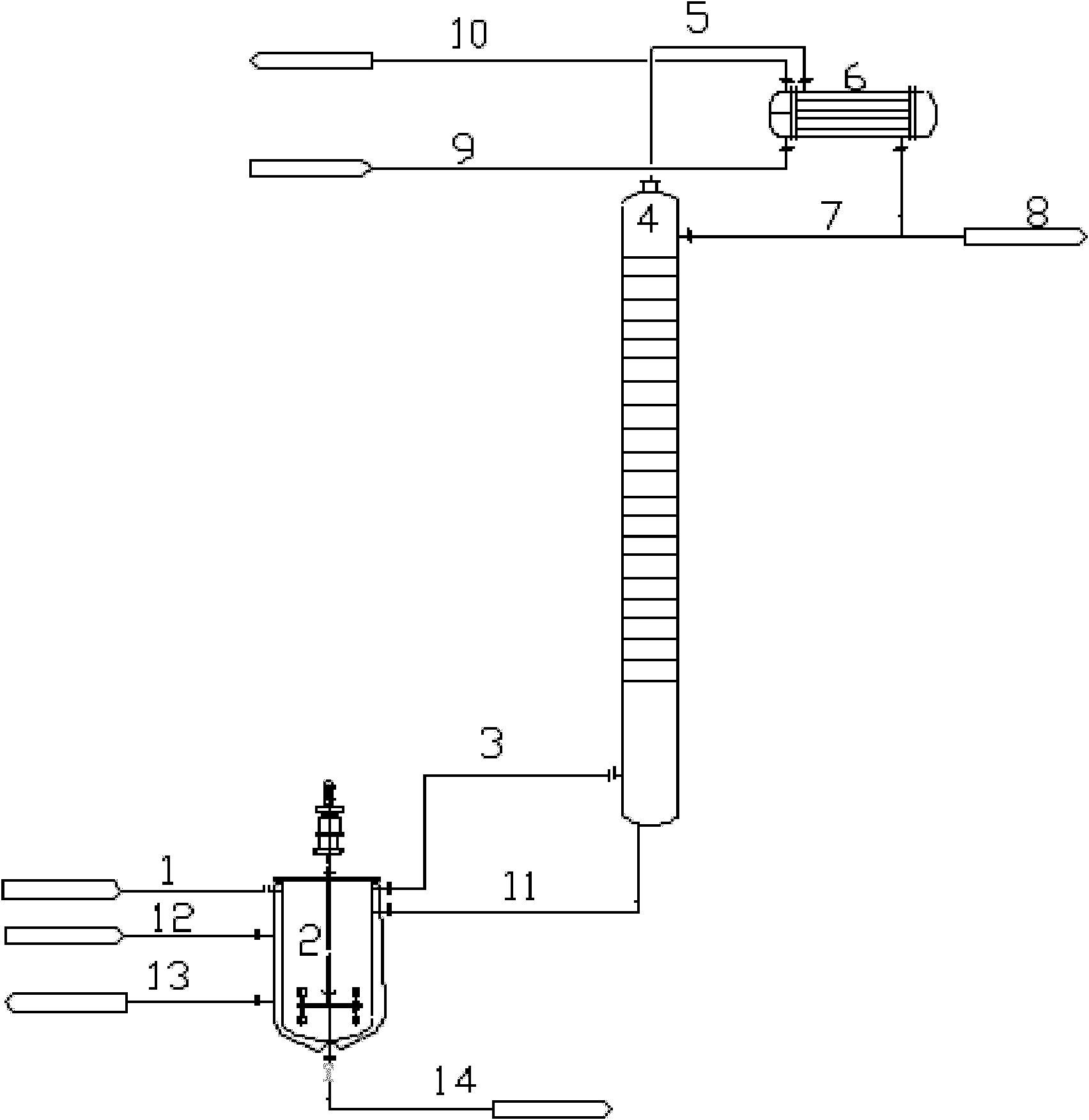

Operation method and device for continuous refining of titanium tetrachloride crude

The invention relates to an operation method for continuous refining of a titanium tetrachloride crude and an operation device for continuous refining of the titanium tetrachloride crude. A multi-stage distillation process of an evaporator with stirring is adopted in the method. Materials are fed to the evaporator with stirring and heated for evaporation. The rotation speed of a stirring motor is 1-200 rpm. The temperature in the evaporator is controlled between 145 DEG C and 160 DEG C by heating. The titanium tetrachloride crude is evaporated in the evaporator. The produced vapor phase is condensed to be a liquid phase by a cooling medium. The condensed liquid phase has a temperature of between 40 DEG C and 145 DEG C. A part of the liquid phase is extracted as a refined titanium tetrachloride product and departed from a system. A part of the liquid phase flows back to the system, and is contacted with the vapor phase generated by the evaporator on a mass and heat transfer element in a multi-stage manner. The titanium tetrachloride is refined through a mass and heat transfer process. The content of the titanium tetrachloride is greater than 99.9%; the content of AlCl3 is not greater than 0.003%; the content of SiCl4 is not greater than 0.01%; the content of VoCl3 is not greater than 0.0025%; the content of FeCl3 is not greater than 0.002%; and the colorimetric degree of K2Cr3O7 is smaller than 5 mg / l. The method is a continuous process, solves problems of low production capability of a single batch or semi-batch refining device and non-acceptable product.

Owner:TIANJIN UNIV

Thermochemical hydrogen produced from a vanadium decomposition cycle

InactiveUS7799315B2Improve reliabilityHigh thermal efficiencyHydrogen separation using liquid contactEnergy inputHydrogenDecomposition

A thermochemical water-splitting process all reactions of which operate at relatively low temperatures and high efficiencies, and in which relatively inexpensive materials and processing methods are made possible. This invention involves the decomposition of a metal halide compound, i.e., one which is capable of being reduced from a higher oxidation state to lower oxidation state, e.g. vanadium chloride III→vanadium dichloride. The process is cyclic and regenerative, and the only net inputs are water and heat; and the only net outputs are hydrogen and oxygen. The process makes it possible to utilize a wide variety of available heat, including solar, sources for the energy input.

Owner:AMENDOLA STEVEN

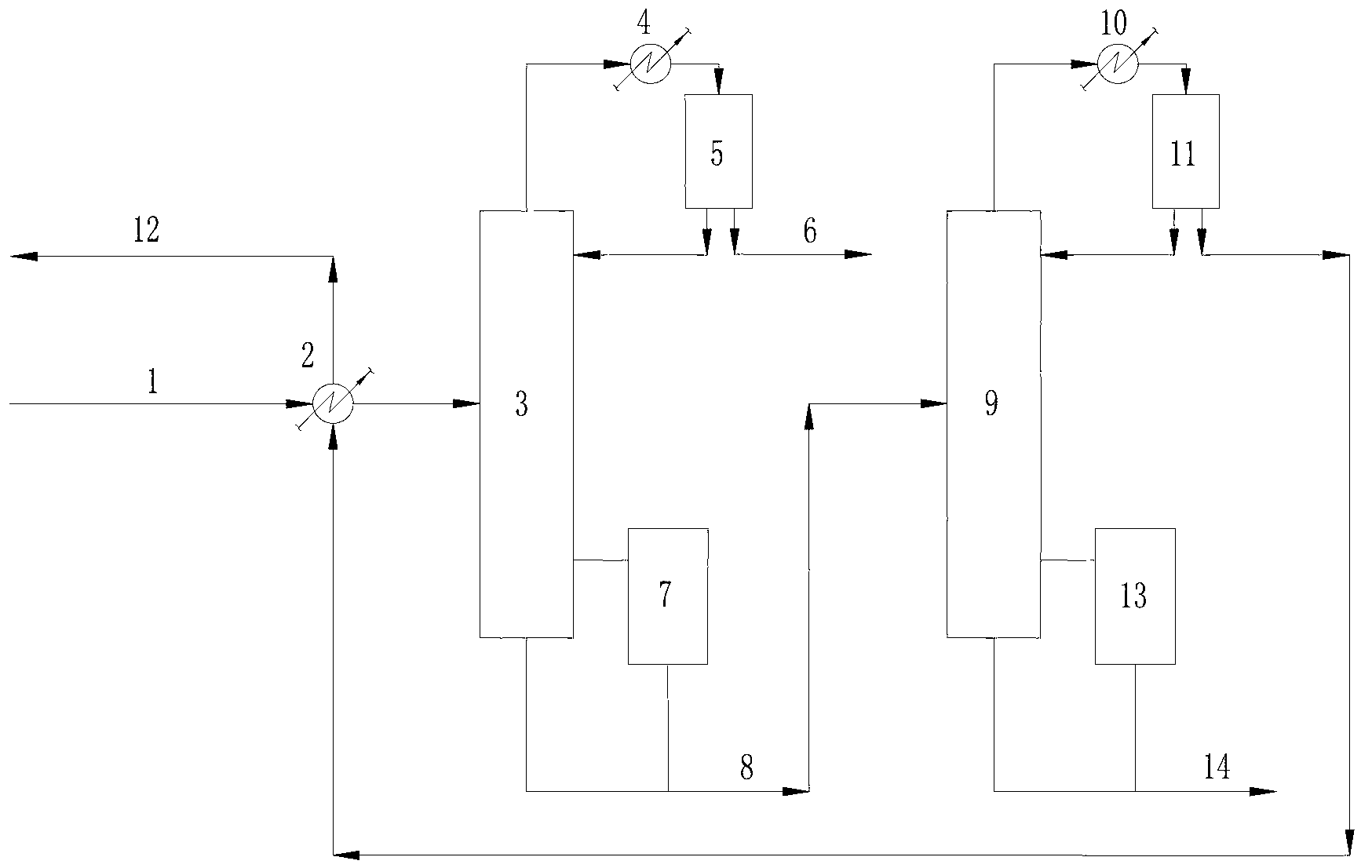

Titanium tetrachloride purification system and method

InactiveCN103011268APlay the role of heat exchangeReduce energy consumptionTitanium halidesTetrachloridePurification methods

The invention relates to a titanium tetrachloride purification system and a titanium tetrachloride purification method, wherein raw titanium tetrachloride material liquid treated by a vanadium removal process is subjected to heat exchange by a preheater and then flows into the middle of a de-light rectifying tower to remove impure light components such as SiCl4 and lose a little amount of titanium tetrachloride; the material flow at the tower bottom contains rather pure titanium tetrachloride and flows into the middle of a de-heavy rectifying tower to remove heavy components such as AlCl3 and FeCl3 and lose a little amount of the titanium tetrachloride; and highly pure titanium tetrachloride is obtained at the top of the tower. The operation pressure at the top of the de-light rectifying tower is the normal pressure, the reflux ratio is 60.0-80.0, and the theoretical stage number is 16-22 in total; and the operation pressure at the top of the de-heavy rectifying tower is the normal pressure, the reflux ratio is 1.0-1.2, and the theoretical stage number is 16-22 in total. The purity of the highly pure titanium tetrachloride is at least 99.99%, and the product recycling rate in the process is higher than 97.0%.

Owner:TIANJIN UNIV

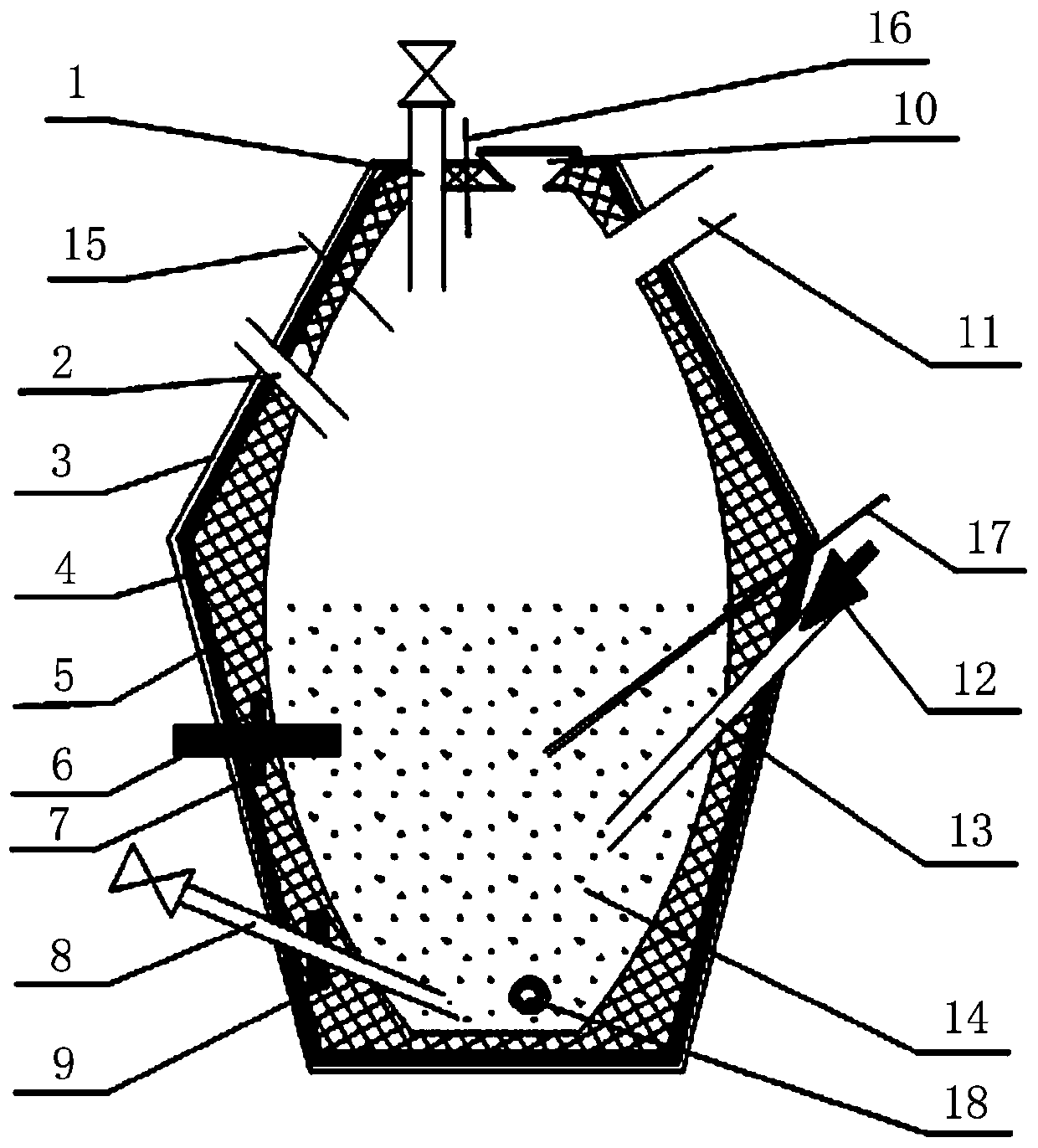

Fused salt chlorination furnace for producing titanium tetrachloride

The invention discloses a fused salt chlorination furnace for producing titanium tetrachloride. A return slurry ore pipe, a feed pipe, an explosion-proof port and a product mixed steam discharge port are formed in the top of the fused salt chlorination furnace; a side salt discharge pipe, a plurality of chlorine pipes and a plurality of heating electrodes are arranged at a side part of the fused salt chlorination furnace; a bottom salt discharge pipe is arranged at the bottom of the fused salt chlorination furnace; the furnace wall of the fused salt chlorination furnace comprises three layers, wherein the outer layer is a metal furnace shell, the middle layer is a buffer packed layer and the inner layer is a fire brick layer; a circle of nozzle plugs are arranged on the outer walls of the chlorine pipes; a circle of electrode lug blocks are arranged on the outer surfaces of the heating electrodes. The fused salt chlorination furnace disclosed by the invention is simple in structure, can prevent gas leakage, and can regularly discharge waste salts and improve the chlorination environment to facilitate production of TiCl4.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Device of boiling chlorination furnace for continuous slagging and slagging method

ActiveCN102774880AContinuous slaggingControlled slaggingTitanium halidesVertical tubeAutomatic control

The invention relates to a device of a boiling chlorination furnace for continuous slagging and a slagging method. The device is formed by a slagging pipe, a slagging valve, a water cooling spiral deslagging machine and a slagging tank that are sequentially connected through pipelines, the slagging valve comprises a vertical tube and a material discharge chamber that are in parallel, the material discharge chamber is communicated with the vertical tube through a hole at the bottom of the material discharge chamber, a material discharge opening is arranged at the upper part of the material discharge chamber, and the vertical tube and the bottom of the material discharge chamber are respectively provided with an air inlet. Slag forms stock columns in the vertical tube so that the device automatically seals, therefore, gas in the boiling chlorination furnace is prevented from leaking, slagging discharge rate is controlled through nitrogen flow regulation, and regulation and control of chlorination slagging rate are realized. According to the device, the boiling chlorination furnace realizes continuous slagging through a sealing and controllable manner without using a mechanical valve, therefore, the chlorination furnace is effectively prevented from leaking gas in the slagging process. The device has the advantages of being good in sealing performance, simple in operation, safe and reliable, easy to realize automatic control and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com