Recovery processing method of titanium-containing waste liquid

A technology for recycling and processing titanium waste liquid, which is applied in water/sewage treatment, chemical instruments and methods, heating water/sewage treatment, etc. It can solve the problems of waste of resources, increase the cost of waste liquid treatment, overflow of hydrogen chloride gas, etc. Ease of handling, avoidance of fouling and blocking tendency, improved recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

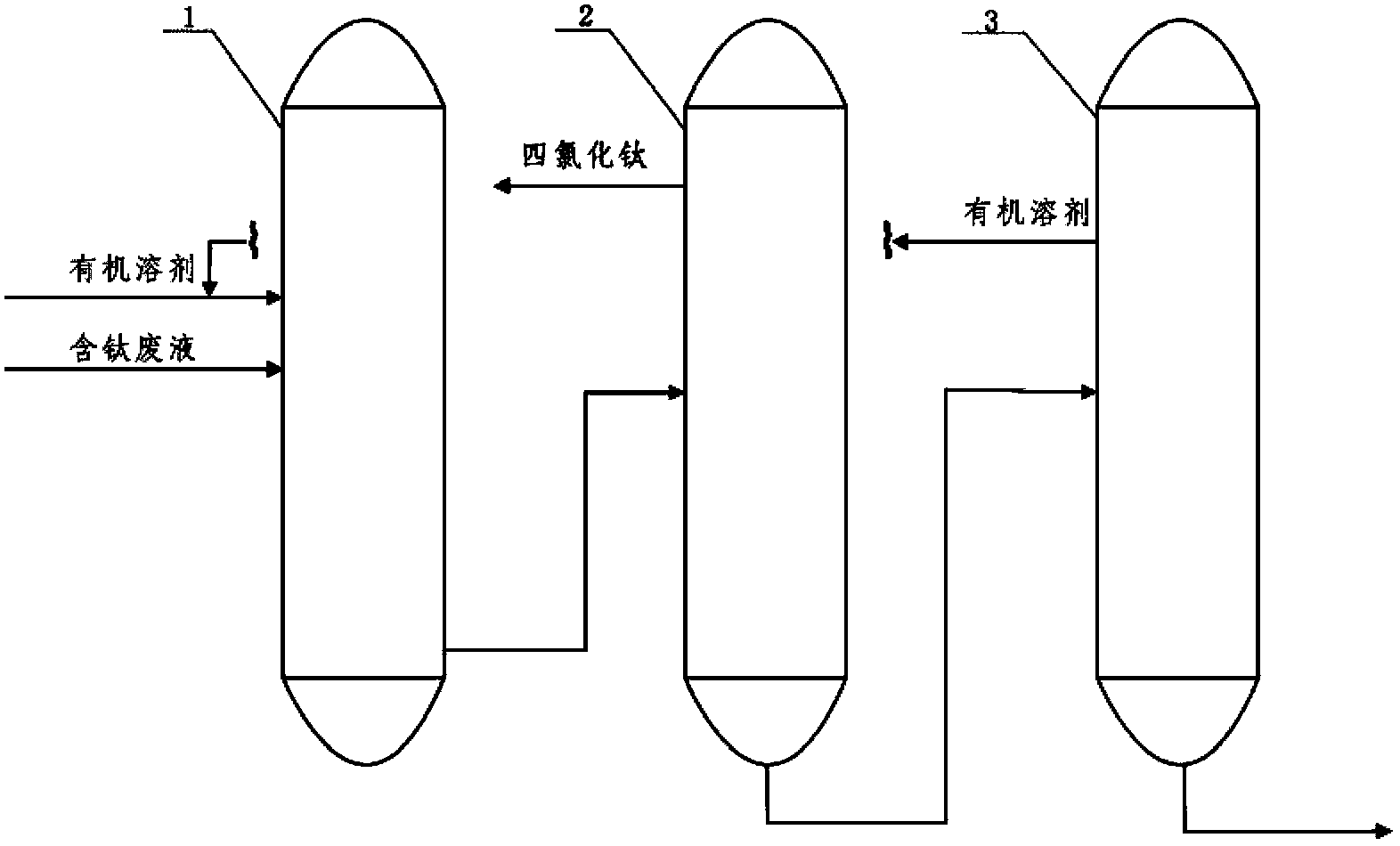

[0026] Add 1000ml of titanium-containing waste liquid produced by the polyolefin catalyst and 1000ml of phenol into the premix tank 1, then fully stir and mix evenly. The obtained mixed liquid is transferred to the still 2 through pipelines for distillation. The temperature of the tower bottom is controlled at 145-150°C, and the distillation time is 60 minutes. The titanium tetrachloride fraction at the top of the tower is collected and reused in the production process. Then the residual liquid in the still 2 is transferred to the recovery unit 3 through the pipeline, and 15% sodium hydroxide solution is added for hydrolysis treatment. Until the pH value of the mixed system is stabilized at 6.5, the layer is separated into a phenol layer and a hydrolyzate layer after standing, and the phenol and hydrolyzate are recovered. Phenol can be used back in distillation still 2. The rate of recovery of titanium tetrachloride is 98.5% in this embodiment.

Embodiment 2

[0028] Add 500 ml of titanium-containing waste liquid from polyolefin catalyst production and 1,000 ml of phenol into premix tank 1, then fully stir and mix evenly. The obtained mixed liquid is transferred to the still 2 through pipelines for distillation. The temperature of the tower kettle is controlled at 137-145°C, and the distillation time is 90 minutes. The titanium tetrachloride fraction at the top of the tower is collected and reused in the production process. Then transfer the residual liquid of the still 2 to the recovery unit 3 through the pipeline, add 5% sodium hydroxide solution for hydrolysis, until the pH value of the mixed system is stable at 6.0, let stand and separate, phenol and hydrolysis After liquid separation, phenol can be recovered for distillation still 2. The rate of recovery of titanium tetrachloride is 97.2% in this embodiment.

Embodiment 3

[0030] Add 1000 ml of titanium-containing waste liquid from polyolefin catalyst production and 500 ml of phenol into the premix tank 1, then fully stir and mix evenly. The obtained mixed liquid is transferred to the still 2 through pipelines for distillation. The temperature of the tower bottom is controlled at 155-160°C, and the distillation time is 30 minutes. The titanium tetrachloride fraction at the top of the tower is collected and reused in the production process. Then the tower still raffinate of still 2 is transferred in the recovery unit 3 through pipeline, adds 30% sodium hydroxide solution and carries out hydrolysis treatment. Until the pH value of the mixed system is stable at 7.0, the mixture is allowed to stand for stratification. After the phenol and hydrolyzate are separated, the phenol can be recovered and used in the still 2. The rate of recovery of titanium tetrachloride is 97.6% in this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com