Deep blockage removal and injection increase method for water injection well of medium-and-high-permeability sandstone reservoir

A technology for sandstone oil reservoirs and water injection wells, which is applied in the field of acidification and plugging removal, can solve the problems of no deep plugging, damage to water injection wells, and increase injection due to under attack, so as to achieve the effects of removing plugging damage, improving seepage capacity, and increasing injection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The long-term injection water quality of the Yong 3-141 well of Dongxin Oil Production Plant in Shengli Oilfield is poor, and the suspended matter content is 10-20 mg / L, which causes blockage near the wellbore and deep parts, resulting in under-injection, and the content of sensitive minerals in the reservoir is relatively low. high.

[0055] 1. Scheme design:

[0056] (1) During the acidizing injection enhancement, soaking and cleaning the scale near the blast hole is helpful to reduce the construction pressure. Secondly, the organic pollution of the reservoir injection water is removed to facilitate the removal of the scale and gray matter near the wellbore. The main acid solution is fluoboric acid and low-damage polyhydrogen retarded acid, and a stabilizer is added to ensure that various organic and inorganic scaling and salt deposition are reduced during the water injection process, so as to extend the validity period of the boost injection.

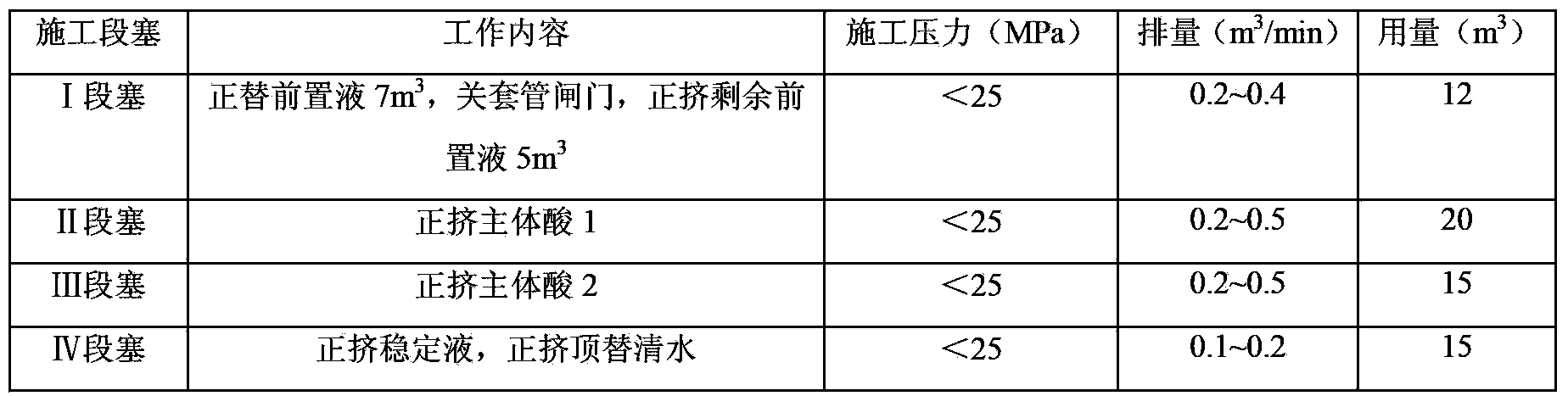

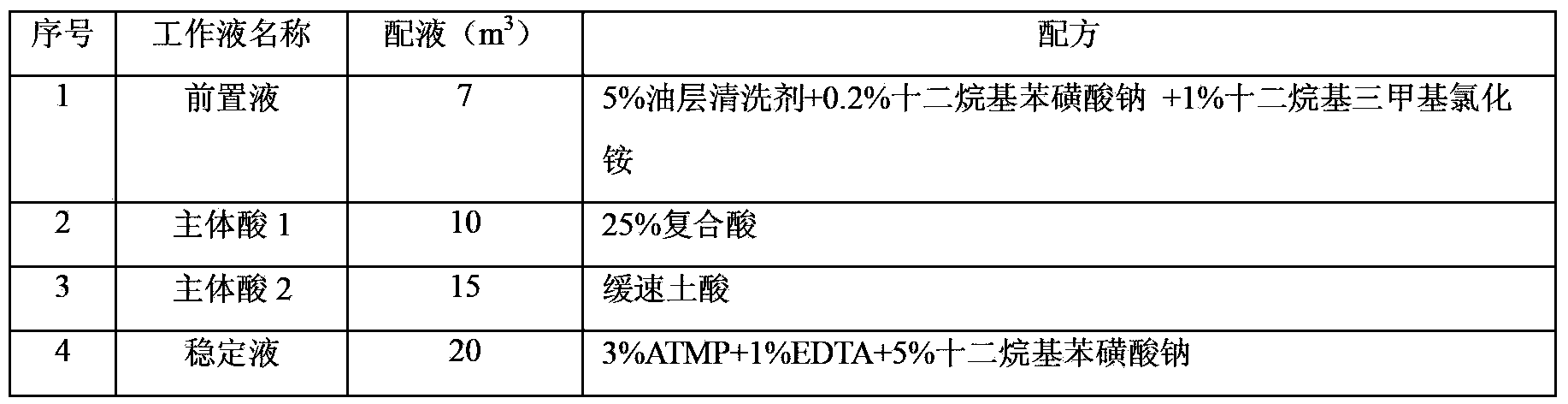

[0057] (2) The acidiz...

Embodiment 2

[0071] Well GDN15-502 of Gudao Oil Production Plant in Shengli Oilfield is a general polymer injection well. According to the previous polymer absorption profile data, the upper layer Ng53 and 54 do not absorb water and cannot be injected at 12MPa, so the upper layer needs to be acidified to remove plugging.

[0072] 1. Scheme design:

[0073] (1) In view of the fact that the injection time of the well is long, the formation has serious retention and clogging, and it is accompanied by the characteristics of clogging near the wellbore, firstly, pretreatment to remove oil pollution is carried out near the blast hole, using organic cleaning agent and active It is a compound product of agent, which is beneficial to remove organic blockage and improve the effect of cleaning oily dirt. In view of the fact that chlorine dioxide has a strong ability to oxidatively degrade polymers, oxidize and kill bacteria, remove bacteria, and dissolve sulfide deposits, the main acid uses chlorine d...

Embodiment 3

[0089] Dongxin Oil Production Plant Ying 12-136 Well of Shengli Oilfield, due to long-term reinjection of unqualified sewage and thick oil in the reservoir, caused serious blockage in the deep part.

[0090] 1. Scheme design:

[0091] (1) Implement multi-slug treatment process by optimizing the plugging solution formula: use organic plugging agent to remove organic pollutants in the early stage; the main acid first uses compound acid water injection well injection booster, this product has a strong ability to dissolve scale, The oil washing rate is as high as 95%; after that, tartaric acid is injected for matrix treatment. The purpose of stabilizing liquid is to stabilize calcium (magnesium), iron ions and other ions that are easy to scale, reduce water injection friction and surface tension, and prolong the validity period of water injection.

[0092] (2) The acidizing construction process is mainly divided into six slugs.

[0093] 2. Formula and quantity of working fluid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com