Patents

Literature

146results about How to "Improve seepage capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fracturing method for supplementing stratum energy of dense oil reservoir

InactiveCN105134158AReduced crack damageOptimize construction parametersFluid removalSpecial data processing applicationsChemical InterferenceEnvironmental geology

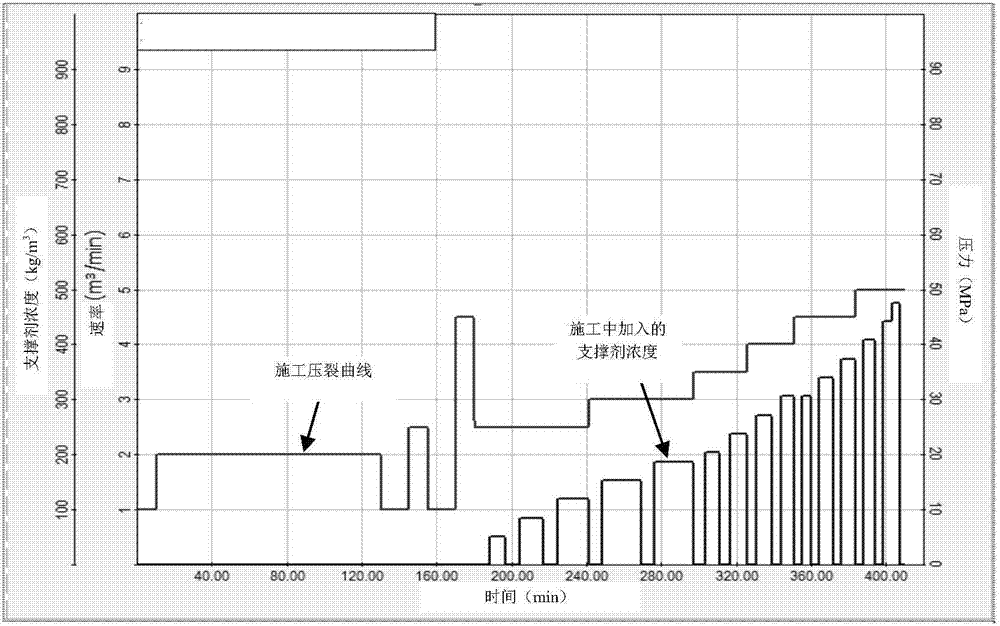

The invention provides a fracturing method for supplementing stratum energy of dense oil reservoir. The method includes the steps that in combination with characteristics of the dense oil reservoir, characteristics of non-darcy seepage are considered, and CMG oil reservoir value simulation software is utilized to simulate and calculate a discharge area controlled by a single fracture under the modes of subdivision cutting and a complex fracture net with the starting pressure gradient considered; in combination with a fracture spacing chemical interference theory, the horizontal well improvement segment spacing improved by dense oil reservoir size fracturing, cluster spacing and perforating parameters are optimized; the dense oil reservoir transformation parameter is determined through a non-darcy seepage equation and the CMG oil reservoir value simulation software; the ram material composition of fracturing liquid is determined according to the wettability and sensitivity of the reservoir; the fracturing liquid and a propping agent are poured, the flow velocity of the eyelet of a single liquid suction and injection hole of the fracturing liquid is 0.25 m<3> / min-0.4 m<3> / min, and the pouring intensity is 10 m<3> / min-15 m<3> / min; the well closing time is determined through the CMG oil reservoir value simulation software, a well is closed according to the determined well closing time, and the fracturing method integrates pressing, pouring, driving and exploiting.

Owner:PETROCHINA CO LTD

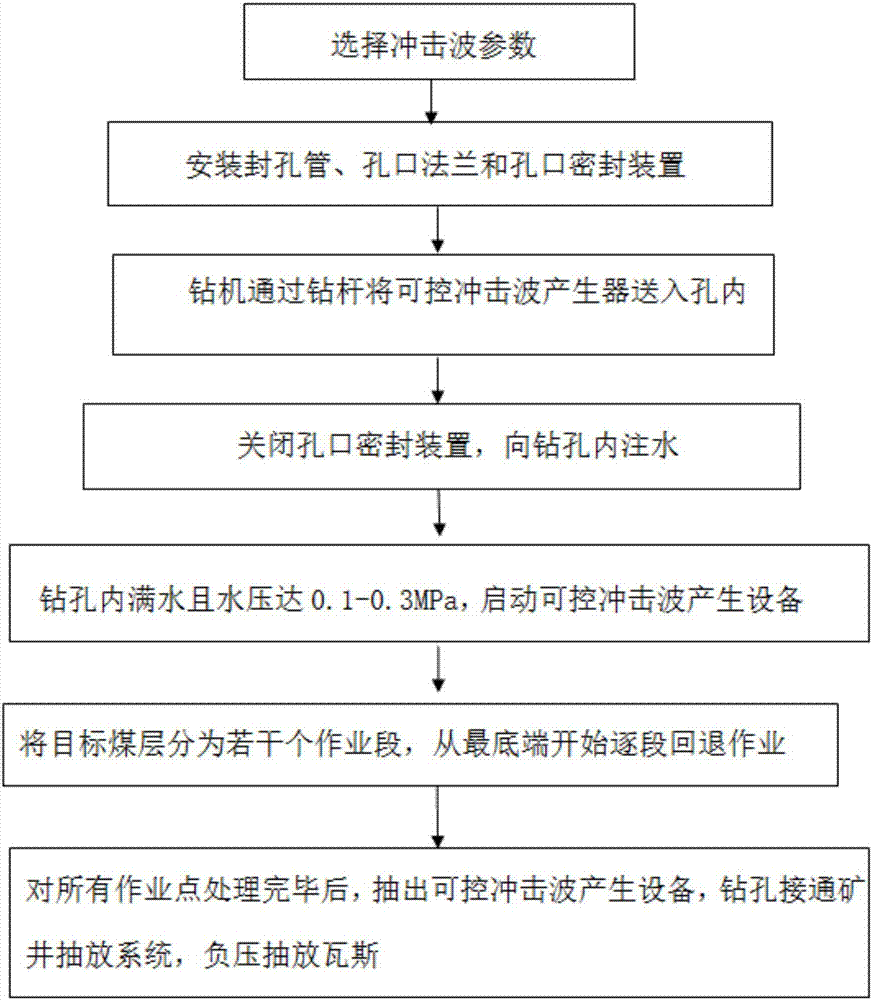

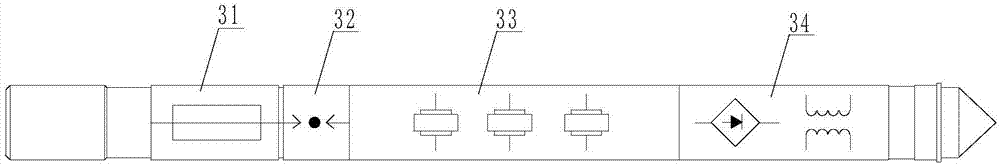

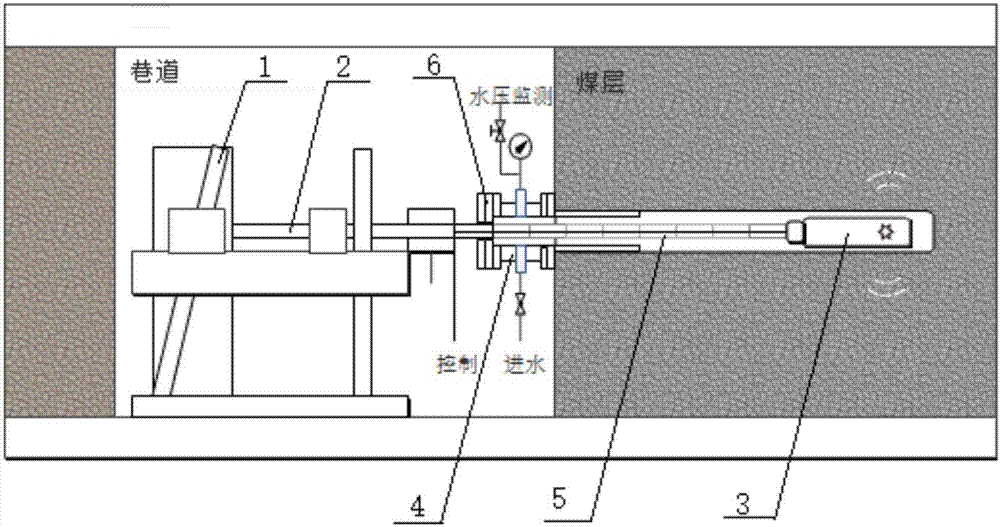

Coal mine down-hole drilling penetration improvement method based on controllable shock wave technology

InactiveCN107956505APrevent collapseAvoid the problem of rock burstFluid removalGas removalShock waveEngineering

The invention belongs to the field of energy and coal mine safety, and particularly relates to a coal mine down-hole drilling penetration improvement method based on a controllable shock wave technology. The method aims at solving the problems of high labor intensity and low safety of an existing gas treatment mode. Controllable shock wave generation equipment is pushed to the interior of a drilling hole, and after a hole opening sealing device is installed at a hole opening of the drilling hole, water is injected to the drilling hole; after the drilling hole is fully filled with the water, operation is conducted segment by segment, the middle of each operation segment is used as an operation point of shock waves, and repeated impact is conducted on each operation point multiple times. Under the effect of the injected water in the hole, the shock wave generation equipment does not need to work under the environment with explosive gas, and the shock waves are also efficiently coupled toa coal bed.

Owner:XI AN JIAOTONG UNIV

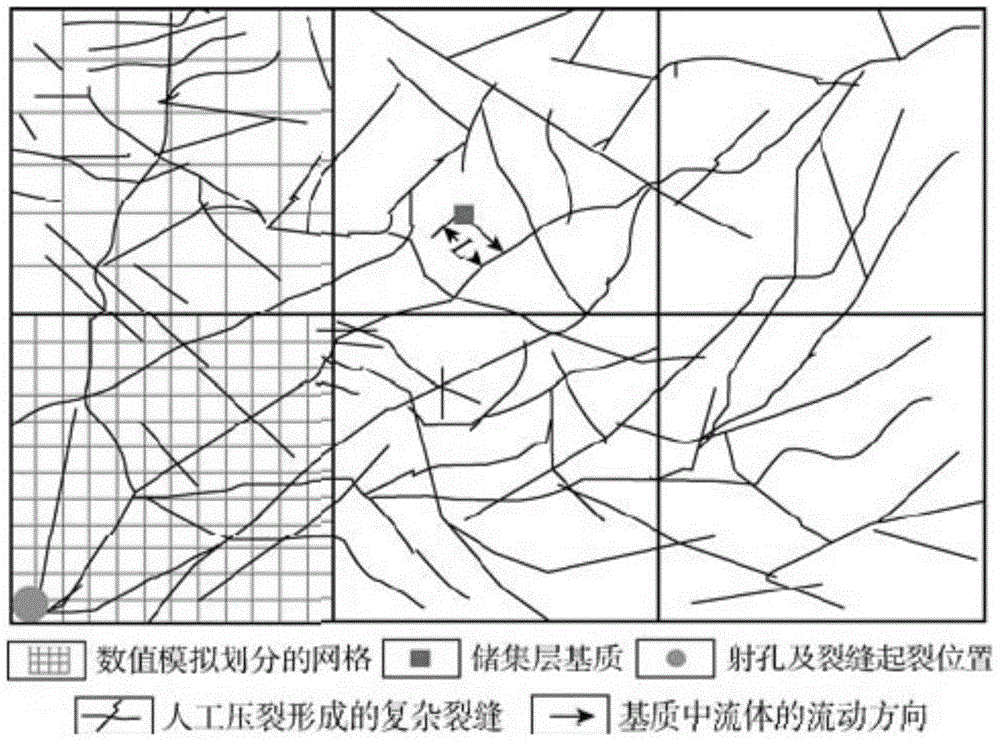

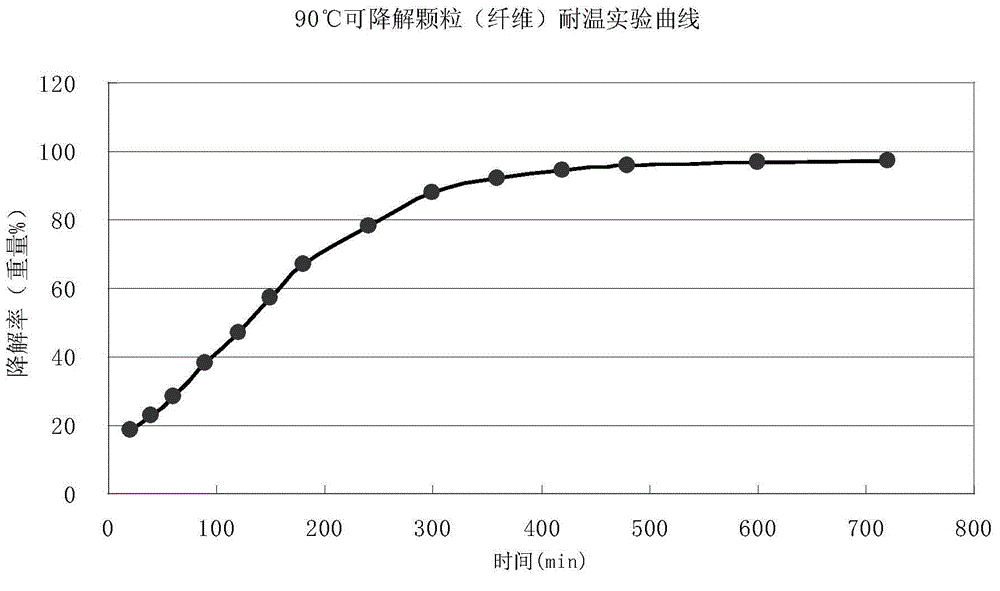

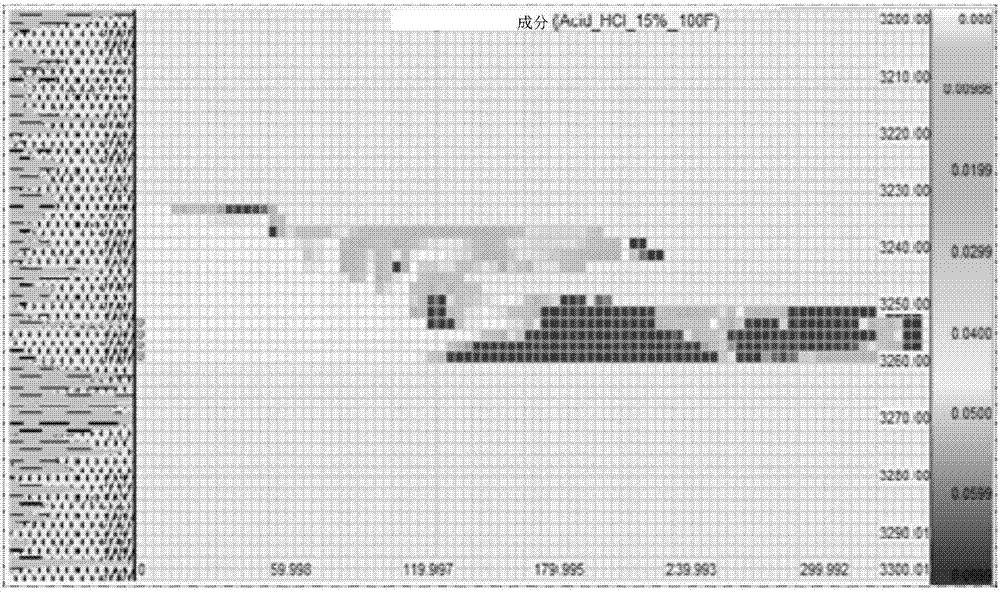

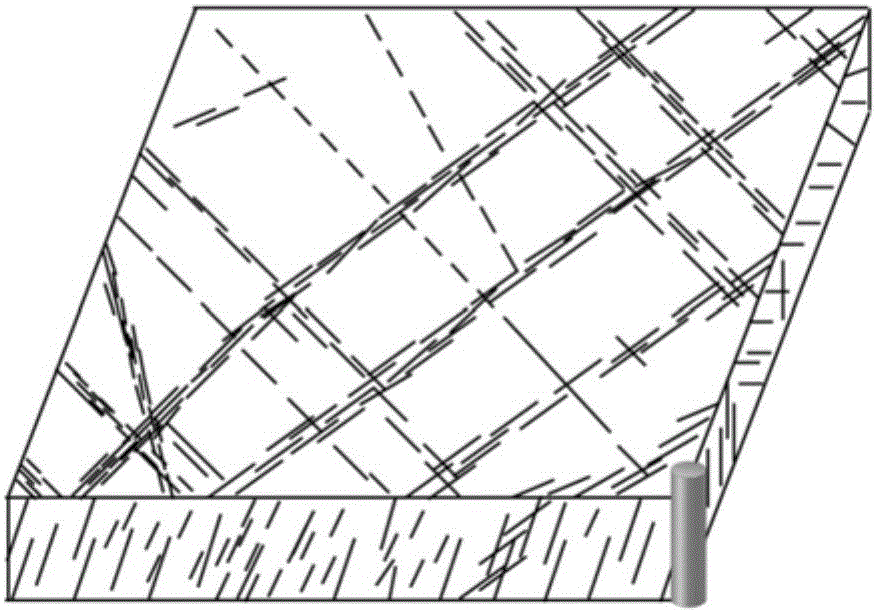

Reservoir modifying method through forming crack network by temporary plugging turning in cracks

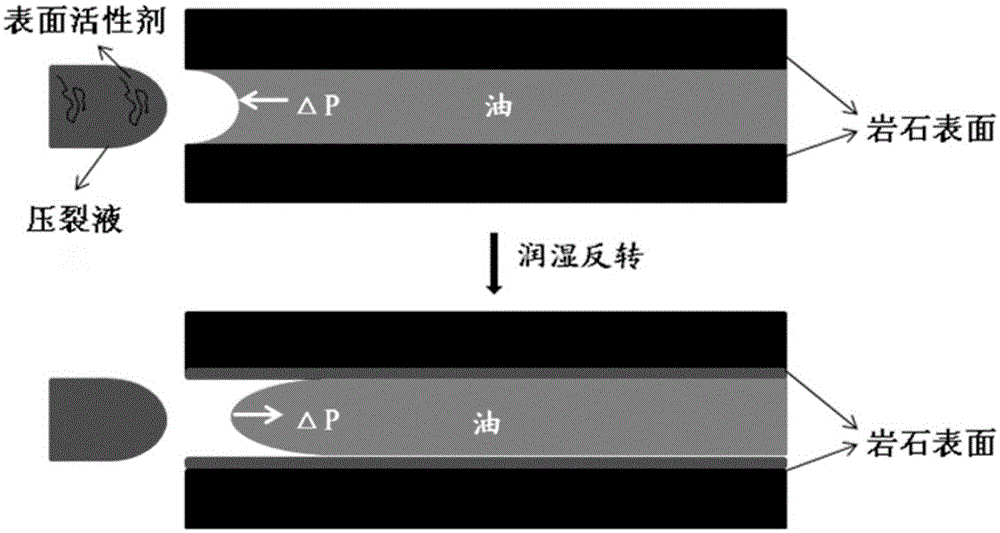

ActiveCN105089603AReduce seepage distanceImprove seepage capacityFluid removalDrilling compositionTight oilEngineering

The invention provides a reservoir modifying method through forming a crack network by temporary plugging turning in cracks. The method comprises the following steps: injecting a temporary plugging turning material liquid into a reservoir man-made crack and forming a bridge plug in the deep part of the crack, forcing the crack to turn and form a plurality of cracks, using an active fluid or an acid fluid to activate reservoir micro-cracks, and forming the crack network. The method can form the man-made crack network in unconventional oil-gas reservoirs such as low-permeability, ultra low permeability oil-gas reservoirs, tight oil reservoirs and shale oil-gas reservoirs, so as to increase the contact area to the reservoirs and greatly shorten the seepage distance and the seepage resistance of the oil and gas in the reservoirs towards the cracks in the arbitrary directions, and furthermore the single well yield and the final recovery efficiency are increased.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +2

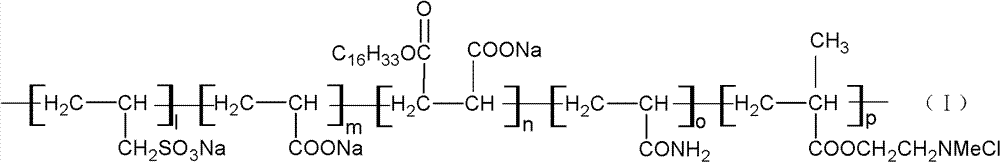

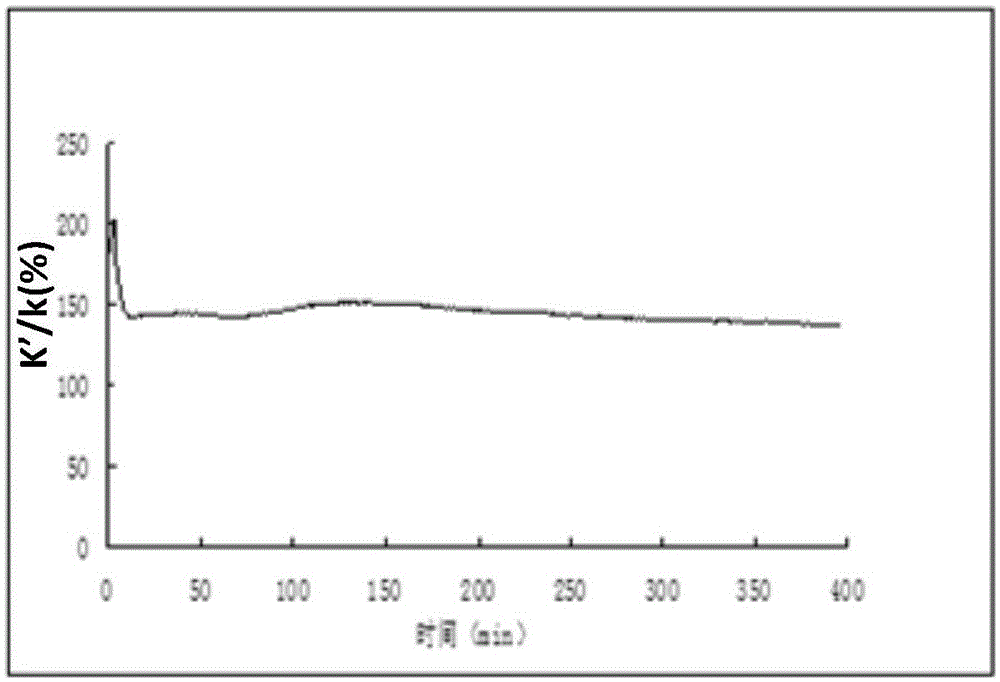

Micro-emulsion viscosity reducer for thick oil, and preparation method thereof

InactiveCN103509541AComposition is stableSimple preparation processDrilling compositionChemistryEmulsion

The invention provides a micro-emulsion viscosity reducer for thick oil, and a preparation method thereof. The viscosity reducer comprises, by weight, 33-37 parts of an oil-soluble viscosity reducer, 16-20 parts of a nonionic surfactant, 18-22 parts of a sulfonate anionic surfactant, 2-4 parts of a Tween emulsifier, 3-5 parts of isomeric alcohol and 20-24 parts of water. The micro-emulsion viscosity reducer is prepared through a reaction of above raw materials in a reaction kettle at a certain temperature under a certain rotating speed. The micro-emulsion viscosity reducer is processed by oilfield hot sewage to prepare an aqueous solution, and the aqueous solution injected to the underground, so the micro-emulsion viscosity reducer has the characteristics of high viscosity reduction, strong economy and the like, allows the viscosity of the thick oil to be decreased by above 98%, can substitute high-pressure steam exploitation, realizes a very high economic input-output ratio, fully solves the problems of high thick oil viscosity, difficult exploitation and the like in oilfield exploitation and extraction processes, and has a large-scale popularization value.

Owner:CHINA PETROLEUM & CHEM CORP +1

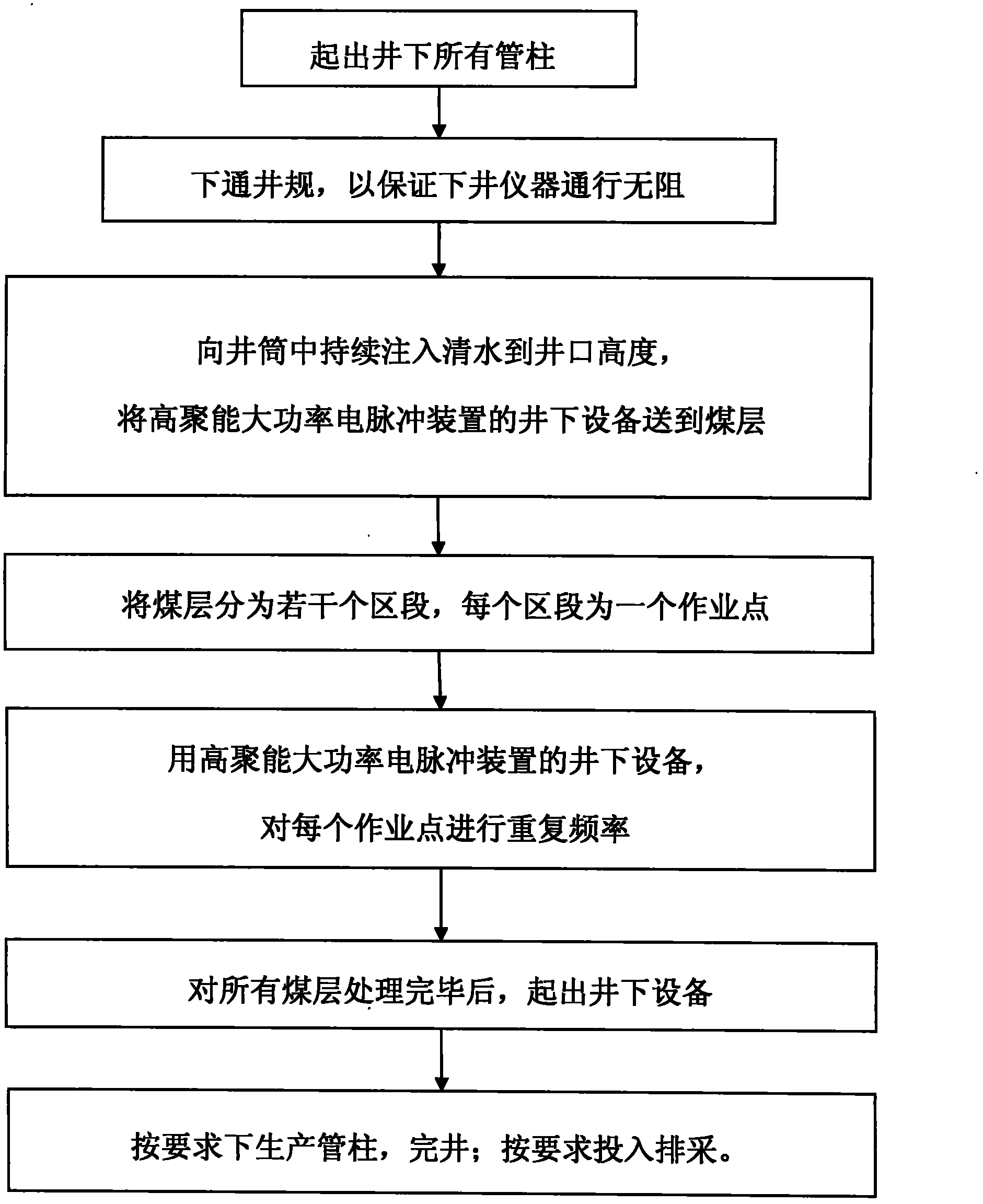

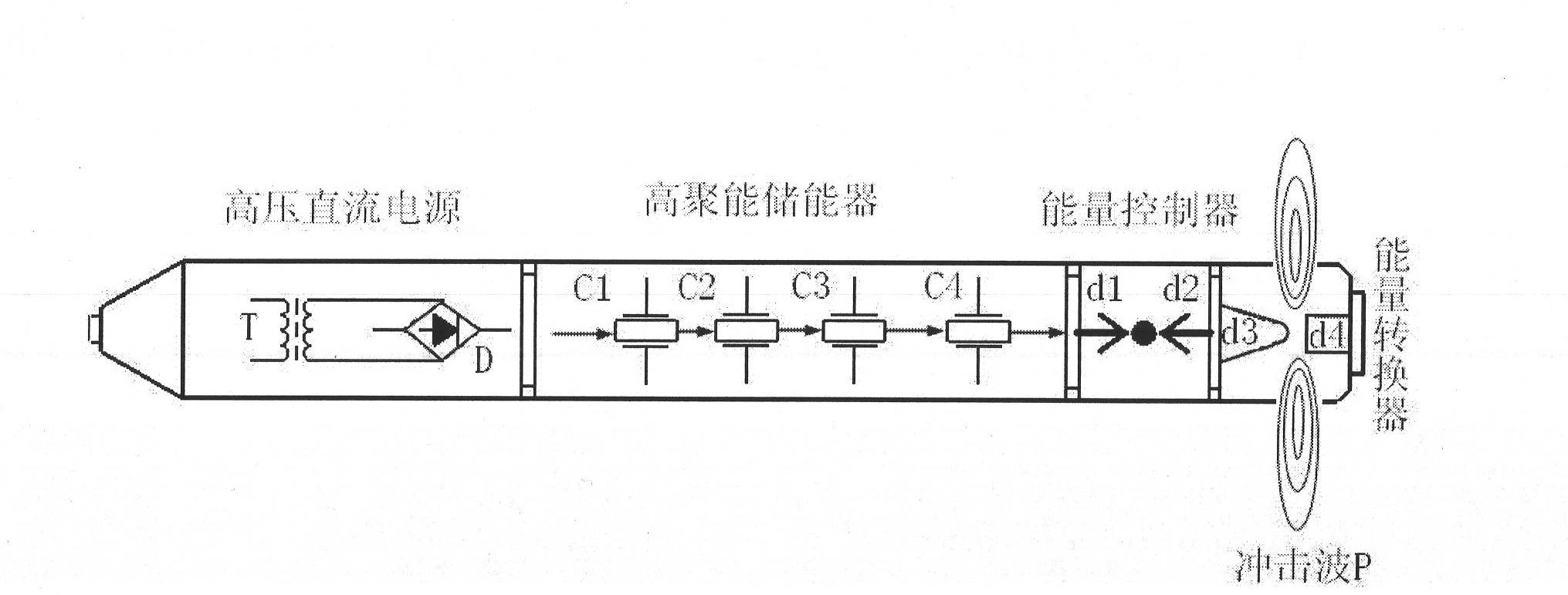

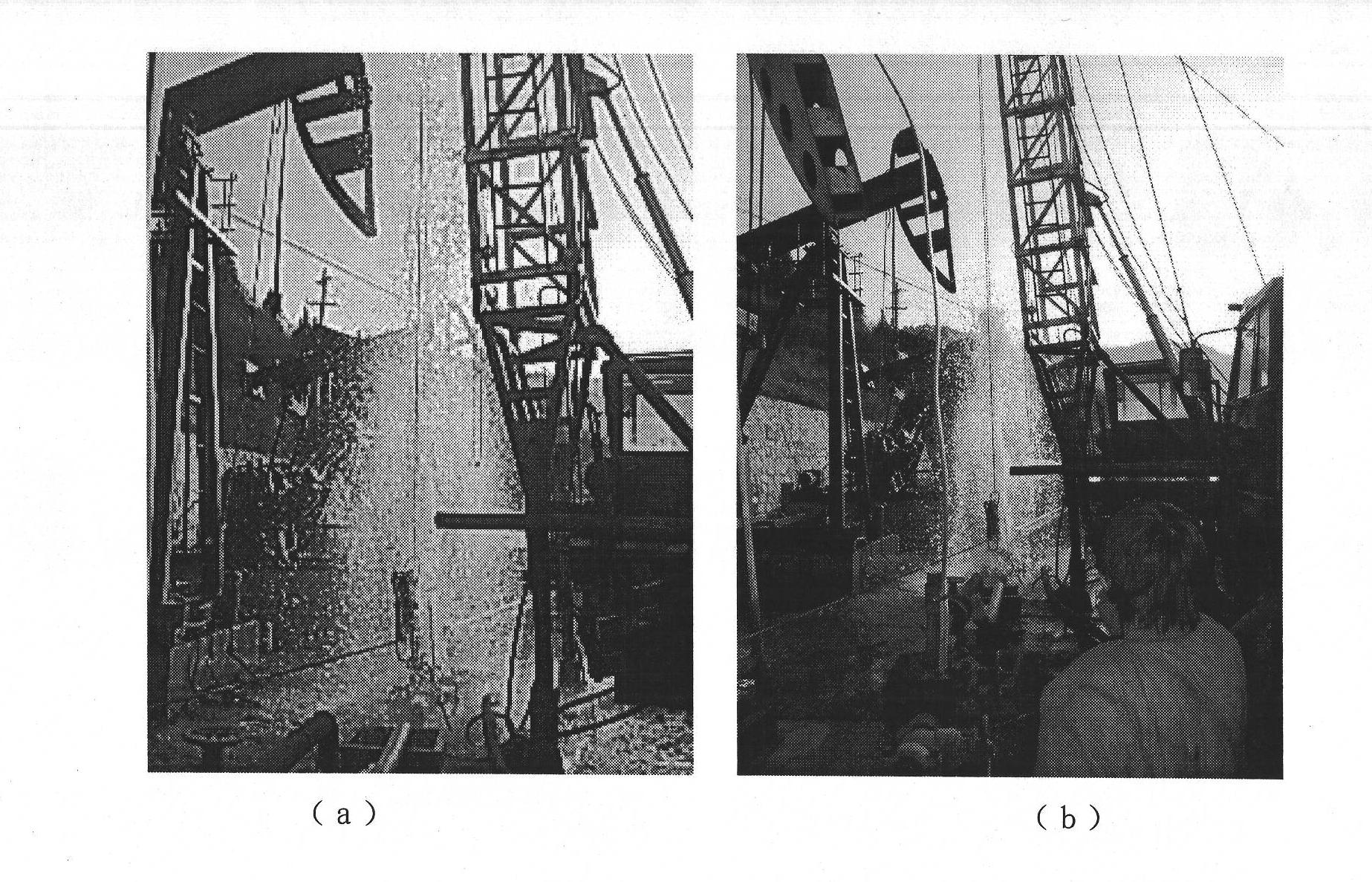

Ground pumping and mining coal seam gas well reformation method based on recurrence frequency impact waves

The invention discloses a ground pumping and mining coal seam gas well reformation method based on recurrence frequency impact waves; the method mainly solves the problem that in the prior art, the coal seam is damaged and compacted and the seepage and deabsorption of the coal seam cannot be improved simultaneously. The method comprises the following operation procedures of: (1) pulling out all tubular columns in a well; (2) putting a drift size gauge tool so as to ensure that downhole instruments go through the well without hindrance; (3) continuously infusing a coal bed gas well with underground water exhausted from the well or an adjacent well till water reaches the mouth of a well, and conveying underground equipment of a high energy-gathering high-power electrical pulse device to thecoal seam; (4) dividing the coal seam into a plurality of sections, wherein each section is an operation point; (5) using the underground equipment of the electrical pulse device for carrying out recurrence frequency impact wave treatment on each operation point; (6) pulling out the underground equipment after all the operation points are treated; (7) putting the production tubular column for well completion according to the requirements, and putting the production tubular column into pumping and mining. The method has the advantages that the method does not damage the coal seam and carries out the single-point recurrence frequency operation on the coal seam, and can be used for increasing the yield and production capacity of the coal bed gas well.

Owner:XIAN GUANTONG ENERGY TECH

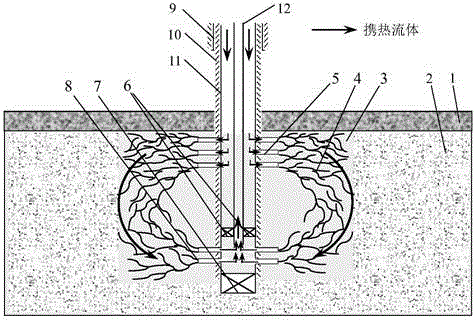

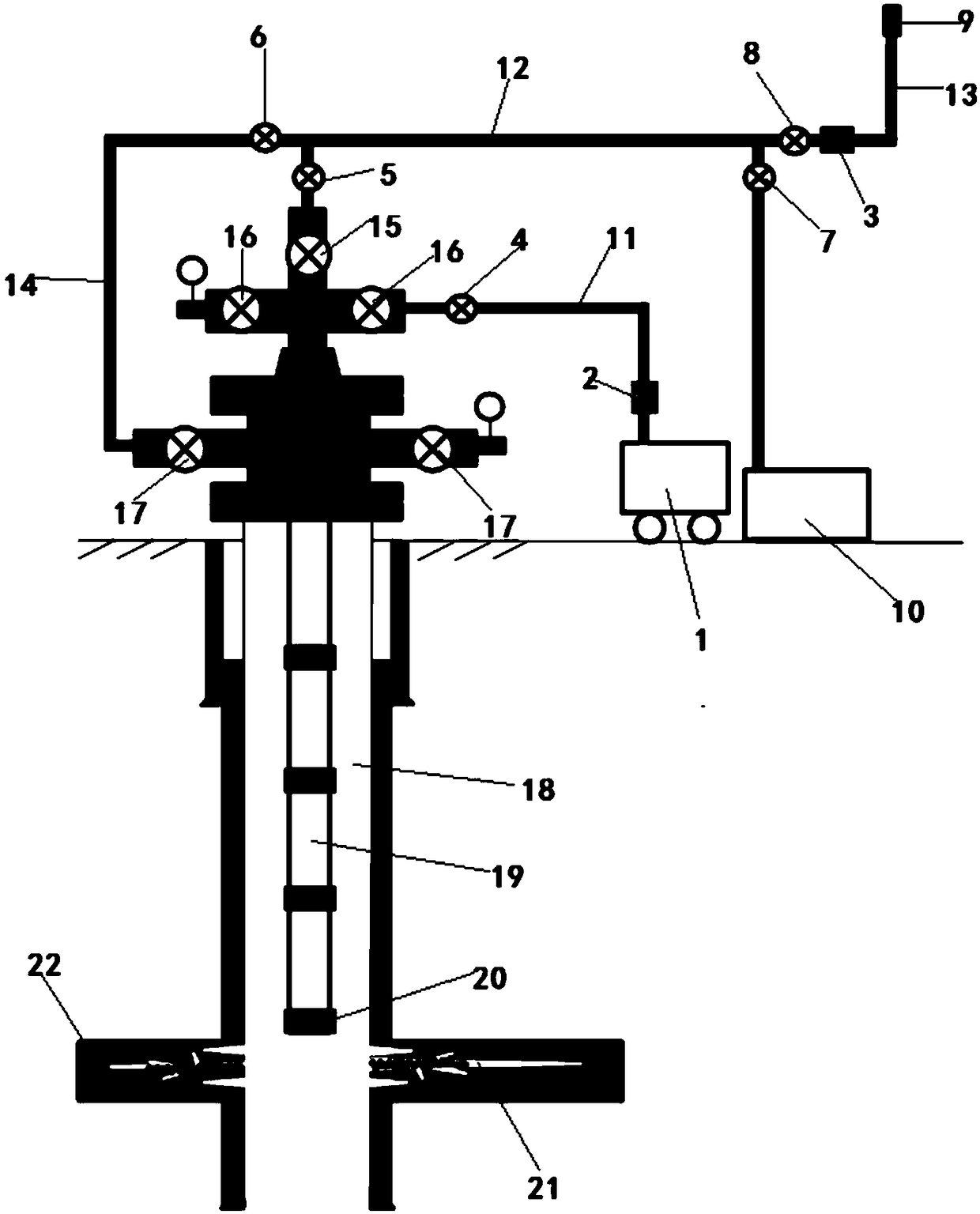

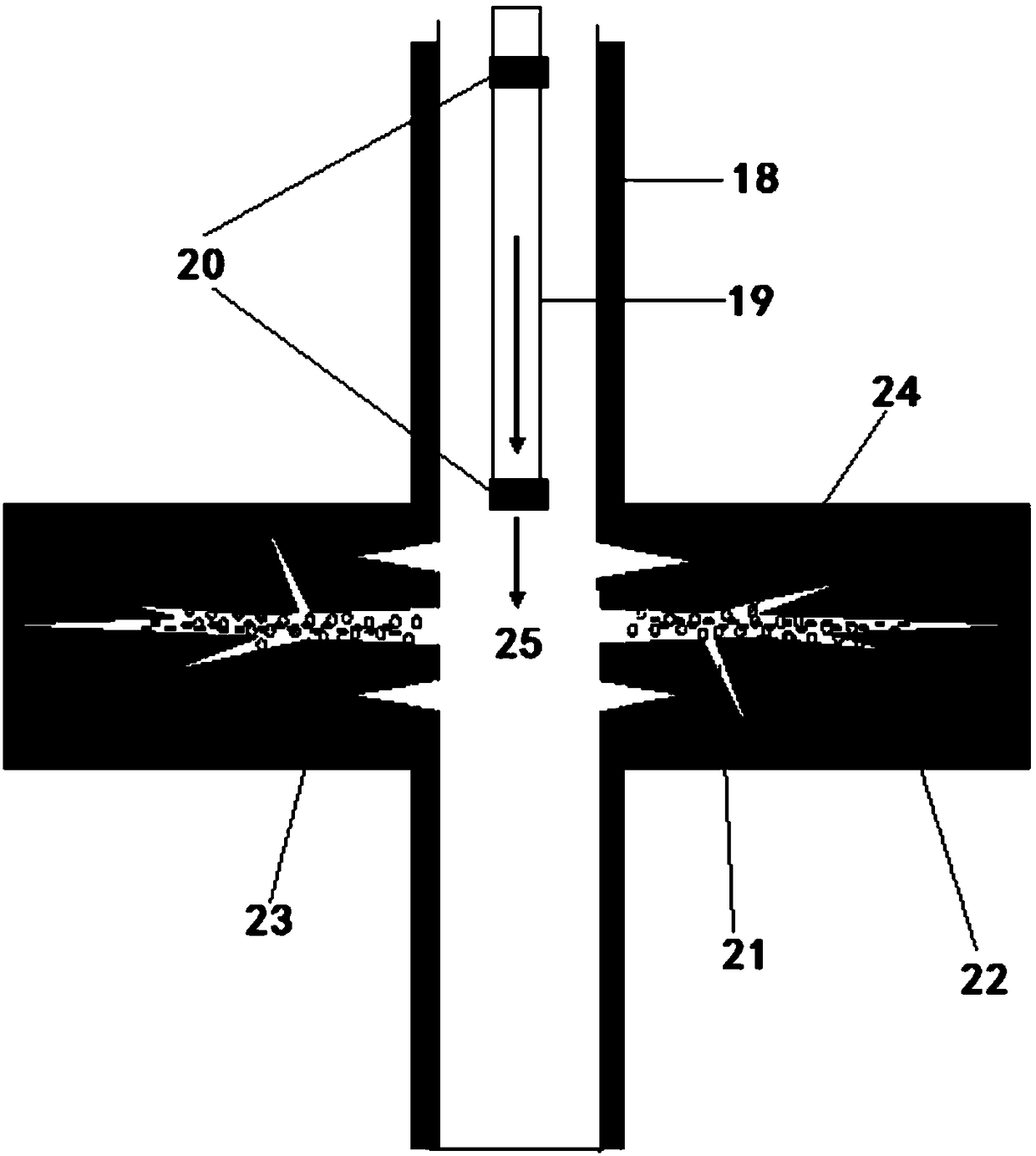

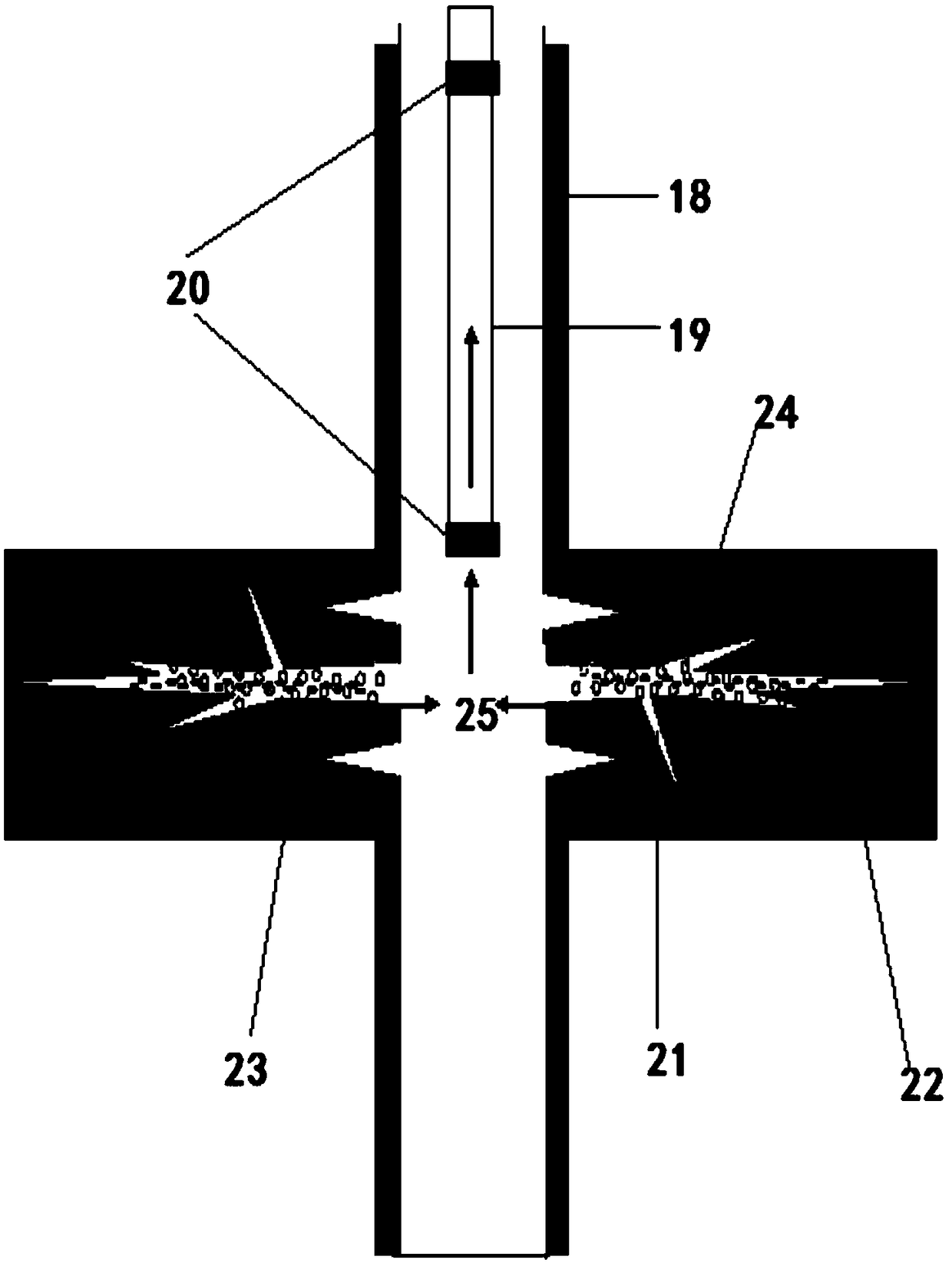

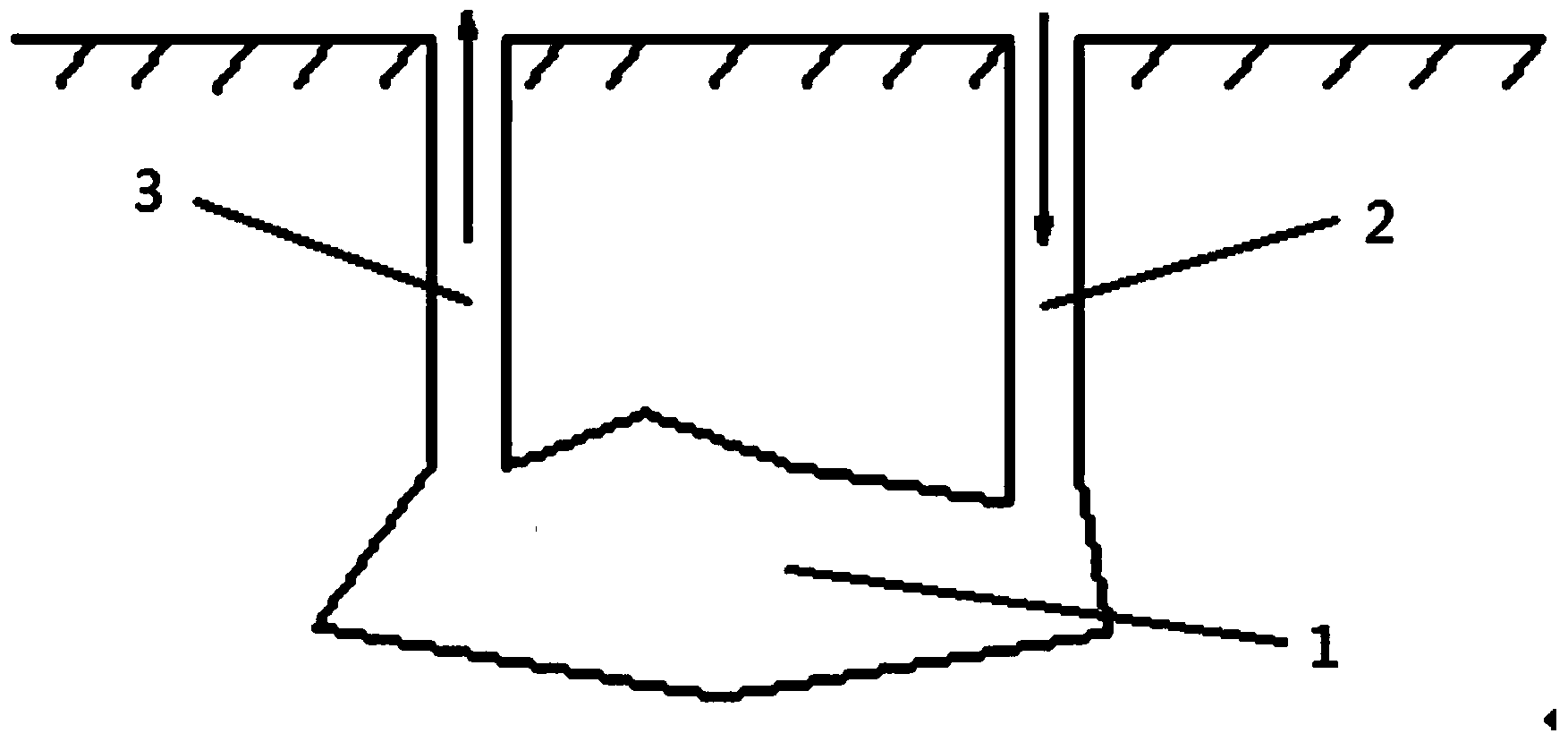

Single-well fracture gravity self-circulation dry-hot-rock geotherm mining method

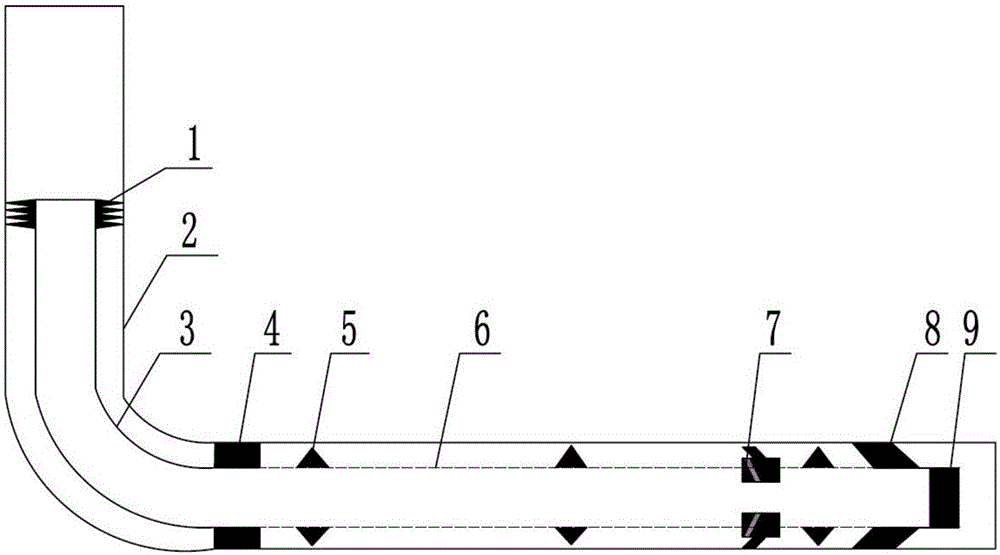

InactiveCN105863569AReduce injection pump powerIncrease temperatureOther heat production devicesGeothermal energy generationHeat lossesDisplacement pressure

The invention relates to the field of geothermal exploitation and provides a single-well fracture gravity self-circulation dry-hot-rock geotherm mining method. According to the method, perforation holes of different depths are utilized, the fracture size of a dry-hot-rock reservoir is increased through a water jet technology and a size fracture technology, and accordingly the upper area and the lower area of the reservoir communicate efficiently through fracture cracks; low-temperature heat-carrying fluid flows to the dry-hot-rock reservoir along the perforation holes in the upper portion after being injected in an annular mode, and then flows to the fracture cracks of the lower area under the actions of displacement pressure and gravity caused by the potential-energy difference of the fracture cracks of the upper portion and the lower portion; and finally, under the action of a ground suction pump, the heated heat-carrying fluid flows back to the ground along the perforation holes in the lower portion via a heat insulating oil pipe. According to the single-well fracture gravity self-circulation dry-hot-rock geotherm mining method, geothermal exploitation is carried out by annular cyclic injection and production of the heat-carrying fluid through the single-well oil pipe, and the expenses for drilling two injection and production wells in the conventional dry-hot-rock geotherm mining process is greatly reduced; and meanwhile, through use of the highly heat insulating oil pipe, the heat loss caused when the heat-carrying fluid is mined out of the oil pipe is reduced, and the heat collection capacity of the heat-carrying fluid is greatly improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

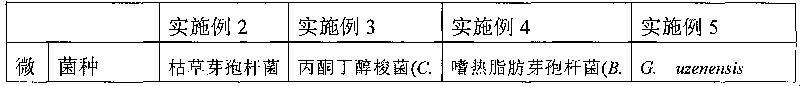

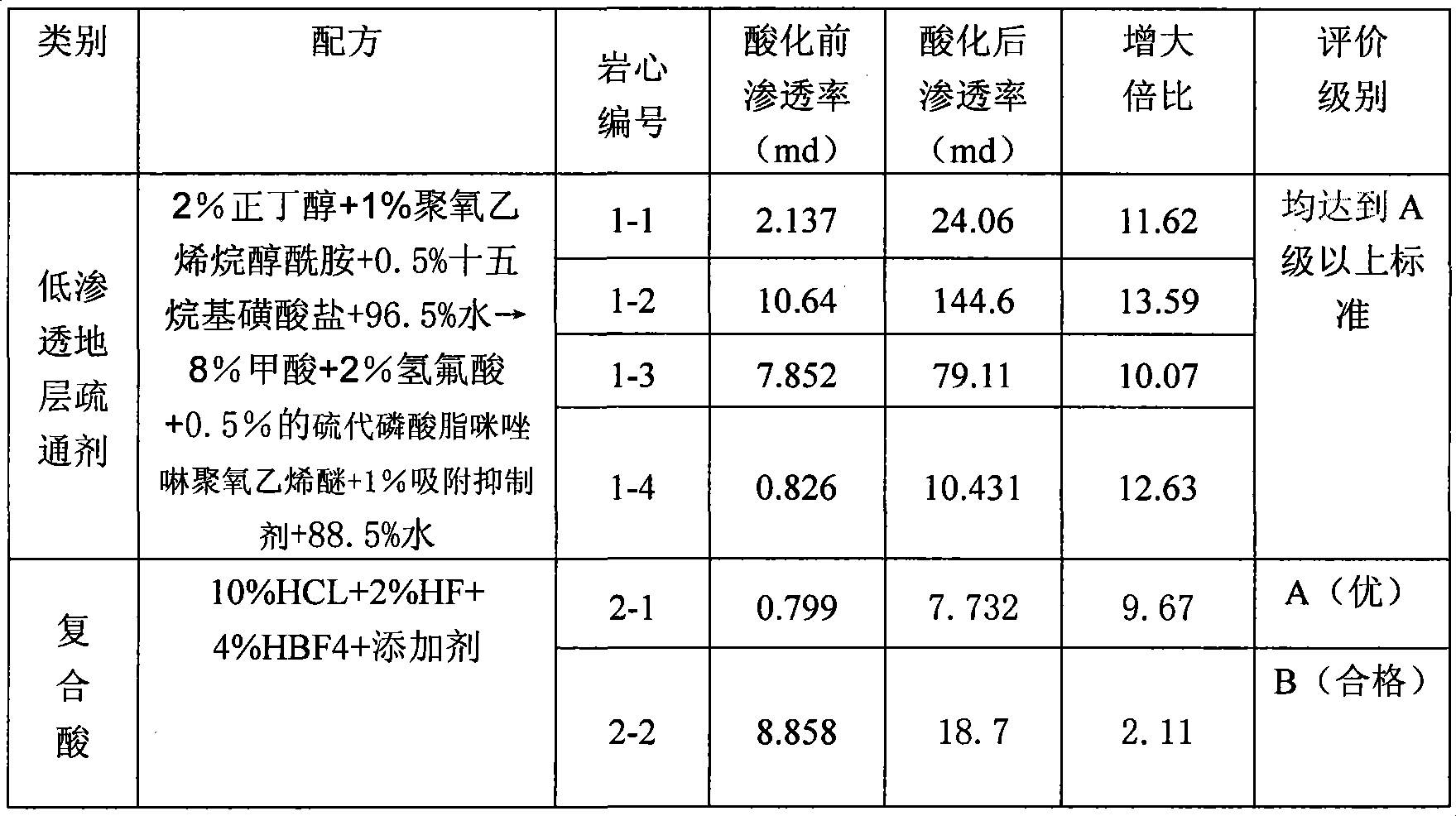

Hyposmosis oil pool microbial oil recovery method

ActiveCN101699026AImprove recoveryImprove seepage capacityMicroorganism based processesFluid removalMicrobial oilRecovery method

The invention relates to a hyposmosis oil pool microbial oil recovery method, comprising the following steps: (1) fracturing production is carried out to the hyposmosis oil pool; (2) microbes and nutrients are filled in an oil layer from cracks formed by fracturing to carry out microbial oil recovery. Compared with the prior art, the oil pool fracturing and the microbial oil recovery are combined together, so as to increase the action range of the microbes in the hyposmosis oil pool on one hand, on the other hand, the metabolic action of the microbes is helpful to keeping seeping channels to be open at the fracturing position, thereby promoting stable output of oil wells and prolonging steady yield time of oil fields; therefore, the invention is a scientific, economic and effective hyposmosis oil pool microbial oil recovery method.

Owner:DAQING HUALI ENERGY BIOLOGICAL TECH

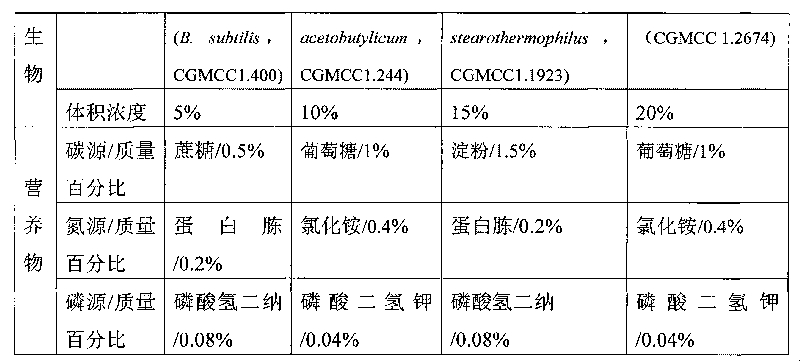

Formation opener agent for low permeable reservoir of oilfield

The invention relates to a stratum opener agent which is applied to oilfield low permeability reservoir. The stratum opener agent comprises two parts: pre-disposal liquid and acid inhibitor system; according to the weight percentage, the pre-disposal liquid consists of solvent and surfactant as follows: 1-3% of organic solvent such as higher alcohol, 0.2-1% of non-ionized surfactant polyoxyethylene alkylolamide, 0.3-0.5% of tenthfive alkyl sulfonate, and the residual quantity of stratum water; according to the weight percentage, the acid inhibitor system comprises 5-10% of low-carbon organic acid, 1-3% of hydrofluoric acid, 0.5% of inhibitor thio-phosphate imidazoline polyoxyethylene ether, 1% of adsorption inhibitor and the residual quantity of water; the adsorption inhibitor comprises 0.5-2% of ethyl dimethylene-bi-cetyltrimethylammonium ammonium bromide, 0.2-1% of quaternary ammonium salt small kation, 2-5% of inorganic salt, 0.2% of 1,3-amine group propyl alcohol N-methyl sodium phosphate or potassium dihydrogen phosphate or sodium hexametaphosphate. The opener agent can effectively improve the seepage capability of reservoir and achieve the objects of decompression and augmented injection and improving the yielding.

Owner:DAQING PETROLEUM ADMINISTRATION +1

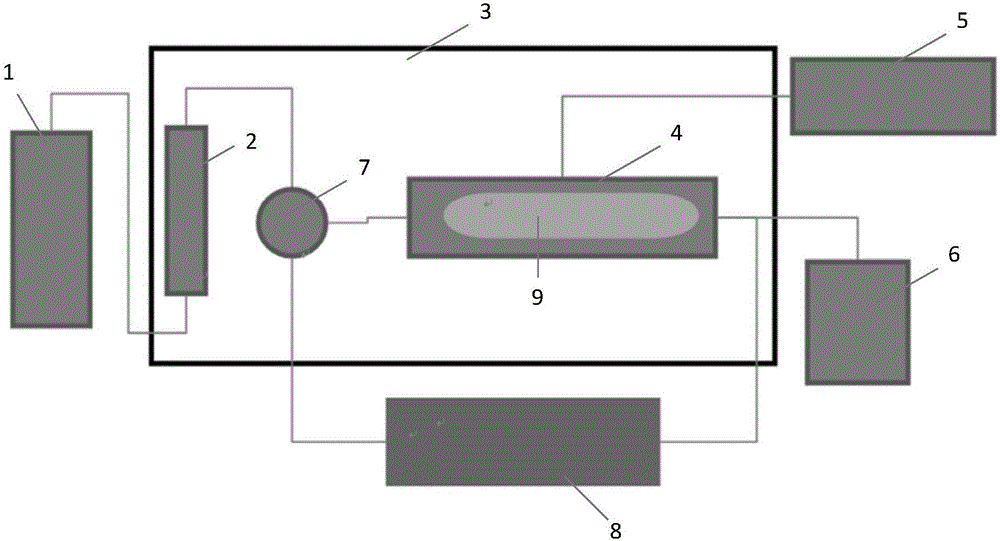

Experimental evaluation method of water trap damage of dense oil reservoir

InactiveCN107121370AImprove utilizationImprove seepage capacityPermeability/surface area analysisExperimental methodsStress conditions

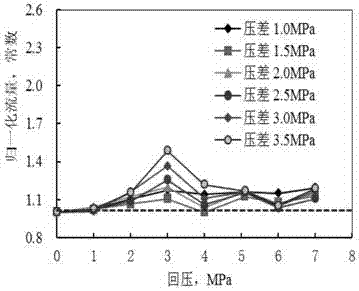

The invention relates to an experimental evaluation method of water trap damage of a dense oil reservoir. In order to solve the problems that by the conventional water trap damage experiment method, when a dense oil reservoir core is used as an evaluation object, liquid permeability cannot be measured and cannot be accurately measured and experimental pressure conditions cannot simulate the underground production pressure and the reservoir pore pressure and the like, the invention provides an experimental method for effectively and objectively evaluating the water trap damage of the dense oil reservoir. Through exertion of a back pressure on the outlet end of the dense core, an underground production pressure condition and a reservoir pore pressure condition are simulated and the defects that the conventional flooding cannot effectively establish the pore pressure inside the core and simulate the underground production pressure are overcome. Through exertion of the back pressure on the outlet end, the movability of a movable pore throat inside the dense core can be significantly improved, the liquid seepage capability is enhanced, the precision and accuracy for measuring the liquid flow of the dense core are improved, an evaluation result can represent the underground production state of the dense oil reservoir and can objectively evaluate the water trap damage of the dense oil reservoir. The experimental evaluation method is an experiment method applied to core analysis and reservoir protection during exploration and development of petroleum and natural gas.

Owner:SOUTHWEST PETROLEUM UNIV

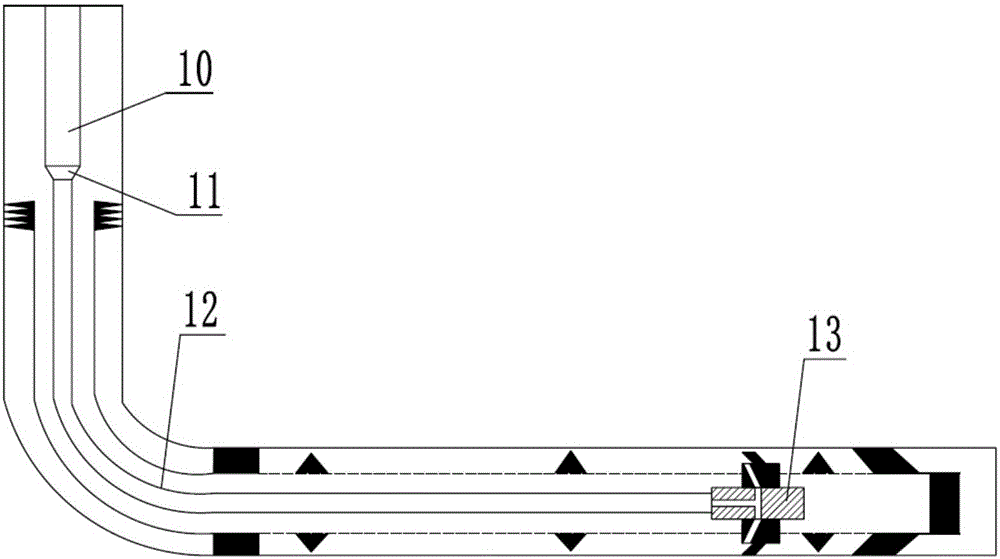

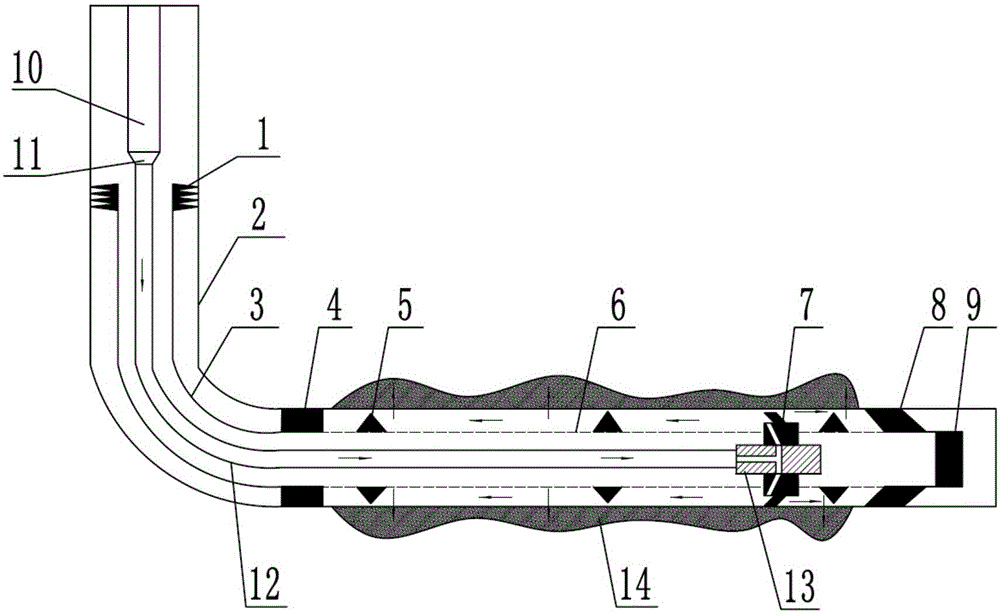

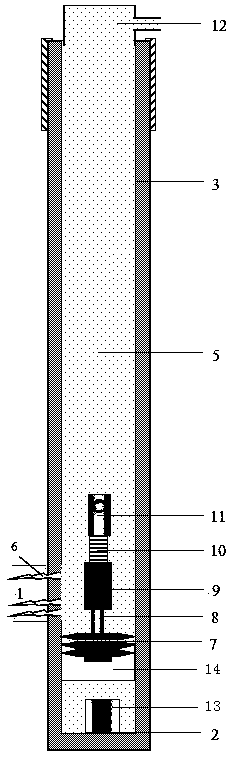

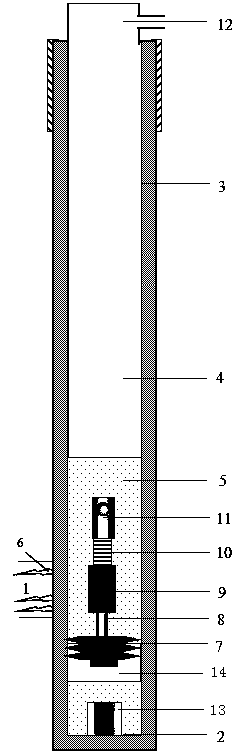

Process pipe column

The invention discloses a process pipe column. The process pipe column comprises a sand prevention pipe column and a filling service pipe column. A reverse packer is installed at the bottom of the sand prevention pipe column and corresponds to a packer at the upper portion of the sand prevention pipe column, pressure balance is achieved in the high-pressure extrusion process, the sand prevention pipe column is prevented from displacing under the effect of high-pressure sand-carrying fluid, cooperation of a bottom filling tool and a filling server is guaranteed, gravel in a horizontal well pipe is effectively extruded for filling sand prevention work, sand prevention well completion is smoothly achieved, and an oil-gas field is efficiently developed. According to the process pipe column, a reservoir can be fractured, wide and short cracks can be formed in a near well-bore zone, the seepage capacity of the reservoir is greatly improved, the yield increase effect is achieved, the sand blocking radius is expanded to the reservoir, the sand prevention effect is better, and the sand prevention efficiency period is longer.

Owner:PETROCHINA CO LTD

Multi-round compressed air deblocking method for coal bed gas well fracturing and blocking

ActiveCN108729891AEnsure construction safetyEasy to get materialsConstructionsFluid removalFast releaseProcess engineering

The invention relates to a deblocking method for coal bed gas well fracturing and powder blocking in the field of coal bed gas exploitation. The method includes adopting an air compressor to slowly inject compressed air from the ground into a shaft of a blocked coal bed gas well to form certain high pressure in the shaft and a coal bed, then opening a well opening discharge valve to quickly release high pressure gas in the shaft, so that blocking coal powder and sand in a fracturing crack will be loosened and move to the shaft with the compressed air and then return to the ground through a delocking pipe column. The process is repeated for multiple rounds to eliminate the well fracturing and coal powder blocking phenomenon, and the gas production will be restored. More importantly, the coal bed is not damaged, and high application value is achieved.

Owner:北京方圆天地油气技术有限责任公司

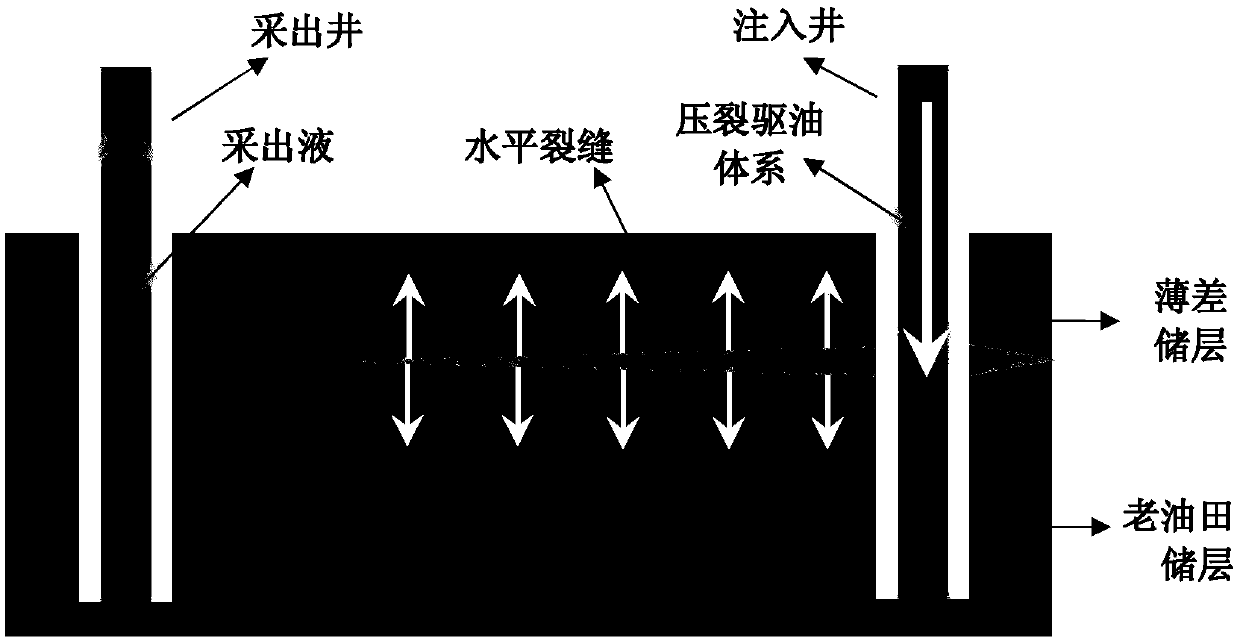

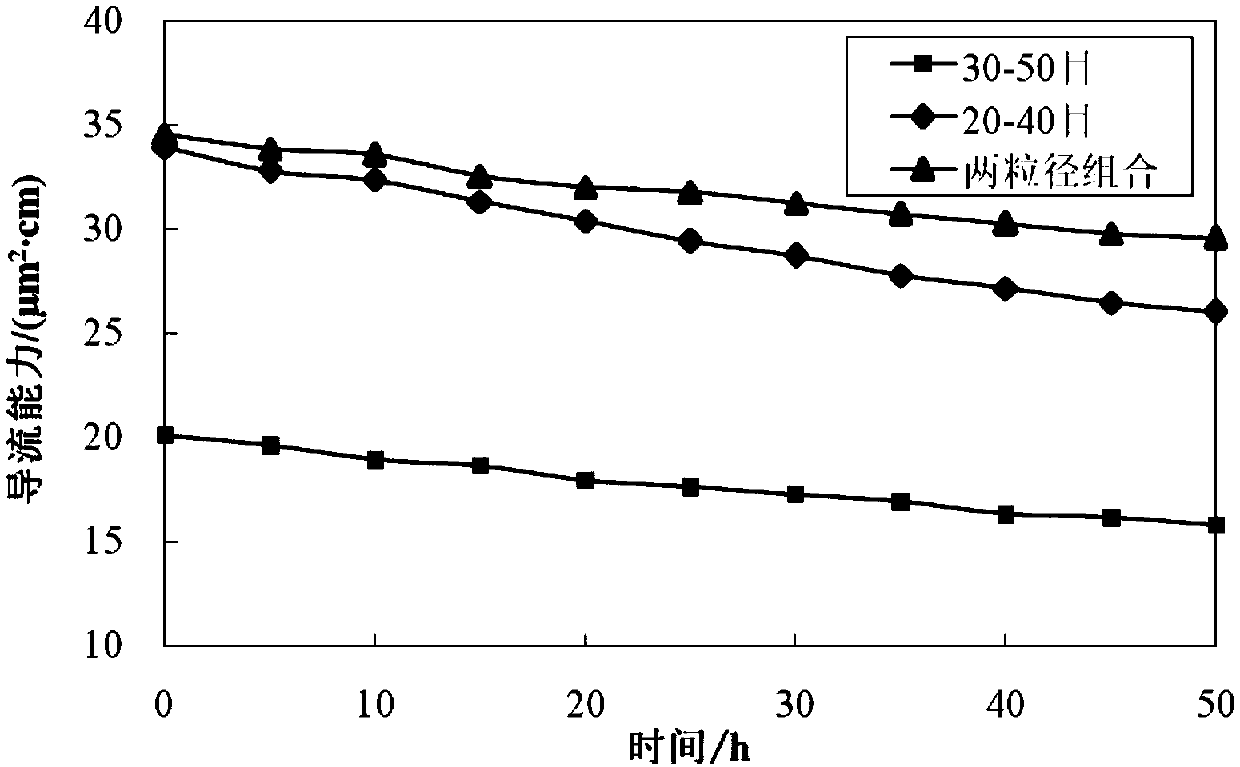

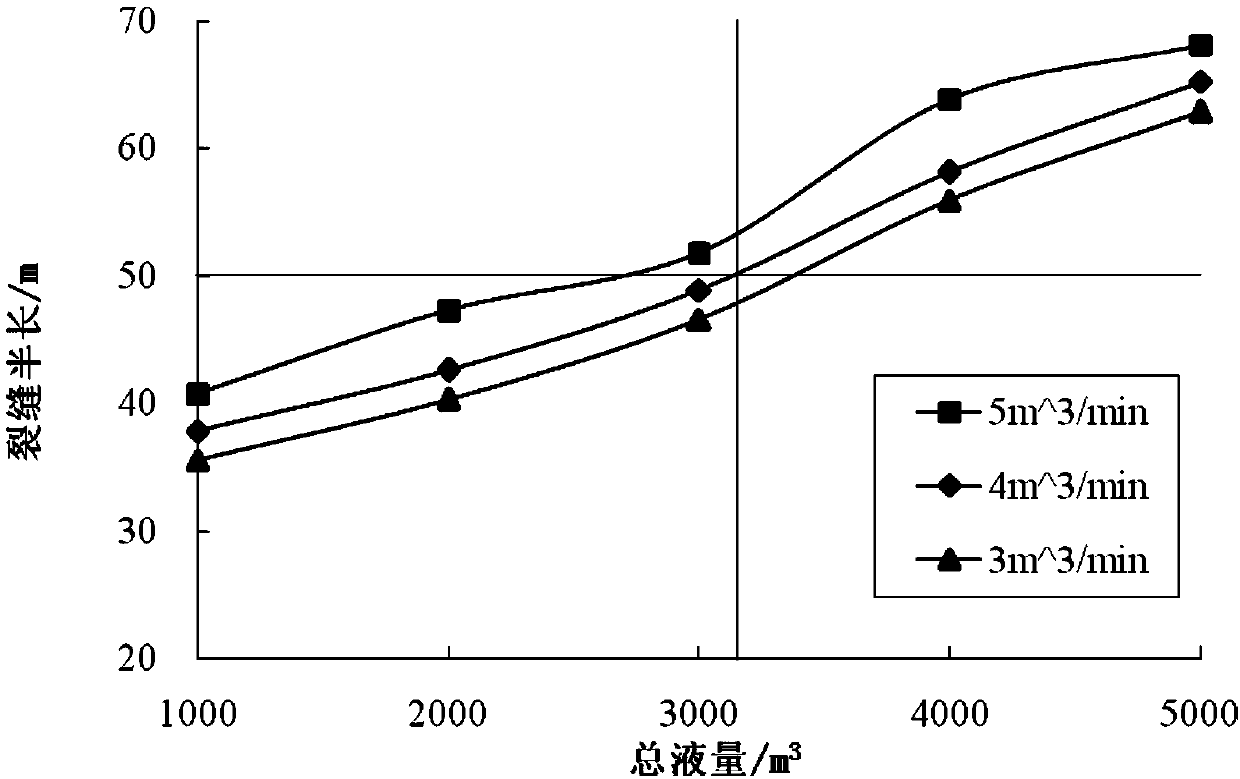

Fracturing oil displacement method for improving the economic efficiency of thin-difference reservoir recovery of an old oil field

ActiveCN109594959AImprove seepage capacityEnhanced overall recoverySurveyFluid removalOil fieldHigh intensity

The invention discloses a fracturing oil displacement method for improving the economic efficiency of thin-difference reservoir recovery of an old oil field. The method is based on oil reservoir evaluation and residual oil description. A fracturing measure process scheme is designed in a targeted manner, and a fine control fracturing technology is adopted the fracturing oil-displacing agent is injected into the stratum at high strength within a short time, the fracturing oil-displacing agent with good fracturing performance and a good displacing and washing effect is used for pressing open thestratum to generate cracks, meanwhile, a large amount of oil permeates into the stratum, the stratum energy is increased, stratum remaining oil can be efficiently displaced and washed, and then the recovery ratio of a thin-difference oil layer is greatly increased. According to the method, reservoir transformation, energy supplementing and chemical flooding washing are combined into a whole, therecovery efficiency can be comprehensively improved, construction parameters and fracturing oil displacement agent performance in fracturing can be reasonably optimized, and fracturing-injection-flooding washing integrated novel technology for improving the recovery ratio, which realizes the organic combination of a reservoir transformation technology and oil reservoir development integration andimproves the economic efficiency of thin-difference reservoir recovery of an old oil field.

Owner:NORTHEAST GASOLINEEUM UNIV

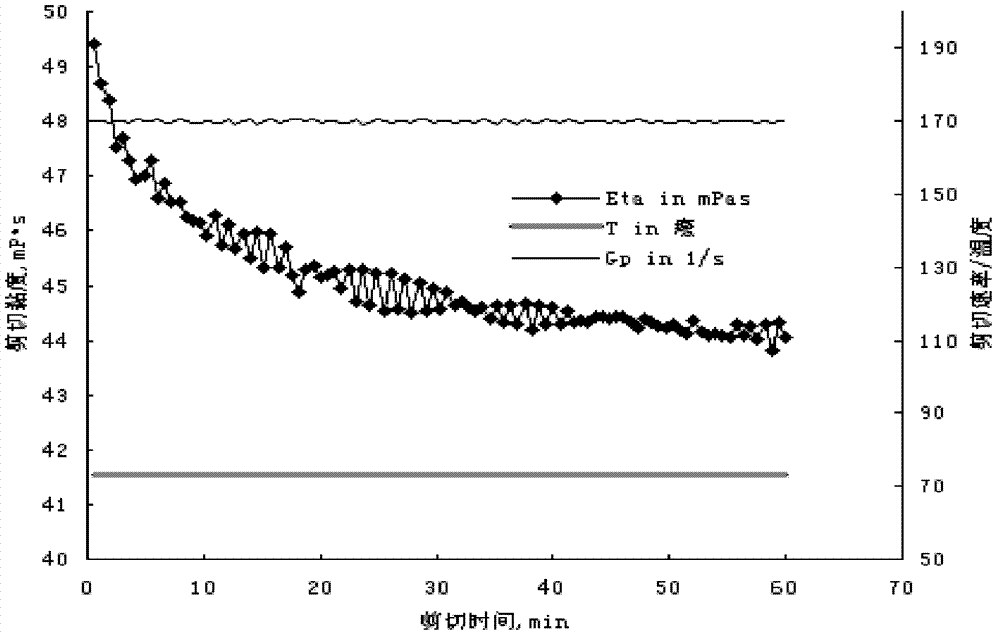

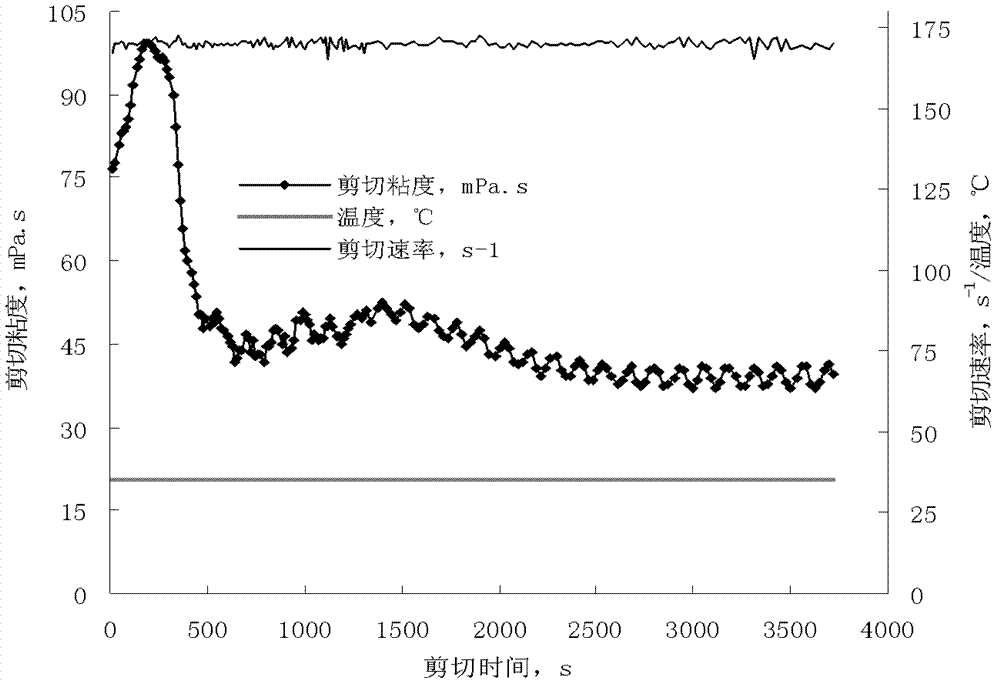

Acid injection fracturing method

The invention provides an acid injection fracturing method. The method comprises the steps that at the front liquid fissure forming stage, an alternative acid injection mode is adopted for fissure fracturing transformation, the alternative acid injection mode comprises the step that 1-5 levels of slugs are alternatively injected into fissures, and each level of slugs are composed of acid liquid and displacing liquid which are injected in sequence. According to the acid injection fracturing method, by combining with technical advantages of fracturing and acidification, through optimization of an alternative injection technology, the relation range of the acid liquid in a fissure fracturing system is enlarged to the greatest extent, and the porosity and permeability of fissure wall rock areimproved; a micro-fissure and branch fissure extension system is expanded and extended, increase of fissure complexity degree and transformation volume is promoted, and the duration time of keeping the flow diversion capacity of the fracturing system is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Self heat-generating and gas-generating clean fracturing fluid

InactiveCN102952535ALess harmfulImprove seepage capacityDrilling compositionPolymer scienceFiltration

The invention relates to a self heat-generating and gas-generating clean fracturing fluid comprising the raw materials of, by mass: 0.2-0.5% of a thickening agent, 2-4% of a structural enhancer, 2-15% of a heat generating agent A, 2-10% of a heat generating agent B, 2% of a structural enhancer solvent, 1-5% of a heat generating catalyst, 0.1-1% of a cleanup additive, 0.05-1.0% of a gel breaker, 0.05-0.15% of a broken plastic additive, and balance of water. The fracturing fluid has good temperature resistance, good shearing resistance, and sand-carrying property. The fluid can automatically generate heat and gas, such that the fracturing fluid is foamed in stratum. The fluid has low filtration loss. Gel breaking can be carried out with conventional persulfate and stratum oil, gas, and water dual gel breaking manner. Quick flow-back after pressure can be realized, and low-pressure oil and gas well self-spraying flow-back effect can be greatly improved. No residue and low harm is caused. The fracturing fluid can be used in fracturing modification of middle-shallow-stratum high-pour-point oil, crude oil with high viscosity, and low-pressure low-permeability oil and gas reservoirs.

Owner:PETROCHINA CO LTD

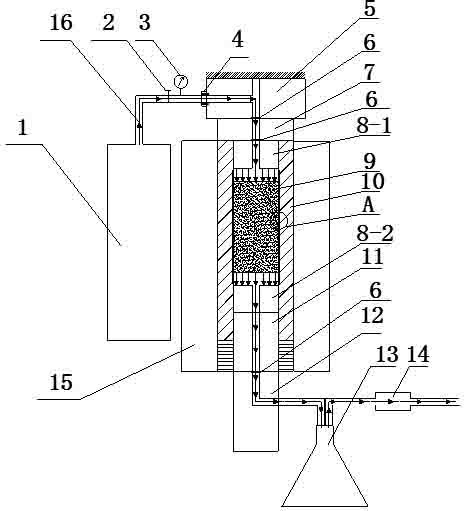

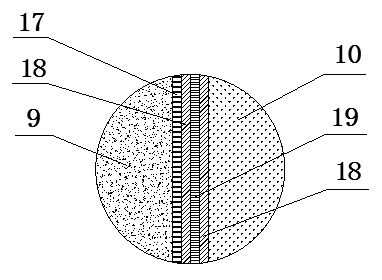

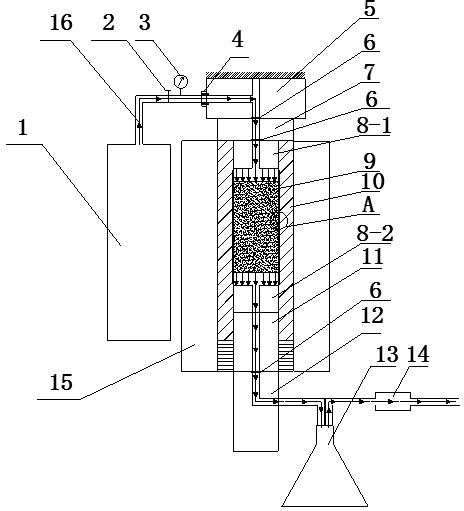

High temperature seepage test device and method

InactiveCN102435539AImprove the lack of small sizeEasy to getPermeability/surface area analysisEngineeringRock sample

The invention discloses a high temperature seepage test device and method. The device is mainly composed of a nitrogen gas bottle, a pressure chamber, a pressure chamber cover plate, upper and lower gas guide pressing heads, a main engine shaft pressing head, a collecting bottle and a gas flow meter. The method comprises the following steps of: filling nitrogen gas to a coal rock sample in the pressure chamber, enabling the nitrogen gas to flow out by a flow guide channel after permeating through the coal rock sample under a certain pressure and temperature, making the nitrogen gas pass through a gas outlet of the main engine shaft and enter in the collecting bottle by a communicating pipe, discharging the nitrogen gas in the collecting bottle by a gas discharging pipe on a top cover of the collecting bottle, and recording flow quantity of the discharged gas at this time by the gas flow meter; closing a pressure control valve by regularly increasing the pressure of the nitrogen gas for multiple times until the pressure of the filled nitrogen gas is increased to 4MPa, meanwhile, stopping work by regularly rising the temperature of the coal rock sample for multiple times until the temperature is rose to 600 degrees centigrade; and analyzing the acquired data to finish the overall test. The test device is simple in structure, the test method is simple and convenient and good simulation effect is realized.

Owner:CHINA UNIV OF MINING & TECH

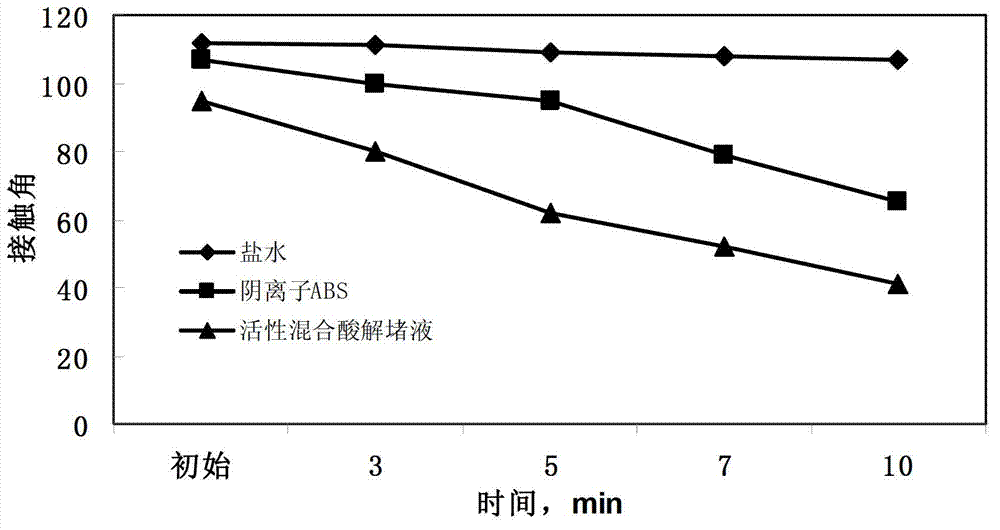

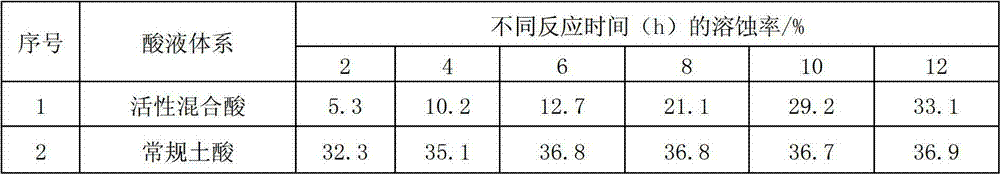

Active mixed acid plugging removal solution applicable to low permeability reservoir

ActiveCN102775974AChange wettabilityProlong the action timeDrilling compositionReaction rateEffective action

The invention relates to active mixed acid plugging removal solution applicable to a low permeability reservoir and mainly solves the problems of short period of validity and poor plugging removal and augmented injection effects when conventional mud acid and composite acid methods are adopted for plugging removal treatment on low permeability formation. The active mixed acid plugging removal solution consists of the following components in proportions according to weight percent: 9-10% of acetic acid, 5-7% of formic acid, 2%-3% of bifluorid acid ammonium, 2%-4% of boric acid, 1.0-2.0% of corrosion inhibitor, 2.0-4.0% of mutual solvent, 2.0% of clay stabilizer, 0.5-1.0% of dewetting active agent and 67.0-76.5% of water. The active mixed acid plugging removal solution applicable to the low permeability reservoir can delay the reaction rate of acid rock, increase the effective operating distance of acid solution, and realize the acidification of deep formation, and simultaneously can improve the oil and water seepage characteristics and increase the water phase permeability.

Owner:DAQING JINGSHENG WEIYE OILFIELD TECH SERVICE +1

Water-injection oil-replacement mining method applicable to fracture-cavity type carbonatite condensate gas reservoirs

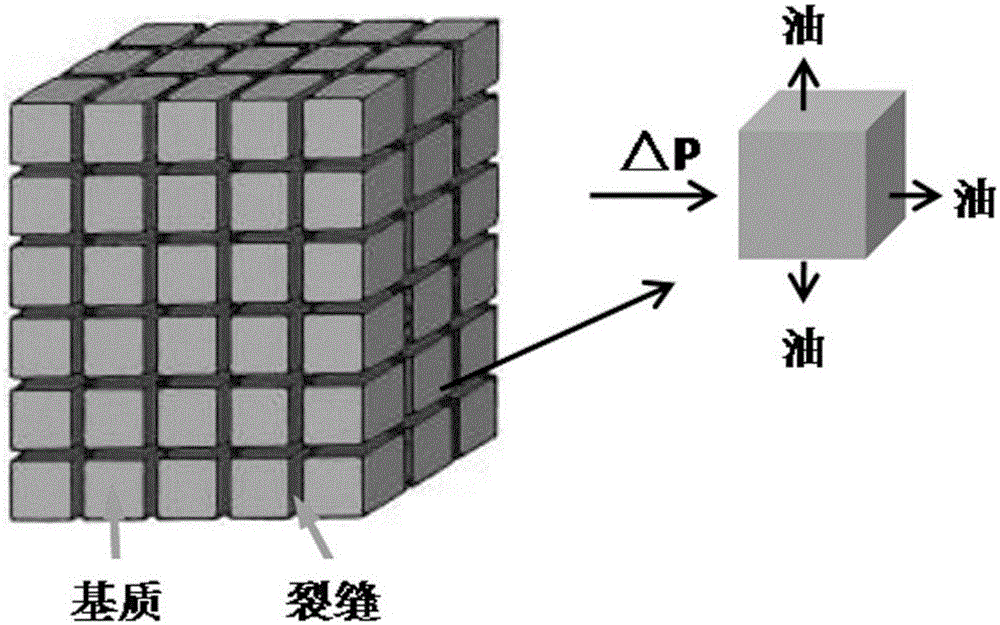

ActiveCN104895537AEnhanced overall recoveryExtend the life cycleFluid removalSpecial data processing applicationsReservoir typeProcess engineering

The invention discloses a water-injection oil-replacement mining method applicable to fracture-cavity type carbonatite condensate gas reservoirs, wherein three-dimensional geologic models of condensate gas reservoirs with different reservoir types and different gas condensate contents are established through a modeling technology in combination with materials related to earthquake, logging, drilling and mud logging and dynamic production; a dual-media water-injection oil-replacement mechanism is then researched by a numerical simulation technology in combination with pilot production characteristics; an injection well, a water injection moment, a water injection amount, a water injection speed, quantity of water injection rounds and water injection intensity are optimized in order to realize multiple rounds of mining after a well soaking period is reached; and the water injection moment, the water injection amount, the water injection speed and the water injection intensity need to be optimized before each round of the mining. By the method, a life cycle of the fracture-cavity type carbonatite condensate gas reservoir can be prolonged, and rate of oil and gas recovery can be effectively increased.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Leaching method for increasing leaching rate of ionic adsorption type rare earth ore

ActiveCN106702181AReduce desorption processReduce the absolute valueProcess efficiency improvementClay mineralsRare earth

The invention discloses a leaching method for increasing the leaching rate of ionic adsorption type rare earth ore. According to the leaching method, a leaching aid agent is added into a leaching agent so that a leaching solution can be prepared, and then, the ionic adsorption type rare earth ore is leached; or the ionic adsorption type rare earth ore is subjected to drip washing through a leaching aid agent solution at first, after drip washing liquid of the ionic adsorption type rare earth ore is collected, a leaching agent is added so that a leaching solution can be prepared, and the ionic adsorption type rare earth ore subjected to drip washing through the leaching solution is leached; and the leaching aid agent is a mixture comprising one or more of succinic acid, sodium succinate, succinic acid and ammonium succinate. According to the leaching method, one or more of the succinic acid, the sodium succinate, the succinic acid and the ammonium succinate are adopted as the leaching aid agent, the aggregation of clay particles in ore is maintained, migration of the clay mineral particles in the leaching process is reduced, meanwhile, the ore penetrating quality can be improved moderately, and the leaching rate is increased.

Owner:JIANGXI UNIV OF SCI & TECH

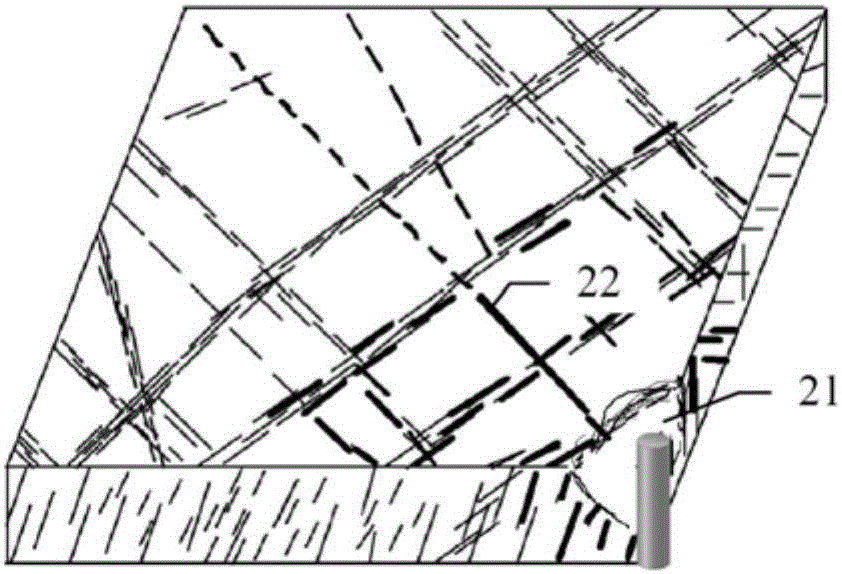

Method for increasing fracturing volume in tight sandstone reservoir

ActiveCN110761762AIncrease in sizeImprove seepage capacityFluid removalMicro fractureHydraulic fracturing

The invention discloses a method for increasing the fracturing volume in a tight sandstone reservoir. The method includes the steps that (1) micro-fractures are formed in the tight sandstone reservoir; step (2) the micro-fractures are expanded and communicated; step (3) hydraulic fracturing is performed to form main fractures; and step (4) a proppant is turned from temporary blocking to form branch fractures. The method is suitable for fracturing transformation production increase operation of the tight sandstone reservoir with micro-fractures not developed. Through innovative process ideas, first, a large number of radial micro-fractures are artificially generated in a sandstone reservoir with the micro-fractures not developed and a dense matrix, then the main fractures penetrating through the micro-fractures are formed through hydraulic fracturing, and in the extension process, the main fractures are turned for multiple times, so that a complex fracture system is formed, and the fracturing transformation volume is increased and the production increase effect is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

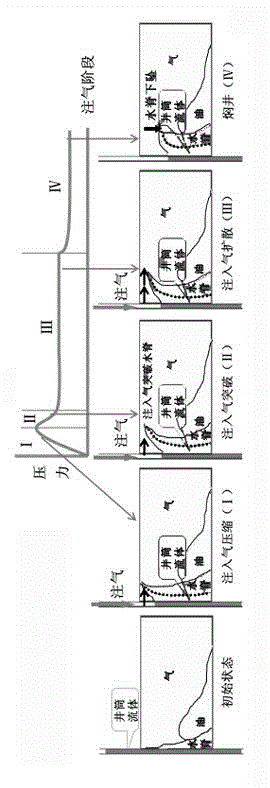

Method for removing sandstone condensate gas reservoir water lock through nitrogen injection

InactiveCN104453806AImprove seepage capacityEnhanced overall recoveryFluid removalSoil scienceGas phase

The invention relates to a method for removing a sandstone condensate gas reservoir water lock through nitrogen injection. The method includes the steps of the nitrogen injection initial stage, the nitrogen injection breakthrough stage, the nitrogen injection diffusion stage and the closing-in stage, wherein at the nitrogen injection initial stage, flow in a shaft and a water crest of a near-shaft region are gradually compressed through the nitrogen and are displaced towards the periphery of a well, and the injected nitrogen tongues along the top of a reservoir stratum; at the nitrogen injection breakthrough stage, the nitrogen is ceaselessly injected, and after the difference value between the pressure at the bottom of the well and the pressure of the stratum during gas injection is larger than the pressure of the water lock, the nitrogen is injected to break through a water lock barrier; at the nitrogen injection diffusion stage, the nitrogen is ceaselessly injected, the water crest on the periphery of the well is dispersed to a farther place, and the gas-phase seepage capacity is improved; at the closing-in stage, the nitrogen injection stops, the water crest is further compressed to fall, and the gas-phase seepage capacity is further improved. By injecting the high-pressure nitrogen to displace the water of the near-shaft region, communication is achieved for natural gas at a far end, and the gas-phase seepage capacity is improved; meanwhile, through the high compressibility and expansibility of the nitrogen, the good emission assisting, displacing and gas lifting effects are achieved when energy is released, and finally the gas well yield is recovered and the condensate gas reservoir recovery efficiency is improved.

Owner:CHINA PETROLEUM & CHEM CORP

Plug removal agent for oil-water well of tight oil reservoir

InactiveCN106634917AStrong cleaning oil abilityChange wettabilityDrilling compositionCarboxylic acidSolvent

The invention discloses a plug removal agent for an oil-water well of a tight oil reservoir. The plug removal agent is prepared from the following components in percentage by mass: 8.0 to 15.0 percent of organic sulfonic acid, 5.0 to 8.0 percent of organic carboxylic acid, 0.5 to 1.5 percent of hydrofluoric acid, 3.0 to 12.0 percent of fluoroboric acid, 0.5 to 1.5 percent of mutual solvent, 0.5 to 1.0 percent of wetting reversion agent, 5.0 to 10.0 percent of chelating agent, 0.5 to 1.5 percent of clay stabilizer, and the balance of water. According to the plug removal agent disclosed by the invention, the problem that the tight oil reservoir is easily plugged by primary particles and secondary particles due to high mud content, poor reservoir physical property and small pore throat radius is solved, the reservoir permeability is recovered and improved to the maximum extent, the percolation capacity of a stratum with actual control radius of the oil-water well is improved, and the aims of improving the production capacity of the oil-water well, and realizing enhanced production of an oil well and intensified injection of a water well are achieved.

Owner:PETROCHINA CO LTD

Multifunctional nano-viscosity reduction profile control agent

InactiveCN101531891AImprove seepage capacitySmall particlesDrilling compositionReduction rateFoaming agent

The invention provides a multifunctional nano-viscosity reduction profile control agent, relating to an additive for thick oil exploitation in the chemical field of oil exploitation and a use method thereof. The agent disperses the continuous thick oil to an oil-in-water oil block by a low interfacial tension mechanism, and has the characteristics of high viscosity reduction rate, dispersed system while flowing, layering while being still, no influence on emulsion breaking, small use concentration and great economical feasibility. The technique combines the viscosity reduction, the profile control with displacement of reservoir oil, which can not only reduce the viscosity of the thick oil and regulate a water absorption profile, but also improve the efficiency of the displacement of reservoir oil, therefore, the integration of displacement and control is realized so that the technique is an organic combination of secondary oil recovery and tertiary oil recovery as well as has remarkable comprehensive economic benefit. By adding an assistant agent of a foaming agent, the method increases fluid film strength, prolongs foaming half life period, enhances foaming stability and sufficiently solves the problems of high viscosity of the thick oil and difficult development in the process of oilfield development and exploitation; the characteristics of nano-particles are utilized to exert cooperative effect between the agents to the maximum extent so as to realize the objective of viscosity reduction, profile control and efficiency increase.

Owner:SOUTHWEST PETROLEUM UNIV

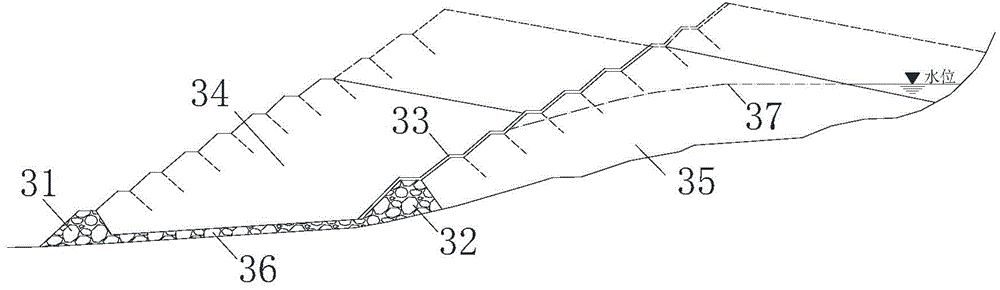

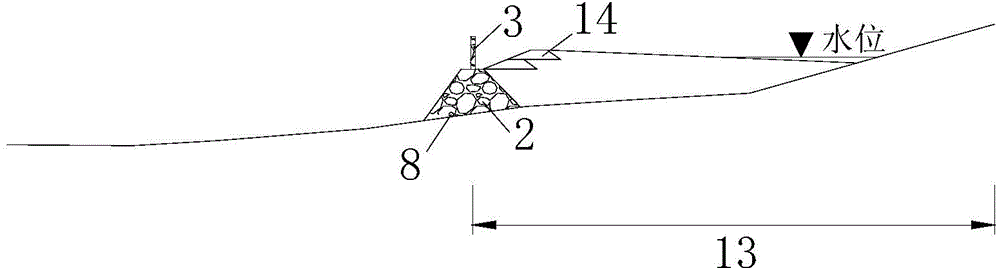

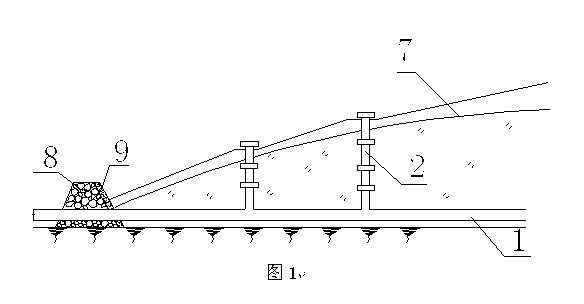

Strong draining and seepage-based upstream type tailings pond fill dam and damming technology thereof

The invention discloses a strong draining and seepage-based upstream type tailings pond fill dam. The strong draining and seepage-based upstream type tailings pond fill dam is built by an upstream type damming method on the basis of a two-level dam structure of a tailings pond, wherein the two-level dam structure comprises a primary dam and a seepage-prevention dam; fine-grain tailings are piled up in an upper pond of the seepage-prevention dam, and coarse-grain tailings are piled up in a lower pond between the primary dam and the seepage-prevention dam; a tailings pond bearing body is formed by the coarse-grain tailings under the action of hydraulic classification; the seepage-prevention dam is taken as a dividing line for the upper pond and the lower pond, and the seepage lines of the upper pond and the lower pond intersect on the seepage-prevention dam. The damming technology of the tailings pond fill dam comprises the following steps: firstly, constructing to build the seepage-prevention dam to cause the upper pond to form a coarse-grain tailings depositing beach; then, constructing the primary dam in the downstream area of the seepage-prevention dam, respectively piling up the fine-grain tailings and the coarse-grain tailings in the upper pond and the lower pond, and lifting the fine-grain tailings to the upper pond by a pump ship in a temporary stagnant area in the upstream area out of the depositing beach; finally, the tailings are piled to a final elevation by an upstream type damming method. The strong draining and seepage based upstream type tailings pond fill dam is favorable for further improving the safety and the economy of the tailings pond by combining with the advantages of the upstream type damming method.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

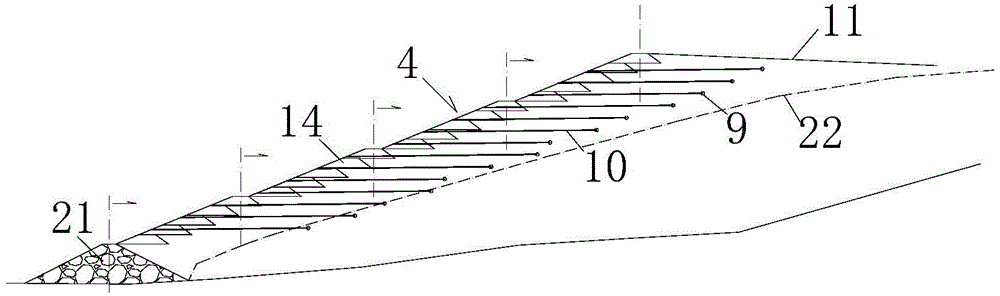

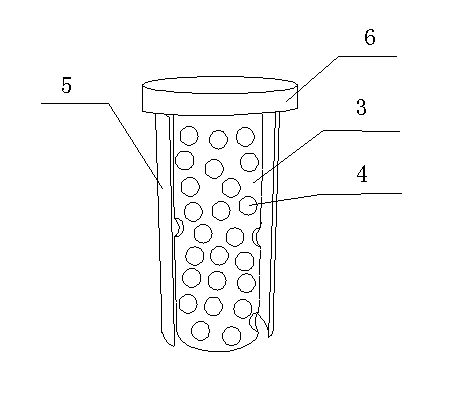

Sectionally constructed seepage drainage pipe for tailings dam

InactiveCN103216003AImprove permeabilityIncreased effectiveness of drainageSewage drainingSewer pipelinesTailings damGeotextile

The invention discloses a sectionally constructed seepage drainage pipe for a tailings dam. The sectionally constructed seepage drainage pipe comprises an aqueduct (1) and a seepage drainage pipe (2) which are communicated with each other, wherein the seepage drainage pipe (2) is arranged at a distance of 1 / 3 to 1 / 2 from the top of the dam and consists of an inner pipe (3), seepage drainage holes (4), a geotextile (5) and a reserved interface (6), and the inner layer of the seepage drainage pipe (2) is the inner pipe (3); the seepage drainage holes (4) are uniformly arranged on the inner pipe (3), and the outer side of the inner pipe (3) is wrapped with the geotextile (5); and the reserved interface (6) arranged at the upper part of the inner pipe (3) is connected with a second-stage seepage drainage pipe. The good permeability and reliability of the seepage drainage pipe are ensured, the loss of accumulated fine particle soil can be prevented, and the seepage failure is avoided, thereby ensuring the stability of the dam.

Owner:HOHAI UNIV

Method of utilizing underground thermal energy

InactiveCN103913004AControl heat hazardsImprove seepage capacityOther heat production devicesGeothermal energy generationThermal energyWell drilling

The invention discloses a method of utilizing underground thermal energy. The method includes that thermal rocks under a mining deep well are crushed through a high-pressure water pump, so that a rock mass is enabled to have cracks good in seepage effect; crack outlets are finally converged in a designed roadway, a thermal-water recycling bin is established nearby the crack outlets, and cold water on the ground is injected into the cracks and flows through seepage in the thermal rocks to absorb the thermal energy of the thermal rock mass and turn into the thermal water to flow into a underground thermal water bin; the mine roadway is transformed and utilized to become a laneway for well drilling to take the thermal water, the thermal water is absorbed from the thermal water bin to the ground to be utilized, and the problems about obsession and drilling expenses of the thermal rock survey technology; after utilization of the thermal water energy is completed, and the thermal water energy is subjected to sedimentation basin treatment and then is injected into the thermal rocks to absorb geothermy to be recycled once again. Inexhaustible clean energy can be obtained with little investment; meanwhile, underground high-temperature harm can be effectively controlled by absorbing the thermal water into the ground, and working efficiency can be greatly improved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Method for mining coalbed methane through coalbed burning assisted fracture forming

ActiveCN106089171AImprove seepage capacityTransformation is effectiveFluid removalOxygenNitrogen gas

The invention discloses a method for mining coalbed methane through coalbed burning assisted fracture forming. The method comprises steps as follows: (1) nitrogen gas and / or carbon dioxide gas are / is injected into a coalbed methane well, near-wellbore area coalbed methane is pushed to a deep position of a stratum by 3-5 m; (2) ignition is performed: air is injected for ignition at the temperature being 500 DEG C or above, and a near-wellbore area coalbed is ignited; (3) air injection is stopped, and the well is closed for 4-5 days; (4) the nitrogen gas or the carbon dioxide gas is injected to dilute involved oxygen in a near-wellbore area, and the mined gas explosion risk is avoided; (5) the coalbed methane is mined normally. The method is suitable for coalbed methane transformation, the cave completion effect in the near-wellbore area can be realized, fissures can be formed with the method instead of through fracturing, and a new thought is provided for effectively improving seepage capability of the coalbed methane.

Owner:BEIJING PUXIN PETROLEUM TECH DEV

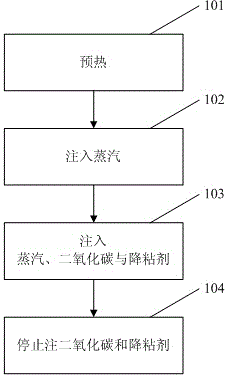

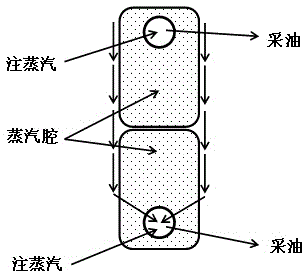

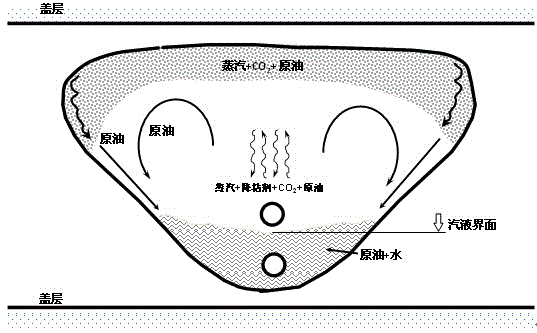

Method for improving recovery ratio of super heavy oil reservoir

InactiveCN104975826AEnhanced overall recoveryIncrease enthalpyFluid removalCarbon dioxideContinuous production

The invention provides a method for improving the recovery ratio of a super heavy oil reservoir. The method for improving the recovery ratio of the super heavy oil reservoir comprises the following steps of: 1, preheating two horizontal wells in parallel distribution; 2, injecting steam into the upper part horizontal well, and maintaining the original stratum pressure in the lower part horizontal well for production; 3, simultaneously injecting steam, carbon dioxide and viscosity reducers into an oil layer through the upper part horizontal well, and maintaining the original stratum pressure in the lower part horizontal well for production; and 4, stopping the injection of the carbon dioxide and the viscosity reducers, continuously injecting the steam into the upper part horizontal well and maintaining continuous production of the lower part horizontal well. The method for improving the recovery ratio of the super heavy oil reservoir has the advantages that the viscosity of crude oil is greatly reduced; the heat loss of top and bottom cover layers is reduced; the steam enthalpy is improved; the elasticity energy of the stratum and fluid is increased; the flow seeping capability in near bore zones is improved; and the crude oil is recovered through the gravity effect so as to improve the recovery ratio of the super heavy oil reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

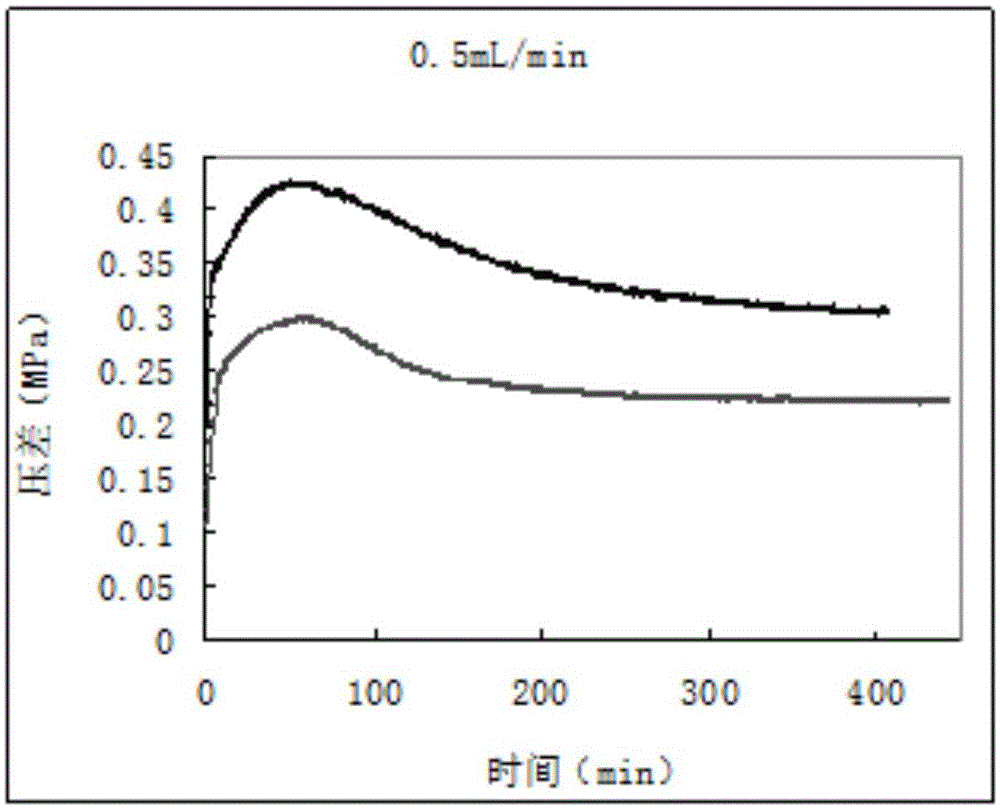

Double-draining chemical modifier and application thereof

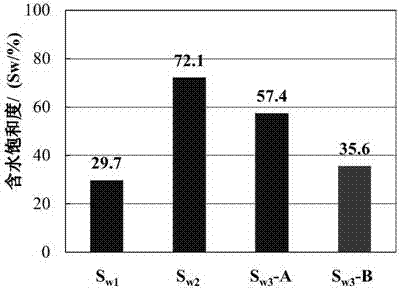

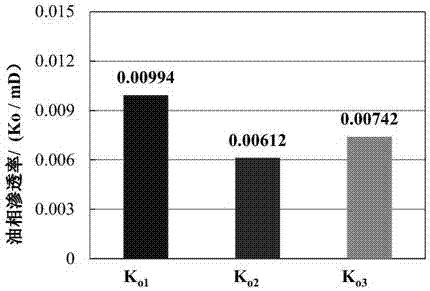

ActiveCN106279578AImprove seepage capacityImprove permeabilityFluid removalDrilling compositionSilanesOil phase

The invention relates to a double-draining chemical modifier and application thereof. A method for preparing the double-draining chemical modifier includes steps of mixing gamma-(methacrylamide acyloxy) propyl trimethoxy silane modified nanometer SiO2 and 4-total fluorine (2-isopropyl-1, 3-dimethyl-1-butenyl) oxygen styrene with each other in the presence of inert gas and first organic solvents to obtain mixtures; adding initiators into the mixtures and carrying out surface grafting reaction to obtain the double-draining chemical modifier. The double-draining chemical modifier and the application have the advantages that the surfaces of pores of cores are modified to have water-draining and oil-draining characteristics after the low-permeability sandstone cores are treated by the double-draining chemical modifier which is a chemical agent, seepage resistance of water phases and oil phases can be simultaneously reduced, the seepage capacity of the low-permeability cores can be improved, and the oil and water permeability of the low-permeability sandstone cores can be improved by 50% at least as shown by indoor experiments.

Owner:CHINA PETROLEUM & CHEM CORP +1

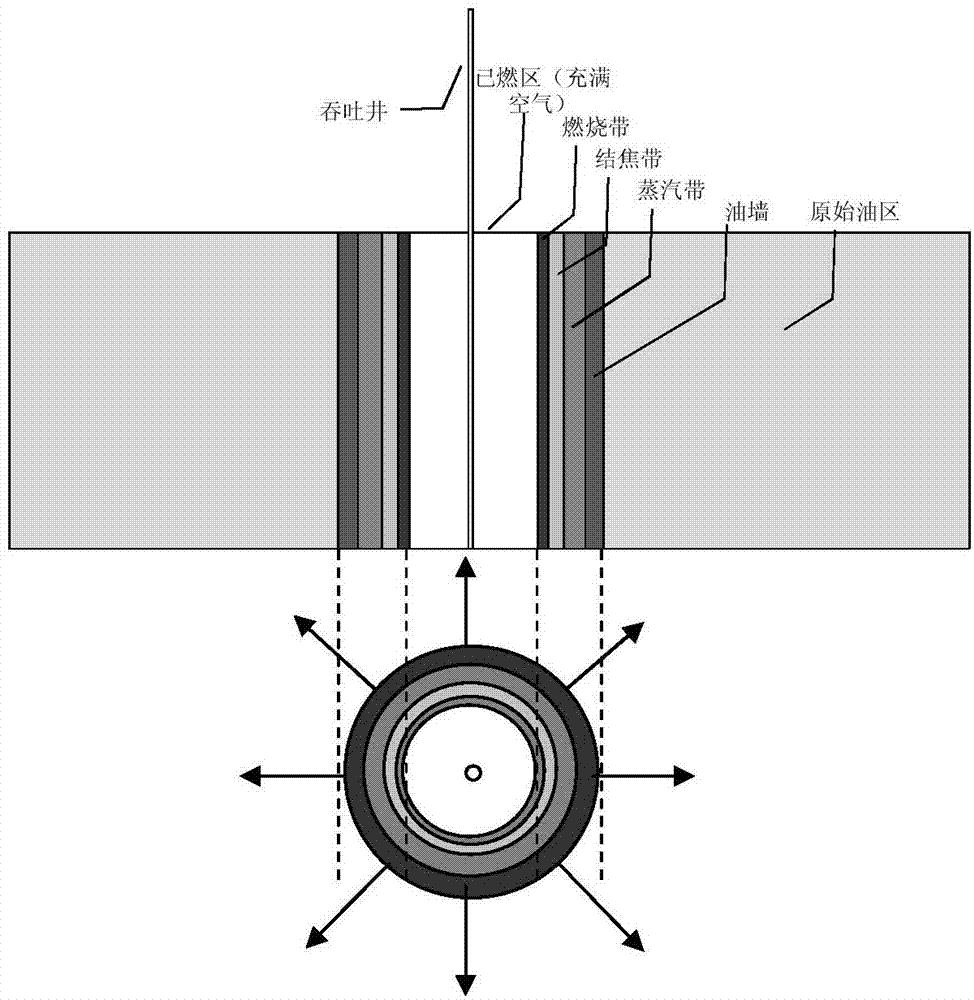

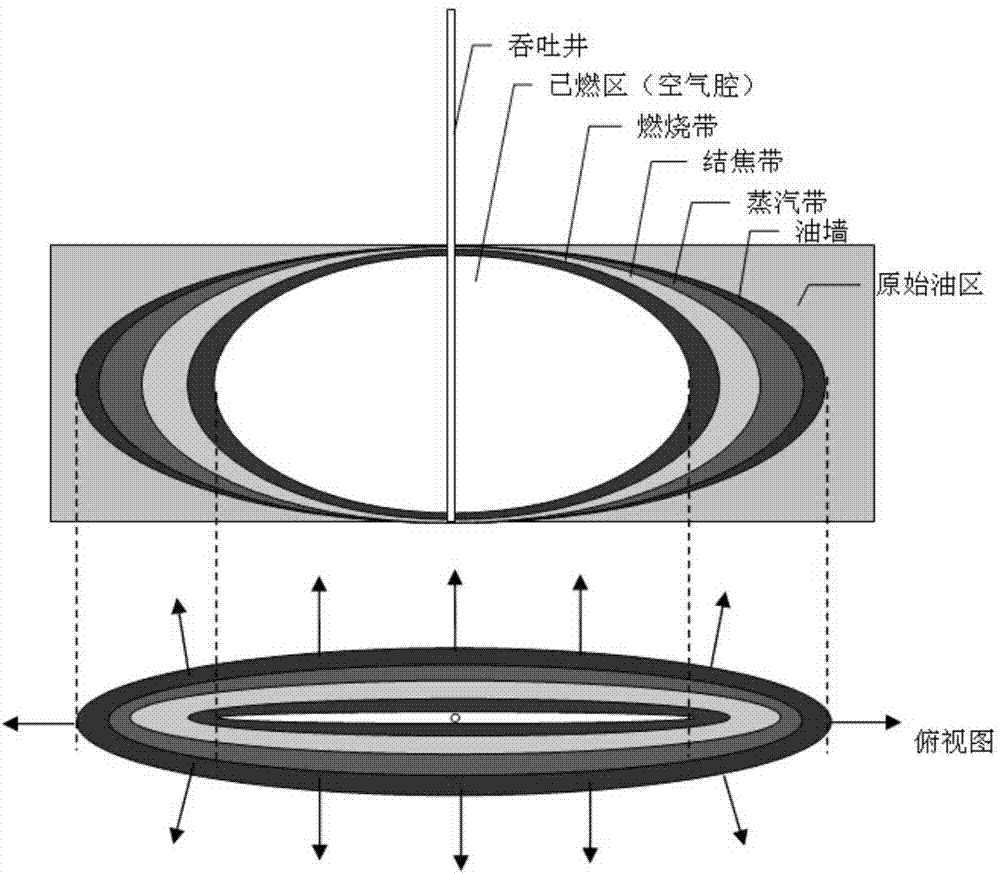

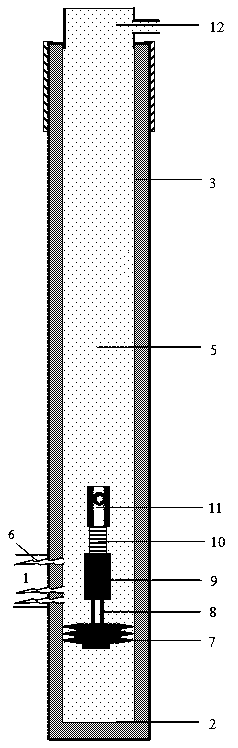

Fracture-assisted combustion of oil in-situ stimulation thickened oil exploiting method

InactiveCN104265258AIncreased air injection capacityExtended heating rangeFluid removalCombustionFlue gas

The invention relates to a fracture-assisted combustion of oil in-situ stimulation thickened oil exploiting method. The method comprises the steps of conducting hydrofracture transformation on the oil reservoir on the perforating section of an oil well casing, forming vertical artificial fractures on both wings of a shaft, adding fracturing propping agents with which the fractures are filled, and conducting sieve tube gravel pack completion inside the casing; making the bottom hole temperature reach the ignition temperature of crude oil by means of the firing technique to ignite the oil layer of an oil well; injecting air into the oil well continuously by means of an air compressor; conducting soaking after air injection; opening the well for stoping. The method is mainly applied to low-permeation heavy oil reservoirs, thin-bedded heavy oil reservoirs and thin-interbed heavy oil reservoirs. Compared with the prior art, the method has the advantages that combustion of oil in-situ stimulation air injection speed and monocyclic cumulative injection rate can be increased by over three times, thermal front and flue gas front swept volume is increased by over three times, well yield is increased by over two times, and cyclic cumulative production is increased by over three times.

Owner:BEIJING PUXIN PETROLEUM TECH DEV

Expansion increment deflagration fracturing method

The invention relates to an expansion increment deflagration fracturing method. The method includes the following steps that perforation is carried out; expansion is carried out; a plug is arranged, specifically, the plug with a blocking function is arranged in the portion, located under the bottom boundary of a perforation well section and above the bottom boundary of a reservoir well section, ofa shaft, the plug blocks and isolates the portion, below the plug, of the shaft and the portion, above the plug, of the shaft, and the plug forms a bottom block; a pressure block is arranged, specifically, a fluid section plug is arranged in the portion, above the bottom block, of the shaft, so that the pressure block with pressurizing and buffering effects is formed; a deflagration fracturing device is arranged, specifically, the deflagration fracturing device connected to the lower end of an oil pipe or a cable is separated from a releasing sub of the oil pipe or the cable, and the deflagration fracturing device independently sits on the upper end face of the bottom block; and the deflagration fracturing device is stimulated and deflagrated, so that expansion increment deflagration fracturing of the reservoir well section is completed. The method can greatly expand the working volume of deflagration fracturing at the near-wellbore region of a reservoir; the limitation of chemical dose for deflagration fracturing is eliminated or reduced, so that the chemical dose for deflagration fracturing is increased; and damage of deflagration fracturing to the shaft or the oil pipe or the cable is lowered or avoided.

Owner:肖毅 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com