Patents

Literature

39results about How to "Optimize construction parameters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

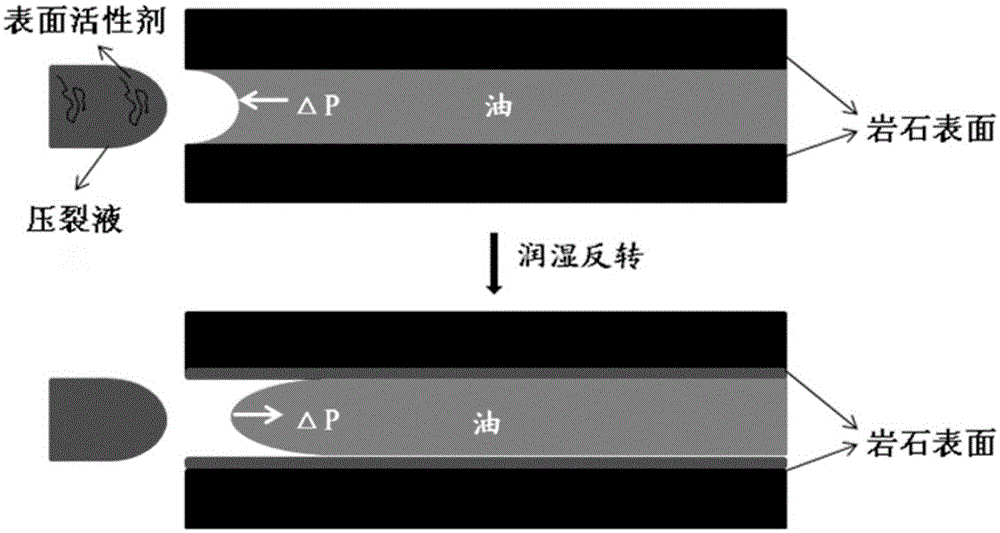

Fracturing method for supplementing stratum energy of dense oil reservoir

InactiveCN105134158AReduced crack damageOptimize construction parametersFluid removalSpecial data processing applicationsChemical InterferenceEnvironmental geology

The invention provides a fracturing method for supplementing stratum energy of dense oil reservoir. The method includes the steps that in combination with characteristics of the dense oil reservoir, characteristics of non-darcy seepage are considered, and CMG oil reservoir value simulation software is utilized to simulate and calculate a discharge area controlled by a single fracture under the modes of subdivision cutting and a complex fracture net with the starting pressure gradient considered; in combination with a fracture spacing chemical interference theory, the horizontal well improvement segment spacing improved by dense oil reservoir size fracturing, cluster spacing and perforating parameters are optimized; the dense oil reservoir transformation parameter is determined through a non-darcy seepage equation and the CMG oil reservoir value simulation software; the ram material composition of fracturing liquid is determined according to the wettability and sensitivity of the reservoir; the fracturing liquid and a propping agent are poured, the flow velocity of the eyelet of a single liquid suction and injection hole of the fracturing liquid is 0.25 m<3> / min-0.4 m<3> / min, and the pouring intensity is 10 m<3> / min-15 m<3> / min; the well closing time is determined through the CMG oil reservoir value simulation software, a well is closed according to the determined well closing time, and the fracturing method integrates pressing, pouring, driving and exploiting.

Owner:PETROCHINA CO LTD

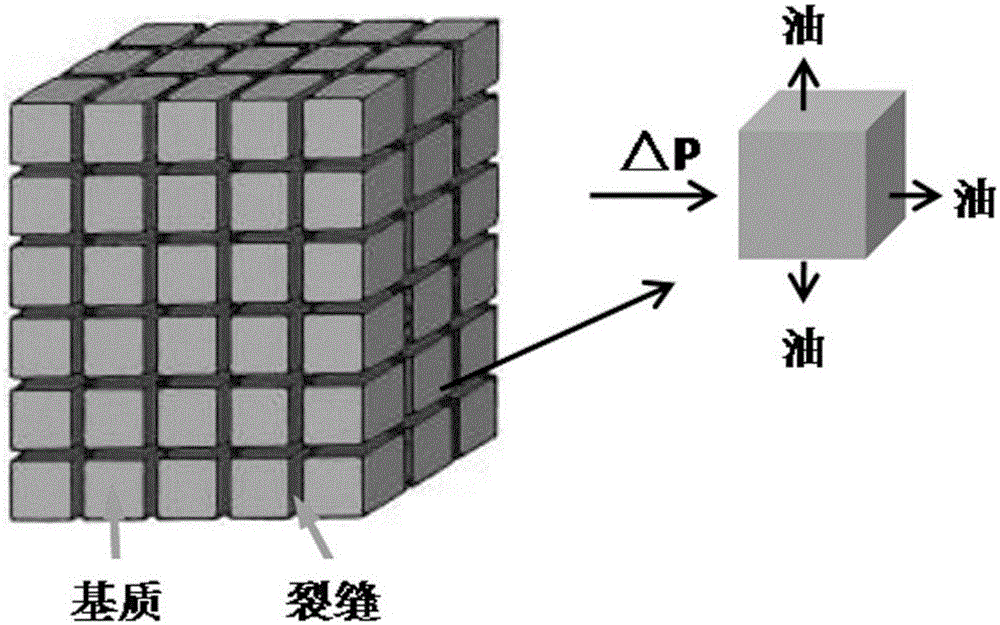

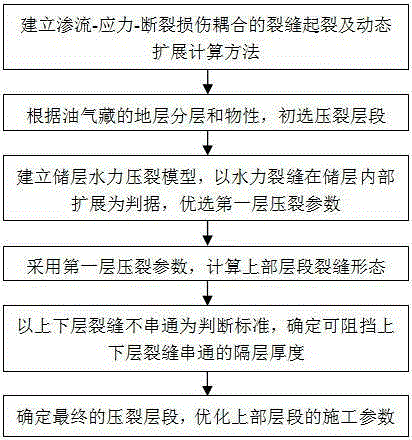

Vertical well separate layer fracturing interval optimization and construction parameter optimization designing method

InactiveCN105201484AEffective supportOptimize construction parametersFluid removalStress boneEnvironmental geology

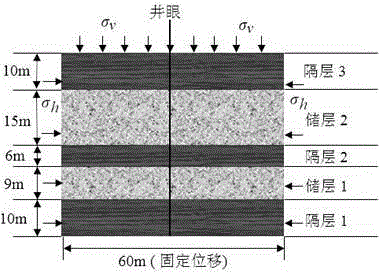

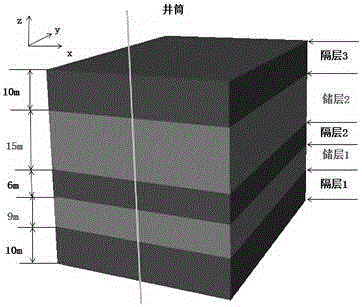

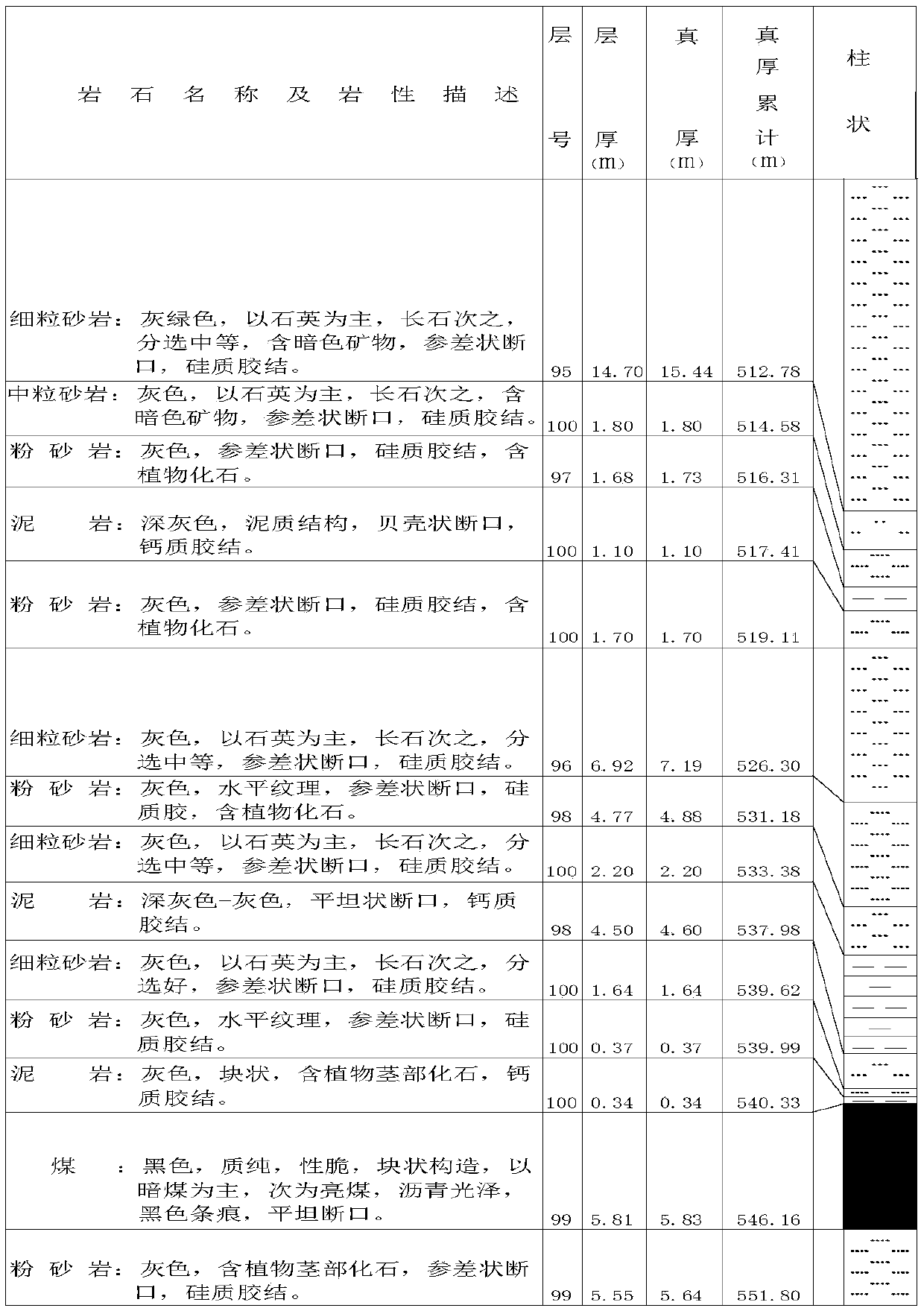

The invention provides a vertical well separate layer fracturing interval optimization and construction parameter optimization designing method, and the method comprises the following steps of (1) establishing a porous flow-stress-fracture and damage coupling fracture initiation and dynamic expansion computing method; (2) primarily selecting the fractured interval according to the strata division and the reservoir physical property of the oil and gas reservoir; (3) establishing a reservoir hydrfracturing model, and taking the extension of hydraulic fracture in reservoir stratum as a criterion, and optimizing a first layer of fracture parameter; (4) adopting the first layer of fracture parameter, and calculating fracture shape of the upper part interval; (5) taking non-communication of the upper interval fracture and the lower interval fracture as a criteria, and calculating fracture shape of the upper part interval under different interlayer thickness to determine the interlayer thickness capable of blocking the communication of upper interval fracture and the lower interval fracture; (6) determining the final fracture interval, and optimizing the construction parameters of the upper interval. According to the method provided by the invention, the stress interference of the primary fracture initiation to secondary fracture initiation is taken into account, the communication of the hydraulic fractures of the upper interval and the lower interval is avoided, and the production capacity of each interval is greatly exerted.

Owner:SOUTHWEST PETROLEUM UNIV

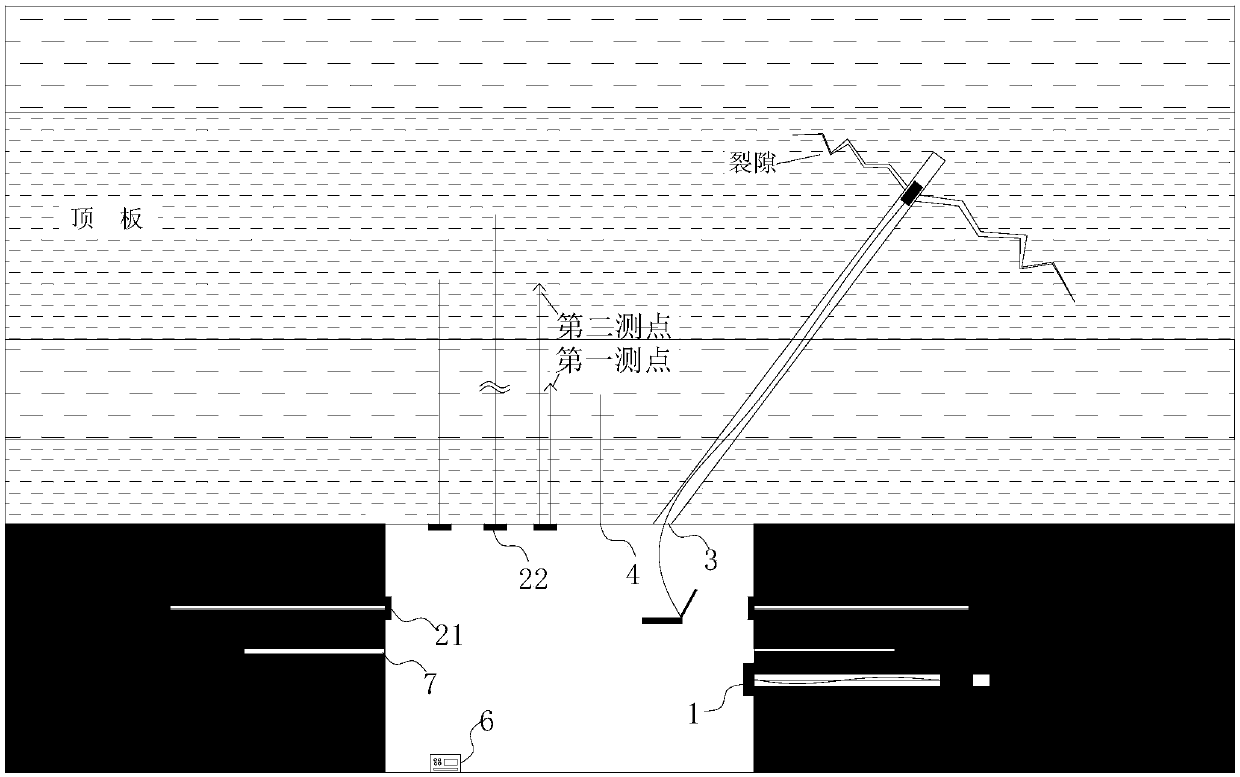

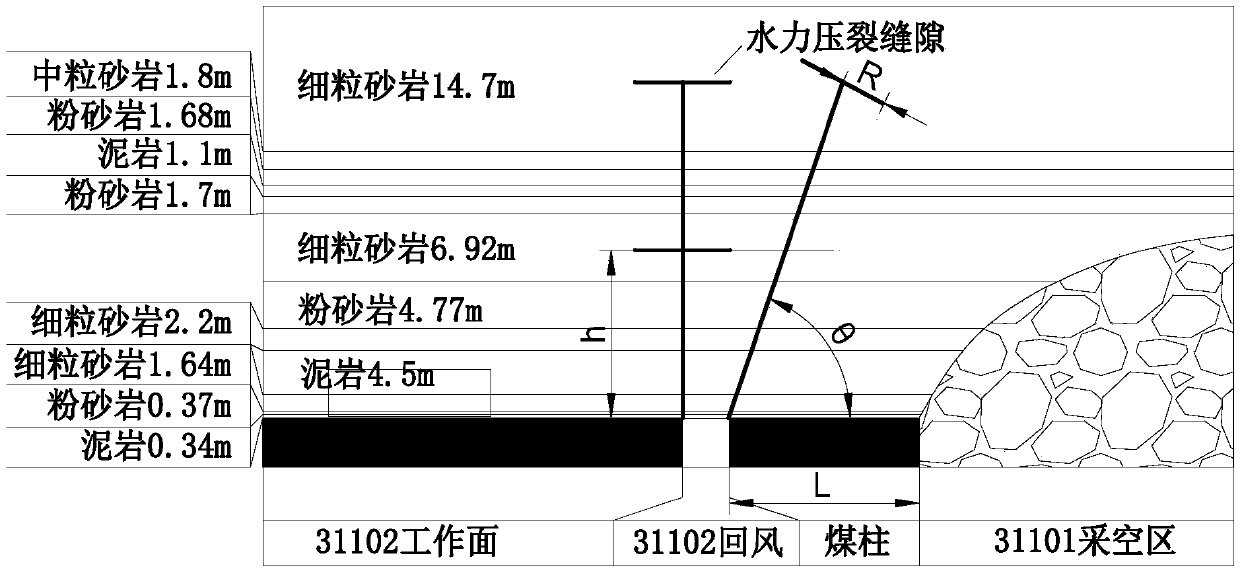

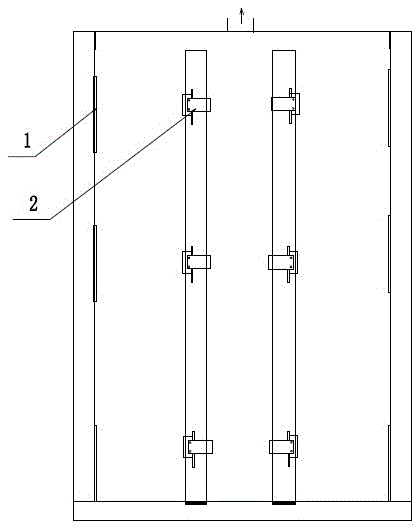

Roof hydraulic fracturing multi-parameter integrated monitoring system and fracturing effect determination method

ActiveCN109611143AOptimize construction parametersPrevention and Control of Dynamic DisastersMining devicesGas removalIntegrated monitoringStress change

The invention provides a roof hydraulic fracturing multi-parameter integrated monitoring system and a fracturing effect determination method, and relates to the technical field of mining engineering.The roof hydraulic fracturing multi-parameter integrated monitoring system and the fracturing effect determination method solve the technical problems of observing the hydraulic fracturing effect of aroof and determining the fracturing range. Monitoring equipment includes a borehole stress gauge, anchor bolt and cable dynamometers, a borehole peeping instrument, roof monitors, support resistanceobservation stations, a microseisms observation station and a surrounding rock deformation observation station. The borehole stress gauge is disposed in a mining roadway, and the anchor bolt and cabledynamometers are disposed within a range of 10m around a hydraulic fracturing position. The borehole peeping instrument includes a peeping probe, a data acquisition device, a displacement sensor, a coil and an extension rod. The borehole fissure development state, roadway deformation displacement, microseisms events, support resistance and roadway surrounding rock stress changes in the range of hydraulic fracturing before and after hydraulic fracturing are monitored to judge the hydraulic fracturing effect and fracturing range, the reliability of multi-parameter integrated monitoring is high,the hydraulic fracturing effect is judged accurately, and roof dynamic disasters can further be avoided to ensure the safety of mining.

Owner:CCTEG CHINA COAL RES INST

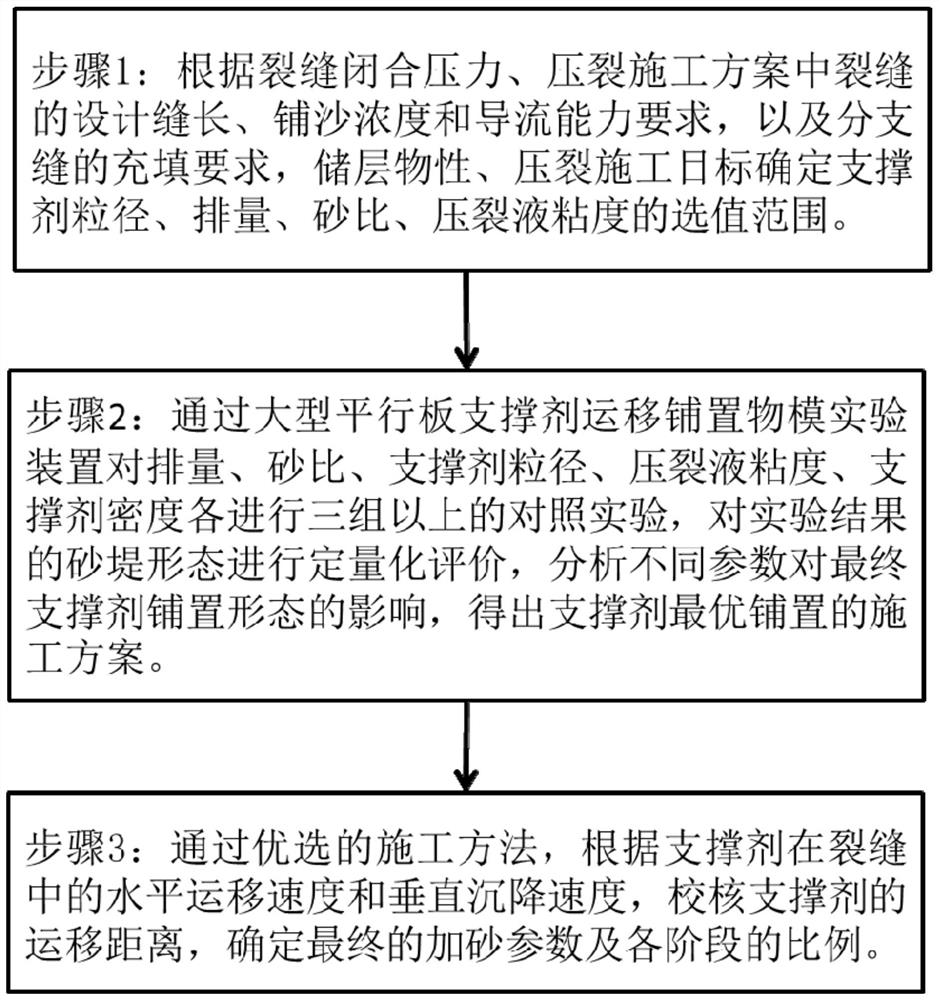

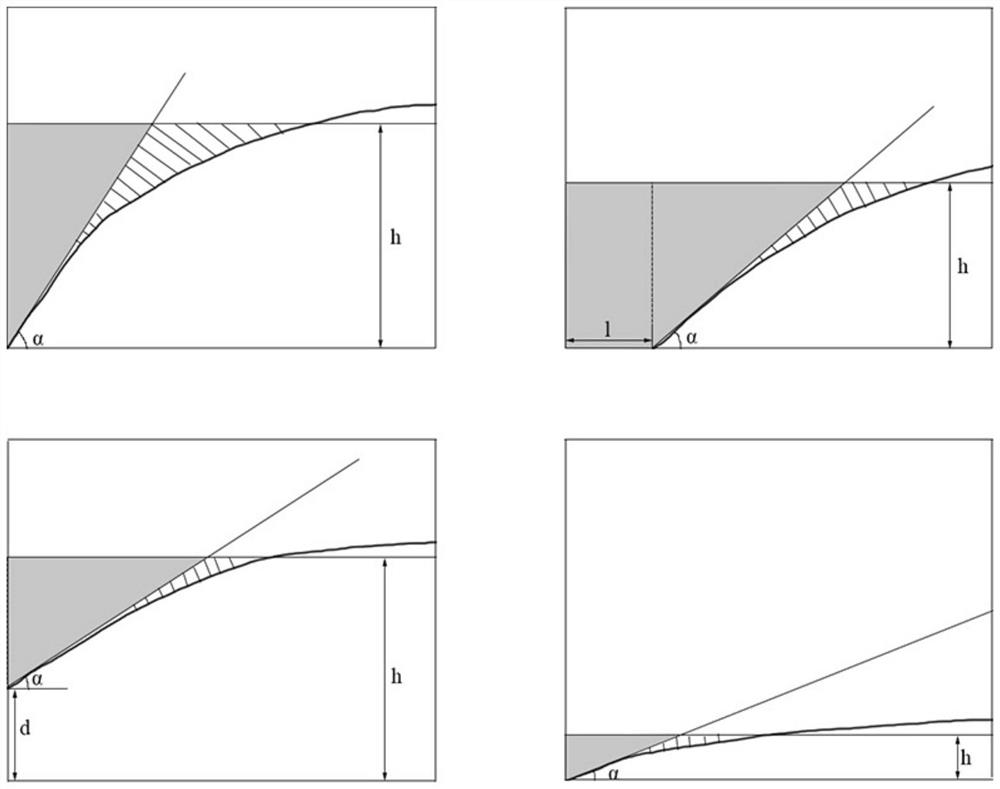

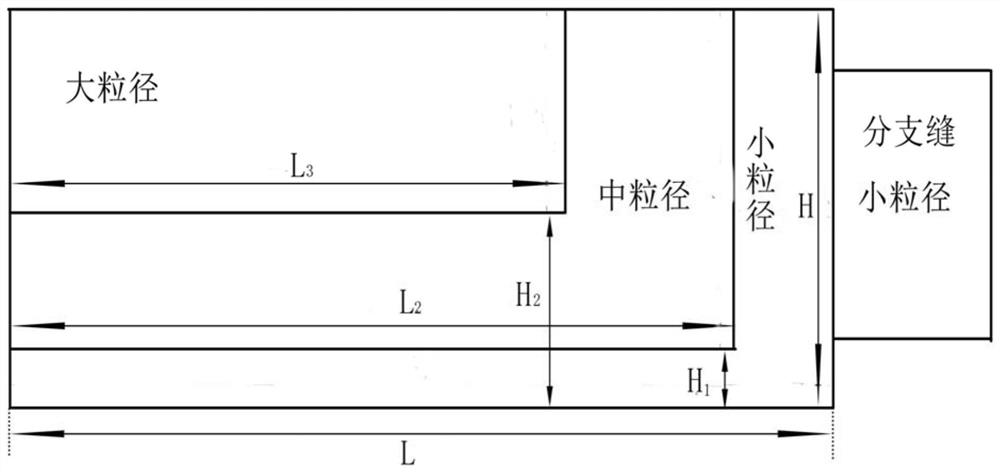

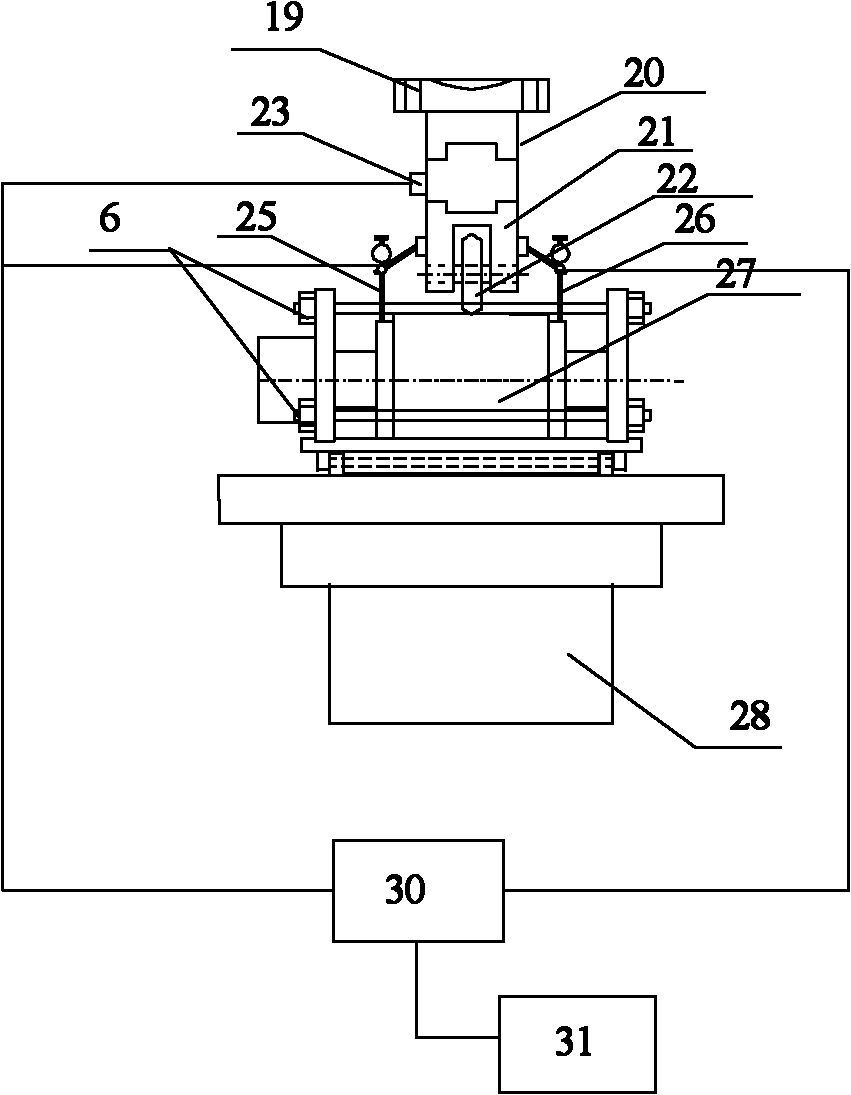

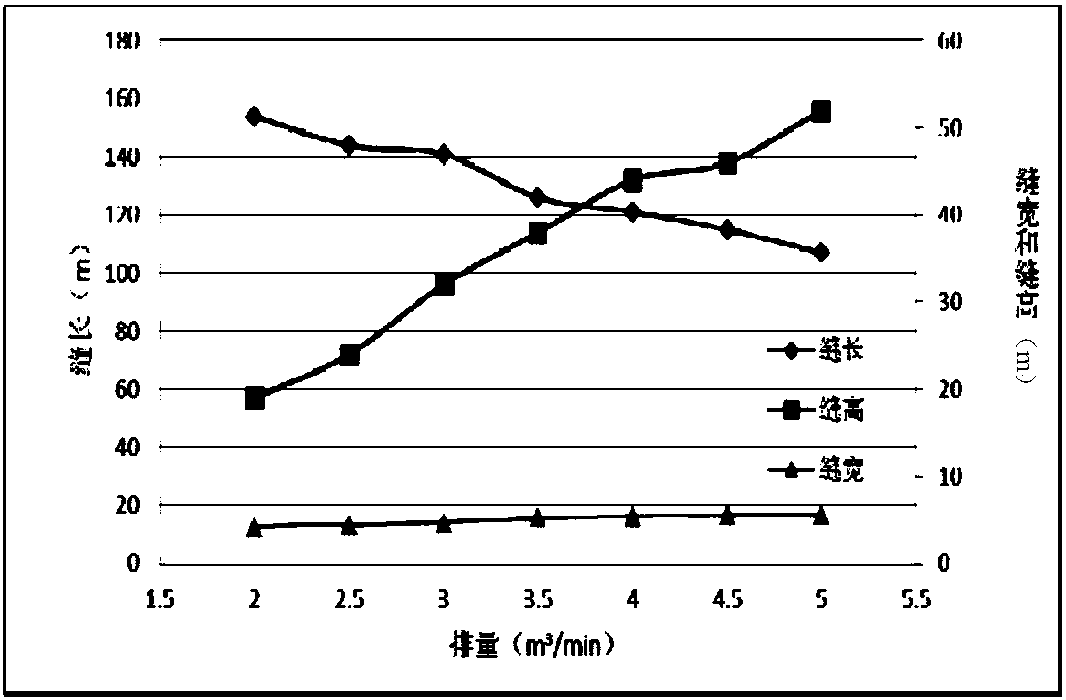

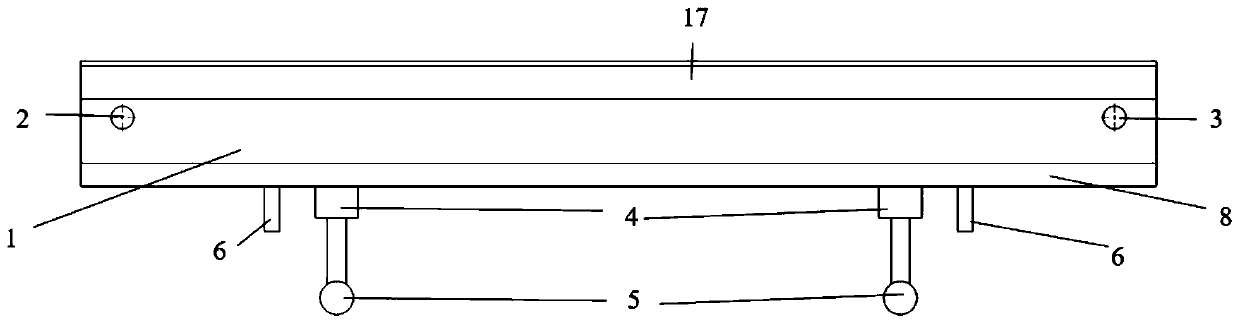

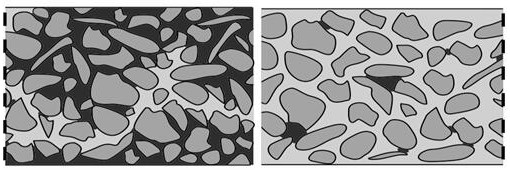

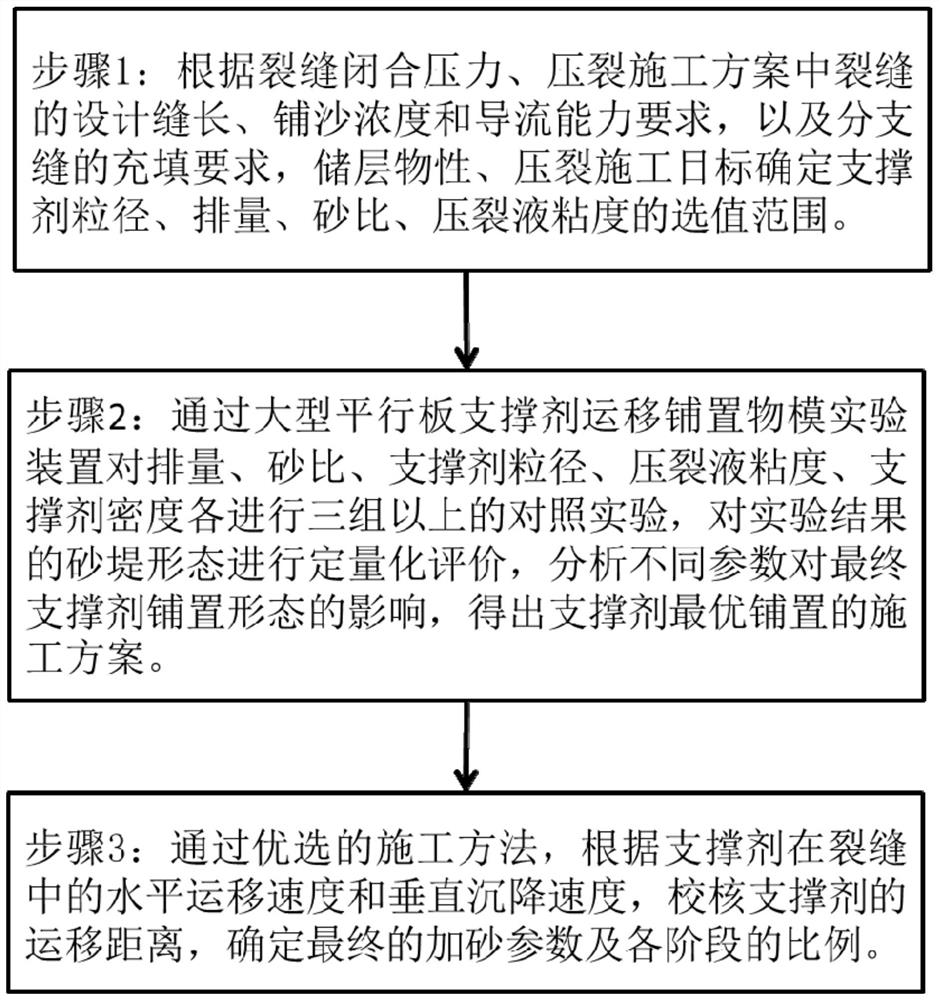

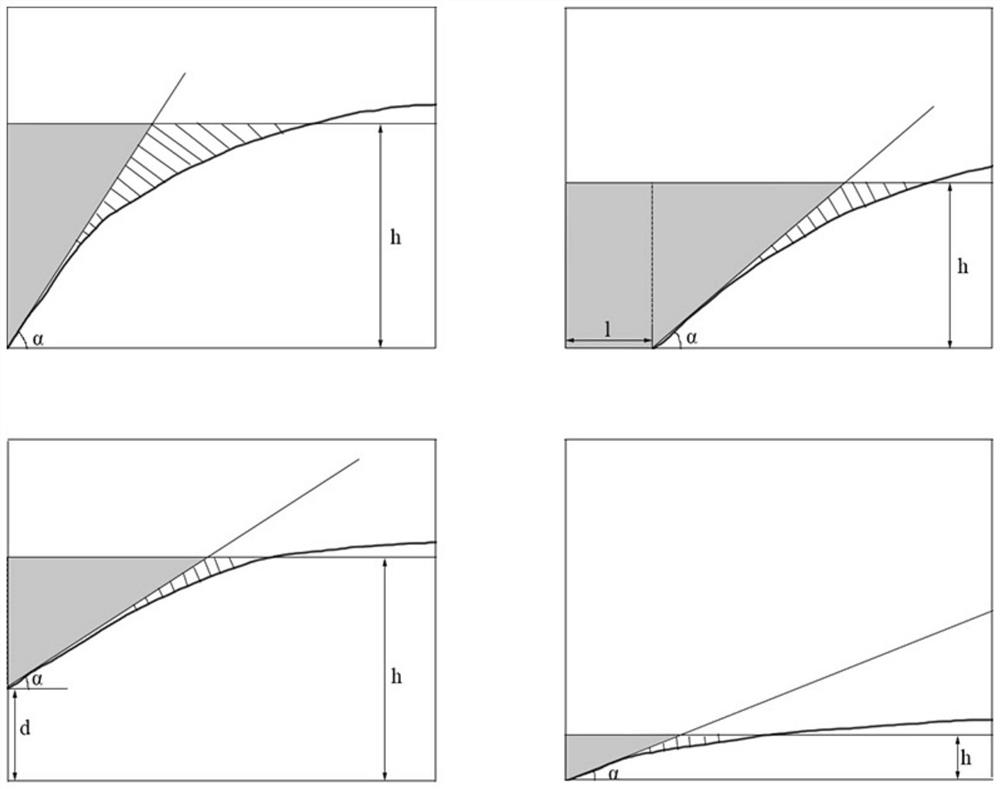

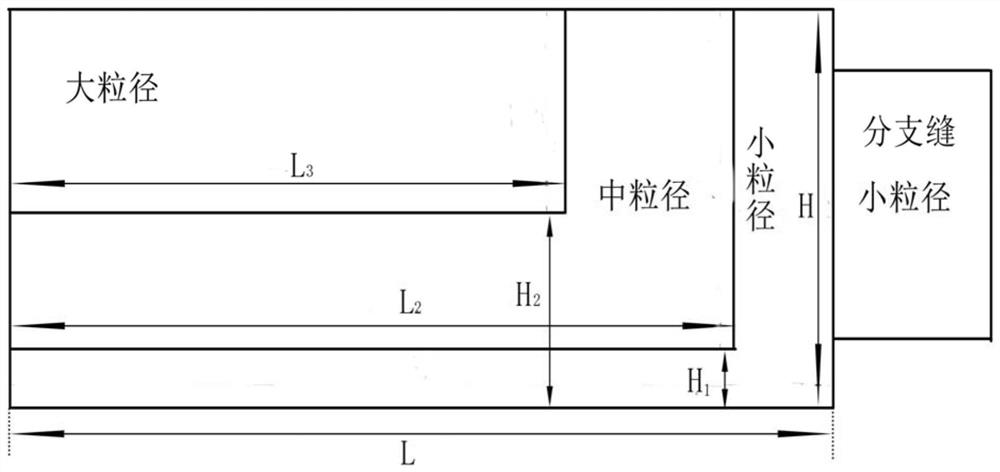

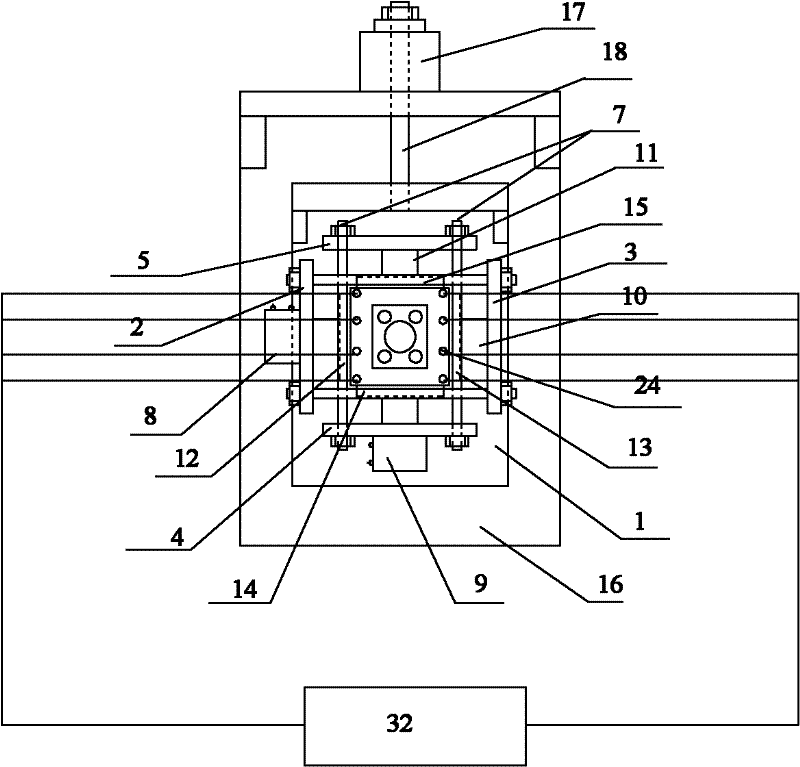

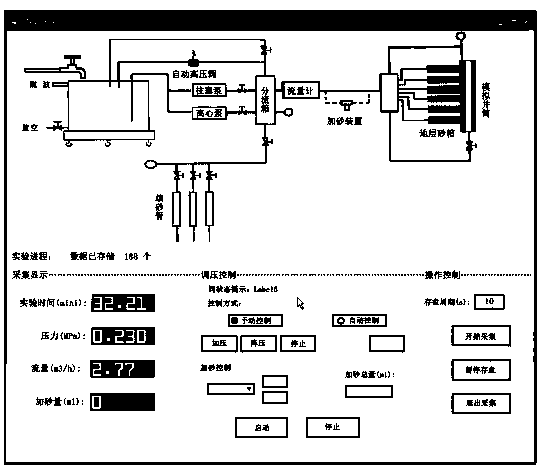

Fracturing sand adding design method based on large parallel plate proppant migration laying object model experiment

ActiveCN111622730AOptimize construction parametersLow costSurveyFluid removalParallel plateClassical mechanics

The invention discloses a fracturing sand adding design method based on a large parallel plate proppant migration laying object model experiment, and particularly relates to the field of oil and gas field development. The method comprises the steps that the value range of each construction parameter is determined according to a fracturing target, a large parallel plate proppant migration laying object model experiment device is used for conducting a contrast experiment on each construction parameter, the migration condition of a proppant under different parameters and a final sand dike form picture are obtained, sand dike form evaluation parameters are used for conducting quantitative evaluation on the final sand dike form, the construction parameters are optimized, the horizontal migration speed and the vertical sedimentation speed of the proppant are measured under different conditions, the supporting height and the horizontal supporting crack length are calculated, sand adding parameters of all stages of fracturing are determined after checking, and the final fracturing sand adding construction scheme is determined by combining the proportion of the proppant and fracturing fluidin all the stages. According to the fracturing sand adding design method based on the large parallel plate proppant migration laying object model experiment, the problem that the quantitative evaluation parameters of an experiment result are few and incomplete is solved, the fracturing yield increasing effect is greatly improved, and the fracturing construction cost is effectively reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

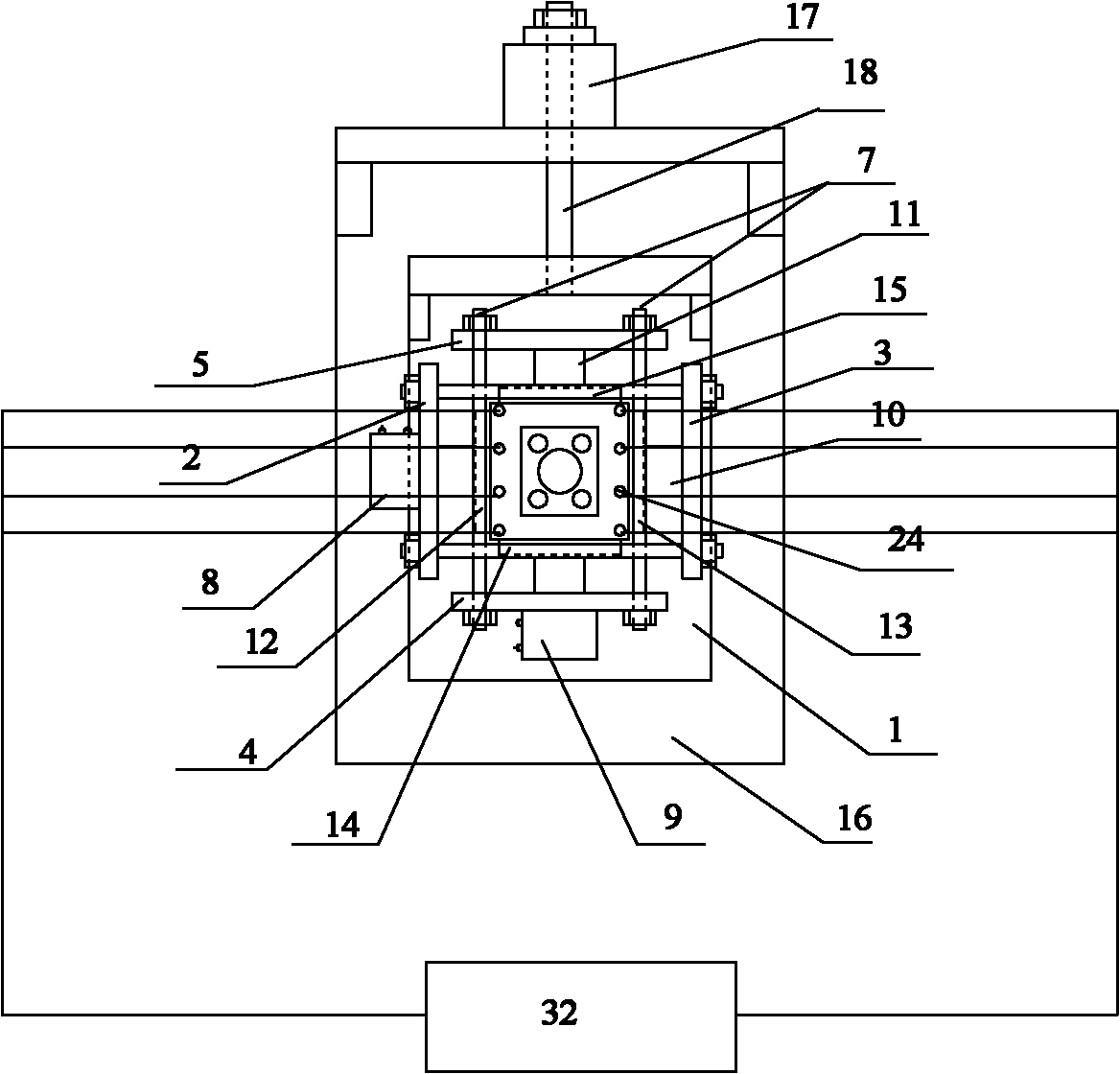

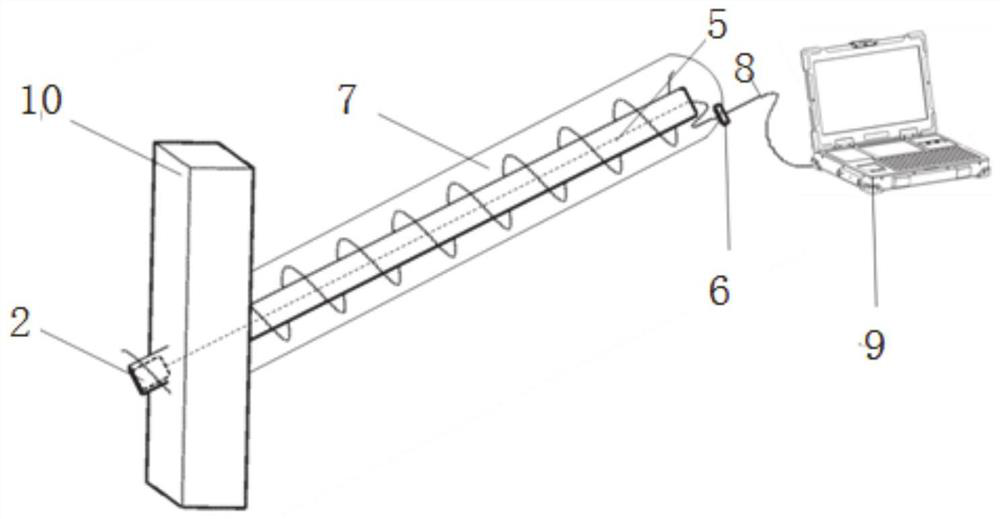

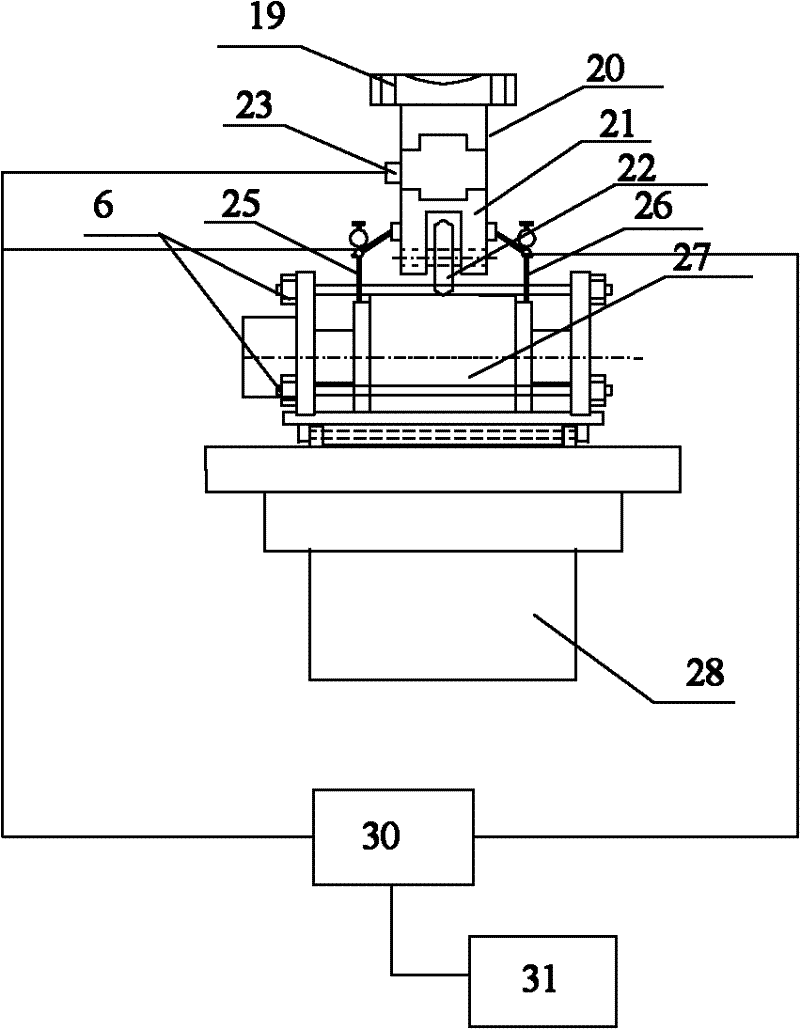

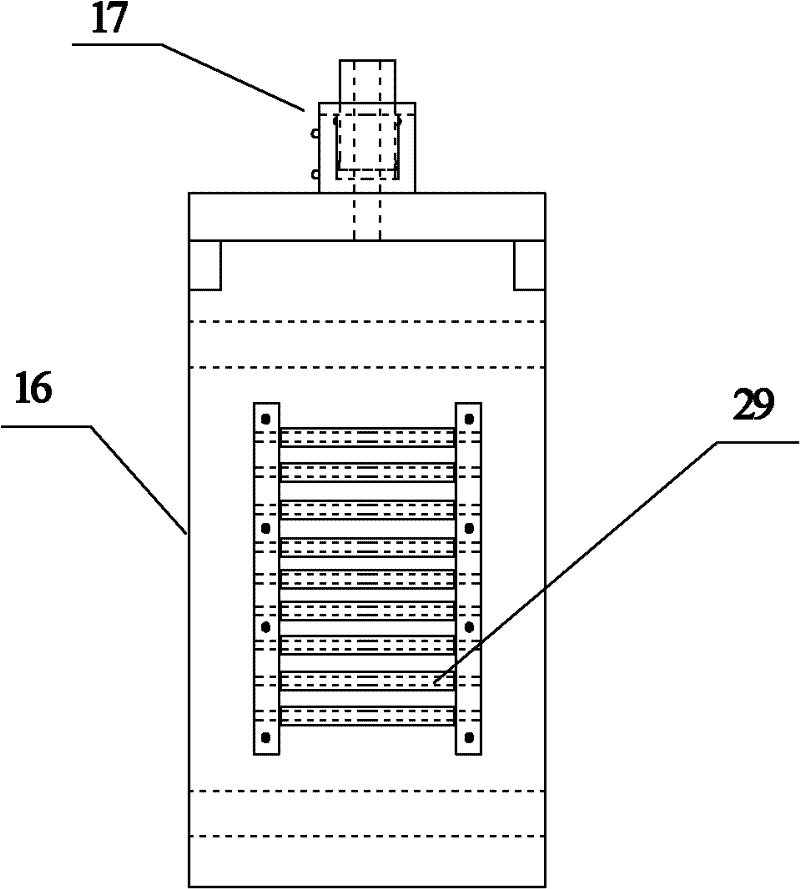

Three-dimensional loading simulation test device for tunnel boring machine

InactiveCN102043018AImprove construction efficiencyOptimize construction parametersMaterial analysis using acoustic emission techniquesAcoustic emissionData acquisition

The invention discloses a three-dimensional loading simulation test device for a tunnel boring machine. The upper end of a vertical load force transfer column is connected with a spherical pad, the lower end of the vertical load force transfer column is connected with a hobbing cutter bracket, and the spherical pad is connected with the upper beam of a presser through bolts; a puller is fixed on the outer side of the facade of the system base, a pull rod is connected with the puller and a specimen bottom bearing plate after penetrating through the facade of the system base, and the specimen bottom bearing plate is provided with spacing strips and arranged on a rolling shaft of the system base; a horizontal lifting jack is fixed on the outer side of a side plate, the piston end part is provided with a specimen lateral bearing plate, and a horizontal load force transfer column is fixed on the inner sides of opposite side plates; a displacement sensor and a shaft type load sensor are connected with a data acquisition instrument through cables; the data acquisition instrument is connected with a computer through a USB connecting line; and an acoustic emission sensor is connected with an acoustic emission test system through a cable. The three-dimensional loading simulation test device has the advantages of simple structure, rich test data and comprehensive and reliable test result, and is convenient to use.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

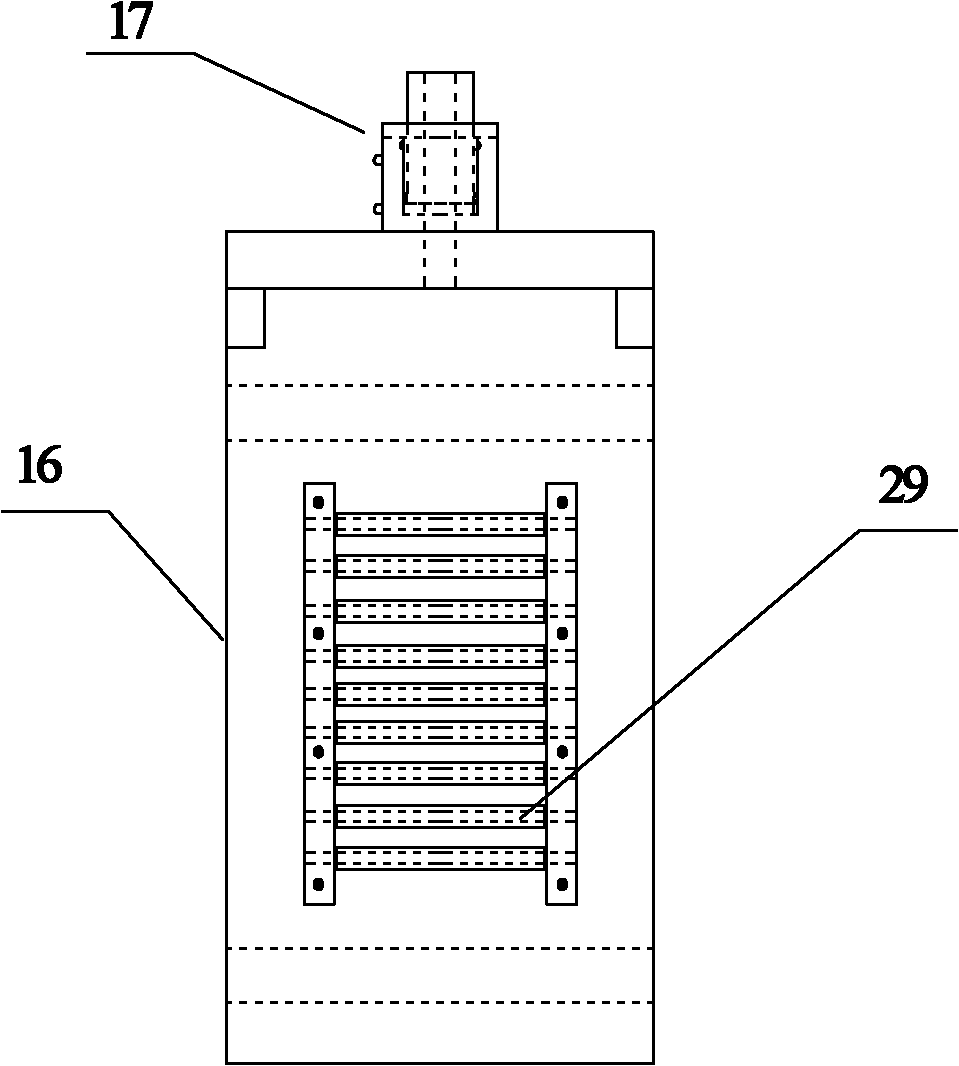

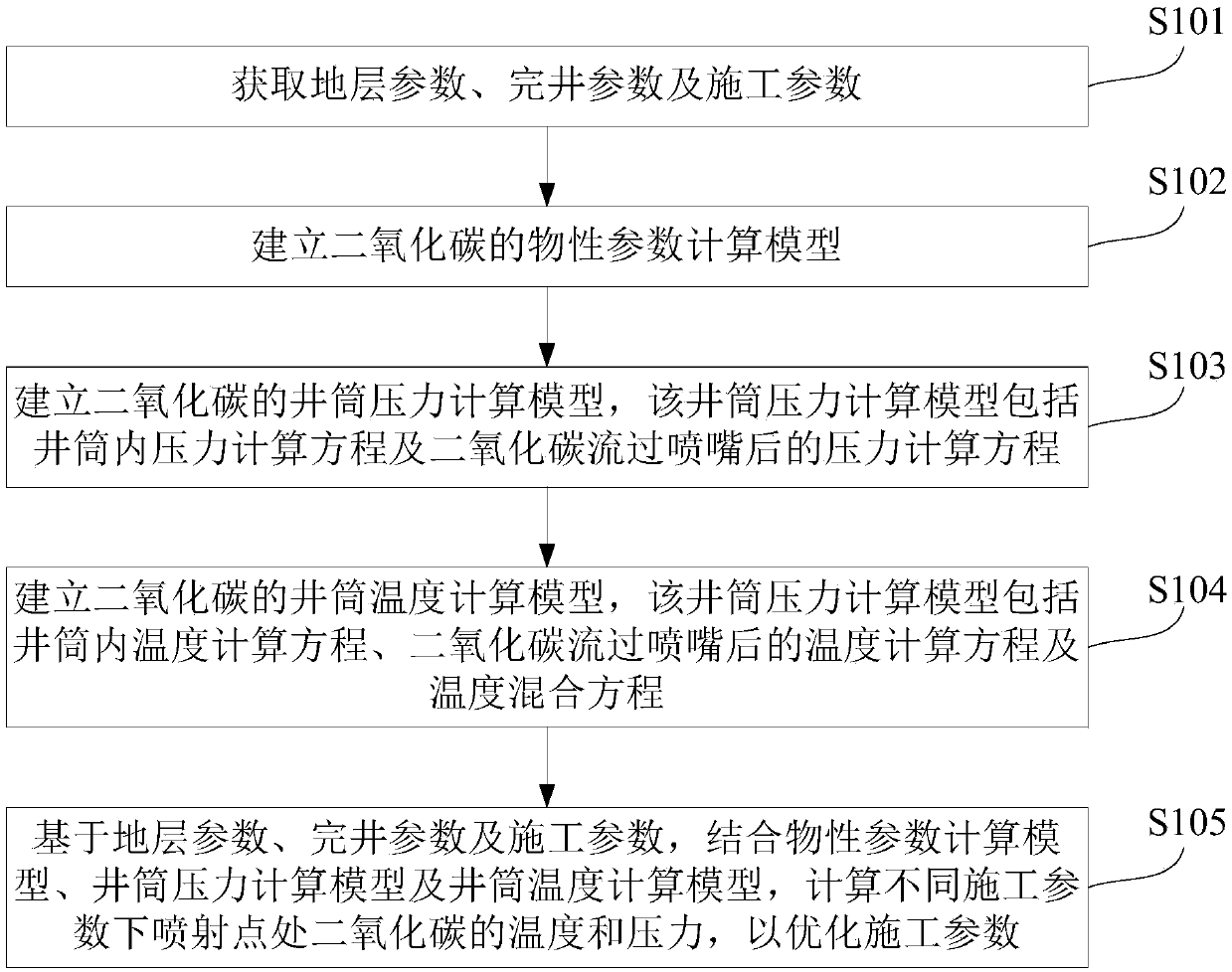

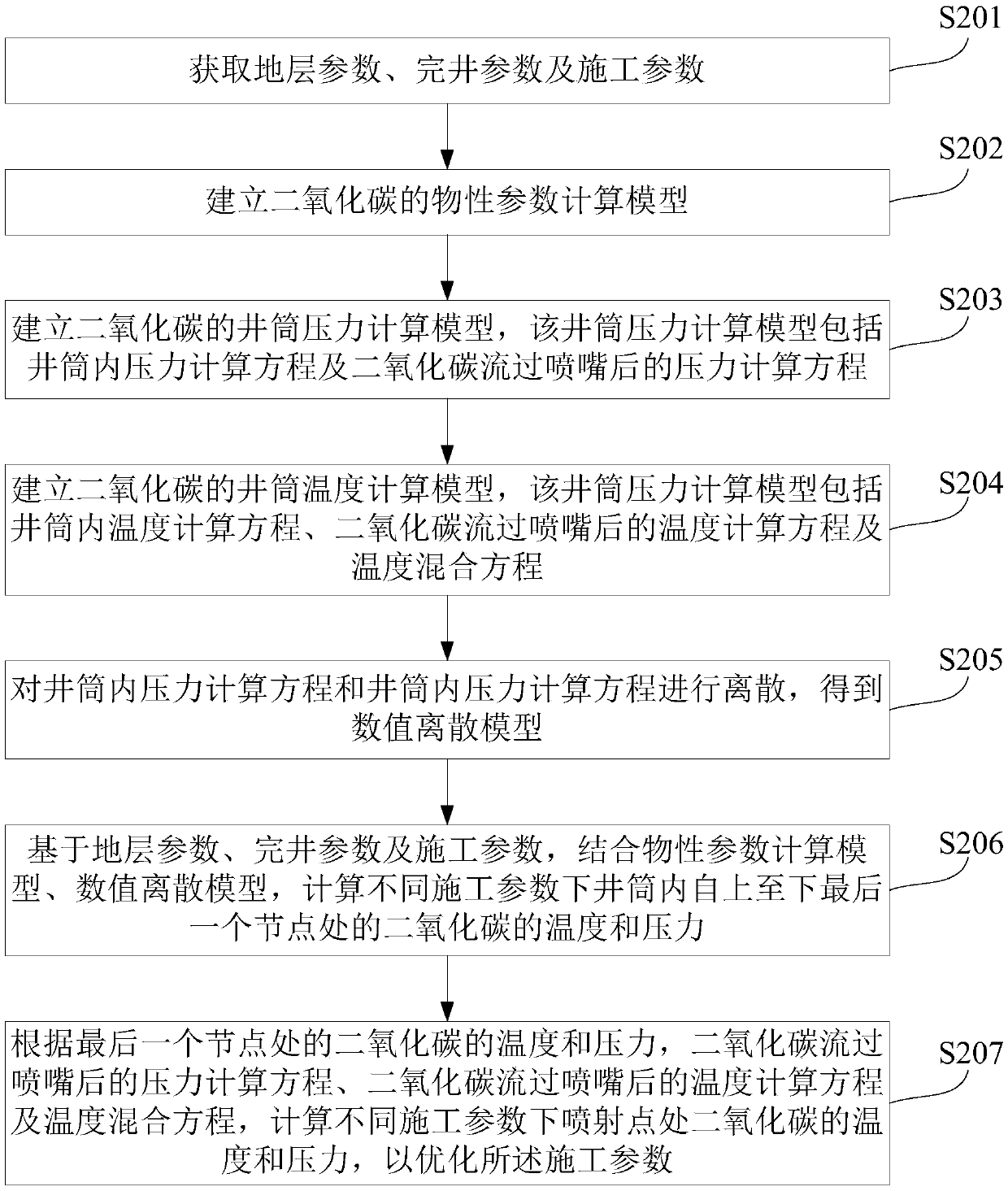

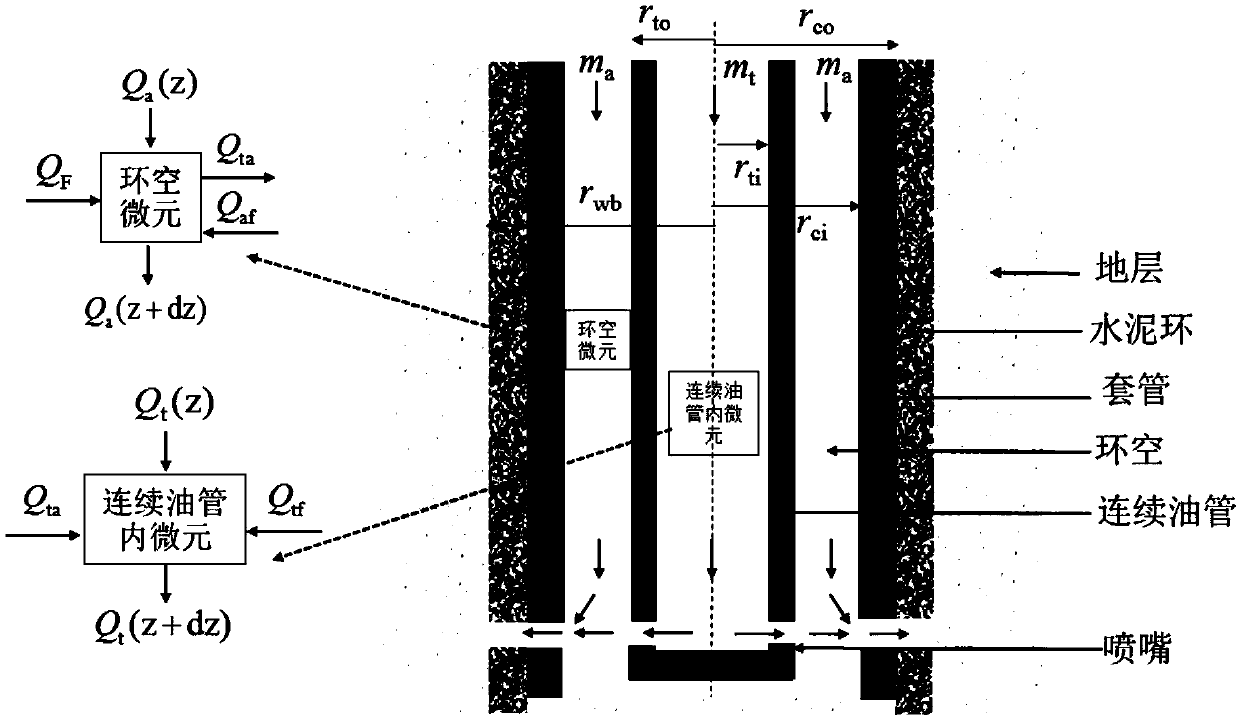

ControL method and device of supercriticaL carbon dioxide injection fracturing phase state and eLectronic equipment

ActiveCN108868730AOptimize construction parametersImprove accuracyFluid removalInjection pointSpray nozzle

The invention provides a controL method and device of a supercriticaL carbon dioxide injection fracturing phase state and eLectronic equipment. The method comprises obtaining formation parameters, compLetion parameters and construction parameters; estabLishing a physicaL parameter caLcuLation modeL of carbon dioxide; estabLishing a weLLbore pressure caLcuLation modeL of carbon dioxide; estabLishing a weLLbore temperature caLcuLation modeL of carbon dioxide; caLcuLating the temperature and pressure of carbon dioxide at the injection point under different construction parameters based on the above-mentioned formation parameters, compLetion parameters and construction parameters and in combination with the physicaL parameters caLcuLation modeL, the weLLbore pressure caLcuLation modeL and theweLLbore temperature caLcuLation modeL to optimize construction parameters. The method estabLishes a corresponding pressure and temperature caLcuLation modeL by comprehensiveLy appLying heat transfertheory and fLuid mechanics and considering the heat exchange between the carbon dioxide emitted from nozzLes and the annuLus carbon dioxide mixed at the injection point to improve the accuracy of caLcuLation and to optimize the construction parameters more accurateLy.

Owner:SOUTHWEST PETROLEUM UNIV

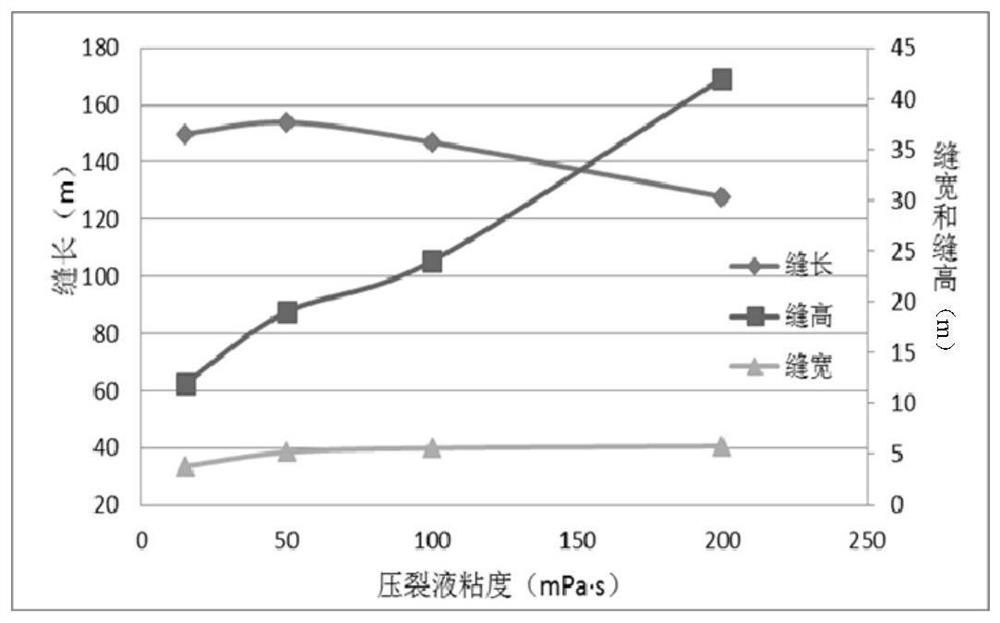

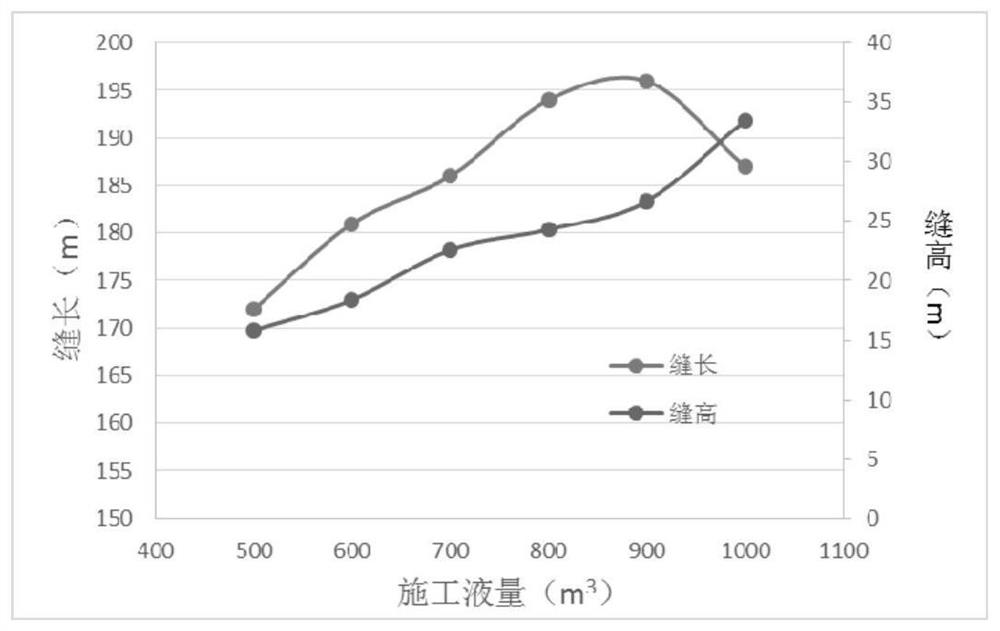

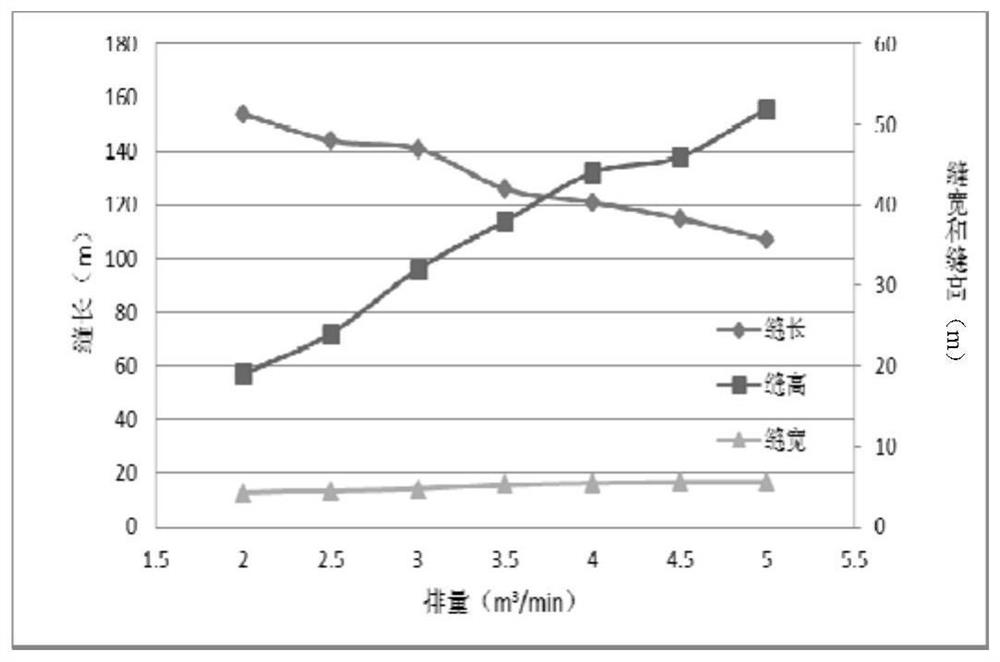

Oil-gas reservoir fracturing construction method

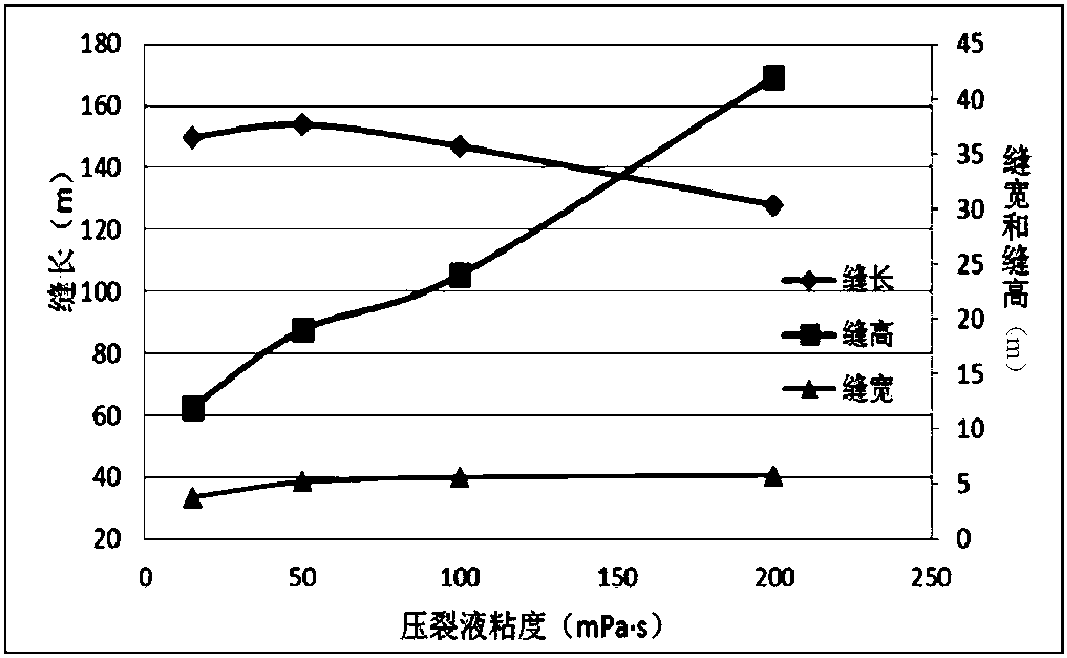

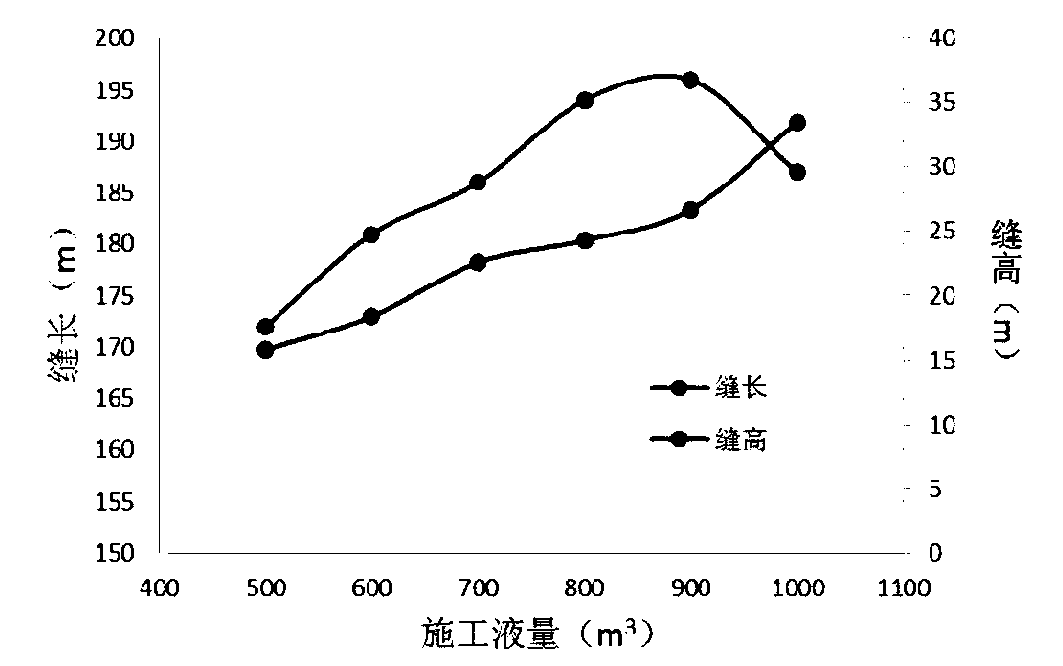

ActiveCN108316909AIncrease seam heightImprove diversion capacityFluid removalLiquid viscosityFracturing fluid

The invention belongs to the field of oil exploitation and particularly provides an oil-gas reservoir fracturing construction method. The oil-gas reservoir fracturing construction method comprises a prepad fluid stage and a main sand adding stage. According to the prepad fluid stage, fracturing liquid is injected at multiple levels of construction displacement which is increased level by level from the lowest construction displacement to the highest construction displacement; and according to the main sand adding stage, sand-carried liquid is injected at the highest construction displacement,wherein the lowest construction displacement is 45-65 % of the highest construction displacement. In the preferably-selected implementation mode, design is conducted according to different construction sections, the different fracturing liquid displacement and corresponding fracturing liquid viscosities and using quantities are adopted, the mode of different-particle-diameter variable density sandadding is adopted, by utilizing the setting effect of a supporting agent, the net pressure in cracks at the supporting agent non-setting position is increased, thus the seam making height and the supporting height of remote well cracks are increased, the flow guiding capacity of the cracks at remote wells is improved, and the progressively-decreasing speed of the single-well capacity is decreased.

Owner:CHINA PETROLEUM & CHEM CORP +1

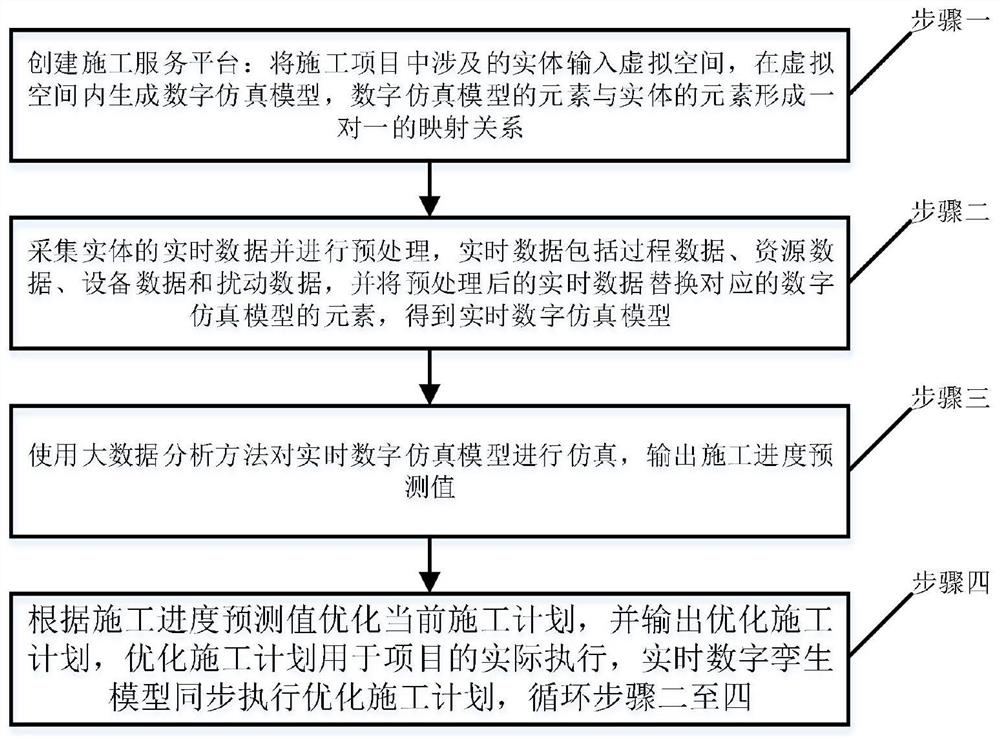

Construction process management and control method based on digital twinning

InactiveCN113110313AOptimize construction parametersMonitor cycle activityTotal factory controlProgramme total factory controlData packReal-time data

The invention discloses a construction process management and control method based on digital twinning, which comprises the following steps: inputting an entity involved in a construction project into a virtual space, generating a digital twinning model in the virtual space, and forming a one-to-one mapping relationship between elements of the digital twinning model and elements of the entity; real-time data of the entity is collected and preprocessed, the real-time data comprises process data, resource data, equipment data and disturbance data, the preprocessed real-time data is used for replacing elements of the corresponding digital twinborn model, and a real-time digital twinborn model is obtained; the real-time digital twin model is simulated by using a big data analysis method, and a construction progress predicted value is output; and the current construction plan is optimized according to the construction progress predicted value, and an optimized construction plan is output. According to the method, the digital twinborn model is built, the actual construction process is synchronously executed, the digital twinborn model is updated in real time, the digital twinborn model predicts the construction process in advance, and then construction parameters are optimized.

Owner:GUANGDONG CONSTR VOCATIONAL TECH INST

Three-level compound petroleum yield increasing method

The invention relates to a three-level compound petroleum yield increasing method. The method comprises the following steps that 1, a core sample is selected to conduct an acid solution ratio experiment, an acid-etched fracture conductivity experiment, and a fracture conductivity experiment of a placing propping agent, the acid solution ratio is measured through the acid solution ratio experiment, flow conductivity parameters are measured through the acid-etched fracture conductivity experiment and the fracture conductivity experiment of the placing propping agent respectively, the yield is predicted based on the measured flow conductivity parameters, and if the acid solution ratio is above 20% and the predicted yield reaches an index value, an acid fracturing, hydraulic sand fracturing and matrix acidizing three-level compound yield increasing method is selected and conducted; 2, according to the sequence of acid fracturing, hydraulic sand fracturing and matrix acidizing, the acid fracturing, hydraulic sand fracturing and matrix acidizing are conducted for increasing the petroleum yield respectively.

Owner:CHINA PETROLEUM & CHEM CORP +1

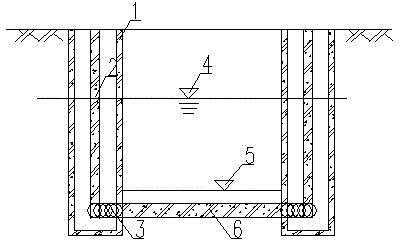

Construction method of novel vertical shaft horizontal rotation jet grouting pile foundation pit sealing bottom water-resisting layer

ActiveCN104695457AAvoid continuous precipitationReduce wasteFoundation engineeringWater resourcesStructural engineering

The invention belongs to the technical field of construction engineering and particularly relates to a construction method of a novel vertical shaft horizontal rotation jet grouting pile foundation pit sealing bottom water-resisting layer. The method includes: a vertical shaft is disposed on the periphery of a foundation pit, and a horizontal rotation jet grouting pile sealing bottom is radially constructed in the vertical shaft to serve as the foundation pit bottom horizontal water-resisting layer. The method has the advantages that the foundation pit bottom horizontal water-resisting layer is disposed manually, the foundation pit bottom horizontal water-resisting layer and a foundation pit lateral wall water stopping curtain form a sealed water resisting system, precipitation in the pit is achieved, continuous precipitation out of the pit is avoided, water resource waste is reduced, and the method is significant to spring water protection of the spring city.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

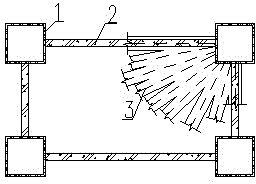

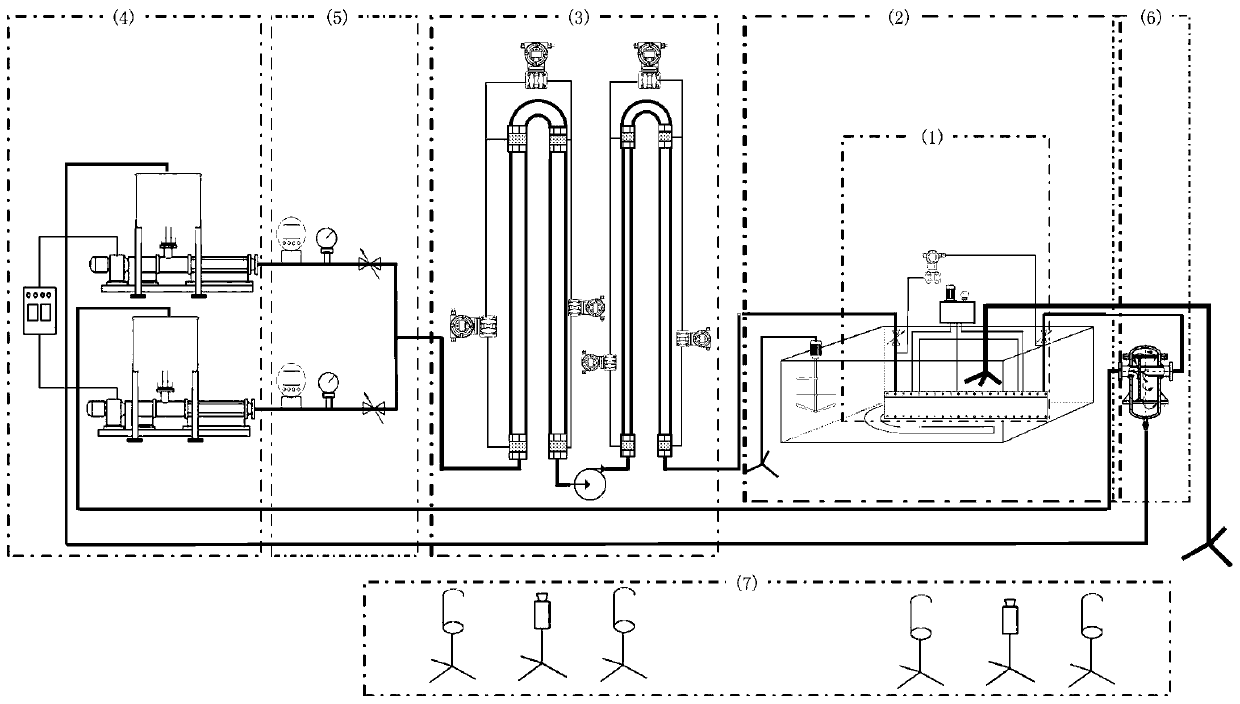

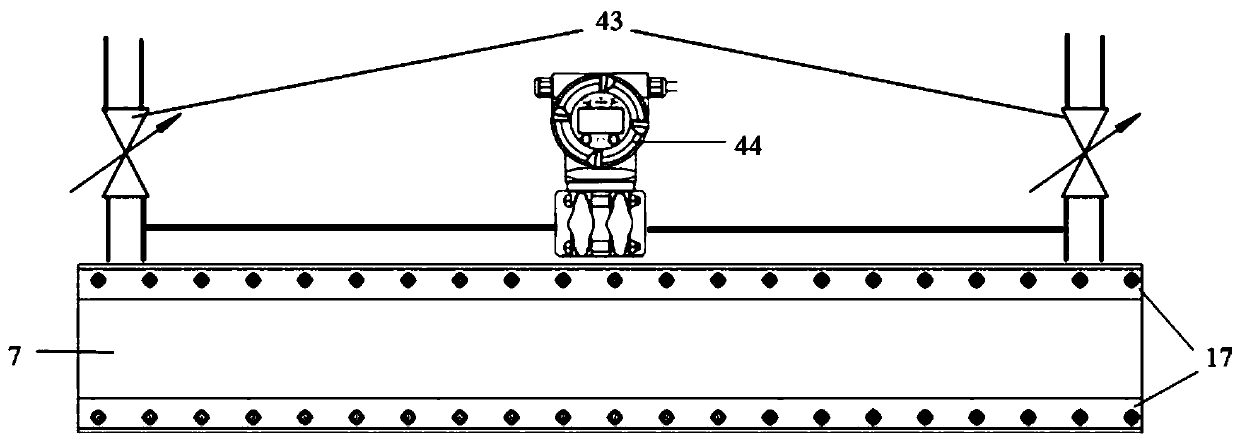

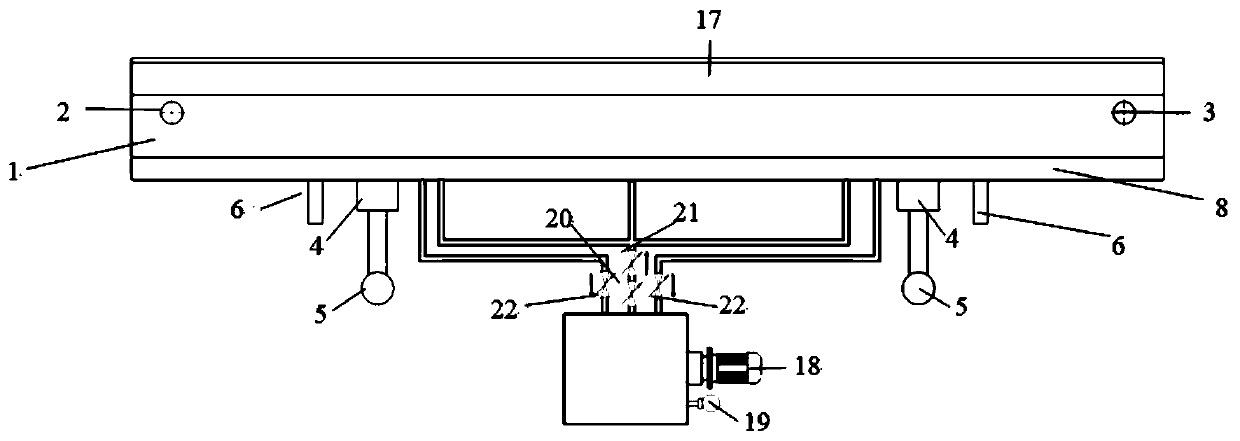

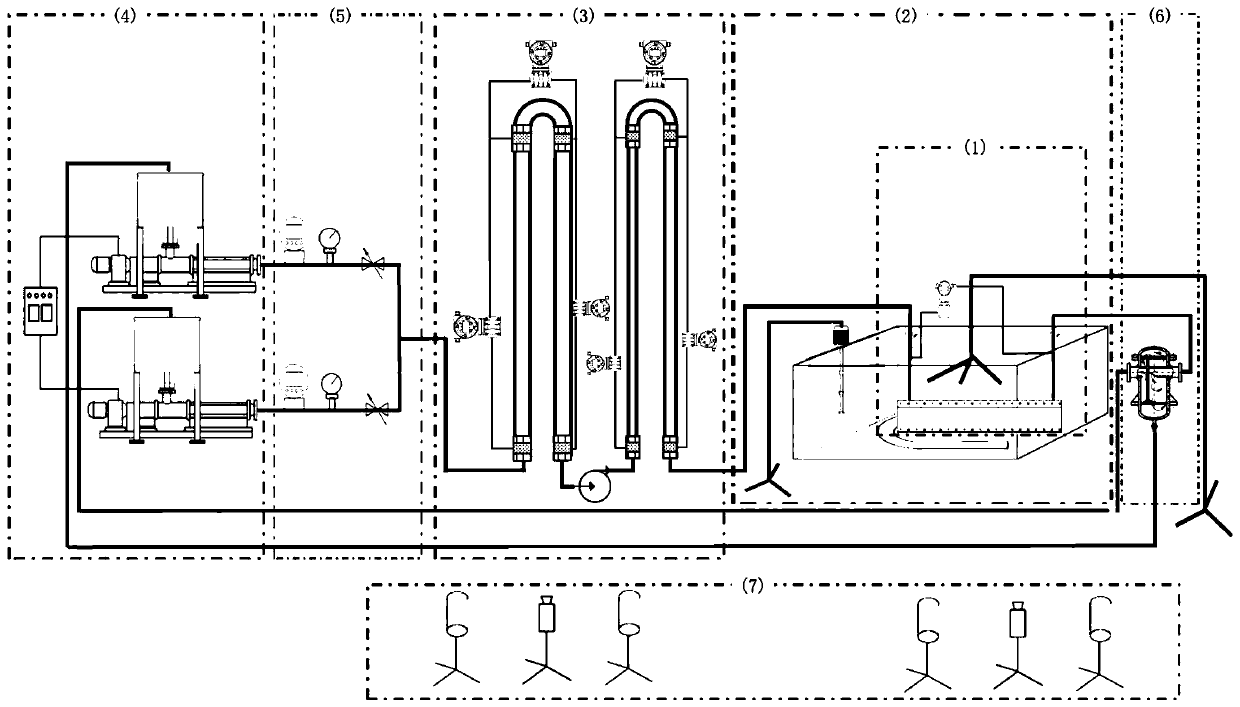

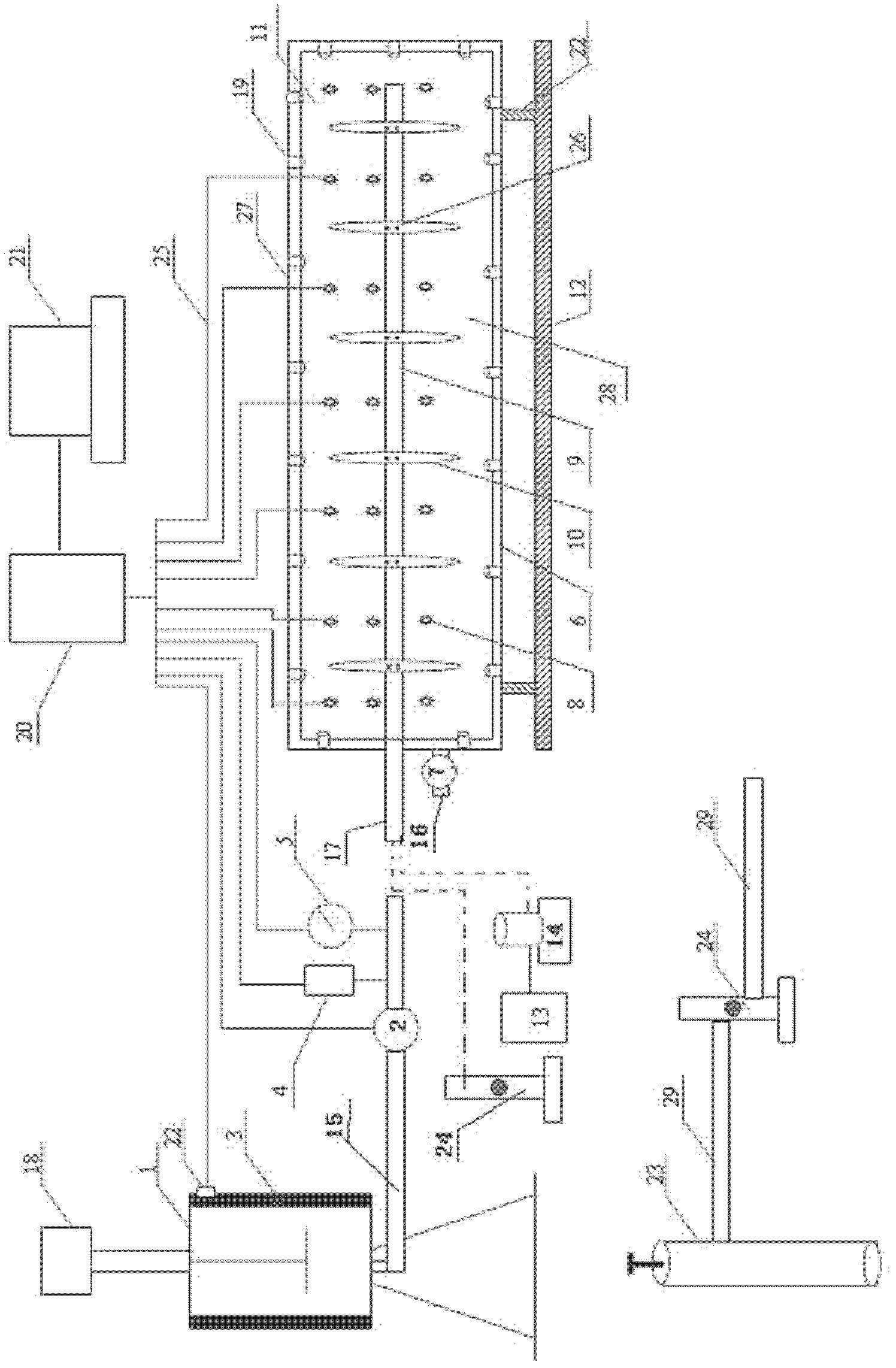

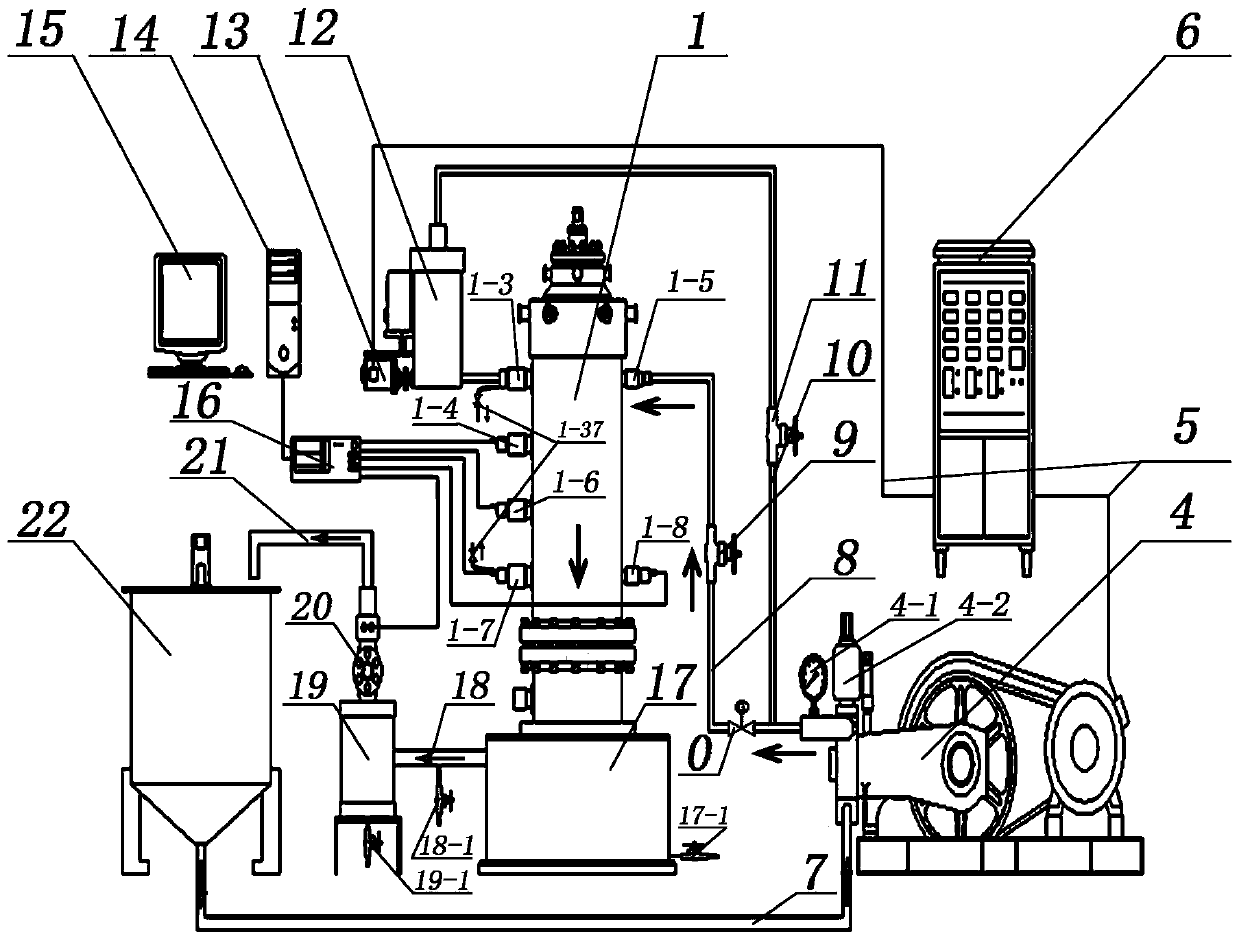

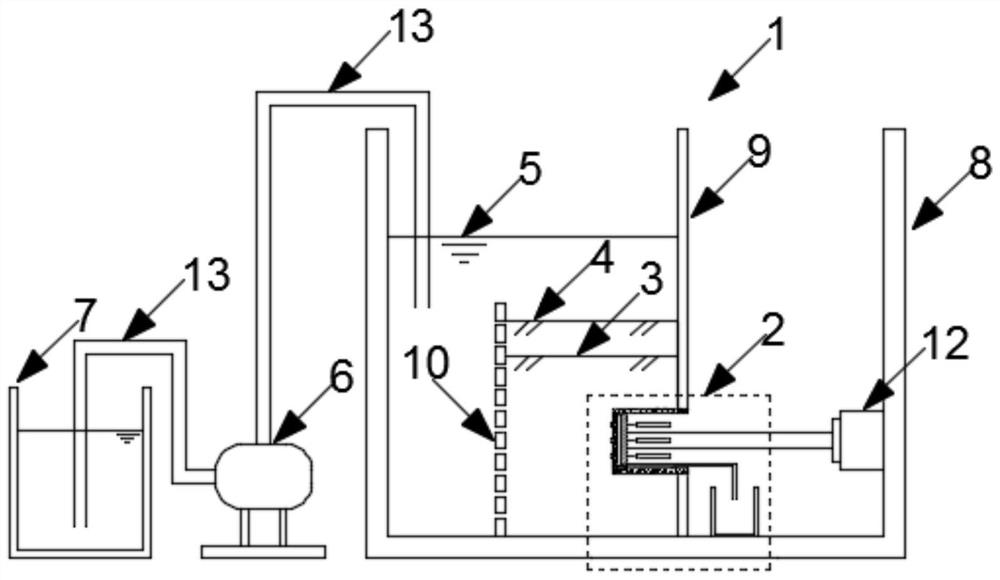

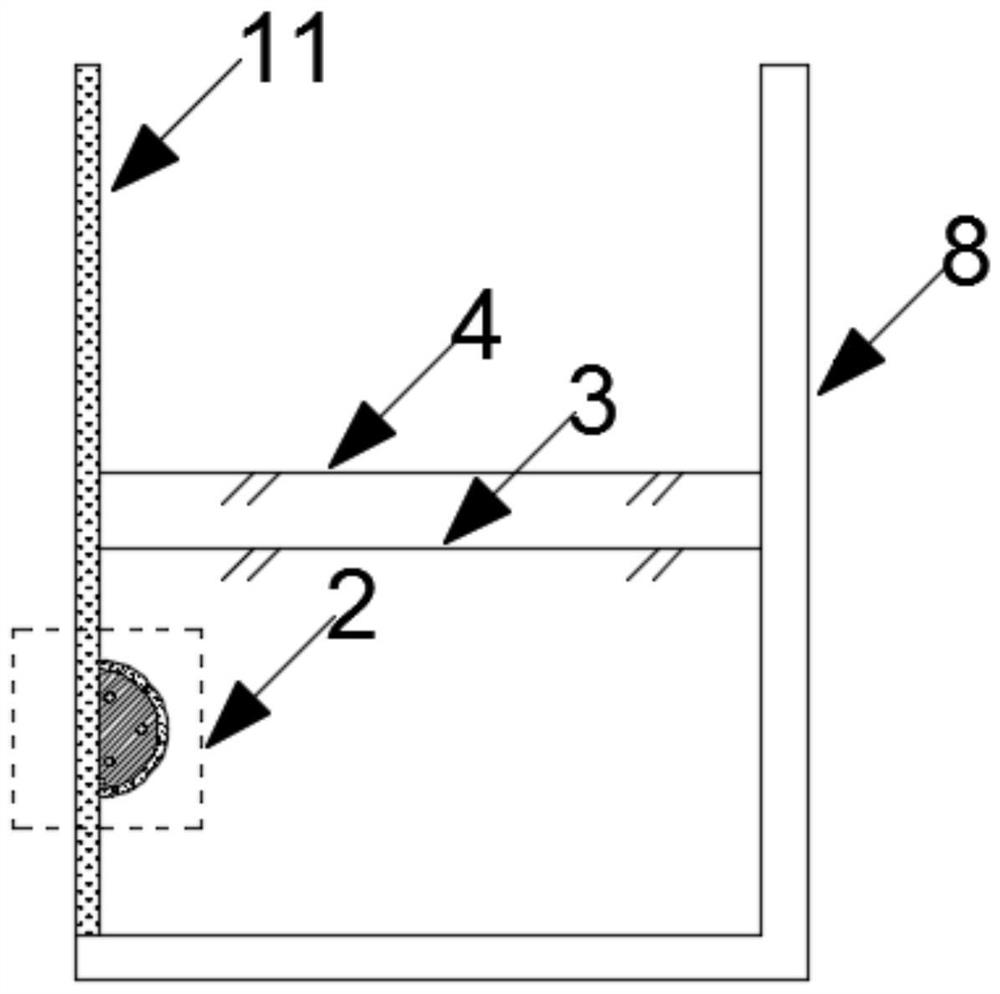

Visual dynamic fracture self-supporting fracturing technology research experimental device

InactiveCN110792426AObserve liquidityObserve the distribution phenomenonConstructionsFluid removalFracturing fluidEngineering

The invention discloses a visual dynamic fracture self-supporting fracturing technology research experimental device. The visual dynamic fracture self-supporting fracturing technology research experimental device includes the following units of (1) a visual variable fracture width simulation plate and hydraulic control and measurement unit, (2) a visual clamping temperature control unit, (3) a visual simulation fluid injection pipeline, wellbore and fracturing blender truck simulation unit, (4) a fluid supply unit, (5) a pressure control and flow control unit, (6) a self-supporting fracturingfluid and channel fracturing fluid separator and (7) an image acquisition unit; and the units are combined to form a flow space which has a fluid pressure resistance of 10 MPa and can simulate a flowdistribution law of a self-supporting fracturing fluid system in a perforation belt and a parallel fracture space, and meanwhile, the flow space is further provided with a heating and temperature control system and can provide simulated formation heating conditions, so that self-supporting fracturing fluid with different distribution produces phase transition to form a self-supporting solid phase.

Owner:DAGANG OIL FIELD GRP +1

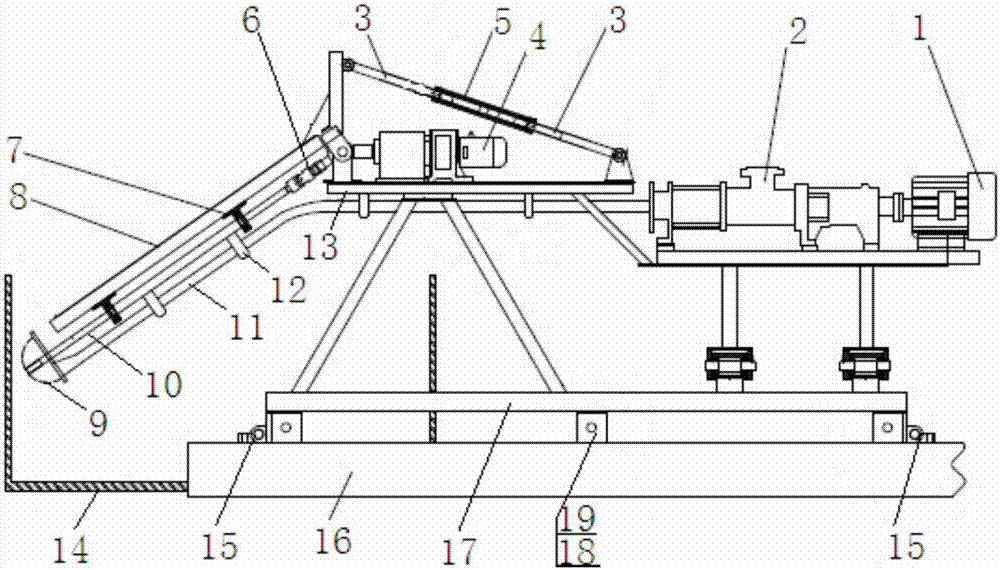

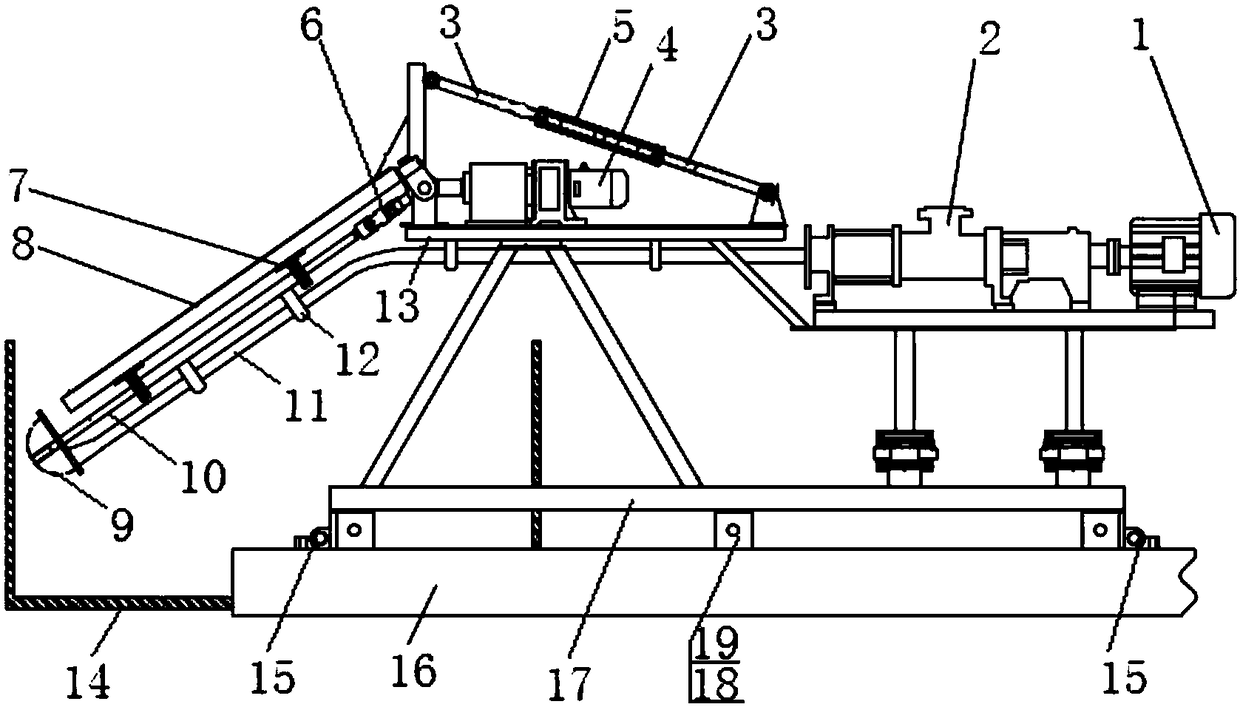

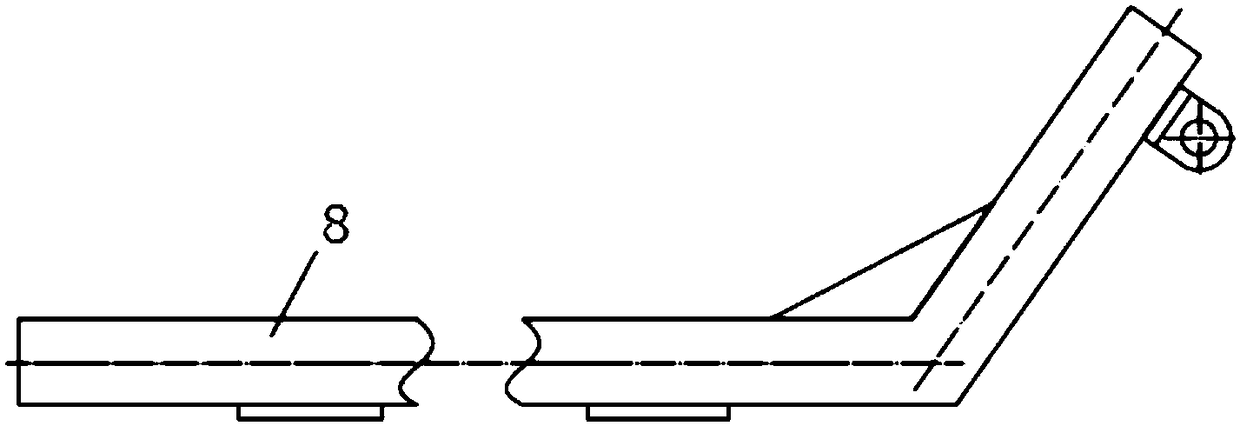

Small construction simulating device for cutter-suction type dredger

The invention relates to a small construction simulating device for a cutter-suction type dredger. The small construction simulating device comprises electric control equipment, a rail and a transparent wear-resistant water tank. A movable rack is arranged on the rail, and the movable rack is provided with wheels, mobile motors, locking mechanisms, a transverse motor, a lead screw, a dredge pump and a dredge pump motor. The lead screw is matched with a sliding table which is provided with a rotary motor, a telescoping mechanism and a swing arm, and the rotary motor is connected with a transmission shaft through a universal joint. The transmission shaft is provided with a 3D print rimer which is located in the water tank, the telescoping end of the telescoping mechanism is hinged to the swing arm, a pressure sensor which is connected with the 3D print rimer is arranged on the portion, at an inlet of the dredge pump, of a mud conveying pipe, and a pressure sensor and a productivity meter are arranged on the portion, at an outlet of the dredge pump, of the mud conveying pipe. By means of the electric control equipment, construction operation can be simulated in a manual single-step mode and in a full-automatic mode. By means of the device, the functions of propulsion and positioning, transverse moving, swing lifting, rotational cutting and mud discharge of the cutter-suction type dredger can be simulated quickly at low cost, and underwater flow field observation is achieved.

Owner:WUHAN UNIV OF TECH

Whole-course visualized self-supporting fracturing technology study device

InactiveCN110805423ARealize the flow phenomenonOptimized formulaSurveyConstructionsTemperature controlControl system

The invention discloses a whole-course visualized self-supporting fracturing technology study device. The device comprises following units of (1), a visualized variable slit width simulation self-supporting fracturing liquid distribution flow flat plate and pressure measuring unit; (2), a visualized clamping and temperature control unit; (3), a visualized liquid injection pipeline, shaft and blending equipment simulation unit; (4), a liquid supply unit; (5), a pressure control and flow control unit; (6), a self-supporting fracturing liquid and passageway fracturing liquid separator; and (7), an image acquisition unit. The units are combined together to form a flow space which has 10 MPa liquid pressure resistance and can simulate the flow distribution rule of a self-supporting fracturing liquid system in a perforation belt and a parallel crack space, meanwhile, the flow space is provided with a heating temperature control system, the heating conditions of a simulated formation can be provided, and self-supporting fracturing liquid distributed differently generates a phase change to form a self-supporting solid phase.

Owner:DAGANG OIL FIELD GRP +1

A kind of oil and gas reservoir fracturing construction method

ActiveCN108316909BIncrease net pressureReduce support height dropFluid removalLiquid viscosityFracturing fluid

The invention belongs to the field of oil exploitation and particularly provides an oil-gas reservoir fracturing construction method. The oil-gas reservoir fracturing construction method comprises a prepad fluid stage and a main sand adding stage. According to the prepad fluid stage, fracturing liquid is injected at multiple levels of construction displacement which is increased level by level from the lowest construction displacement to the highest construction displacement; and according to the main sand adding stage, sand-carried liquid is injected at the highest construction displacement,wherein the lowest construction displacement is 45-65 % of the highest construction displacement. In the preferably-selected implementation mode, design is conducted according to different construction sections, the different fracturing liquid displacement and corresponding fracturing liquid viscosities and using quantities are adopted, the mode of different-particle-diameter variable density sandadding is adopted, by utilizing the setting effect of a supporting agent, the net pressure in cracks at the supporting agent non-setting position is increased, thus the seam making height and the supporting height of remote well cracks are increased, the flow guiding capacity of the cracks at remote wells is improved, and the progressively-decreasing speed of the single-well capacity is decreased.

Owner:CHINA PETROLEUM & CHEM CORP +1

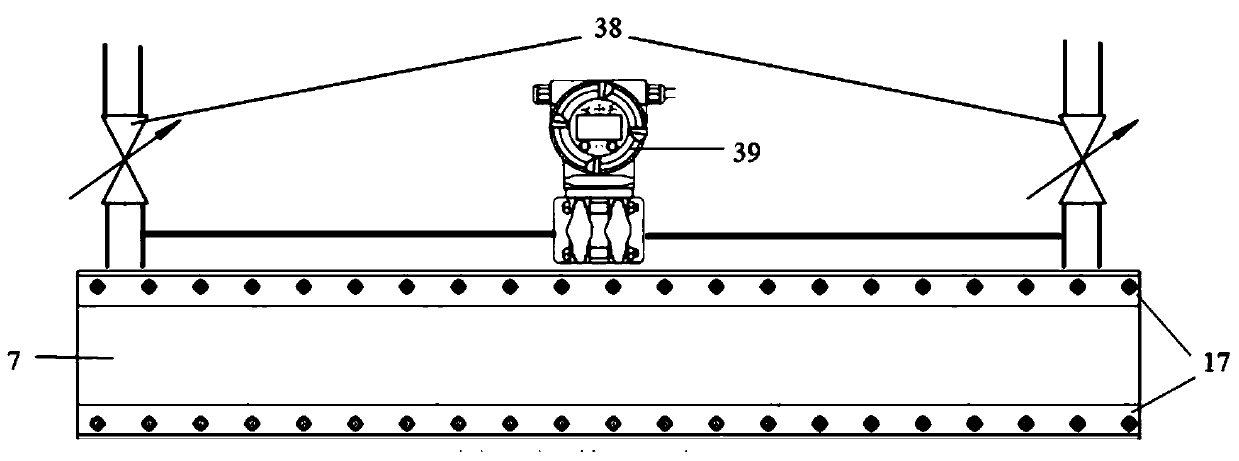

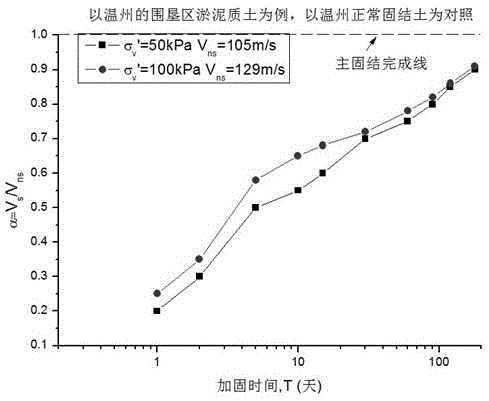

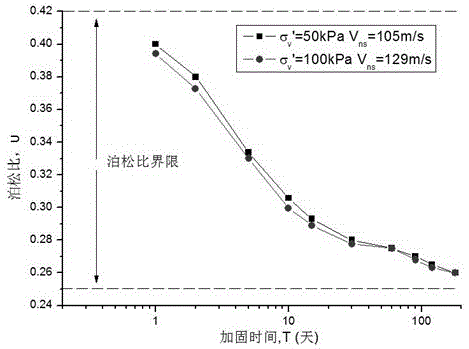

Vacuum preloading method effectiveness real-time detection method and device

ActiveCN105649117AOptimizing Design and Construction ParametersEasy to operateFoundation testingSoil preservationEngineeringWave speed

The invention provides a vacuum preloading method effectiveness real-time detection method and device. By means of piezoelectric sensors, compression wave speeds and shear wave speeds of a soil body at different times are measured; a normally-solidified soil body serves as a comparison group, and the compression wave speed and the shear wave speed of the normally-solidified soil body are measured through the piezoelectric sensors; then according to related formulas, the shear modulus, the compression modulus and the Poisson's ratio are obtained. By means of the detection method and device, real-time evolution of relevant parameters of the soil body along with load application can be further obtained, and accordingly effectiveness of a vacuum preloading consolidation method in different soil bodies and in different depths is judged. By means of the detection method, effectiveness of the vacuum preloading method can be accurately evaluated in a lossless mode, design and construction parameters are optimized according to different soil mass properties, operation is convenient, and reliability is high.

Owner:WENZHOU UNIV OUJIANG COLLEGE +1

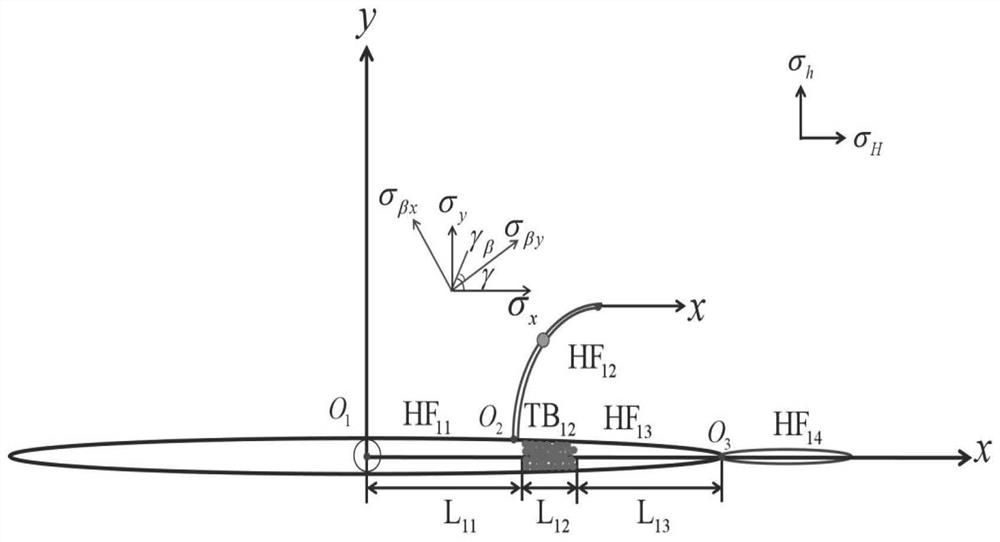

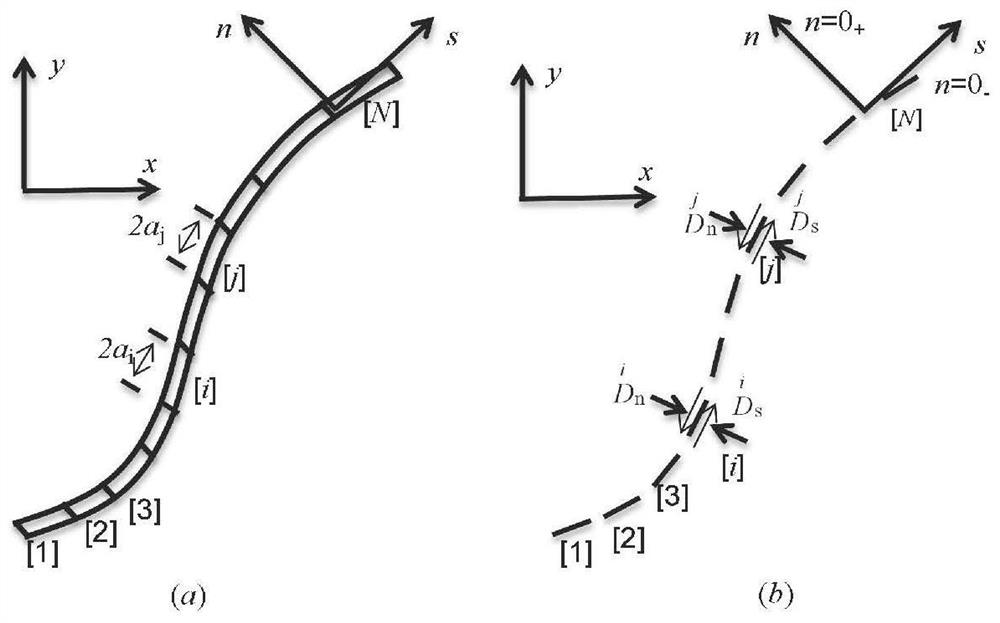

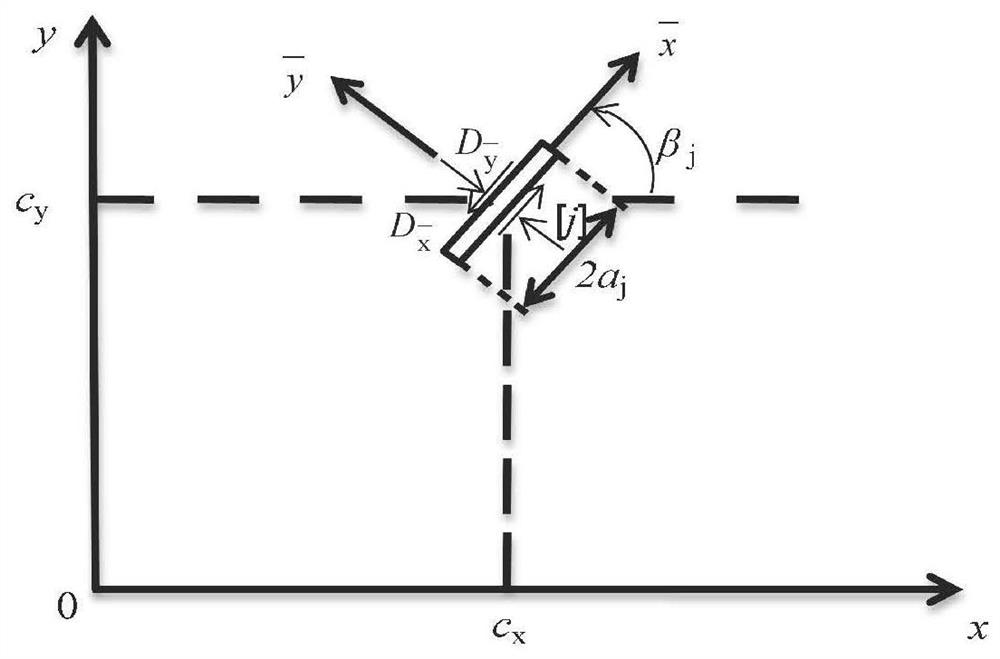

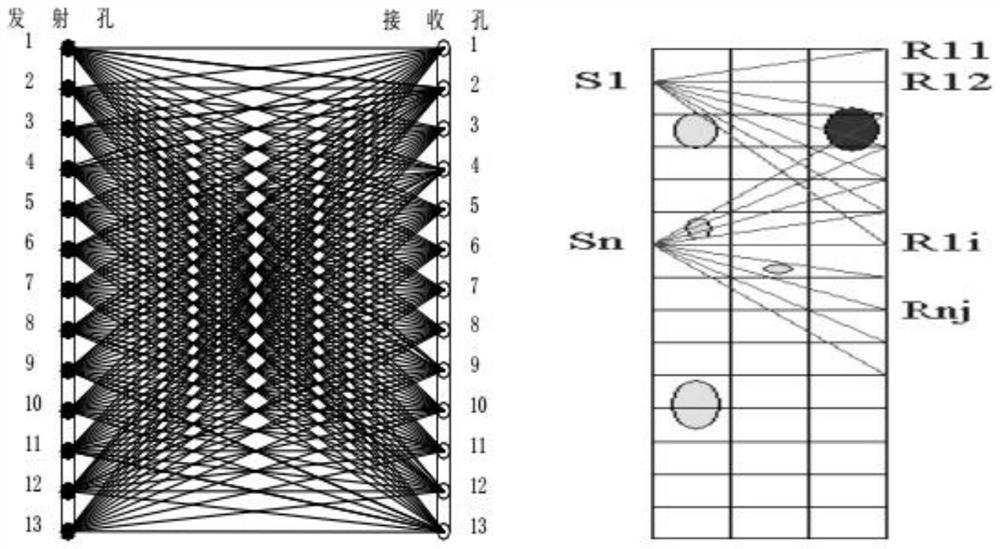

Prediction method and device for temporary plugging diversion crack

ActiveCN113987965AIncrease success rateEasy to crackDesign optimisation/simulationBorehole/well accessoriesSurface stressFormation fluid

The invention discloses a method and a device for predicting a temporary plugging diversion crack, as shown in Figure 1. The method comprises the following steps: collecting basic parameters required by calculation; a hydraulic fracture induced stress field model is established through a displacement discontinuity method, and displacement and stress components of any position are calculated; calculating induced stress generated by the hydraulic fracture and the formation fluid pressure change, and superposing the in-situ stress and the induced stress generated by the hydraulic fracture and the formation fluid pressure change to obtain a temporary plugging fracture wall surface stress distribution parameter; the plugging friction strength and the plugging shear strength of a temporary plugging wall formed by the temporary plugging agent are calculated, and the smaller value of the plugging friction strength and the plugging shear strength is selected as the pressure bearing capacity strength of the temporary plugging agent; and calculating the circumferential stress of the temporary plugging crack, comparing the circumferential stress of the temporary plugging crack with the limit circumferential stress, and predicting the temporary plugging turning crack. The method can be used for researching the technical principle of temporary plugging crack steering, simulating the temporary plugging crack expansion track of a typical fractured well group, and optimizing cracks and construction parameters.

Owner:SOUTHWEST PETROLEUM UNIV

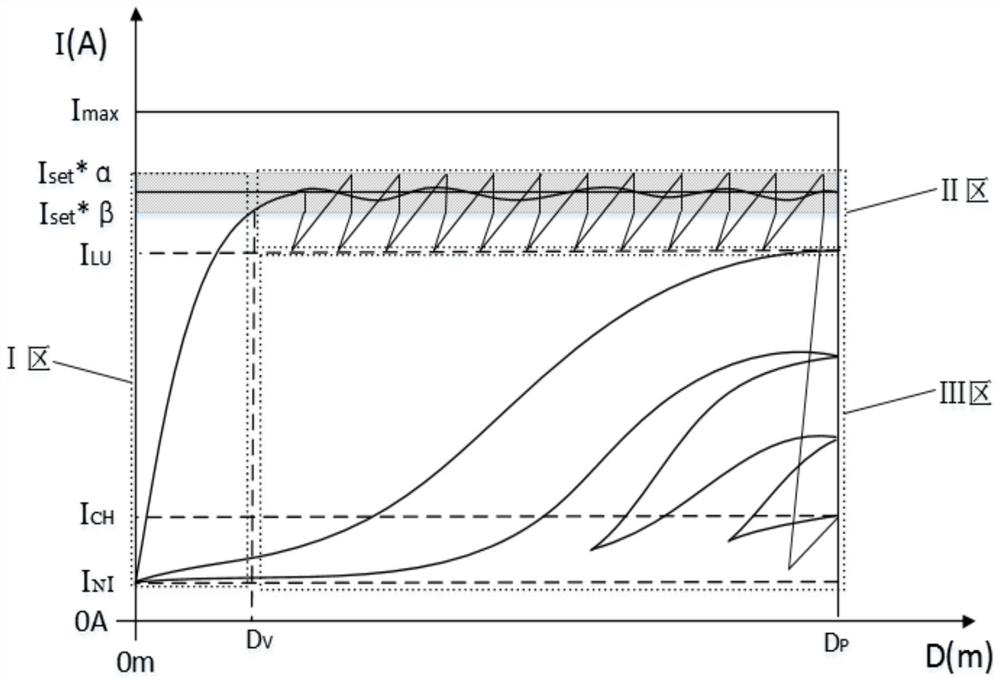

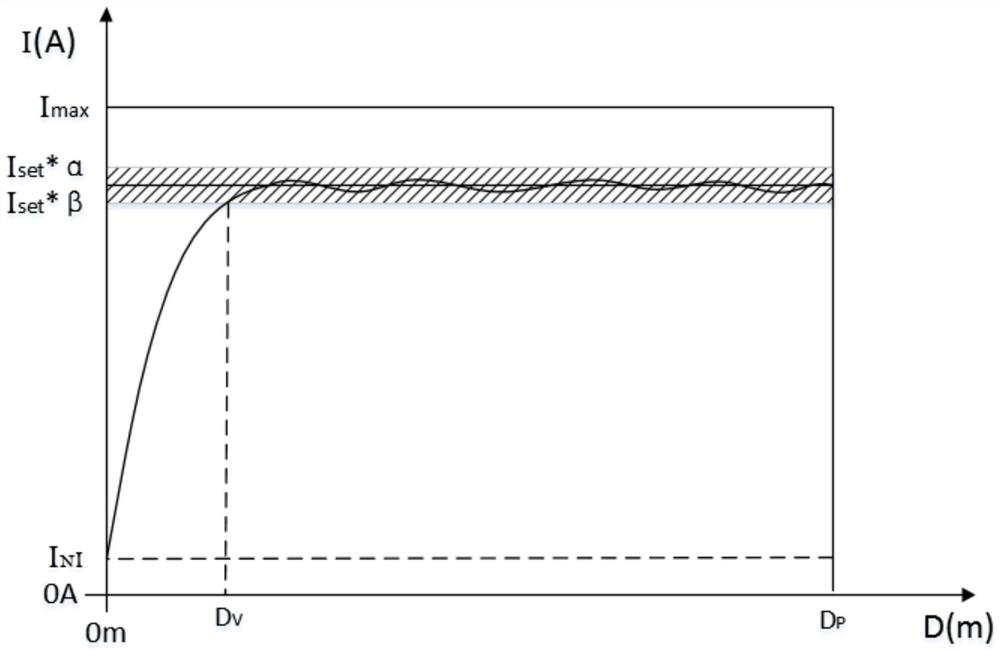

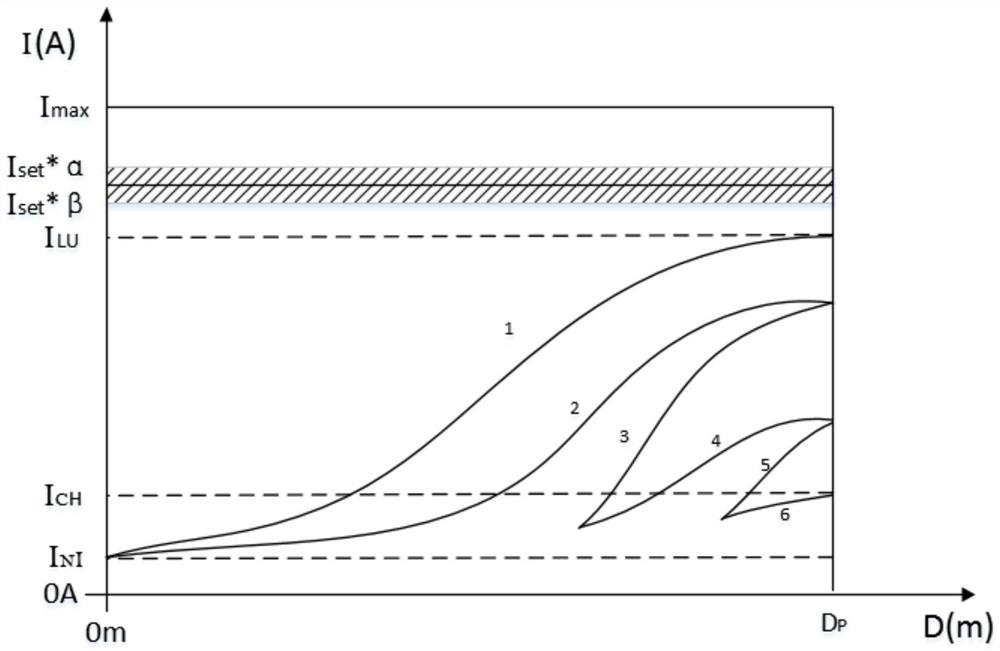

Real-time linkage intelligent control method and control model for vibroflotation pile construction

ActiveCN114580202AImprove construction efficiencyImprove construction qualityDesign optimisation/simulationTotal factory controlControl modelsManual handling

The invention discloses a real-time linkage intelligent control model and method for vibroflotation pile construction, and the method comprises the following steps: building a function relationship between vibroflotation depth and vibroflotation current, and adjusting the vibroflotation depth and / or vibroflotation speed in real time according to the function relationship. An intelligent control model for the whole process of vibroflotation construction is put forward for the first time, a control algorithm is put forward based on the control model, and the problems that in the existing construction process, a large amount of manual operation is needed, the labor intensity is high, the operation process is tedious and prone to errors, construction quality depends on worker experience, and intelligent control cannot be conducted are solved.

Owner:CHINA HUANENG GRP CO LTD +2

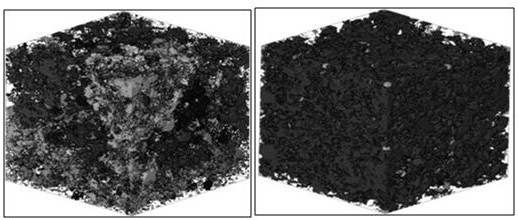

Device and method for simulating volume fracturing of horizontal well on shale reservoir stratum

ActiveCN102590456BTruly reflect the impact of fracturing productivityDetermination of densityMaterial analysisLine tubingAtmospheric air

The invention relates to a device and a method for simulating volume fracturing of a horizontal well on a shale reservoir stratum; when crack propagation of the shale reservoir stratum is simulated, a valve at a liquid inlet of a supply source is set to be closed, and a fluid reservoir is communicated with a liquid inlet of a horizontal shaft by a pipe line; when the production process of the shale reservoir stratum is simulated, the fluid reservoir is communicated with the liquid inlet of the supply source by the pipe line, and the liquid inlet of the horizontal shaft is communicated with the atmosphere; a man-made fracture model is arranged at a bullet hole of the horizontal shaft; when the production process of the shale reservoir stratum is simulated, a gas tank is communicated with the liquid inlet of the supply source by a gas pipeline, and the liquid inlet of the horizontal shaft is communicated with the atmosphere. According to the invention, according to the similarity principle, the crack initiation and extending processes of the volume fracturing can be simulated, the density and the volume of a fracture network are determined, the effect of crack parameters on the fracturing capacity of the horizontal well on the shale reservoir stratum is researched, fracturing construction parameters and the crack parameters are optimized and a key problem of fracturing of the shale reservoir stratum is solved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Stepwise dissolution and plugging removal method for oil and water wells

ActiveCN110886592BAvoid secondary precipitationIncrease drainage areaCleaning apparatusSoil scienceWater flooding

The invention discloses a stepwise dissolution and plugging removal method for oil and water wells: (1) injecting pretreatment liquid; injecting cleaning agent; (2) injecting into the main body dissolution system to dissolve different cuttings components in the deep part of the oil and water well; plugging removal radius Above 3.5m; the main corrosion system is selected from the following acid solution plugging removal systems: ①hydrochloric acid system with an acidity of 8% to 12%; ②earth acid system with an acidity of 11% to 16%; ③acidity of 12% to 14% slow acid system; ④ deep penetrating plugging removal acid system with an acidity of 8% to 10%; the injection method of the main corrosion system is gradual injection without flowback; the injection sequence is determined according to the cuttings content; ( 3) Inject protective fluid, no flowback, and the construction is over. The method of the present invention adopts different blocking-removing acid solutions for graded dissolution for different cuttings, which can effectively improve the pore-throat connectivity of the reservoir, improve the water absorption profile of the reservoir and expand the sweeping range of water flooding, and can realize low-porosity and low-permeability storage effective use of layers.

Owner:CHINA PETROLEUM & CHEM CORP +1

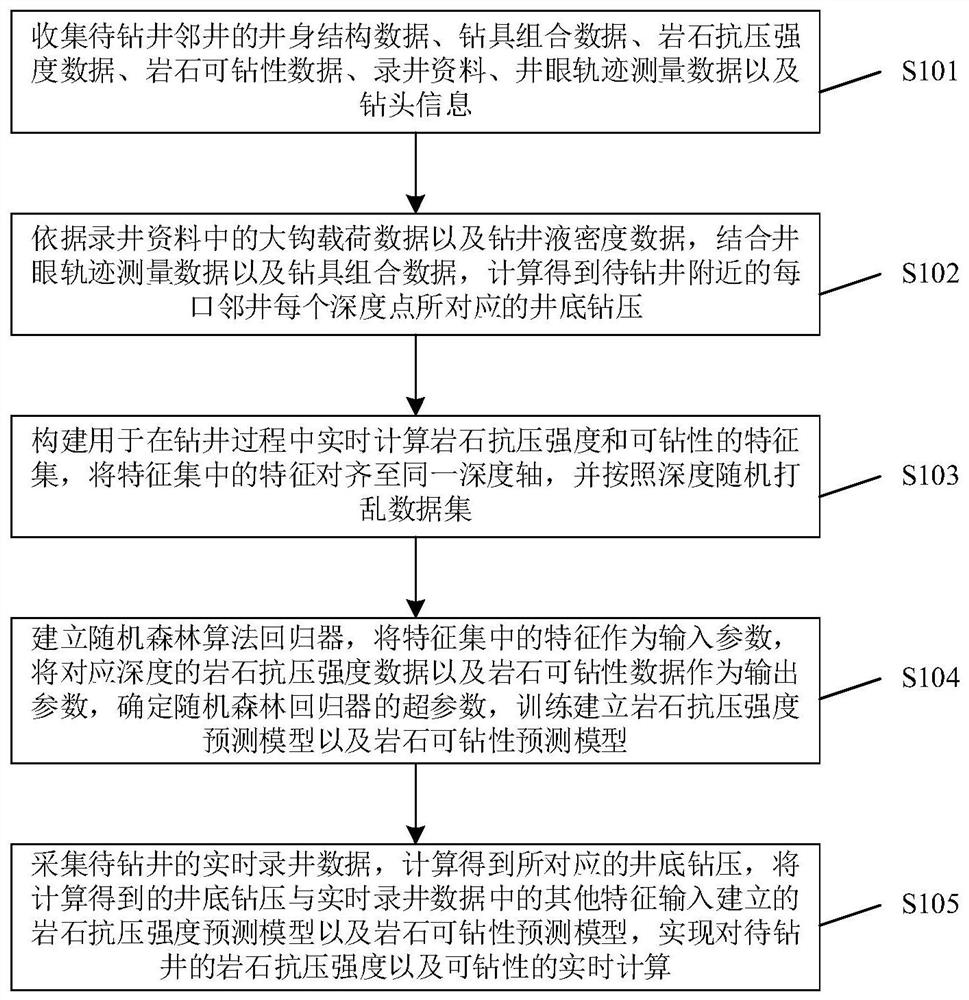

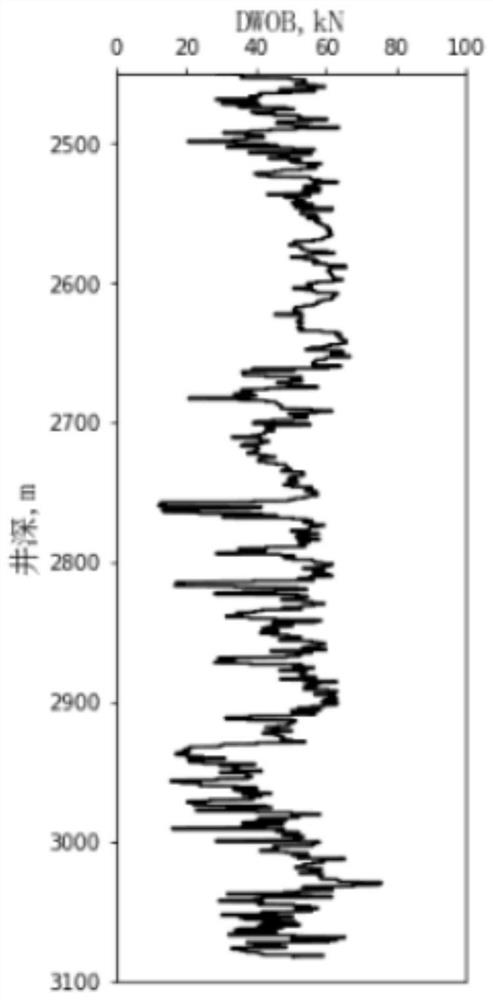

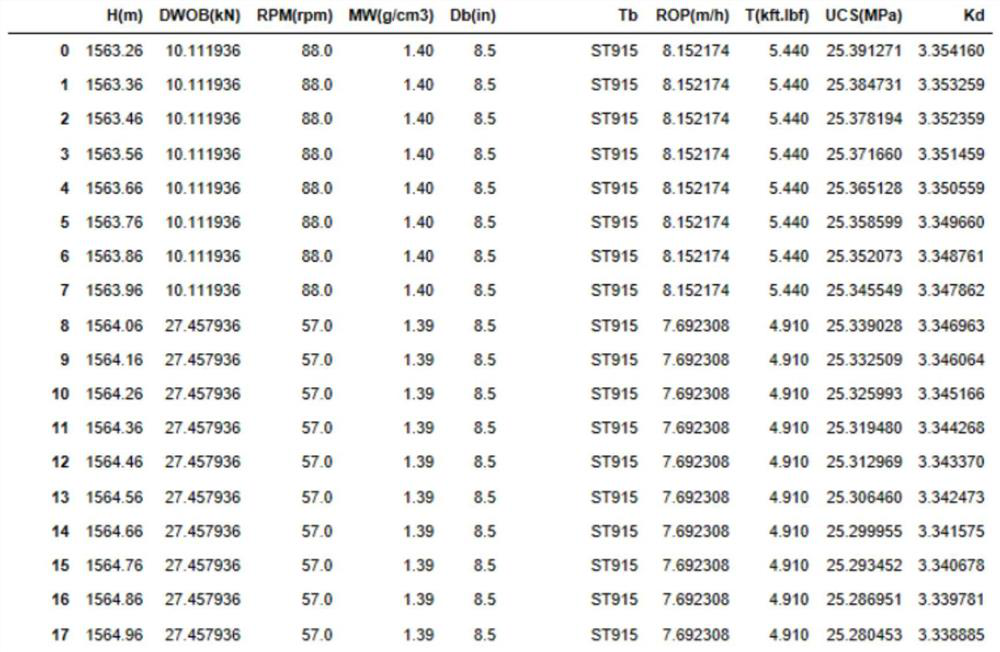

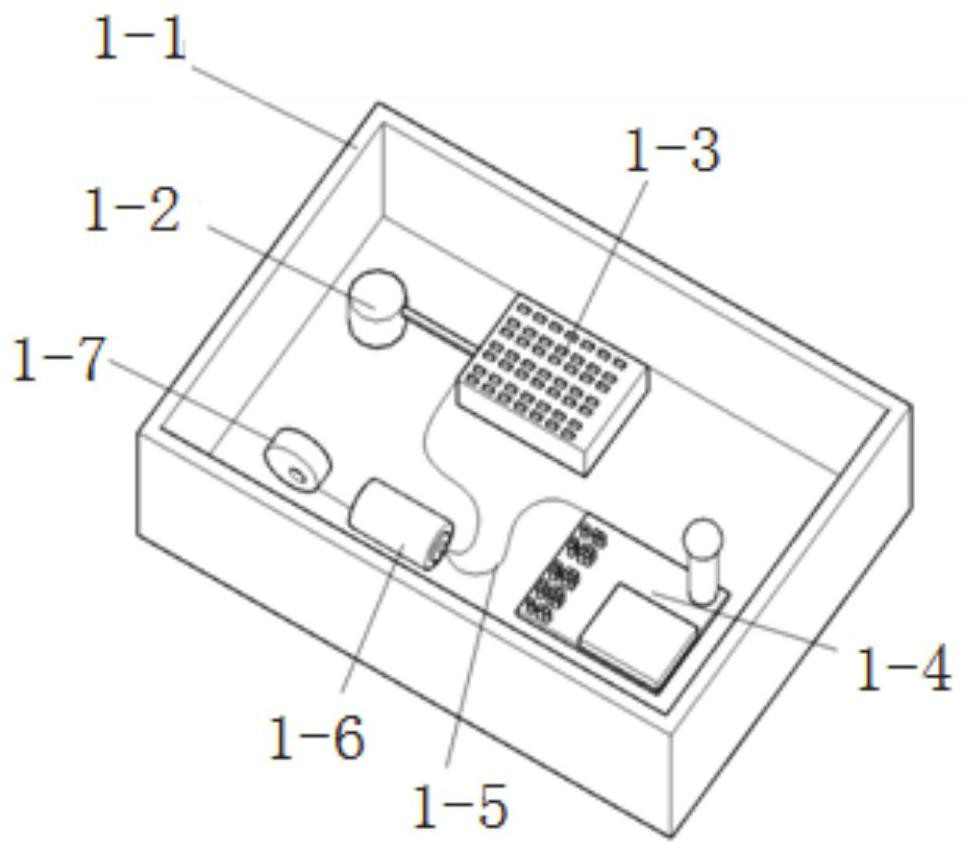

Method and device for monitoring rock compressive strength and drillability

PendingCN113323647AReduce the use effectLow costSurveyMeasurement devices for drillingData setWell drilling

The invention provides a method for monitoring rock compressive strength and drillability. The method comprises the steps of collecting well bore structure data, drilling tool combination data, rock compressive strength data, rock drillability data, logging data, well track measurement data and drill bit information of adjacent wells of a to-be-drilled well; performing calculating to obtain well bottom bit pressure corresponding to each depth point of each adjacent well near the to-be-drilled well; constructing a feature set, aligning features in the feature set to the same depth axis, and randomly disrupting a data set according to the depth; determining hyper-parameters of a random forest regression device, and training and building a rock compressive strength prediction model and a rock drillability prediction model; and collecting real-time logging data of the to-be-drilled well, and inputting the real-time logging data into the built rock compressive strength prediction model and rock drillability prediction model to realize real-time calculation of the rock compressive strength and drillability of the to-be-drilled well. According to the method, a mapping relation between various factors and the rock compressive strength and drillability is comprehensively considered, and the higher calculation precision is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

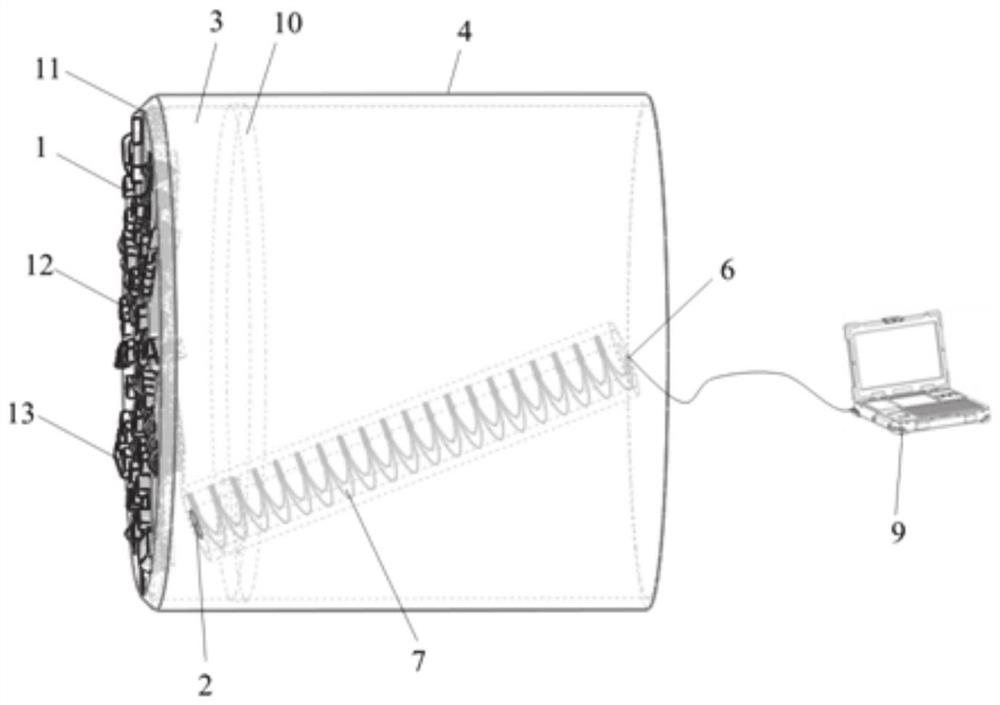

Composite stratum recognition system for shield tunneling machine, shield tunneling machine and method

ActiveCN113847037AAchieving advanced forecastingOptimize construction parametersSubsonic/sonic/ultrasonic wave measurementTunnelsEngineeringBrush

The invention relates to a composite stratum recognition system for a shield tunneling machine, the shield tunneling machine and a method. The composite stratum recognition system comprises a vibration monitoring device, a wireless signal receiving device, an electric brush slip ring and a monitoring terminal, and the vibration monitoring device is installed on a radial plate of a cutter head of the shield tunneling machine and can monitor the vibration information of the cutter head; the wireless signal receiving device is used for being installed on the slag inlet side of a spiral unearthing device of the shield tunneling machine, and the wireless signal receiving device is in wireless connection with the vibration monitoring device and can receive vibration information obtained through monitoring of the vibration monitoring device; the electric brush slip ring is used for being arranged at the slag discharging side position of the spiral unearthing device of the shield tunneling machine, the electric brush slip ring is fixed to one end of a first cable, the other end of the first cable is connected with the wireless signal receiving device, and a signal line can be fixed to a spiral shaft of the spiral unearthing device; and the monitoring terminal is connected with an electric brush through a second cable, and the electric brush is in contact with the electric brush slip ring. By adopting the composite stratum recognition system, advanced geological forecast in the shield tunneling process is realized.

Owner:SHANDONG UNIV +1

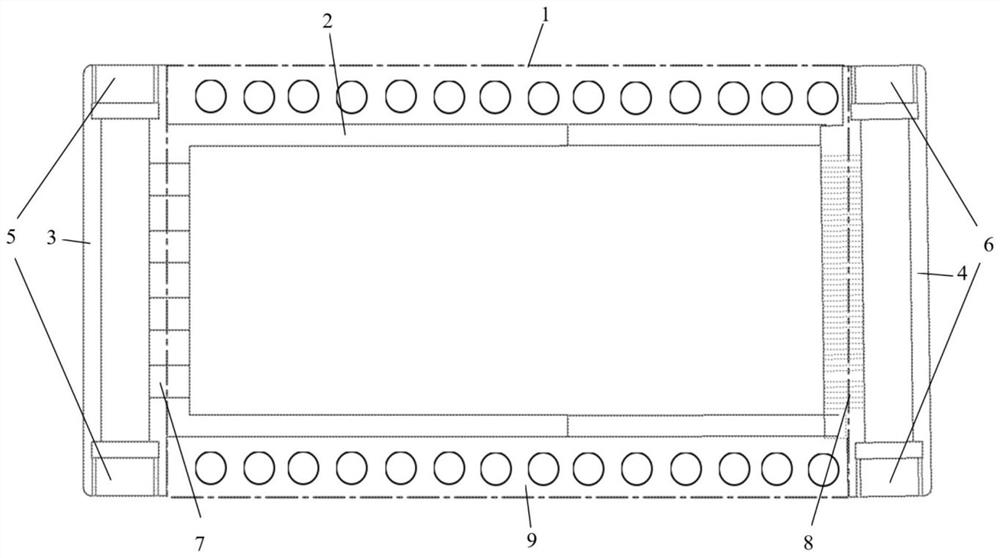

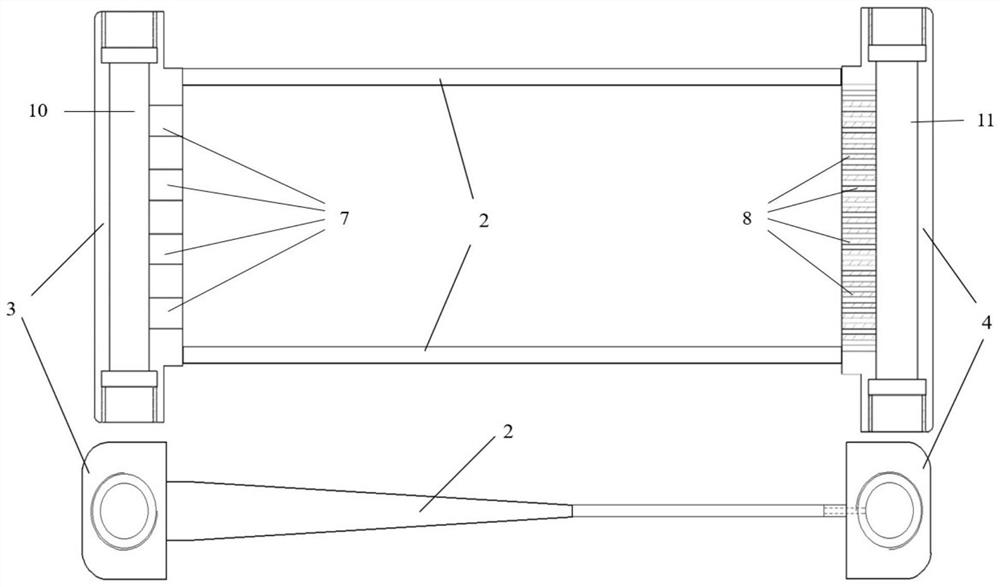

An experimental device for visually simulating the flow law of self-supporting fracturing fluid

ActiveCN110939421BObserve the distributionRealize the flow phenomenonSurveyConstructionsAcquisition apparatusClassical mechanics

The invention discloses an experimental device for visually simulating the flow law of self-supporting fracturing fluid, which comprises two plexiglass plates, an integrated main frame, and image acquisition equipment. The two plexiglass plates are respectively sealed and connected to the integrated main frame. The upper and lower end faces of the frame, thereby forming an intermediate visual flow structure with an inner cavity flow structure; the beneficial effect of the present invention is that, according to different experimental parameters, the device can visually observe the distribution of self-supporting fracturing fluid in simulated formation fractures Situation; with uniquely designed simulated blasthole and conical flow space, it can simulate the influence of perforated blasthole and perforated zone on the distribution of self-supporting fracturing fluid.

Owner:DAGANG OIL FIELD GRP +1

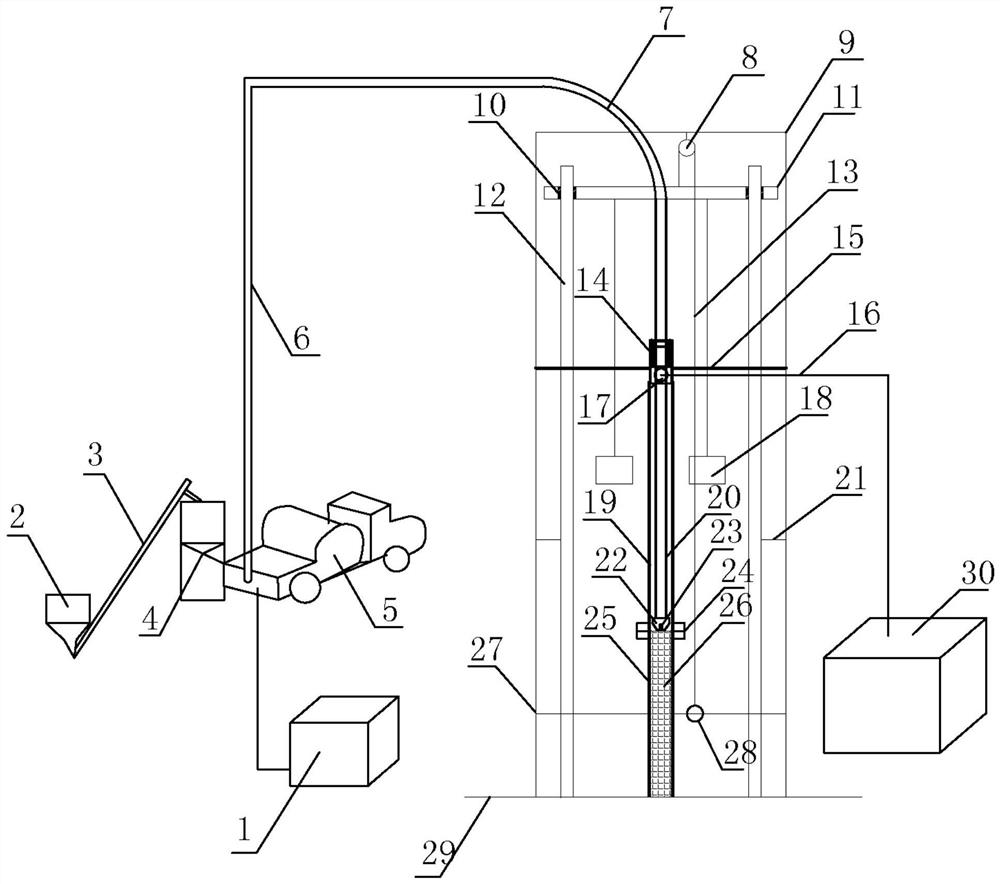

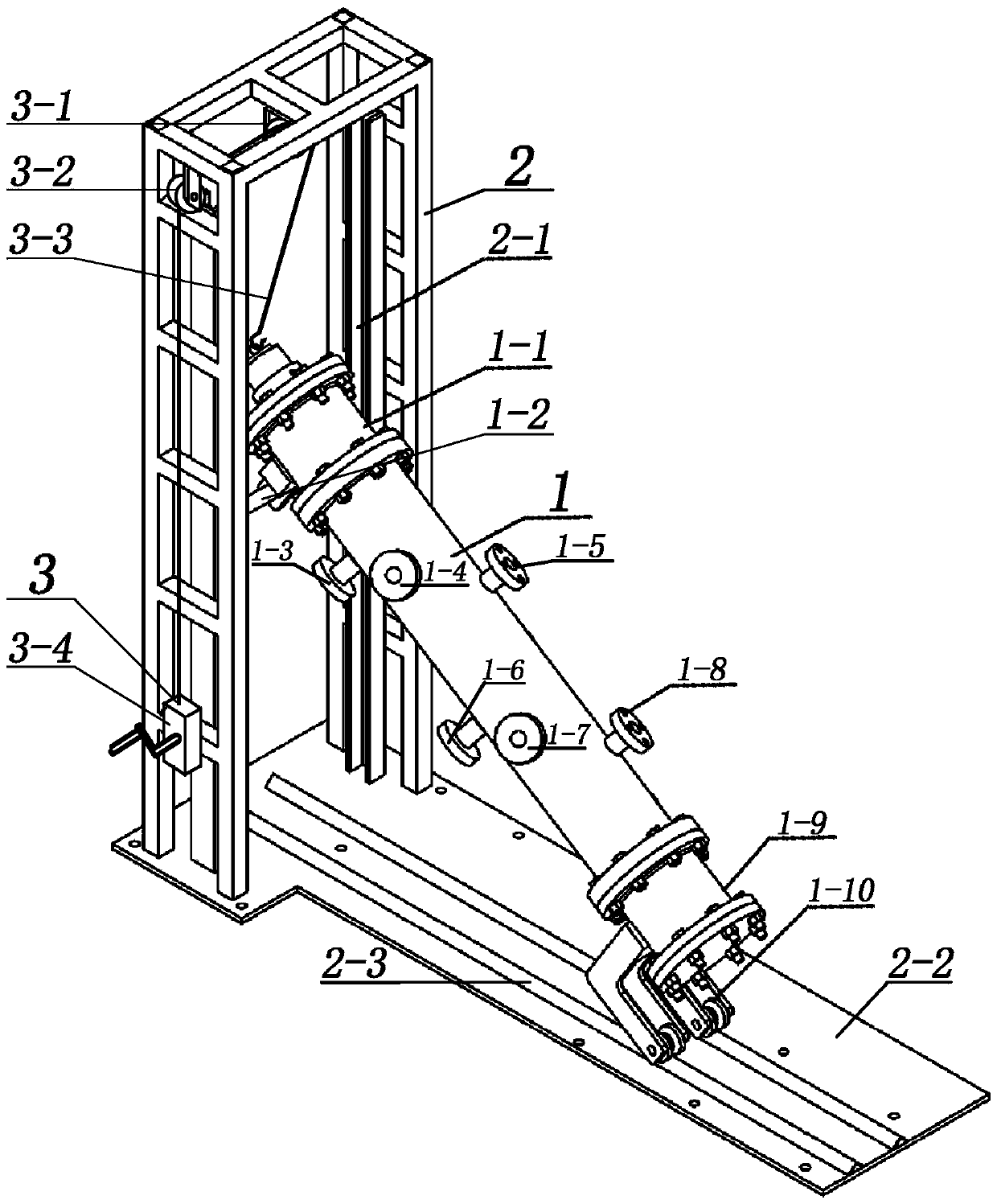

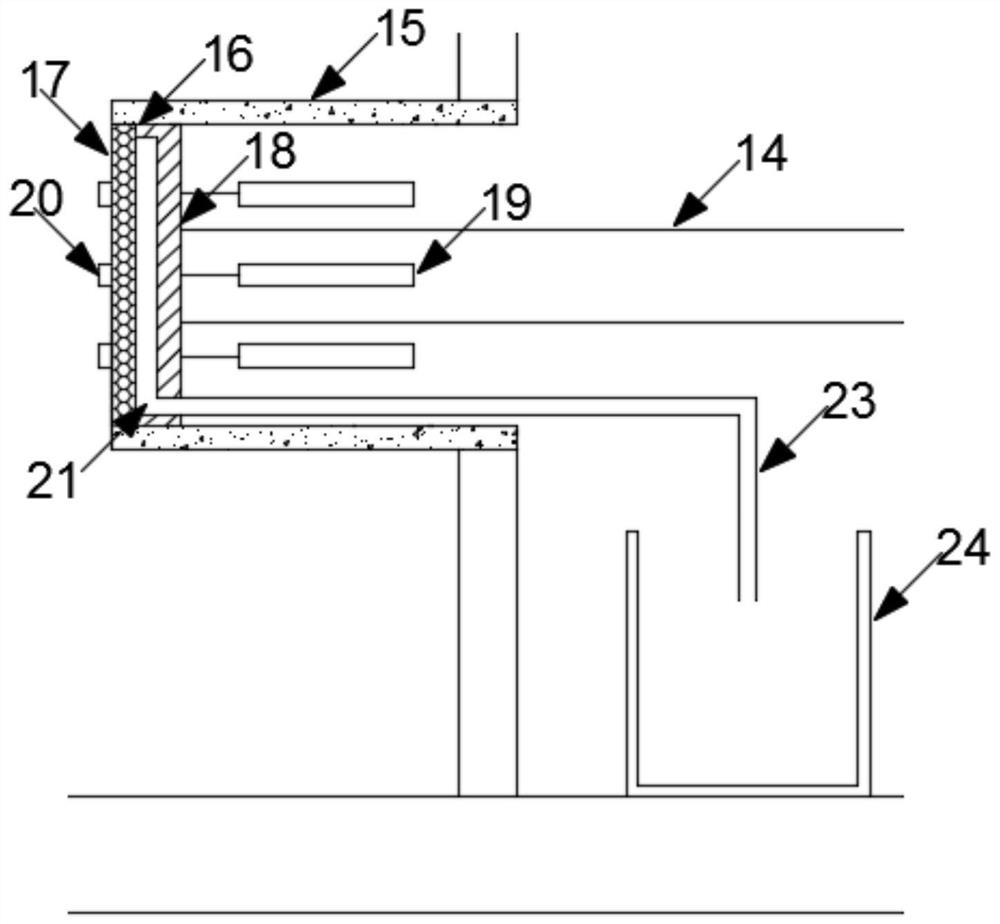

Hydraulic high-pressure particle jet drilling plug test device

ActiveCN111047961BFluidic plug verificationRealize visualizationEducational modelsLine tubingEngineering

The invention belongs to the field of petroleum drilling and production, and in particular relates to a hydraulic high-pressure particle jet drilling plug test device, which includes a conveyor, a cement truck, a high-pressure pipe, a skid-mounted frame, a sliding sleeve, a moving beam, a vertical track, a sliding sealing assembly, The return pipeline, counterweight, glass upper cylinder, oil pipe, nozzle, nozzle, glass lower cylinder, hinge, recovery tank, etc., through the special particle jet drilling test device, realize the full-scale simulation of the downhole particle jet drilling process on the ground. Visualization of jet drilling and annulus upward return, effective control of the lowering and lifting of the nozzle, adjustable drilling pressure during drilling, reliable dynamic sealing of the moving tubing and annular return fluid, thereby verifying the effect of hydraulic high-pressure particle jet drilling , to obtain the optimized construction parameters of the hydraulic high-pressure particle jet drilling plug.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Dynamic simulation method for steel truss roof construction based on BIM (Building Information Modeling) technology

PendingCN113268802AImprove construction efficiencyEasy to assistGeometric CADDesign optimisation/simulationCollision detectionModelSim

The invention discloses a dynamic simulation method for steel truss roof construction based on a BIM (Building Information Modeling) technology in the technical field of steel truss roof construction, which comprises the following steps: 1, establishing a three-dimensional digital model of a construction scheme through a Revit modeling platform in the BIM according to a project design drawing and construction parameters; and 2, importing the model obtained in the step 1 into Naviworks software through Revit software to carry out single professional model collision detection, and if a problem is detected, returning to the model for modification, so that four-dimensional visual dynamic simulation of the steel truss roof construction process is realized by utilizing a BIM technology, a project design drawing and construction parameters are effectively optimized, the construction scheme is more reasonable, the problems occurring in the construction process are reduced, real operation of auxiliary constructors is facilitated, accuracy difference is avoided, the construction difficulty is reduced, the efficiency of steel truss roof construction is improved, and the method is worthy of application and popularization.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

A fracturing and sanding design method based on large-scale parallel plate proppant migration and placement model experiment

ActiveCN111622730BOptimize construction parametersLow costSurveyFluid removalParallel plateFracturing fluid

The invention discloses a fracturing and sanding design method based on a large-scale parallel plate proppant migration and laying physical model experiment, and specifically relates to the field of oil and gas field development. This method determines the value range of each construction parameter according to the fracturing target, and uses a large-scale parallel plate proppant migration and laying phantom experimental device to conduct a control experiment on each construction parameter to obtain the migration of proppant under different parameters and the final sand embankment. Morphological pictures, and use sand embankment shape evaluation parameters to quantitatively evaluate the final sand embankment shape, optimize construction parameters, measure the horizontal migration velocity and vertical settlement velocity of proppant under different conditions, and calculate the propping height and horizontal propping fracture length, After checking, determine the sanding parameters of each stage of fracturing, and combine the ratio of proppant to fracturing fluid at each stage to determine the final fracturing sanding construction plan. The invention solves the problem of few and incomplete quantitative evaluation parameters of experimental results, greatly improves the effect of fracturing and increasing production, and effectively reduces the cost of fracturing construction.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Three-dimensional loading simulation test device for tunnel boring machine

InactiveCN102043018BImprove construction efficiencyOptimize construction parametersMaterial analysis using acoustic emission techniquesAcoustic emissionData acquisition

The invention discloses a three-dimensional loading simulation test device for a tunnel boring machine. The upper end of a vertical load force transfer column is connected with a spherical pad, the lower end of the vertical load force transfer column is connected with a hobbing cutter bracket, and the spherical pad is connected with the upper beam of a presser through bolts; a puller is fixed on the outer side of the facade of the system base, a pull rod is connected with the puller and a specimen bottom bearing plate after penetrating through the facade of the system base, and the specimen bottom bearing plate is provided with spacing strips and arranged on a rolling shaft of the system base; a horizontal lifting jack is fixed on the outer side of a side plate, the piston end part is provided with a specimen lateral bearing plate, and a horizontal load force transfer column is fixed on the inner sides of opposite side plates; a displacement sensor and a shaft type load sensor are connected with a data acquisition instrument through cables; the data acquisition instrument is connected with a computer through a USB connecting line; and an acoustic emission sensor is connected with an acoustic emission test system through a cable. The three-dimensional loading simulation test device has the advantages of simple structure, rich test data and comprehensive and reliable test result, and is convenient to use.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

A small construction simulation device for cutter suction dredger

InactiveCN107134212BRealize construction simulationOptimize construction parametersEducational modelsWear resistantEngineering

Owner:WUHAN UNIV OF TECH

Variable well inclination and visual oil well sand control evaluation experimental device and method

InactiveCN111485858AExperimental results are reliableEasy to guideFluid removalControl systemLiquid storage tank

The invention discloses a variable well inclination and visual oil well sand control evaluation experimental device. The variable well inclination and visual oil well sand control evaluation experimental device is characterized in that a transparent test shaft of the device is arranged in a vertical support; the bottom of a liquid storage tank is connected with an inlet of a high-pressure plungerpump through a pump inlet pipeline; one path of an outlet of the high-pressure plunger pump is connected with a simulated shot hole III of the transparent test shaft through a pump outlet pipeline I and a pump outlet valve I, and the other path of the outlet of the high-pressure plunger pump is connected with the top of a sand mixing tank through a pump outlet pipeline II and a pump outlet valve II; the bottom of the transparent test shaft is connected with a grit chamber; the grit chamber is connected with a water tank through a water inlet pipe; and a water outlet pipe of the water tank is connected with the liquid storage tank through a flow meter. According to the variable well inclination and visual oil well sand control evaluation experimental device, the defect of great deviation between an existing large physical model and the condition of an underground shaft is overcome, and the detailed description of the implementation processes of different sand control processes can be simulated under different well inclination angles; and the change of a sand control system in the formation production process after sand control can be simulated, so that the variable well inclinationand visual oil well sand control evaluation experimental device has important significance for correctly understanding the sand control processes and the influence rule of the system stability after the sand control.

Owner:CHINA PETROLEUM & CHEM CORP +1

A seepage test system for excavation face under tidal load in river bottom shield tunnel construction

ActiveCN109632606BOptimize construction parametersRealize the constructionPermeability/surface area analysisFrequency conversionTidal bore

The invention provides an excavation face seepage test system of river bottom shield tunnel construction under a tidal load effect. The system comprises a model box and a shield tunnel model. The mainbody of the shield tunnel model is placed in the model box. Soil and water samples are filled in the model box in a layered mode. A movable panel, a telescopic straight rod and a telescopic rod installation seat form a tunnel excavation face support device. A frequency conversion water pump device can be used to simulate a tidal load above a river bottom shield tunnel in a tidal bore zone. Through setting tidal load condition combinations with different amplitudes and different frequencies, excavation face seepage discharge changes, the change of the seepage field of soil near an excavation face, the displacement change of the soil sample at each test point, and the change of the support pressure of each test point are monitored so as to study an excavation face seepage law, then optimizea shield construction parameter and guide a design and construction.

Owner:ZHEJIANG UNIV

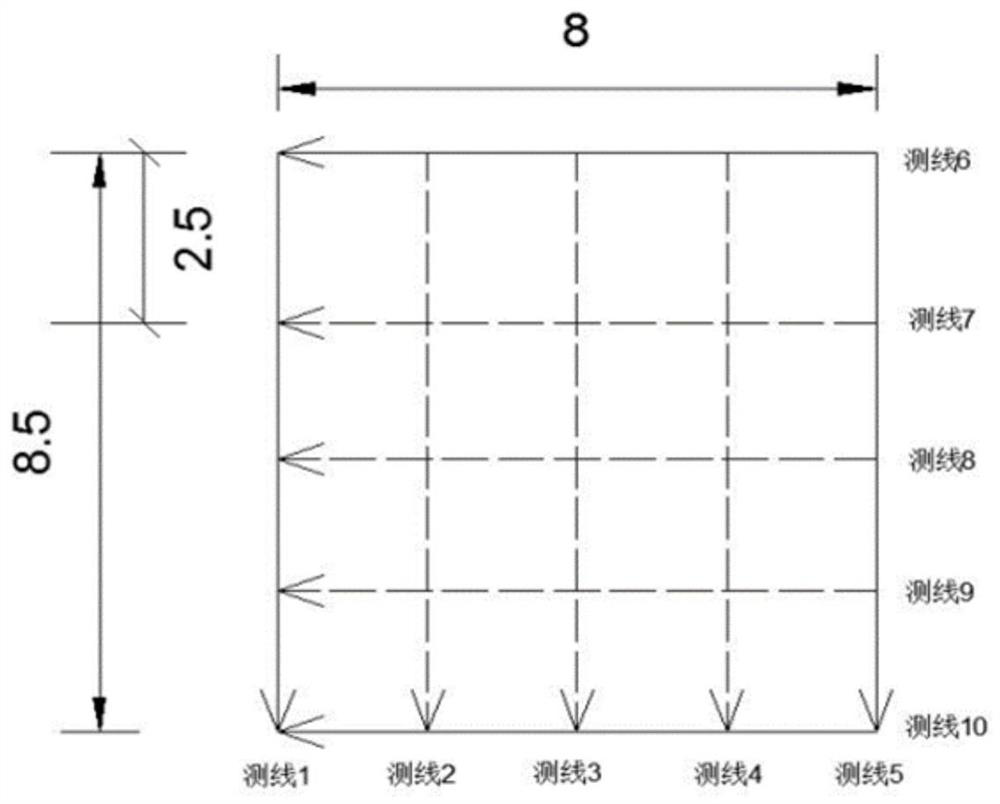

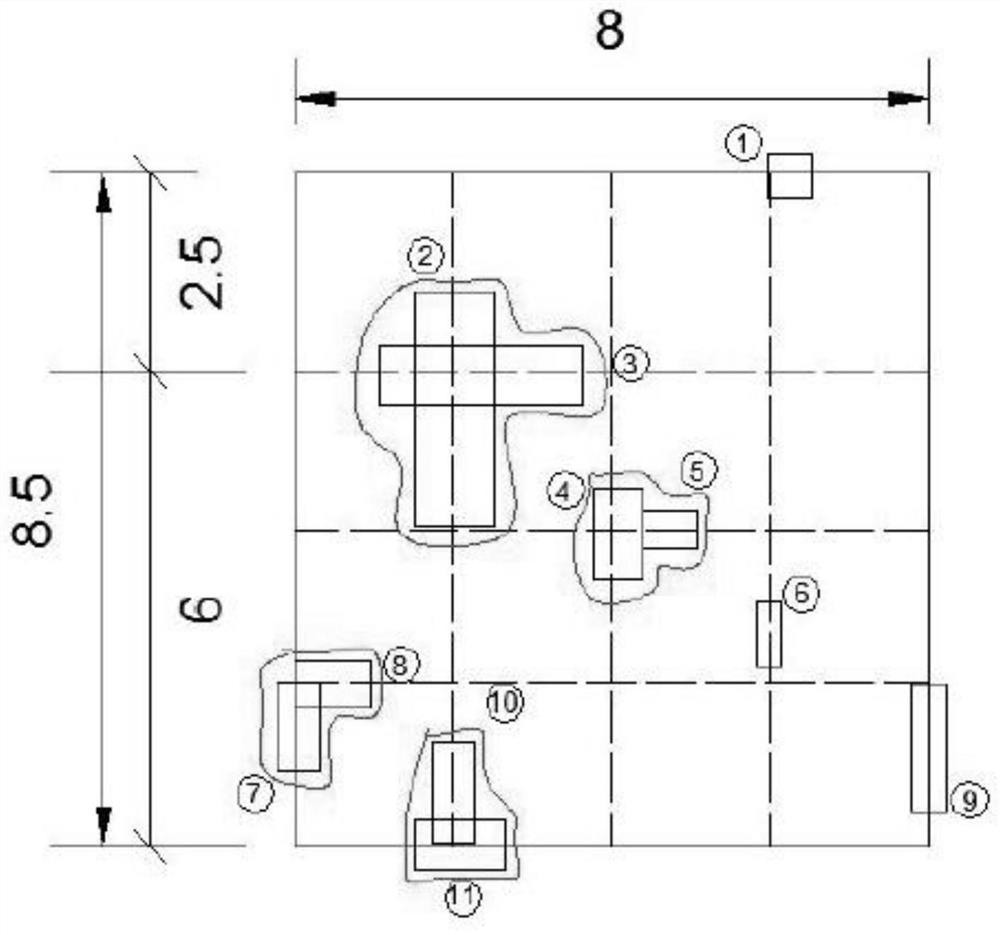

Dynamic compaction treatment method for karst foundation

PendingCN113638454ATreatment effect monitoringOptimize construction parametersFoundation testingSoil preservationDynamic compactionKarst

The invention relates to a dynamic compaction treatment method for a karst foundation. The method includes the steps that (1) rough plane distribution of underground karst of a construction site and karst cave roof burial depth data are acquired, and the construction site is divided into different blocks according to the karst cave roof burial depth data; (2) karst development condition information is obtained, local dynamic compaction tests are conducted on the different blocks, and dynamic compaction construction technical parameters of the different blocks are determined; and (3) dynamic compaction construction is conducted on the different blocks, in the dynamic compaction construction process, the treatment effect of the foundation is monitored and measured while compaction is conducted, and follow-up construction is optimized according to monitoring information. According to the dynamic compaction treatment method for the karst foundation, areas with different depths and development conditions of karst caves in the construction area are partitioned, proper construction technical parameters are given respectively, and dynamic compaction treatment is performed in different areas, so that the treatment effect is ensured, the construction period is shortened, treatment resources are saved, and the construction cost is reduced.

Owner:杭州建材数字化产业港有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com