ControL method and device of supercriticaL carbon dioxide injection fracturing phase state and eLectronic equipment

A carbon dioxide and control method technology, applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problems of insufficient consideration of influence and low calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

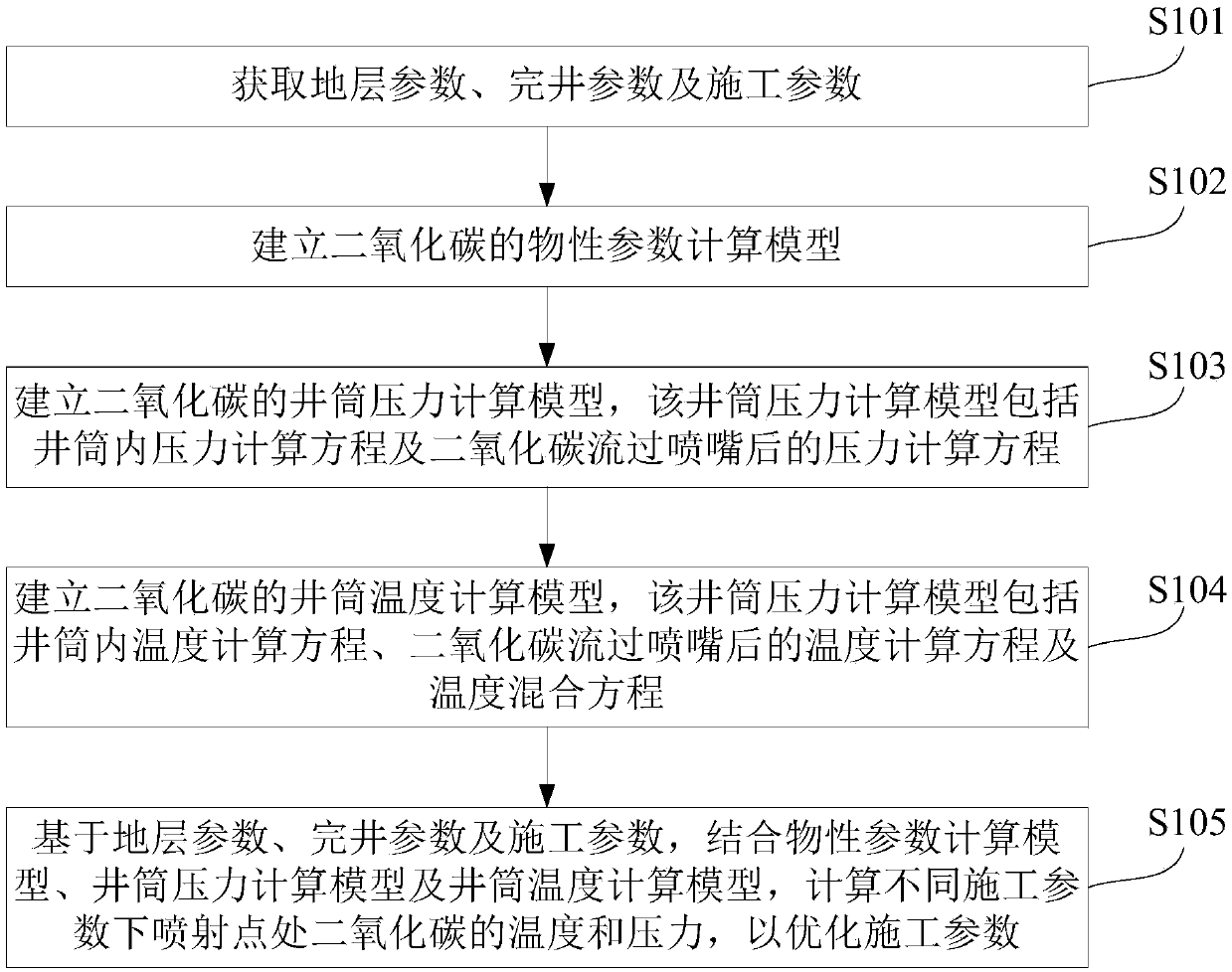

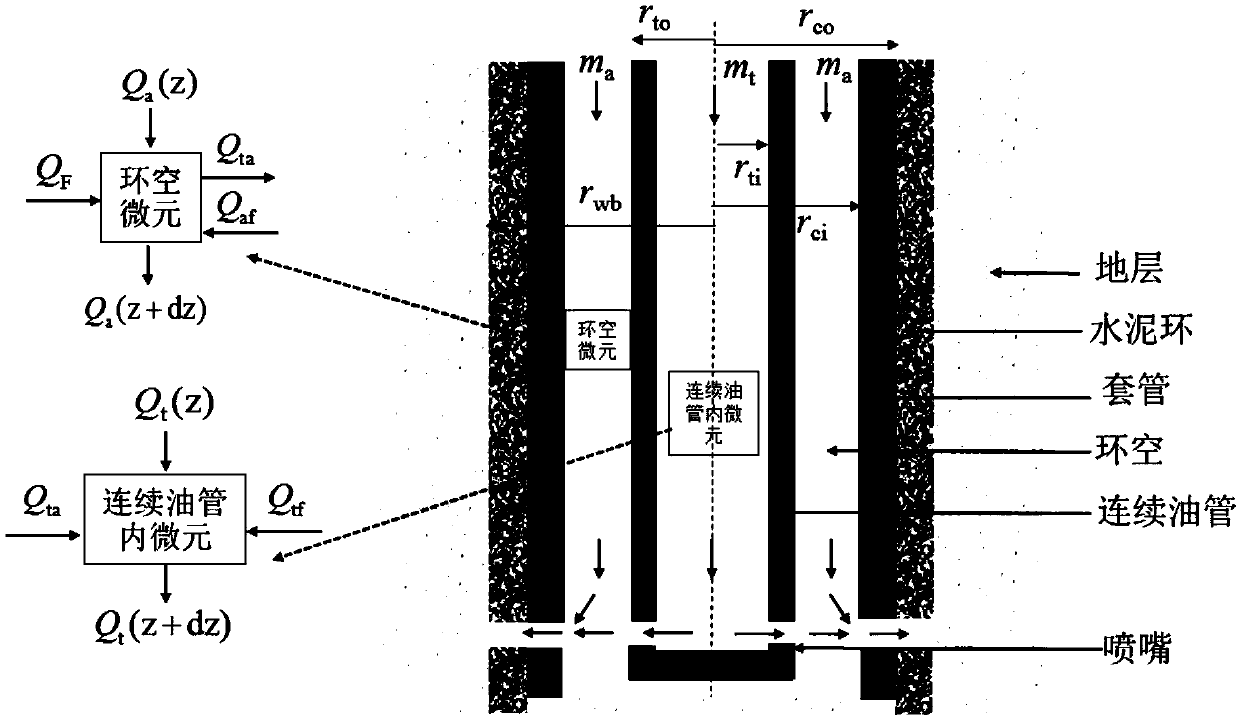

[0035] figure 1 A supercritical carbon dioxide injection fracturing phase state control method provided by an embodiment of the present invention is shown, including:

[0036] Step S101, obtaining formation parameters, well completion parameters and construction parameters.

[0037] In a possible embodiment, formation parameters include geothermal gradient, rock thermal conductivity, rock specific heat capacity; well completion parameters include well depth, casing size, coiled tubing size, cement sheath size, wellbore size, casing thermal conductivity, casing specific heat capacity , thermal conductivity of coiled tubing, specific heat capacity of coiled tubing, thermal conductivity of cement sheath, specific heat capacity of cement sheath; construction parameters include nozzle diameter, injection speed, injection temperature, and injection time.

[0038] Step S102, establishing a calculation model of physical property parameters of carbon dioxide.

[0039] Step S103, esta...

Embodiment 2

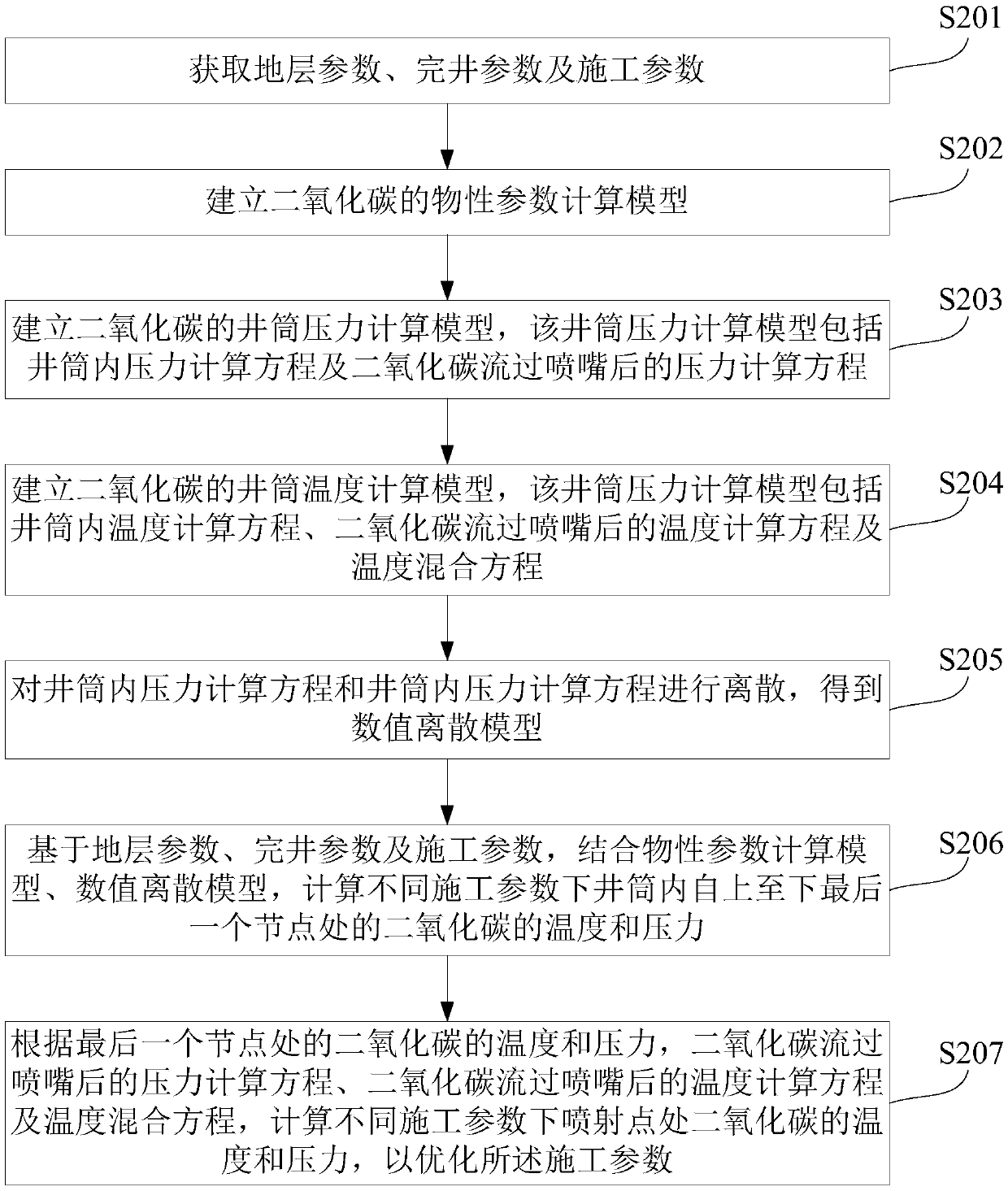

[0045] figure 2It shows another supercritical carbon dioxide injection fracturing phase state control method provided by the embodiment of the present invention, including:

[0046] Step S201, obtaining formation parameters, well completion parameters and construction parameters.

[0047] In a possible embodiment, formation parameters include geothermal gradient, rock thermal conductivity, rock specific heat capacity; well completion parameters include well depth, casing size, coiled tubing size, cement sheath size, wellbore size, casing thermal conductivity, casing specific heat capacity , thermal conductivity of coiled tubing, specific heat capacity of coiled tubing, thermal conductivity of cement sheath, specific heat capacity of cement sheath; construction parameters include nozzle diameter, injection speed, injection temperature, and injection time.

[0048] Step S202, establishing a calculation model of physical property parameters of carbon dioxide.

[0049] In a pos...

Embodiment 3

[0160] For the supercritical carbon dioxide injection fracturing phase state control method in the first embodiment above, see Image 6 , the supercritical carbon dioxide injection fracturing phase state control device includes:

[0161] A parameter acquisition module 11, configured to acquire formation parameters, well completion parameters and construction parameters;

[0162] In a possible embodiment, formation parameters include geothermal gradient, rock thermal conductivity, rock specific heat capacity; well completion parameters include well depth, casing size, coiled tubing size, cement sheath size, wellbore size, casing thermal conductivity, casing specific heat capacity , thermal conductivity of coiled tubing, specific heat capacity of coiled tubing, thermal conductivity of cement sheath, specific heat capacity of cement sheath; construction parameters include nozzle diameter, injection speed, injection temperature, and injection time.

[0163] The physical property ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com