A seepage test system for excavation face under tidal load in river bottom shield tunnel construction

A technology of shield tunneling and test system, which is applied in permeability/surface area analysis, suspension and porous material analysis, instruments, etc. Excessive seepage flow on the excavation surface of the tunnel, etc., to optimize the construction parameters and achieve the effect of guiding the design and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

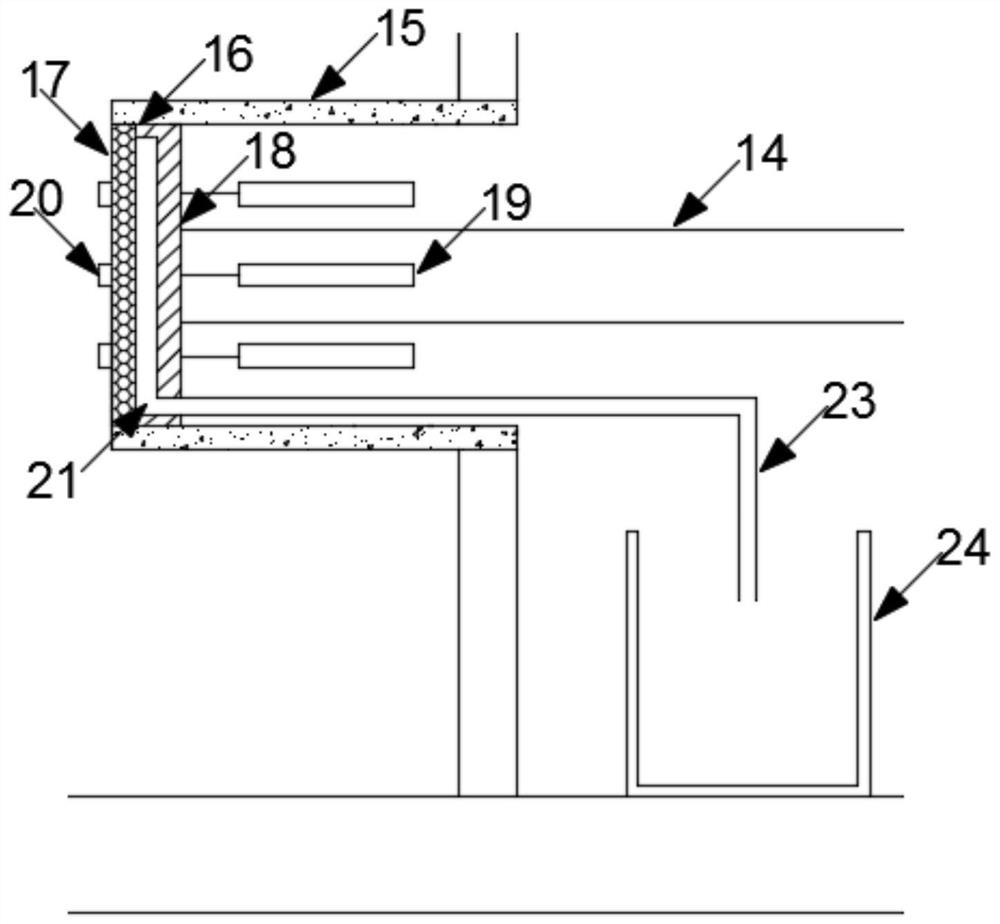

[0027] Construction sequence: the first step is to prepare cement mortar with a certain mix ratio, and complete the production of semi-circular concrete lining 15 through steps such as pouring, curing, formwork removal, and installation;

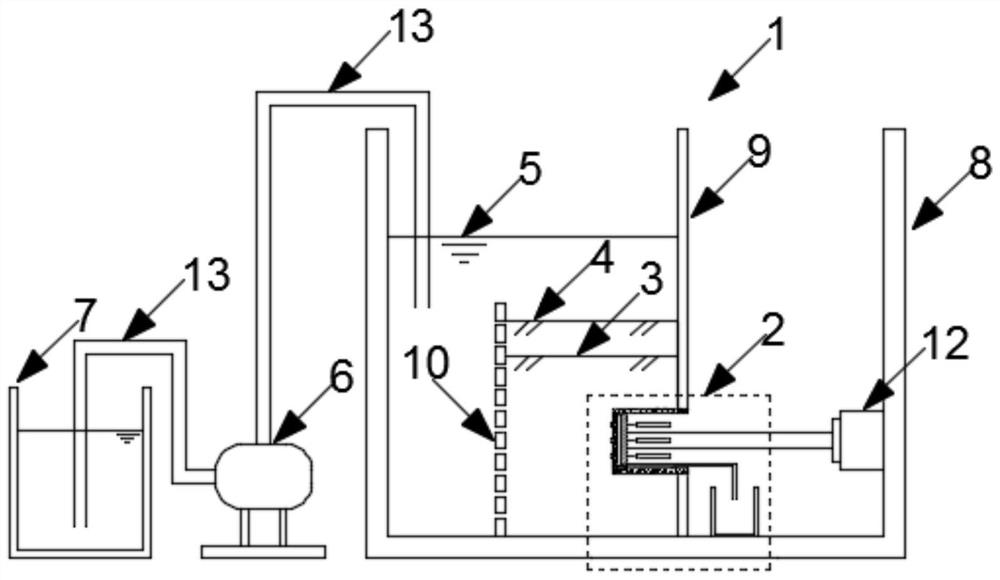

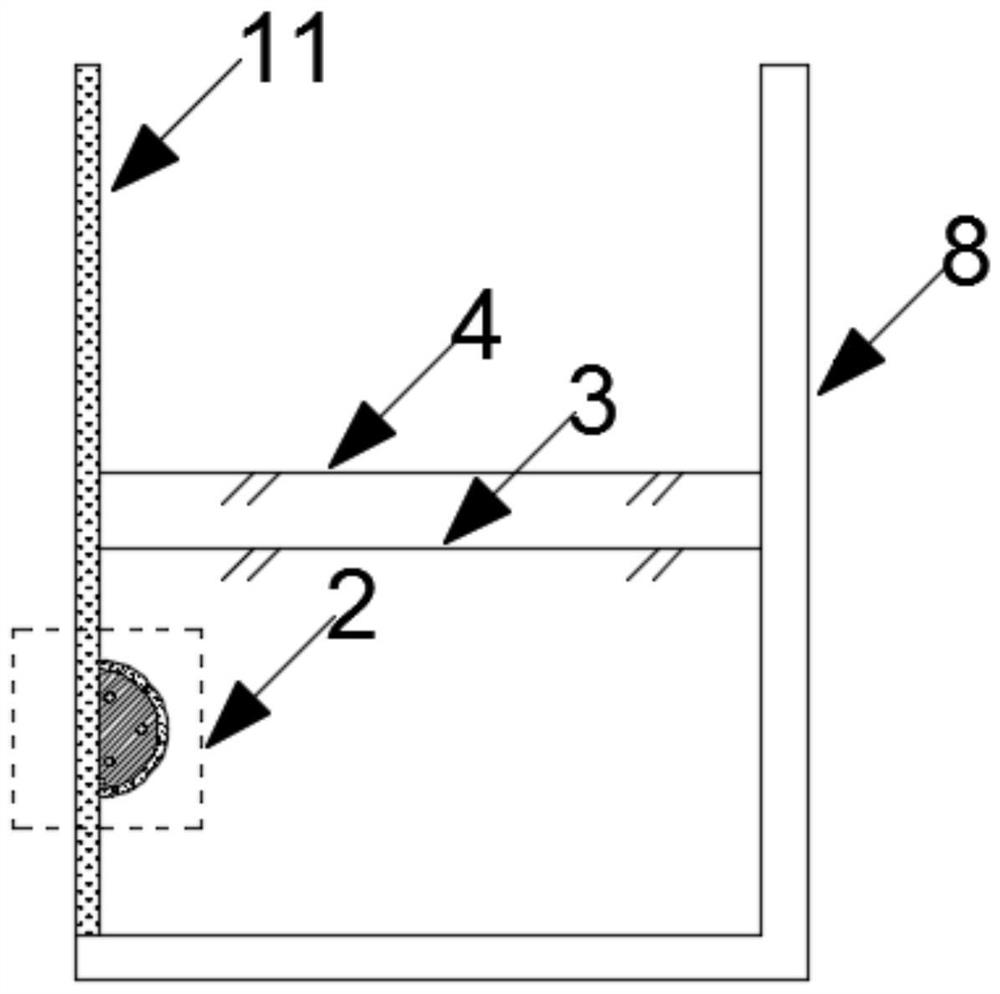

[0028] In the second step, install the soil-retaining glass plate 9, the water-permeable soil-retaining steel plate 10, the expansion rod mounting seat 12 and the measuring cylinder 24 at the corresponding positions in the model box 1, and apply vaseline on the inner wall of the model box 1 to avoid the gap between the soil and the model box. Boundary effects caused by friction. The diameter of the filter hole of the permeable soil retaining steel plate 10 needs to be smaller than the median particle size of the soil sample particles in the permeable soil layer, so as to avoid formation loss caused by a large amount of soil particles in the permeable soil layer entering the water sample. Permeable soil retaining steel plate 10 as attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com