Stepwise dissolution and plugging removal method for oil and water wells

An oil-water well and corrosion technology, which is applied in the direction of earthwork drilling, wellbore/well components, cleaning equipment, etc., can solve the problems of technical target retention, serious secondary sedimentation, high construction cost, etc., to increase the oil drainage area and prevent clay The effect of migration and avoiding secondary precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Oil-water well staged dissolution plugging removal method

[0032] Before construction, first understand the basic situation of the target well, including the following aspects:

[0033] (1) Obtain the reservoir geological parameters and fluid characteristics of the target well, and clarify the sand body distribution law, physical property changes, oil saturation, crude oil viscosity, permeability, produced fluid and other parameters.

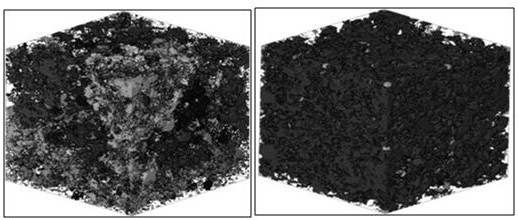

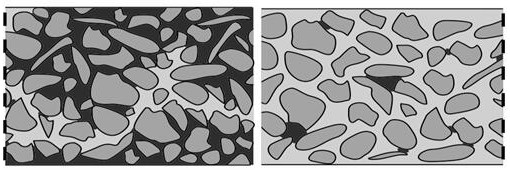

[0034] (2) Clarify rock composition, porosity, component content of rock minerals, distribution of natural pore-throats, filling debris composition, and clay mineral composition of different components of gel structure, while clarifying reservoir wettability, oil saturation, sensitivity sex.

[0035] (3) According to the previous production dynamic changes, tests, etc., combined with the production fluid, injection water quality, and pipe string scaling, the type and degree of pollution are determined; and this is used as a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com