Patents

Literature

134results about How to "Increase drainage area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

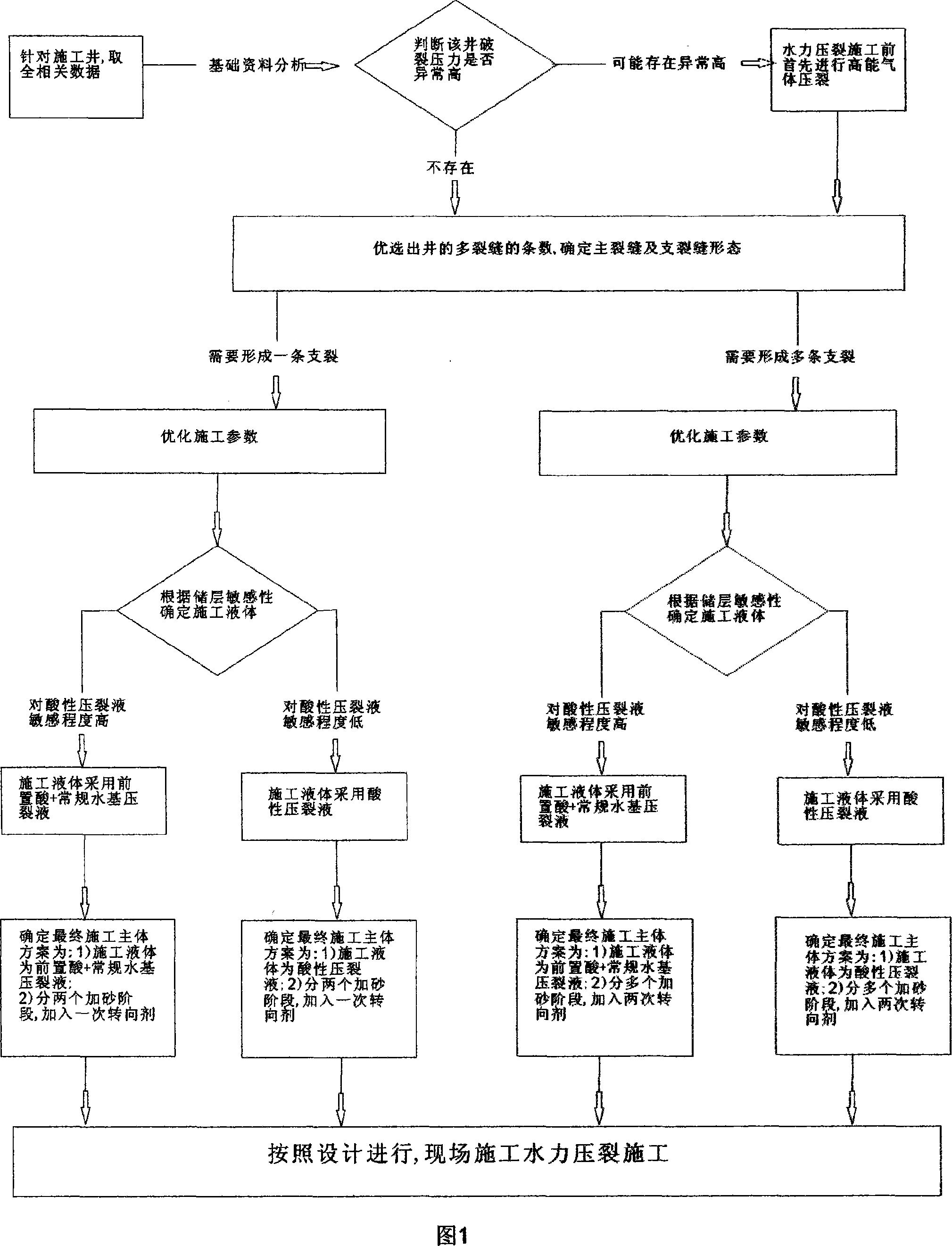

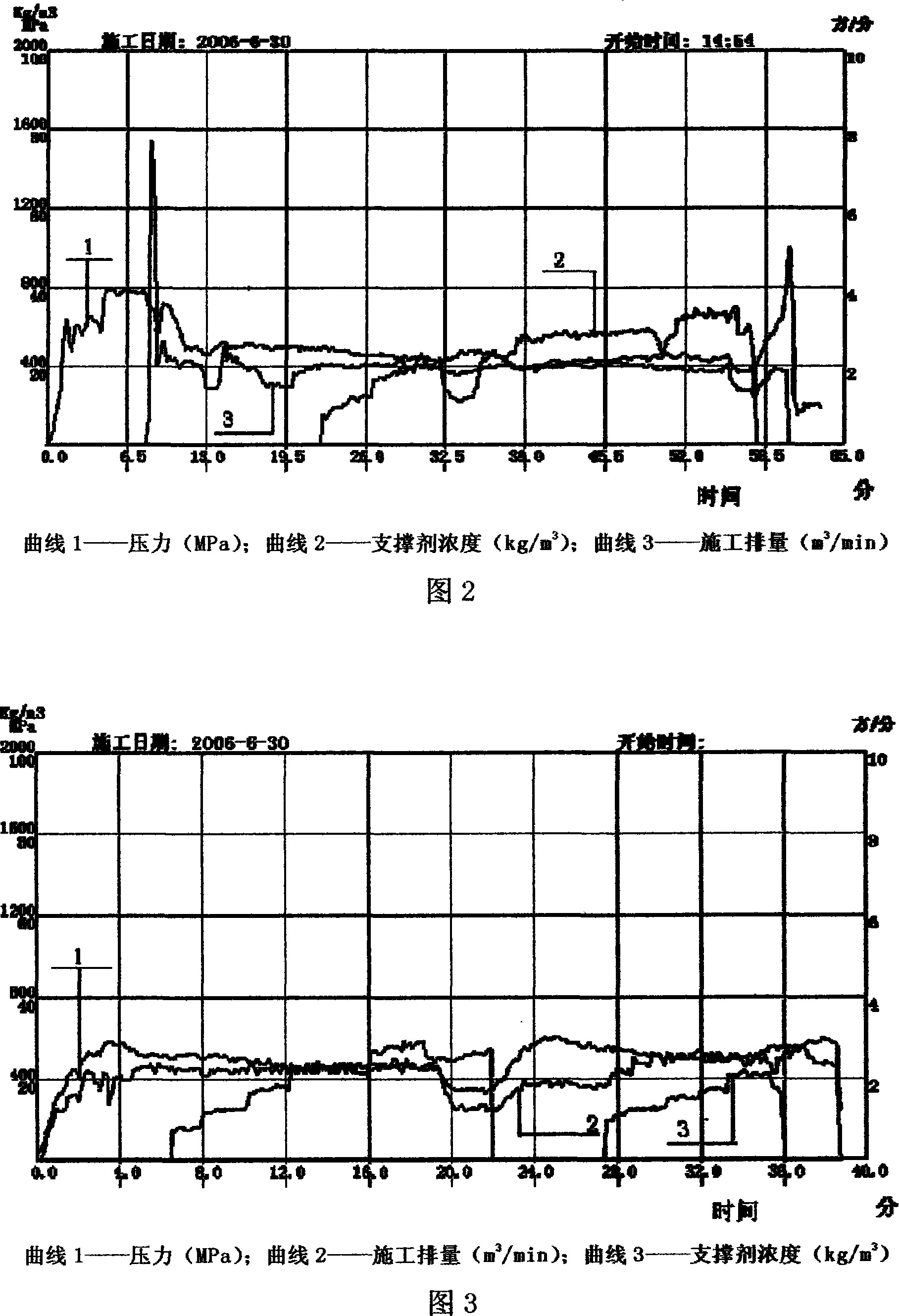

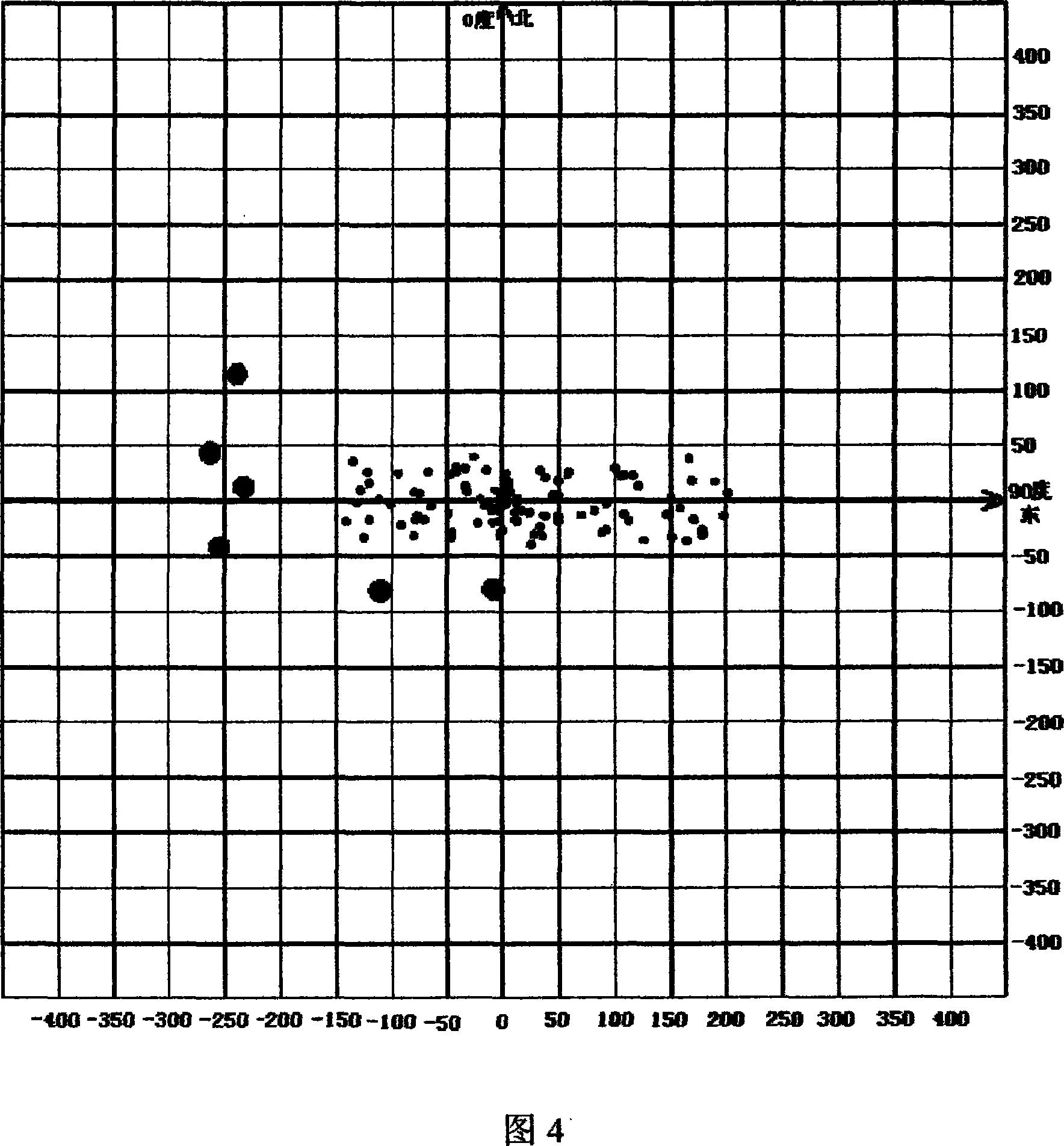

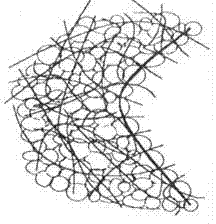

Fracturing process for enhancing low permeability reservoir deliverability

ActiveCN101113669AGuaranteed permeabilityIncreased productivity after pressingFluid removalAcid fracturingClay minerals

The invention relates to an oil field production technique, in particular to a fracturing method applied under the oil well to improve new well production capacity of low permeability reservoir before being brought into production. The fracturing reformation course at least comprises common fracturing technique and is characterized in that the method uses a compound application of more than two techniques of the use of acid fracturing liquid, or diversion agent or acid liquid and diversion agent by adopting high-energy gas fracturing technique; the upper sealed fracturing pipe is adopted during the working of hydraulic fracturing; the acid liquid is adopted during a pad fluid stage as the working liquid; the diversion agent is added for one or more times to seal fractured cracks; an increasing working flow rate is adopted before and after the adding of the diversion agent. The method of the invention can increase oil discharging area after fracturing, reduce expansion rate of clay minerals in fractured reservoir and improve completion of oil well reformation, fracturing effect and production capacity of low permeability reservoir after fracturing.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

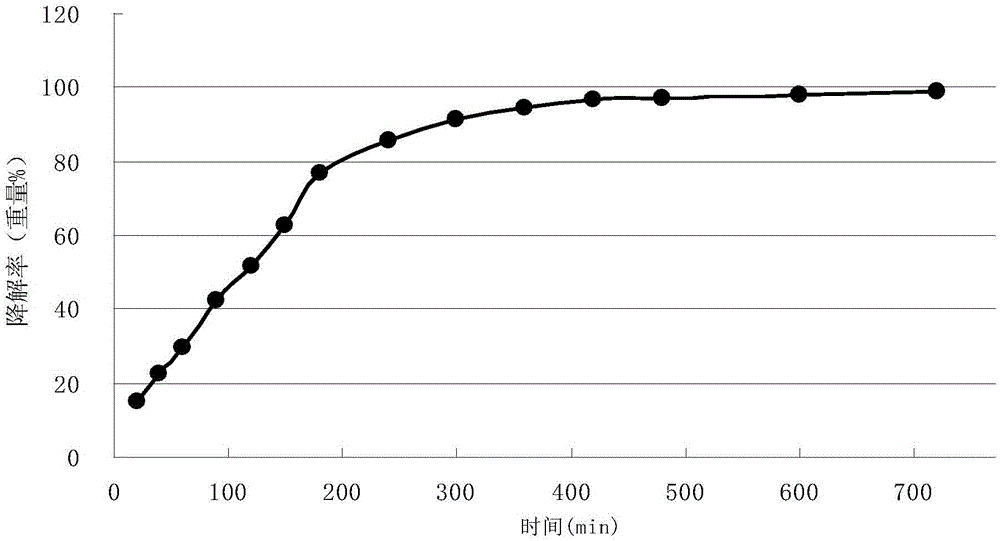

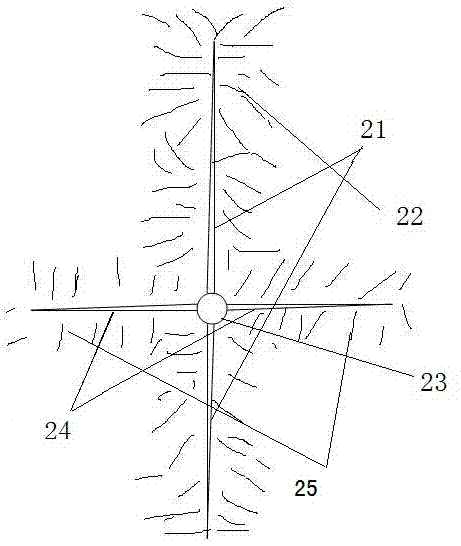

Temporary blocking turnaround fracturing method based on surface modified polyvinyl alcohol fibers

ActiveCN104727800AImprove production efficiencyIncrease drainage areaFluid removalDrilling compositionFiberPolyvinyl alcohol

The invention particularly provides a temporary blocking turnaround fracturing method based on surface modified polyvinyl alcohol fibers. The method comprises the following steps that 1, the surfaces of the water-soluble poly(vinyl alcohol) fibers are modified; 2, fracturing work liquid is prepared; 3, liquid in a shaft is extruded out by and replaced with active water; 4, setting is carried out on a facture packer; 5, prepad fluid is injected, and a major fracture is formed; 6, the water-soluble degradable fiber temporary blocking fracturing liquid is injected into the formed major fracture in a step mode and injected into a stratum to form a new branch fracture; 7, the prepad fluid is injected into the formed new branch fracture, and the length of the fracture is expanded; 8, sand-carrying liquid is injected into the formed new branch fracture in a step mode; 9, the sand-carrying liquid in the shaft is extruded out by and replaced with active water. An old facture or a facture filled with sand is temporarily blocked, the new fractures are made on the original fracture in a certain angle direction, more unused areas of natural fractures and primary fractures are communicated, a new fracture flow leakage system is formed, oil and gas production and the ultimate recovery factor of an oil and gas field are improved, and the aims of restoring the yield of an old well and achieving facture production increase of a new well are achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

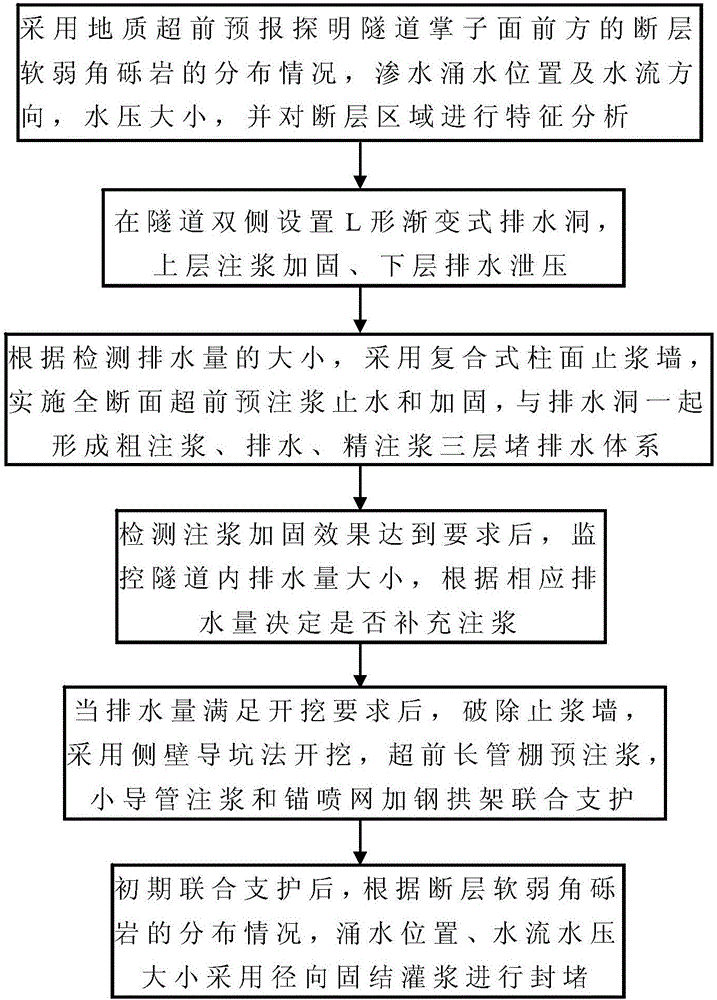

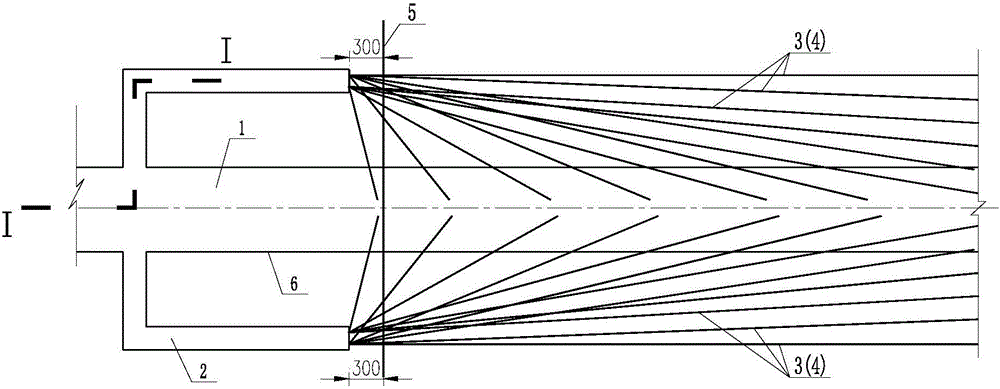

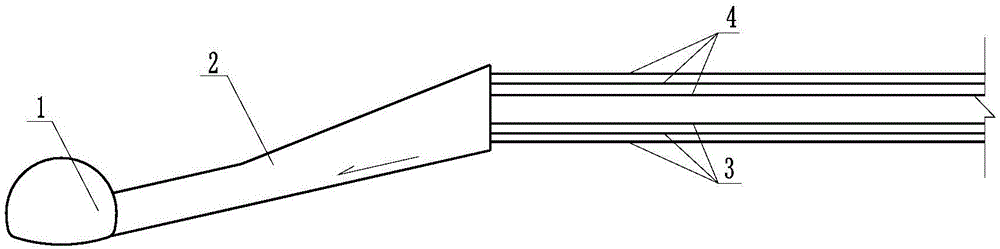

Construction method of high-tension water-rich extra-large-section weak breccia tunnel

The invention discloses a construction method of a high-tension water-rich extra-large-section weak breccia tunnel. The method includes the steps of exploring distribution of fault weak breccia in front of a tunnel face by an advanced geological forecast method; distributing L-shaped gradient drain holes in two inner sides of the tunnel, providing sector drain holes and grouting holes, and allowing upper grouting and lower drainage; providing a combined cylinder grout-stopping wall, and performing a full-face advanced chemical grouting consolidation; constructing an advanced long tube shed with a circumferential closed advanced tube shed guide wall having a foundation, distributing tapered quincunx examining drain holes to detect grouting effect, and finally excavating the tunnel. Through the use of the techniques such as three-layer stereoscopic grouting and drainage, and cement-water glass and epoxy resin sequential grouting, the problem that a high-tension water-rich surrounding rock area with loose weak breccia has ineffective grouting consolidation and non-obvious water plugging effect is solved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

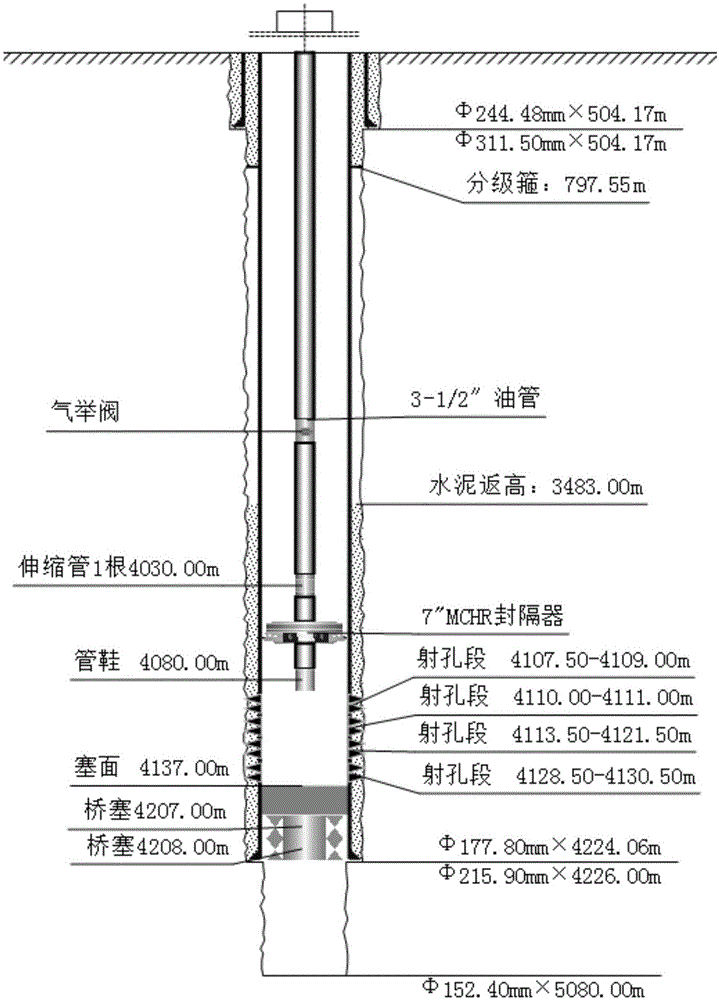

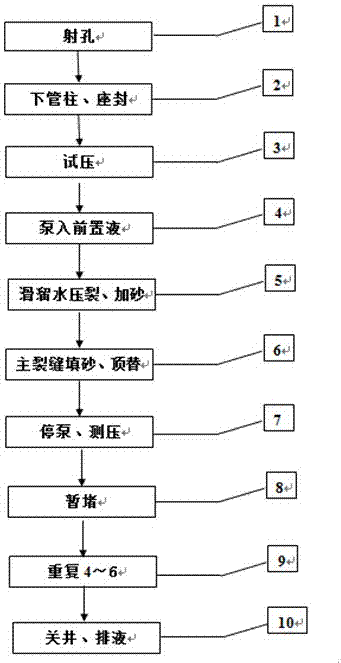

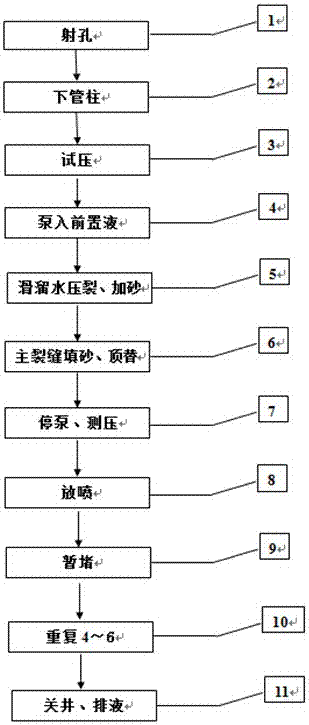

Hydraulic fracturing treatment method of an unconventional reservoir oil and gas well

The invention provides a hydraulic fracturing treatment method of an unconventional reservoir oil and gas well. The hydraulic fracturing treatment method comprises the following steps: injecting a material liquid into existing fractures of a reservoir; enabling a temporary plugging material in the material liquid to form bridge blinding at the seams of the fractures; performing hydraulic fracturing construction to force the fractures to turn; and injecting an active liquid to activate microfractures of the reservoir, and the steps are performed at least once. By the adoption of the hydraulic fracturing treatment method of the unconventional reservoir oil and gas well, not only can a plurality of man-made fractures be formed, the microfractures of the reservoir can be activated, the drainage area is enlarged, and the single-well yield and the economic benefits are improved. The hydraulic fracturing treatment method provided by the invention is not only suitable for unconventional oil and gas reservoirs such as shale gas, coal bed gas and tight oil and gas but also applied to low-permeability and superlow-permeability conventional oil and gas reservoirs; and meanwhile, the method can be used for straight-well capacity increasing revamp construction and can also be used for capacity increasing revamp construction of horizontal wells, deviated wells and the like.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +2

Well lid for emergency drainage

ActiveCN103696444ASmooth precessionUnscrew smoothlyArtificial islandsSewerage structuresEngineeringMechanical engineering

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

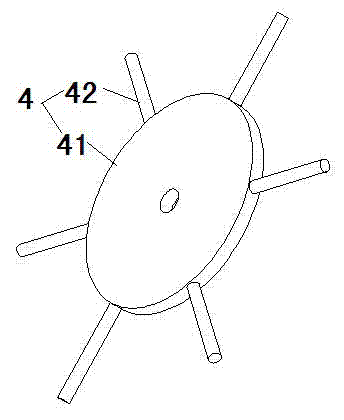

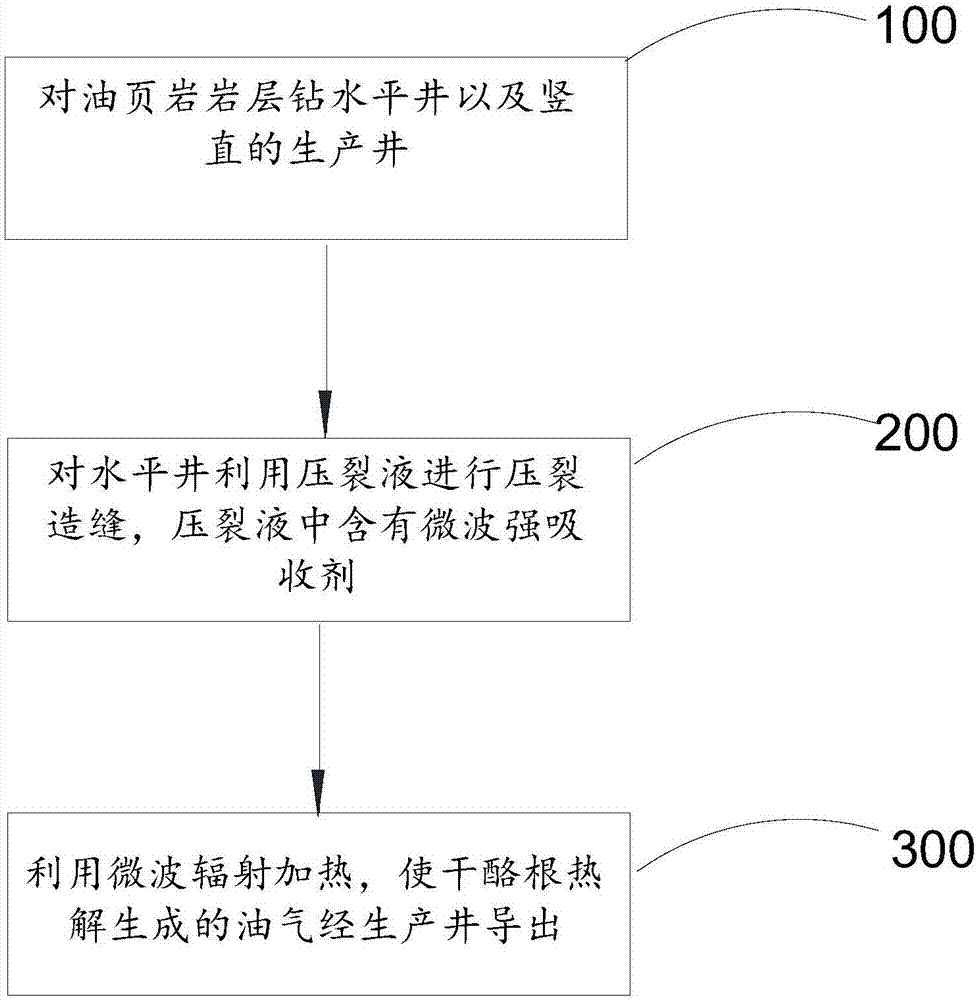

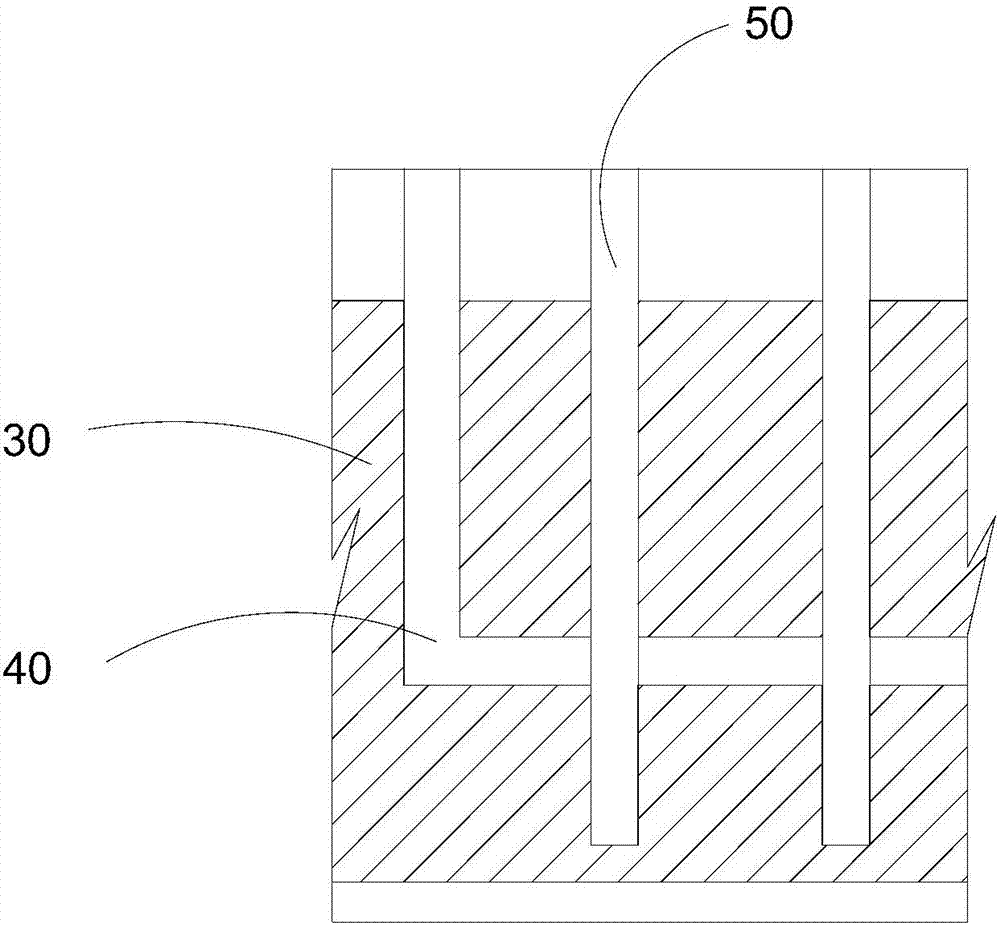

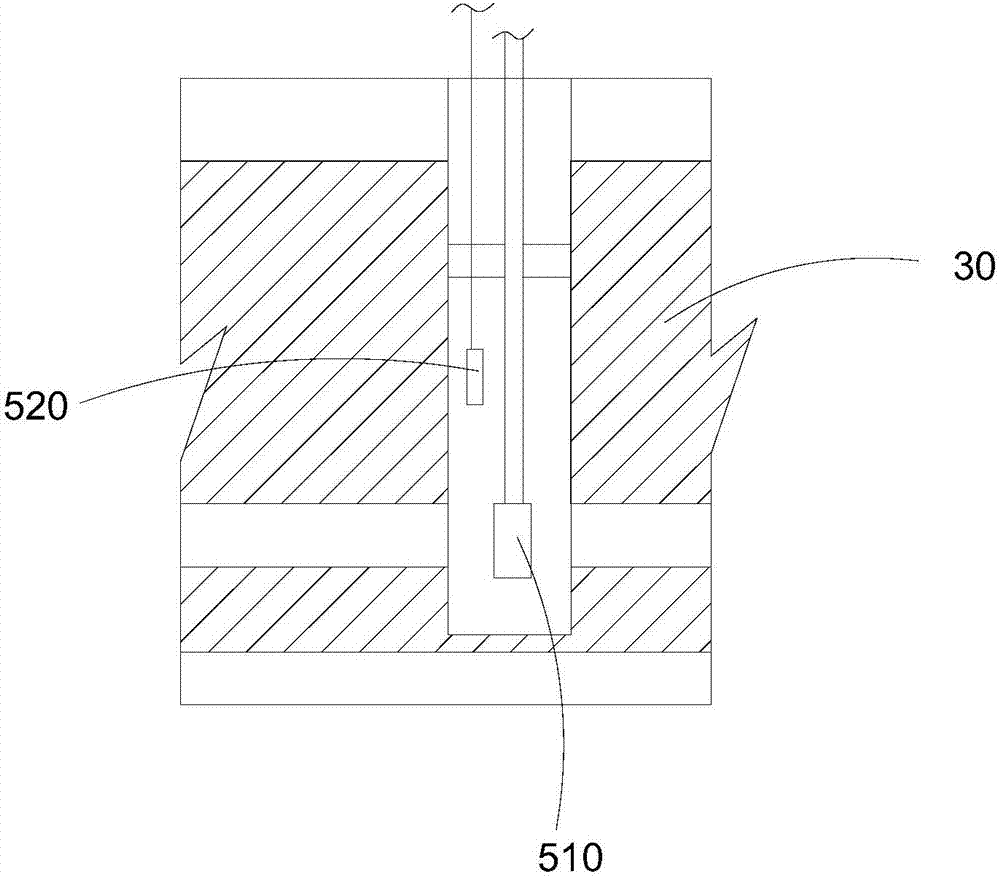

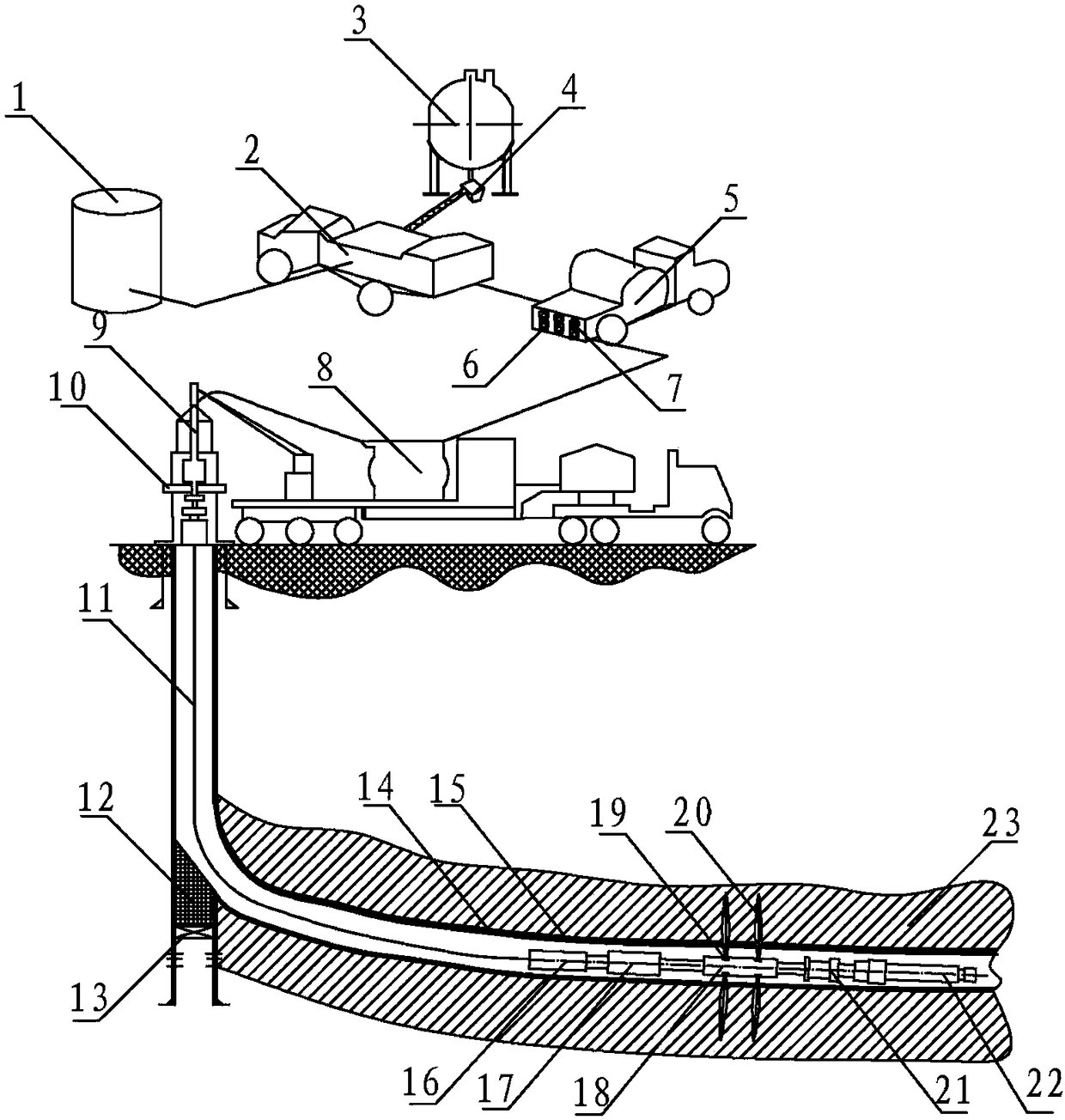

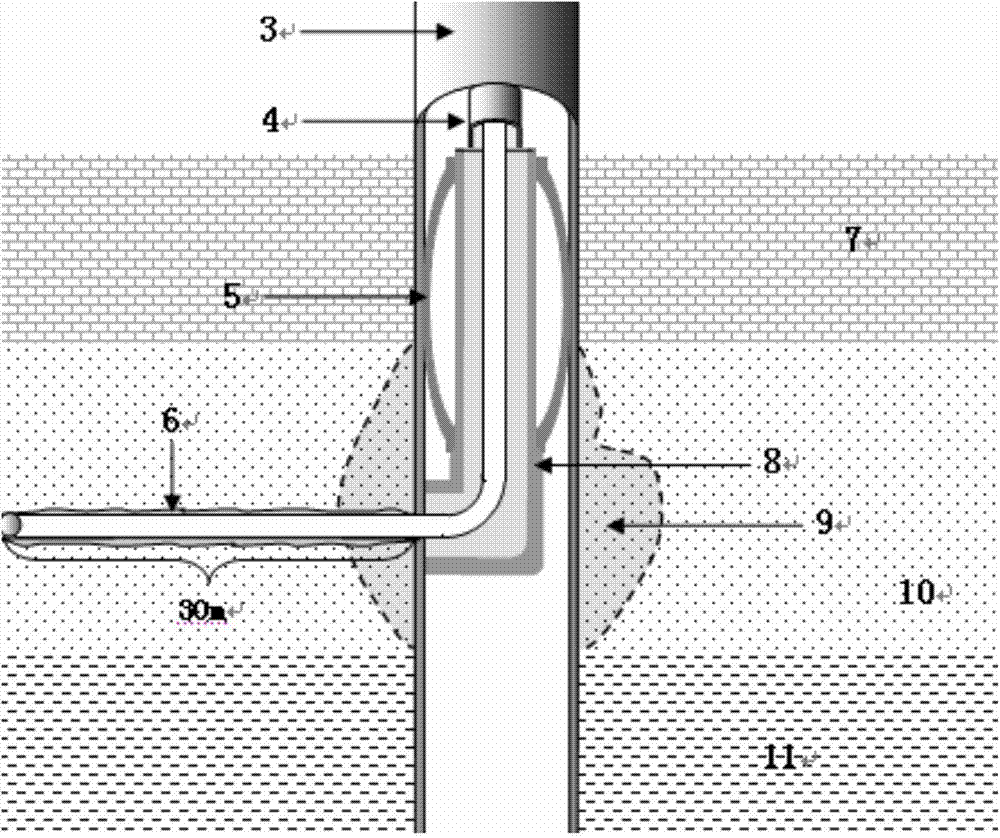

Horizontal well seam forming method and method for extracting oil gas from underground oil shale

The invention relates to a horizontal well seam forming method and a method for extracting oil gas from an underground oil shale, and relates to technical field of petroleum extraction. The horizontal well seam forming method adopts fracturing fluid containing a microwave strong absorber to conduct fracturing seam forming, so that the microwave strong absorber can be uniformly distributed in the seam formed through fracturing by the method, and the utilization rate of microwave heating is increased. The method for extracting the oil gas from the underground oil shale comprises the steps that a horizontal well and a vertical production well are drilled in the oil shale layer; the horizontal well is subjected to fracturing seam forming through the fracturing fluid, and the fracturing fluid contains the microwave strong absorber; and microwave radiation is used for heating, so that the oil gas produced by kerogen pyrolysis is led out through the production well, and the heated efficiency of the oil shale and the extraction rate of shale oil are effectively improved.

Owner:SOUTHWEST PETROLEUM UNIV

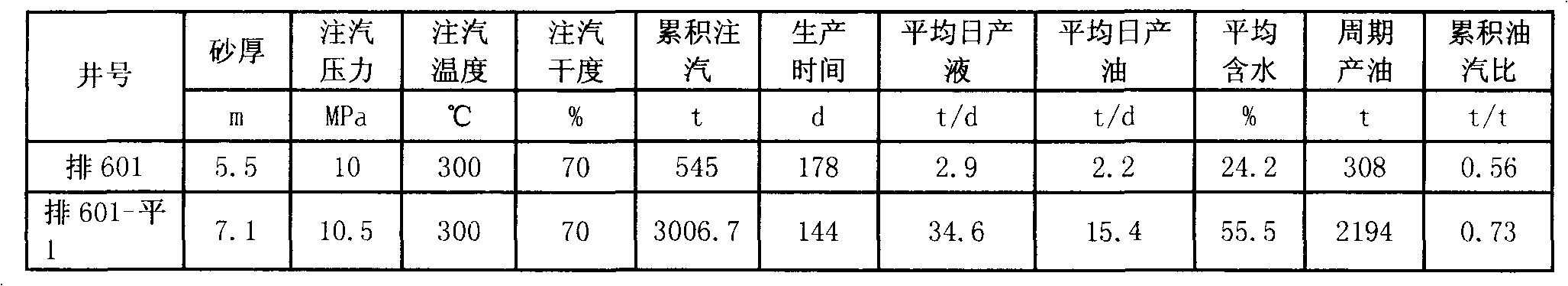

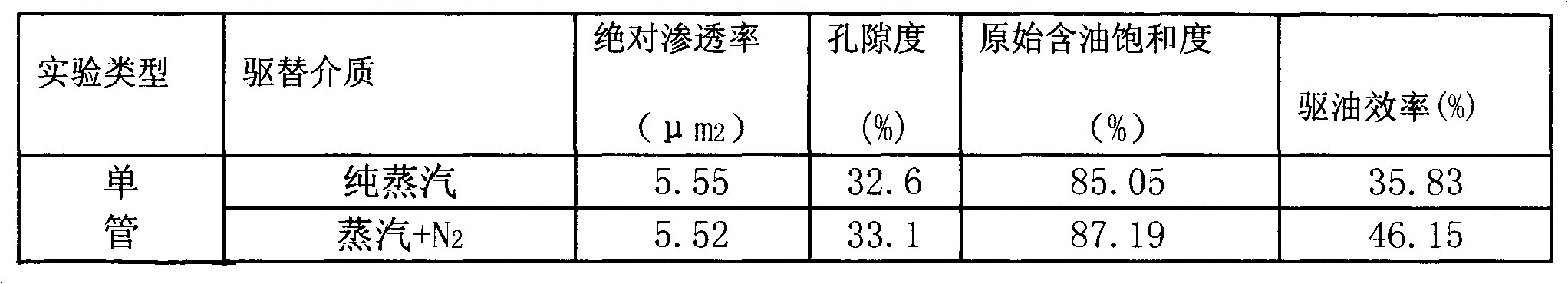

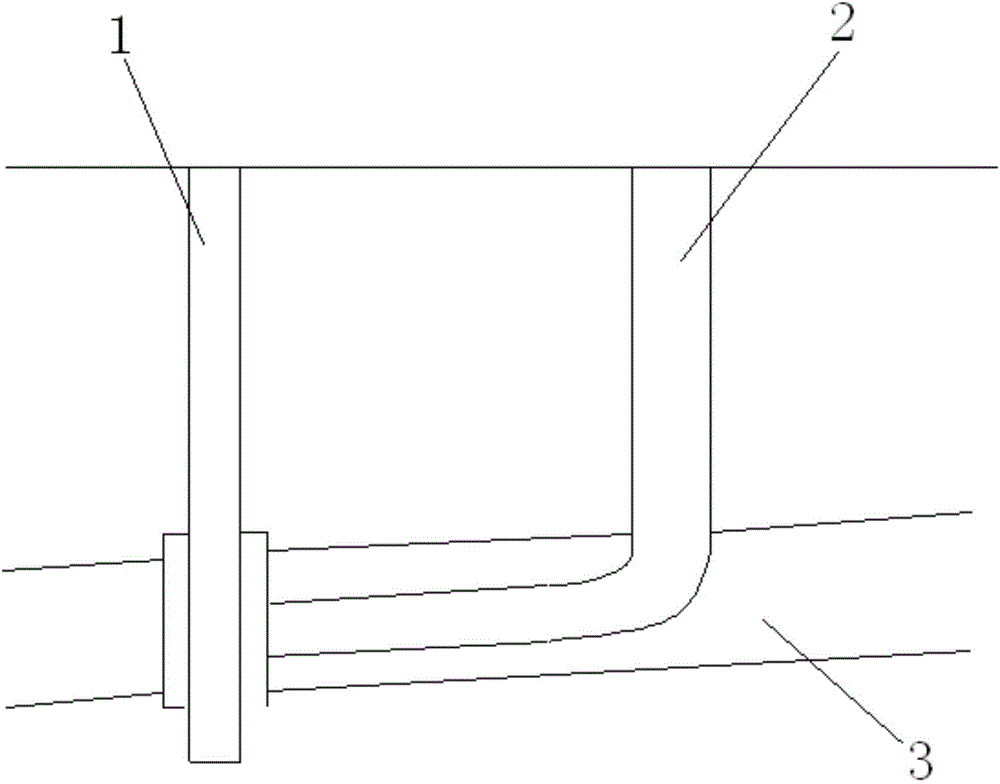

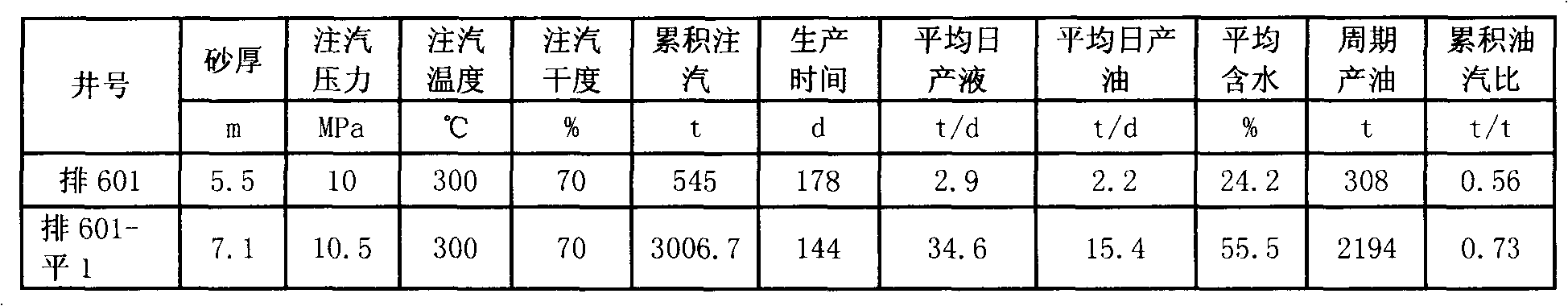

Steam and nitrogen composite swallowing-spitting oil extraction method

InactiveCN102146782AImprove displacement efficiencyIncrease drainage areaFluid removalThermodynamicsNitrogen gas

The invention provides a steam-and-nitrogen composite swallowing-spitting oil production method, comprising the following steps: a, steam injection string laying: a pipe column structure successively comprises an even steam distribution pipe column provided with an even steam distribution valve and a compensator, an injection and extraction integrated pump connected to the even steam distribution pipe column, an oil pipe arranged on the pump, and a subcritical steam injection well from bottom to top; b, N2 and steam injection: steam is injected through an oil jacket annulus, meanwhile, nitrogen is injected into an oil well through the oil pipe, nitrogen injection speed is regulated to evenly allocated and injected during the whole steam injection process; c, soaking: soaking is carried out for 2-7 days after steam injection and nitrogen injected are over; d, blowout: when the well pressure drops to 0.5Mpa / day, blowout is controlled by an oil nozzle; and e, pumping start: when open-flow liquid amount reaches 3t / d, the injection and extraction integrated pump is used to start pumping.

Owner:CHINA PETROLEUM & CHEM CORP +1

Locating high-strength blocking crack deflection fracturing resin coated sand and application process technology

InactiveCN106047322AImprove diversion capacityChange the law of seepage displacementDrilling compositionSealing/packingHigh water contentRaw material

The invention relates to a resin coated sand locating high-strength blocking crack deflection fracturing technology. Resin coated sand is prepared, the surface of a main raw material support is coated with a coupling agent, resin and a curing agent through heating equipment, and the finished resin coated sand product is obtained through further processing. The resin coated sand is used in the locating high-strength blocking crack deflection fracturing construction of an oil and gas well, during fracturing construction, sand-carrying fluid or water is used for carrying the resin coated sand into a target layer, and an artificial crack, or a natural crack or a low-pressure dominant passage in a high-water-content state can be deeply blocked. After the resin coated sand is cured, second fracturing is carried out, fluid is made to deflect through changes of fracturing pressure and crack extending pressure, and new cracks are formed in other directions and portions of a stratum. The fracturing construction effective rate can be greatly increased through the resin coated sand locating high-strength blocking crack deflection fracturing technology, new oil drainage area can be increased or added, a remaining oil enrichment region is communicated or produced, a reservoir stratum which is low in producing degree or not produced at all can be produced, and the oil and gas yield of the oil and gas well is substantially increased.

Owner:唐山市金沙工贸有限公司 +1

Coal bed gas U-shaped well staged fracturing exploitation technology

Owner:CNPC GREATWALL DRILLING ENG

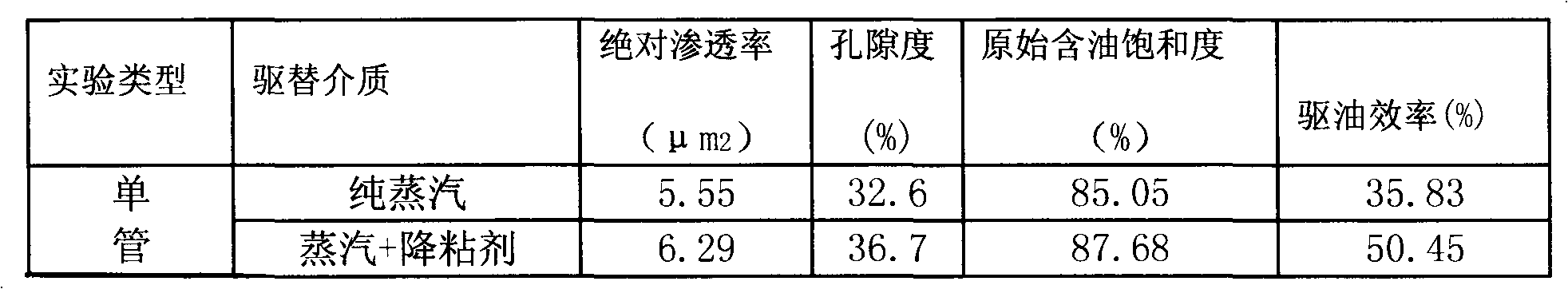

Compound huff-puff oil recovery method by using steam and oil-soluble viscosity reducer

InactiveCN102080523AIncrease the drainage areaReduce steam injection pressureFluid removalWellheadOil soluble

The invention provides a compound huff-puff oil recovery method by using steam and an oil-soluble viscosity reducer. The method comprises the following steps: a. embedding of a steam injection pipe column: the structure of the pipe column is a uniform steam distribution pipe column which is sequentially provided with a uniform steam distribution valve and a compensator from the bottom to top, an injection and recovery integrated pump is connected with the upper part of the pipe column, an oil pipe is arranged on the pump, and a sub-critical steam injection well mouth is adopted; b. injection of the viscosity reducer: firstly the oil pipe is filled with the oil soluble viscosity reducer, then a casing valve is closed, and the oil soluble viscosity reducer is continuously injected into a well bore; c. steam injection: the steam is annularly injected via an oil jacket; d. well soaking: the well remains soaking for 2-7 days after the steam is completely injected; e. open flow: when the pressure of the well mouth drops to 0.5MPa / day, open flow is controlled by an oil nozzle; and f. pumping startup: in the case of open flow up to the liquid quantity of 3t / d, the injection and recovery integrated pipe column is adopted for starting pumping.

Owner:CHINA PETROLEUM & CHEM CORP +1

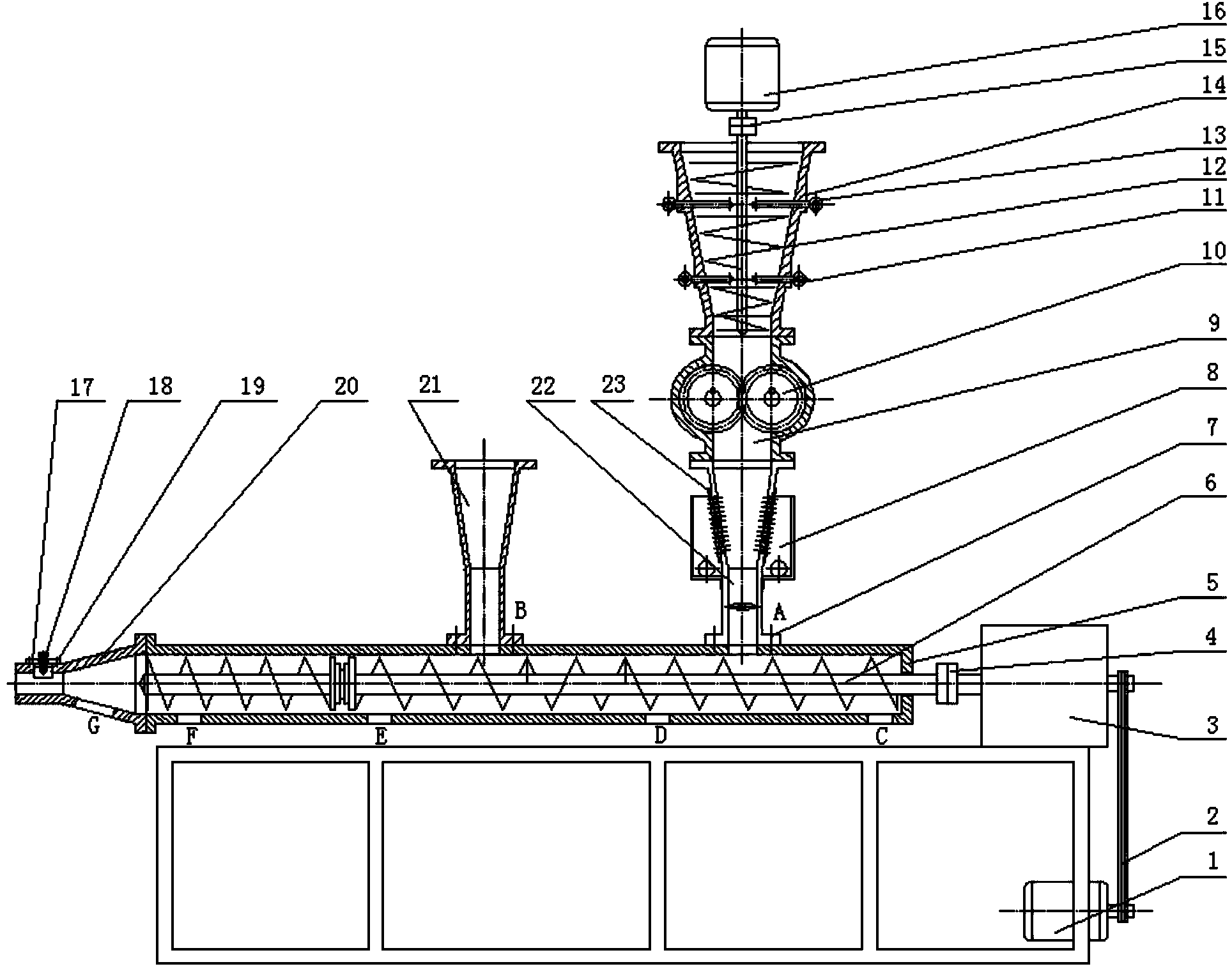

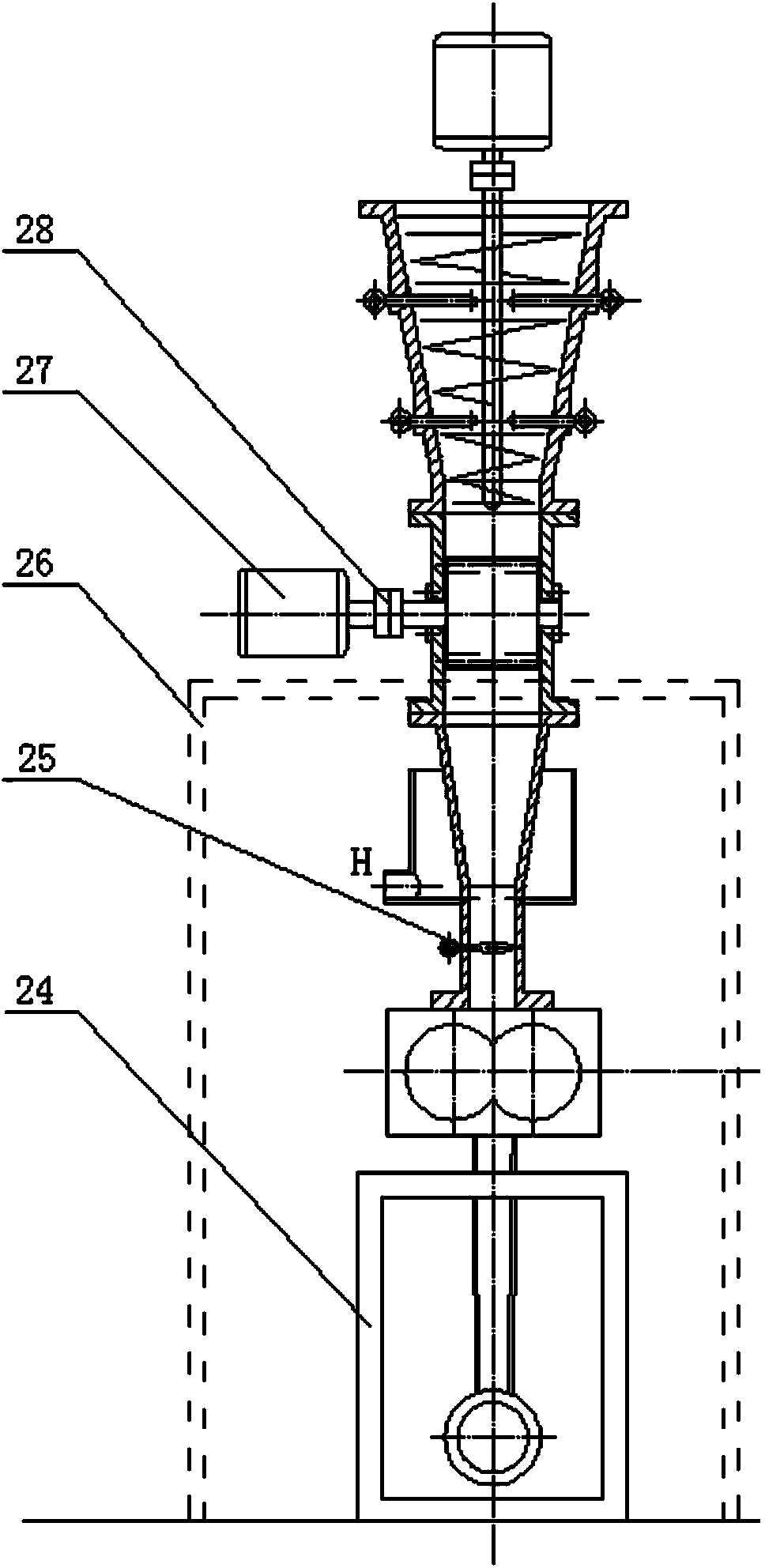

Twin screw breaking and dehydrating integrated processing equipment with gear pump

The invention belongs to the field of material breaking and dehydrating processing, and discloses a twin screw breaking and dehydrating integrated processing equipment with a gear pump; the equipment can be used for integrated processing of material friction breaking, extruding and forming, cell wall breaking, and solid-liquid extraction. The equipment comprises a main motor, a transmission belt, a reducing gear mechanism, a first coupling, a cylinder pair, a combined twin screw pair, connecting screws, an upper filtering cylinder fluid collecting device, the gear pump, a gear pump gear pair, a secondary breaking cutter, a forcing feeding spiral, a primary breaking cutter, a forcing feeder cylinder, a second coupling, a forcing feeding motor, a machine head covering plate, an indexing adjustment screw, a damping block, a dehydrating machine head, an auxiliary feeding cylinder, an upper filtering cylinder, upper filtering cylinder filtering plates, a frame, an upper filtering cylinder indexing adjusting mechanism, a support seat, a gear pump motor, a third coupling and an automatic control system. The forcing feeder breaks material primarily. The upper filtering cylinder is provided with two upper filtering cylinder filtering plates. The cylinder pair is provided with two feeding ports and four dehydrating ports, and the dehydrating machine head is provided with one four dehydrating port. Material breaking and dehydrating processing can be implemented efficiently.

Owner:BEIJING UNIV OF CHEM TECH

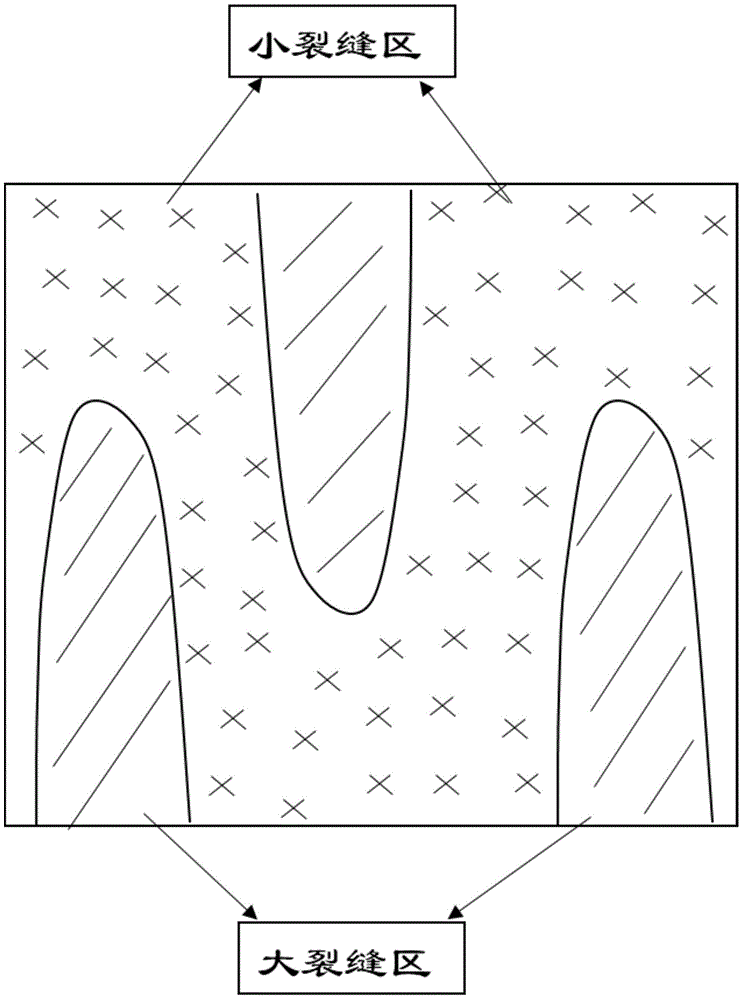

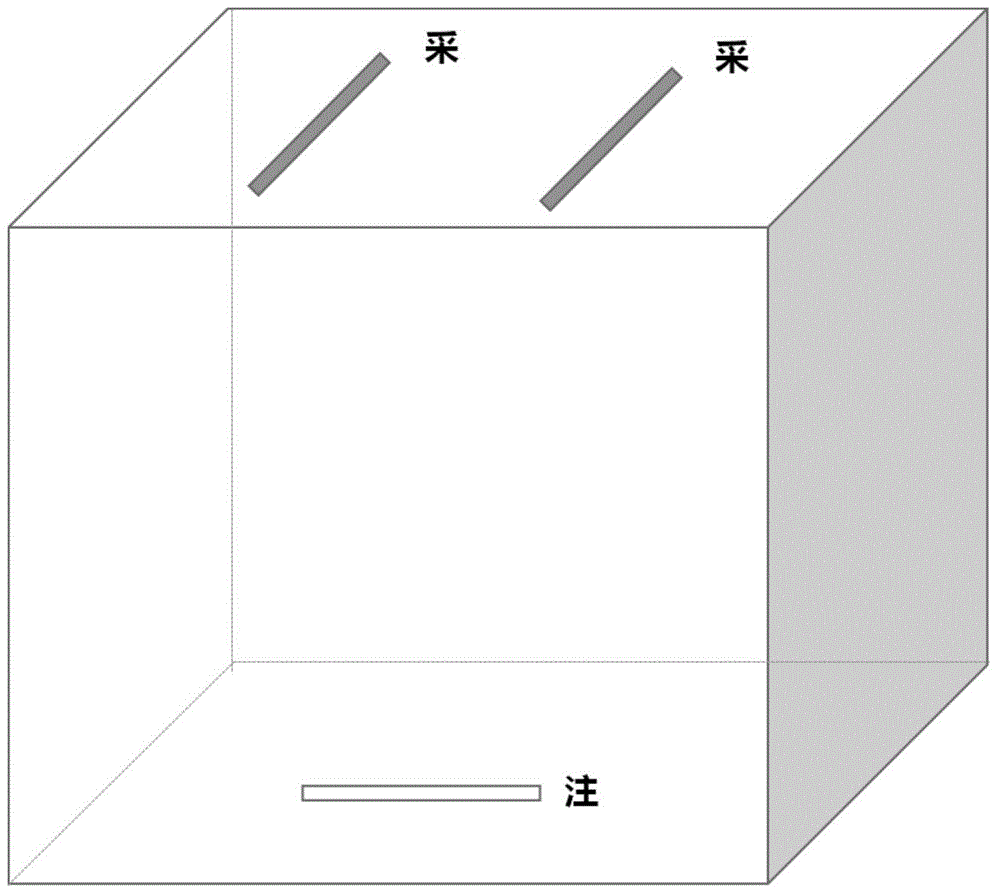

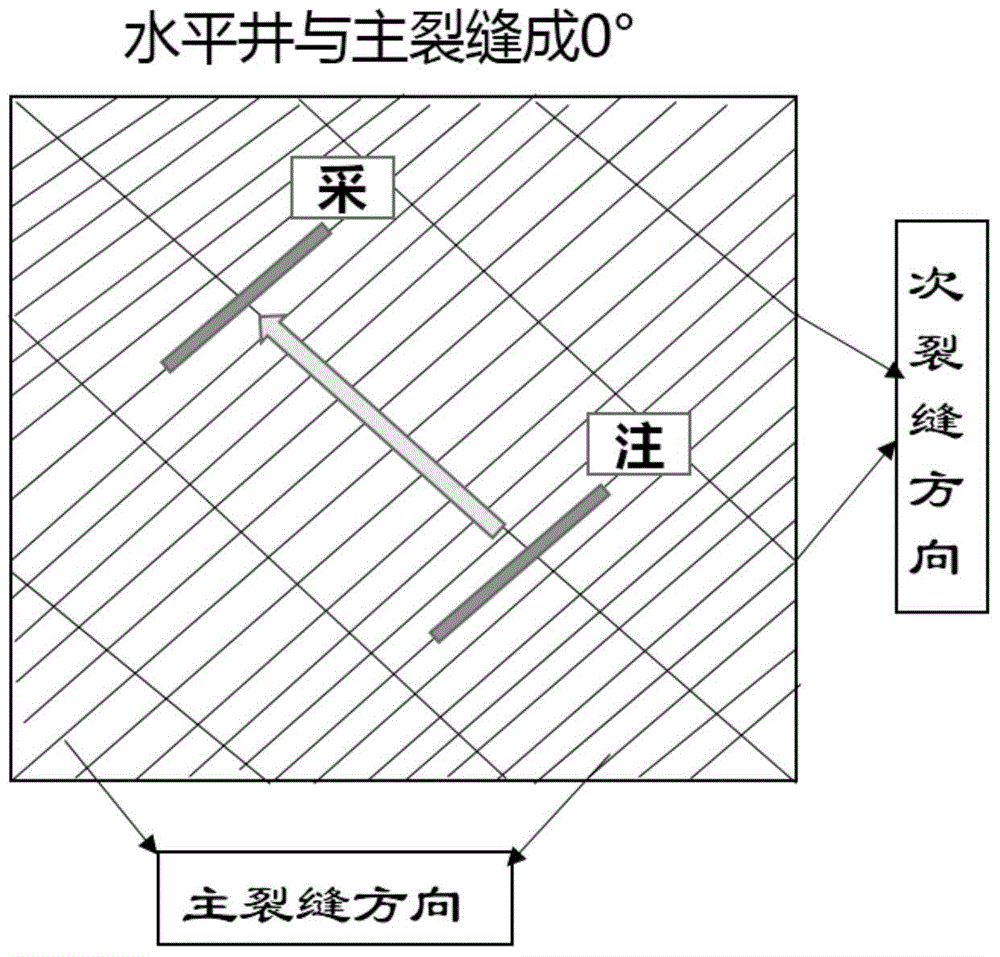

Well network deployment method of giant thick fractured and buried hill reservoir

ActiveCN104912537AGuaranteed encounterReduce production differential pressureFluid removalNetwork deploymentDistribution method

The invention relates to a well network deployment method of a giant thick fractured and buried hill reservoir. The method is characterized in that a set of large-fracture-injection small-fracture-production plane-staggering longitudinal-three-dimension bottom-injection and top-production horizontal well injection-production well network is deployed in the giant thick fractured and buried hill reservoir, wherein for the large-fracture injection, an injection well is deployed at a large fracture region of the giant thick fractured and buried hill reservoir; for the small-fracture production, a production well is deployed in a small fracture region of the giant thick fractured and buried hill reservoir; for the plane staggering, the projection of the injection well and the projection of the production well on the plane are mutually parallel but not rightly aligned; for the longitudinal three-dimension, the horizontal wells are in parallel arrangement at different depths in the giant thick fractured and buried hill reservoir, and a three-dimensional well network is formed in a direction parallel to the gravity and in a cross section perpendicular to a main shaft; and for the bottom injection and top production, a water injection well is arranged at the bottom of the giant thick fractured and buried hill reservoir, and a production well is arranged on the top of the giant thick fractured and buried hill reservoir. The well network deployment method can effectively solve the problem of well distribution difficulty of the giant thick buried hill reservoir, and belongs to an effective well distribution method of the giant thick fractured and buried hill reservoir.

Owner:CHINA NAT OFFSHORE OIL CORP +1

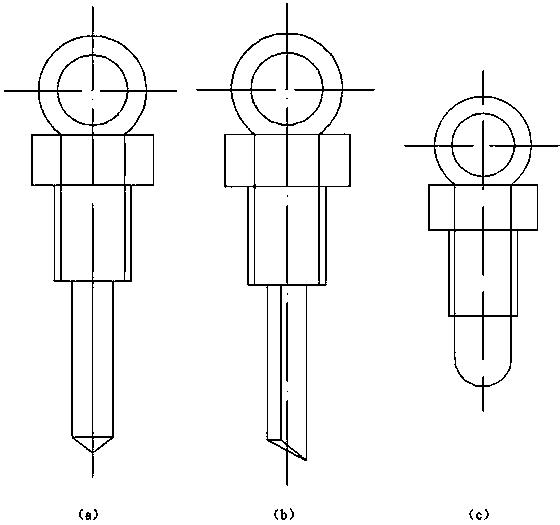

Coiled tubing steel shot jet flow perforating device

PendingCN108425661AIncrease productionFast penetrationFluid removalWell/borehole valve arrangementsLiquid storage tankInlet valve

The invention belongs to the field of oil drilling, and particularly relates to a continuous tubing steel shot jet flow perforating device, which comprises a perforating liquid storage tank, a sand mixing pump, a steel shot storage tank, a screw conveyor, a fracturing pump, a liquid inlet valve body, a drain valve body, a cable car, a coiled tubing, a whipstock, an anchoring device, a centralizingdevice, a perforating device, a nozzle and the like. The effective high-pressure sealing of the solid-liquid two-phase fluid of large-diameter high-density steel shots can be realized by the fracturing pump, and the steel shots and fluid are conveyed through the coiled tubing to improve the tripping efficiency; the steel shots and fluid underground are sprayed out through a well-designed nozzle to achieve rapid penetration of a casing and a cement ring, thereby effectively increasing the depth and diameter of a formation perforation, increasing the drainage area of reservoirs and improving the production of the reservoirs.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

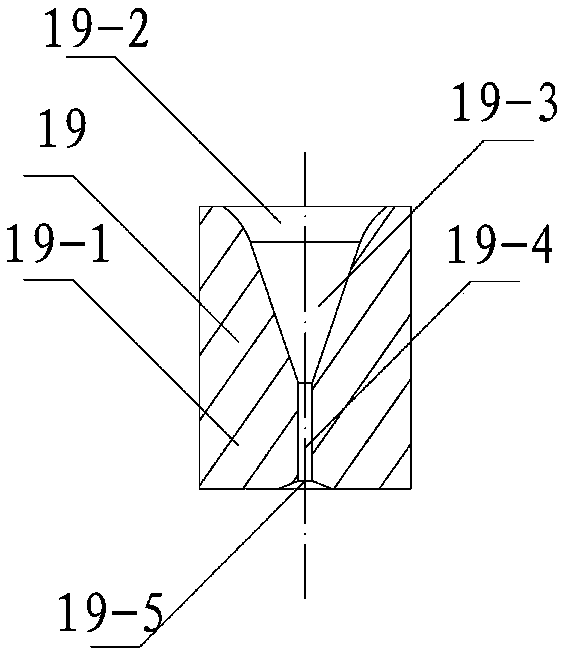

Three-cavity negative-pressure wound irrigation and drainage tube

ActiveCN104941015AHigh hardnessImplanted smoothlyMulti-lumen catheterIntravenous devicesGynecologyDrainage tubes

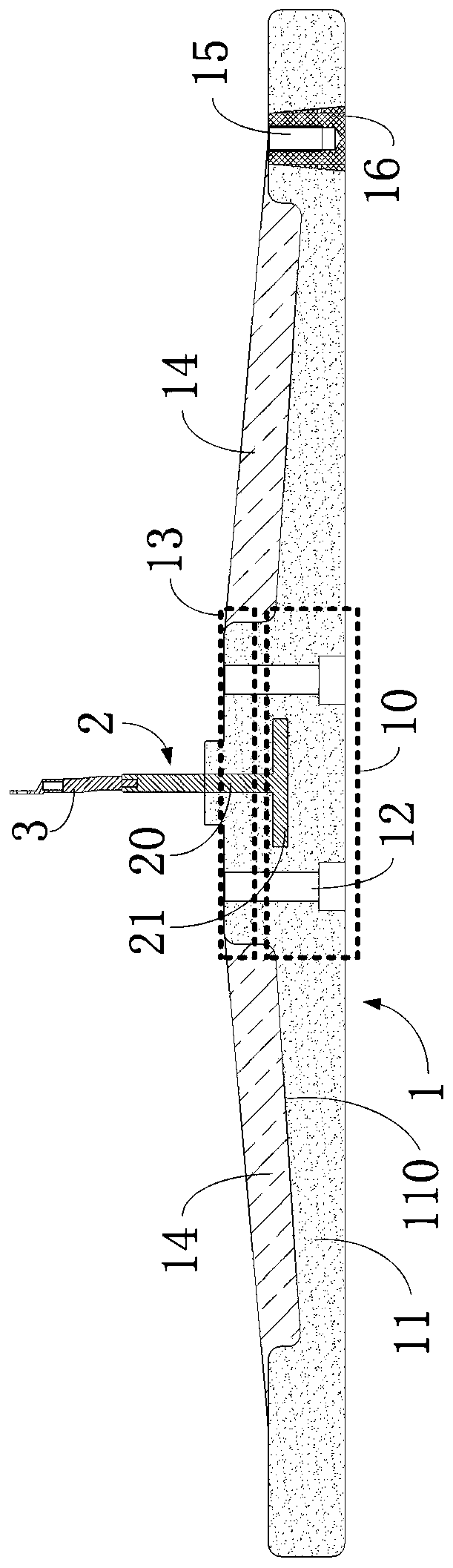

The invention relates to medical human body wound drainage consumables and provides a three-cavity negative-pressure wound irrigation and drainage tube. The negative-pressure wound irrigation and drainage tube comprises an in-vivo drainage tube and an in-vitro connection tube, wherein the in-vivo drainage tube adopts an integral structure and is provided with a main drainage tube, an irrigation tube and a guide wire implanting tube which are parallelly arranged lengthways; the main drainage tube is arranged in the geometric center of the in-vivo drainage tube, and the irrigation tube and the guide wire implanting tube are located at the periphery of the main drainage tube; a lower groove is formed in the outer wall of the in-vivo drainage tube, and a plurality of drainage openings are formed in the lower groove and communicated with the main drainage tube; the in-vitro connection tube comprises an in-vitro drainage tube, an in-vitro irrigation tube and an in-vitro guide wire implanting tube which are mutually independent; the in-vitro drainage tube, the in-vitro irrigation tube and the in-vitro guide wire implanting tube are respectively communicated with the main drainage tube, the irrigation tube and the guide wire implanting tube which are arranged at the outer end of the in-vivo drainage tube. The three-cavity negative-pressure wound irrigation and drainage tube mainly adopts a three-cavity structure, is used for drainage of wounds deep in a human body and has the effects of being accurate in implanting, favorable in drainage and irrigation, resistant to blockage, and the like.

Owner:LANZHOU UNIVERSITY

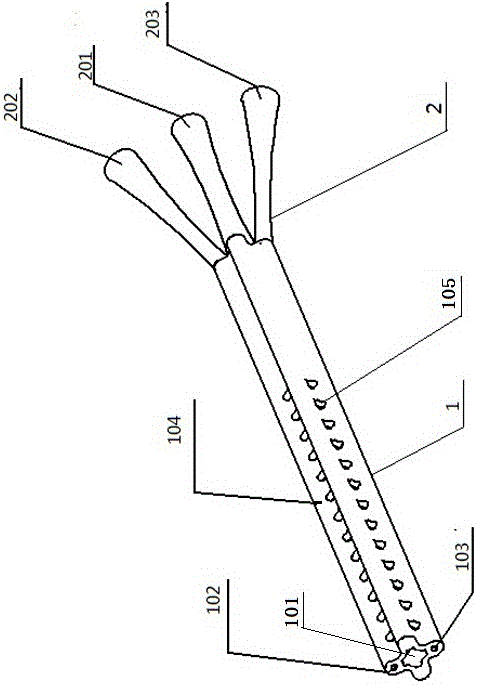

Leakage-preventing fixation-free bead string type drainage tube

InactiveCN1666783AIncrease drainage areaIncrease the areaWound drainsSuction devicesGynecologyCancer

The invention provide a leaf-proof free-mounted pearls shape drainage tube, which is mainly used to breast vomica conduction after the operation of breat cancer and other coelom conduction. It comprises tube and bursa as a whole, and made from silica gel or rubber. The bursa comprises an imperforate bursa body and another bursa body with holes. The full length of drainage tube is 40 cm while the first imperforate 20 cm is out of body and the left 20 cm with holes is shaped strings of pearls and in the body. In the drainage tube, every 5 cm is mounted a pearls shaped expanded bursa with holes on the wall. The middle of tube is a ball shape imperforate bursa while the thickness of tube wall and bursa wall is 1-3 mm, which solve the problems of easy leak and demand for mounted, also increase the area of drainage hole by the ball shaped bursa, in particular having significantly effect on the preventing leak and block when suck the drainage tube in negative pressure. It can reduce the suffering of patients and related complications.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

Highly anti-drag slickwater and application thereof

InactiveCN104927829AOverall performance is perfectGood low temperature stabilityDrilling compositionDrag reducing agentChemistry

The invention relates to low-damage, low-cost and highly anti-drag and high-flowback slickwater comprising the components of 0.05-0.2 parts of a drag reducing agent, 0.15-0.3 parts of a discharge aid, 0.2-0.4 parts of a clay stabilizer, and 99.1-99.6 parts of clear water. The drag reducing agent is obtained by polymerizing acrylic acid, acrylamide, and sodium allylsulfonate. In field engineering science, large-displacement continuous dosing and fast flowback of the slickwater can be realized, and the slickwater has a good oil displacement function, such that a reservoir transformation effect is greatly improved.

Owner:北京千永科技股份有限公司

Automatically opened and closed rainwater grate

PendingCN109653339ARealize automatic opening and closingAutomatic opening and closing meetSewerage structuresEngineeringControl circuit

The invention provides an automatically opened and closed rainwater grate. The automatically opened and closed rainwater grate comprises a rainwater grate module and a control circuit controlling opening / closing of the rainwater grate; the movable baffle of the rainwater grate module is embedded with or released from every drainage port of a grate component through protruded units to achieve opening and closing of the rainwater grate, which are driven by a driving device; the control circuit is used for controlling connection and disconnection of a rainfall control circuit and a fine weather control circuit according to detected rainfall signals to achieve control over forward or backward rotation of the motor of the driving device as well as automatic opening and closing of the rainwatergrate. The automatically opened and closed rainwater grate can ease the condition of clogging of drainage pipes and achieve good drainage effects.

Owner:HEFEI UNIV OF TECH

Comprehensive mining technology of drowned well

InactiveCN102767353AIncrease the blocking radiusImprove water blocking effectFluid removalPre treatmentOil production

The invention discloses a comprehensive mining technology of a drowned well, comprising the step 1: stratum unblocking pretreatment prior to water plugging; step 2: shallow plugging; step 3: deep plugging adjustment; and step 4: hydraulic deep penetration perforating and oil production recovery of an oil well. According to the characteristics of the drowned well, multiple mature technologies are organically comprehensively applied, with the combination of first dredging and subsequent plugging, the problem that no oil is produced after plugging is effectively solved. By first shallow plugging and subsequent deep plugging adjustment and in combination with hydraulic deep penetration perforating, the period of validity of mining is effectively prolonged and the input-output ratio is improved.

Owner:XINJIANG HUAYOU TECH SERVICE

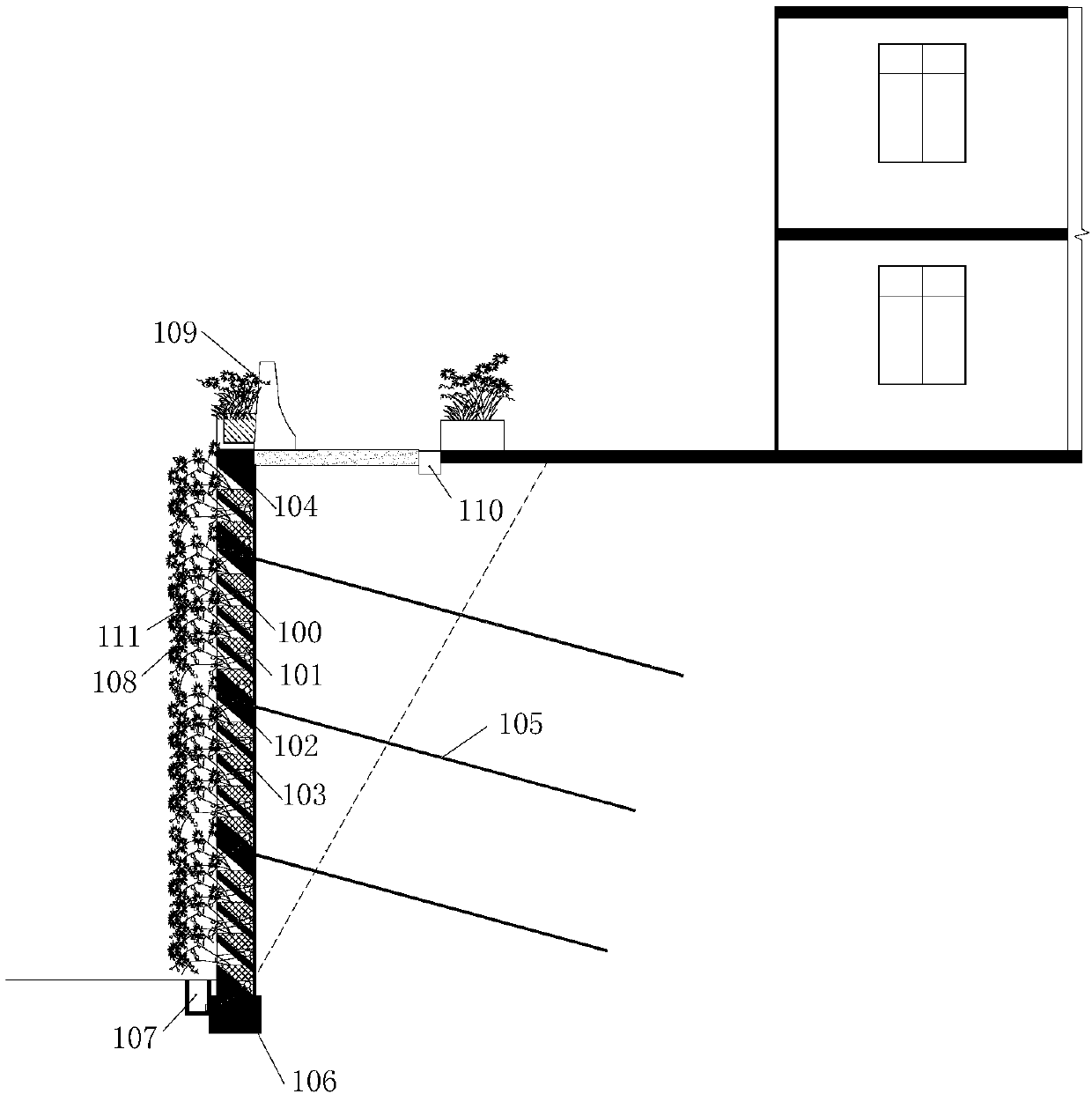

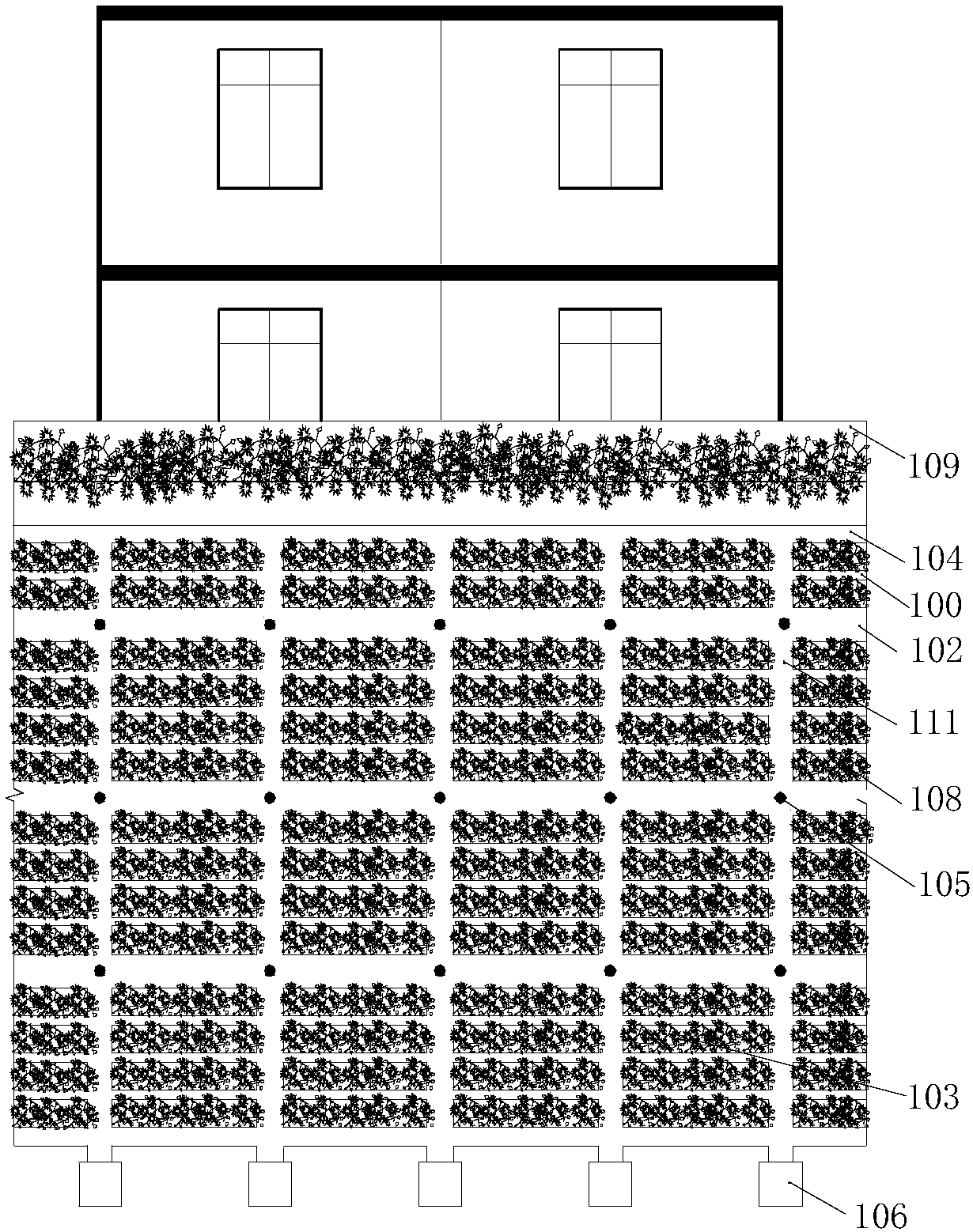

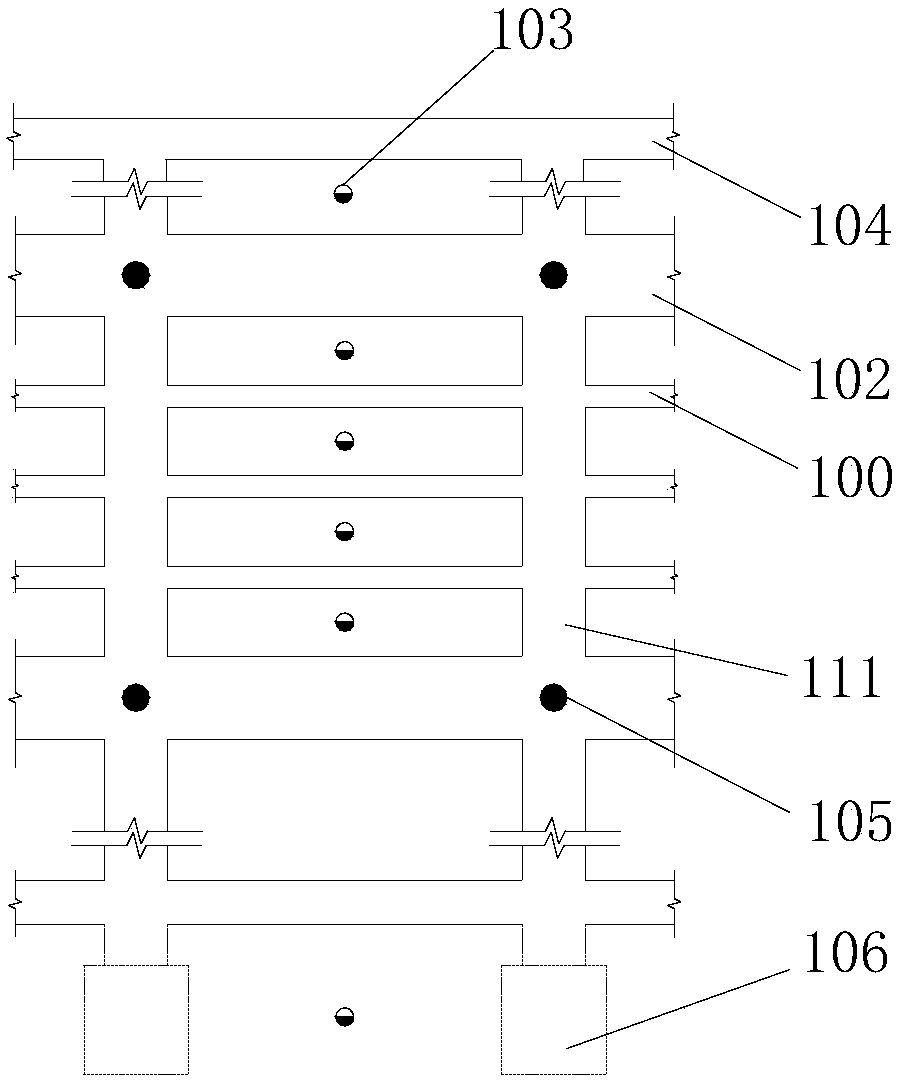

Ecological landscape retaining wall

ActiveCN108049423AImprove stabilityPrevent thinningArtificial islandsBreakwatersVegetationEngineering

The invention discloses an ecological landscape retaining wall which comprises a frame beam, vegetation growing grooves and a slope surface supporting, retaining and inverse filtering structure. The frame beam is of a frame structure composed of longitudinal beams and cross beams. The slope surface supporting, retaining and inverse filtering structure is arranged on the reverse side of the frame structure, and the vegetation growing grooves are formed in the frame beam and composed of oblique partition plates arranged between the frame beam longitudinal beams and the slope surface supporting,retaining and inverse filtering structure. The vegetation growing grooves are filled with filled earth and provided with drain holes. Ecological landscape plants are planted in the vegetation growinggrooves to green a slope body. The vegetation growing grooves penetrate through the slope surface supporting, retaining and inverse filtering structure to form water and nutrient channels with the slope body, vegetation growth is ensured, and the vegetation survival rate is greatly increased. The bottoms of the vegetation growing grooves are provided with inverse filtering layers and the drain holes, wall back earth body accumulated water is effectively discharged, and the stability of the slope body is improved. The ecological landscape retaining wall has the characteristics that the supporting and retaining capacity is high, the adaptability is high, the landscape effect is good, and the economical benefits are remarkable, and is suitable for slope supporting engineering, hydraulic engineering and ecological landscape engineering.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

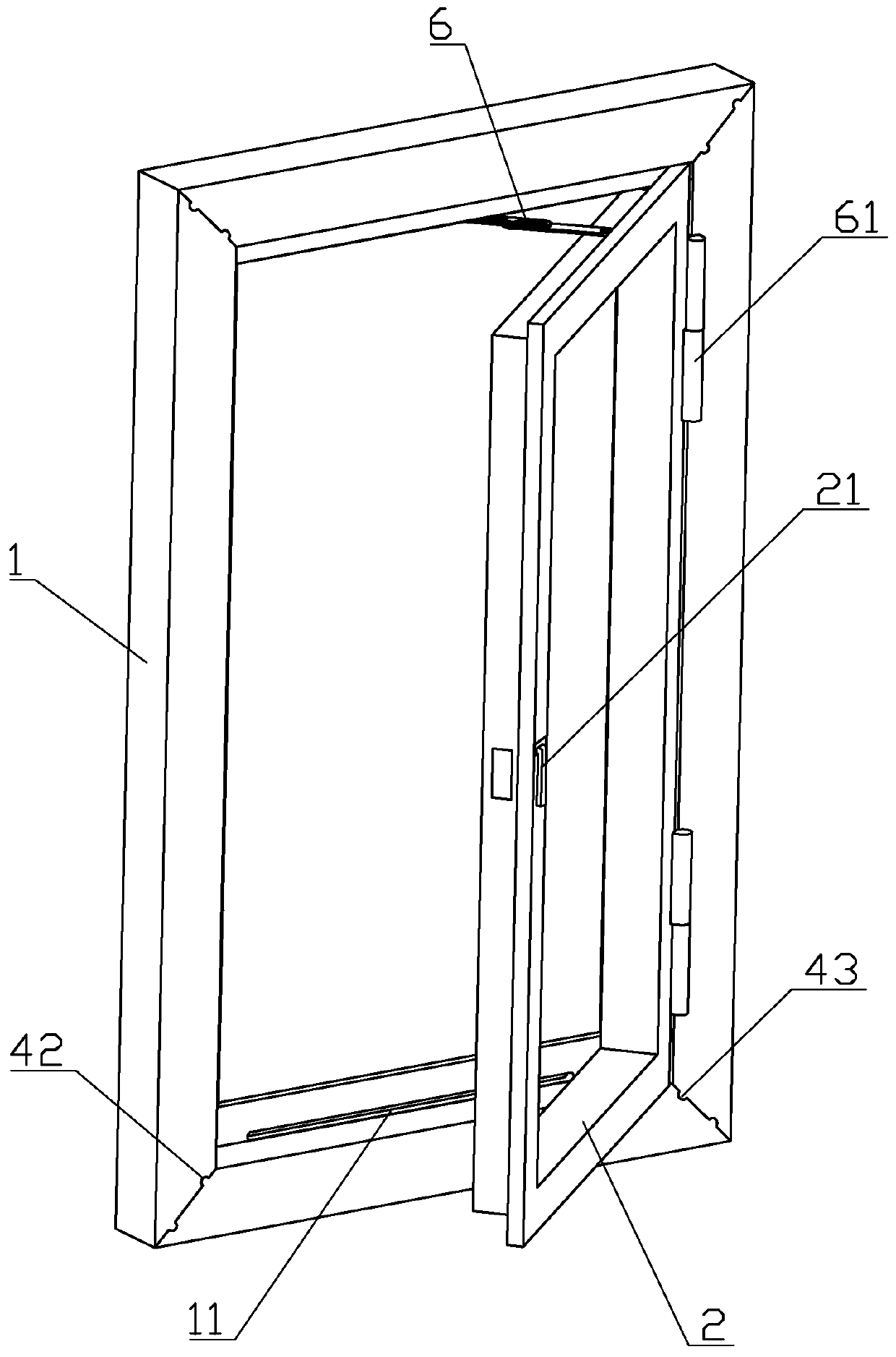

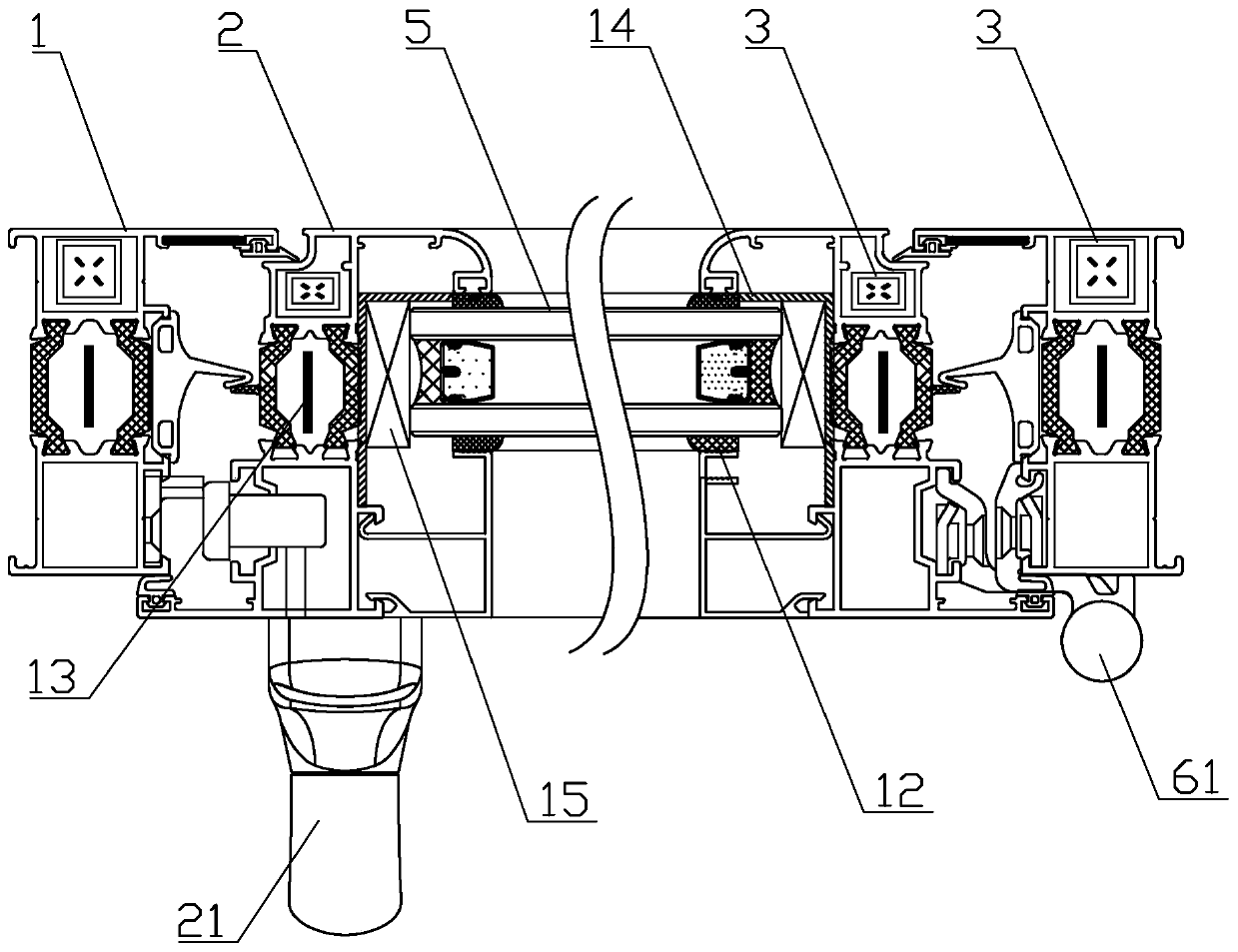

Manufacturing process of high-efficiency and energy-saving aluminum alloy fireproof window

ActiveCN110259351AExcellent strengthExcellent high temperature resistanceFireproof doorsBuilding braking devicesMetallurgy

The invention relates to the technical field of fireproof doors and windows, and discloses a manufacturing process of a high-efficiency and energy-saving aluminum alloy fireproof window. The manufacturing process comprises the following steps that S1, profiles are processed, specifically, all parts of structures are cut, and then slotting and drilling operations are carried out; S2, inner parts are assembled, specifically, steel linings, sliding seats and cross columns are assembled, and then the assembled steel linings, sliding seats and cross columns are put into frames of a window sash and a window frame to assemble the window sash and the window frame; S3, punching is carried out, specifically, corners of the window sash and corners of the window frame are punched; S4, painting is carried out, specifically, antirust paint is sprayed; S5, glass is installed, specifically, double-layer glass is installed into the frame of the window sash and is sealed; and S6, accessories are installed, specifically, hardware accessories of the fireproof window are installed into slots and holes formed in the step S1. According to the manufacturing process of the high-efficiency and energy-saving aluminum alloy fireproof window, the cross columns, the sliding seats and the steel linings are installed in the window frame and the window sash, the steel linings and the cross columns are both made of steel, and the strength and the high-temperature resistance of the steel linings and the cross columns are superior to that of aluminum alloys, when the fireproof window encounters a fire, the strength and the fire resistance of the window frame and the window sash are enhanced by the steel linings and the cross columns, so that the stability of the fireproof window when encountering the fire is improved.

Owner:安徽钟南消防科技有限公司

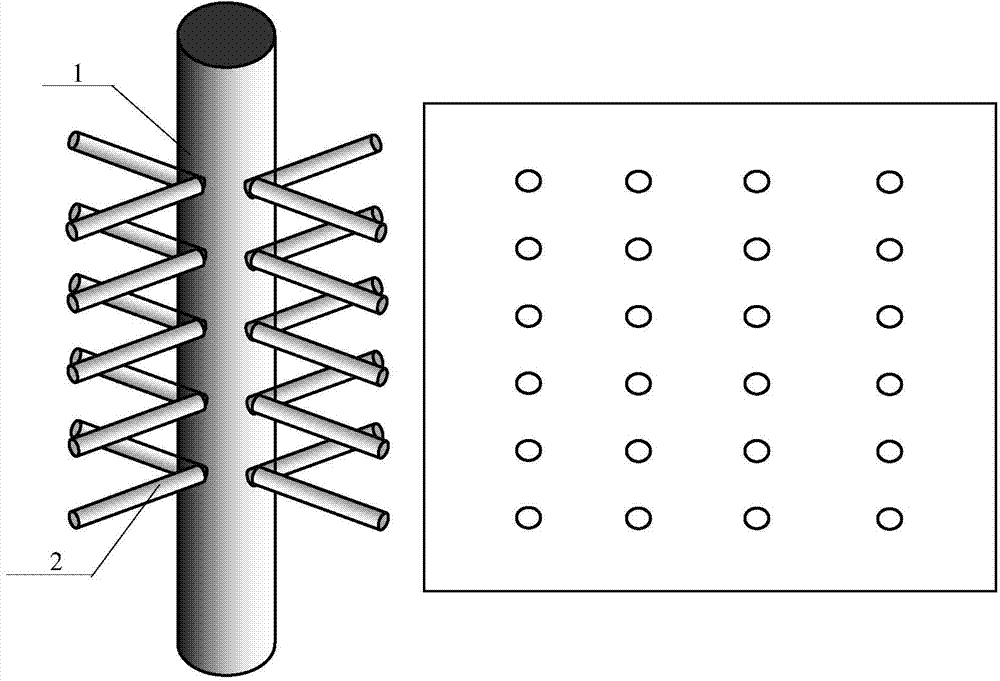

Oilfield water injection method capable of realizing balanced displacement of remaining oil

The invention provides an oilfield water injection method capable of realizing balanced displacement of remaining oil. The oilfield water injection method is mainly used for solving the problems of poor oil displacement efficiency and low petroleum recovery efficiency of the existing water injection development applied to a nonhomogeneous reservoir stratum. The method comprises the steps of forming holes in a shaft uniformly and densly, wherein the hole density in the transverse direction of the shaft is determined according to crustal stress, well network, remaining oil and physical properties, and the distance between two rows of holes in the longitudinal direction of the shaft is determeined according to the physical properties of an oil layer during the hole distribution process; carrying out construction according to the distributed holes, and forming a hole in the side direction; arranging a flow rate-adjustable water nozzle in the formed side hole; carrying out underground butt joint between an underground comprehensive testing and controlling meter in an automatic flow rate testing and controlling system and the flow rate-adjustable water nozzle, and adjusting the opening degree of the water nozzle to realize accurate control of the water injection quantity at each point; and beginning the water injection work. When the oilfield water injection method provided by the invention is used for injecting water, water injection quantities at all points are different according to the nonhomogeneity of each point of a reservoir stratum, and therefore, balanced displacement of remaining oil is realized, the water absorption profile of a water well is improved and the oilfield recovery efficiency is improved.

Owner:NORTHEAST GASOLINEEUM UNIV

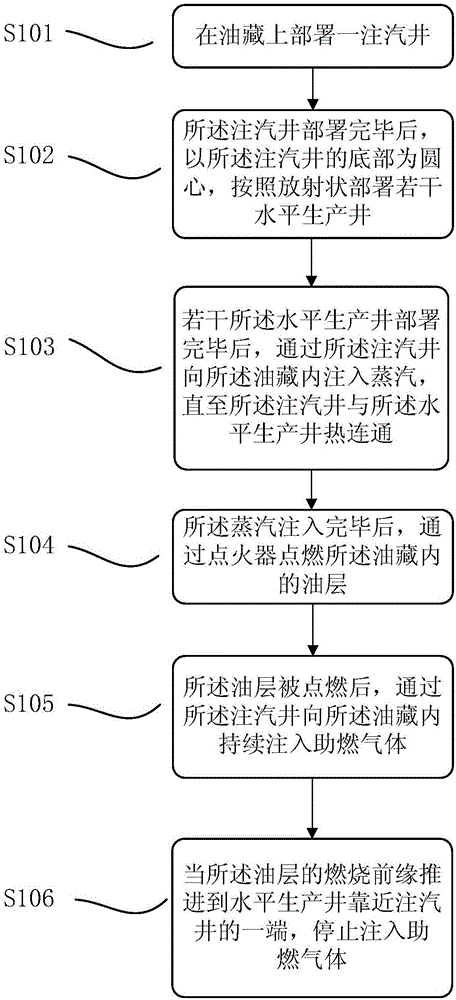

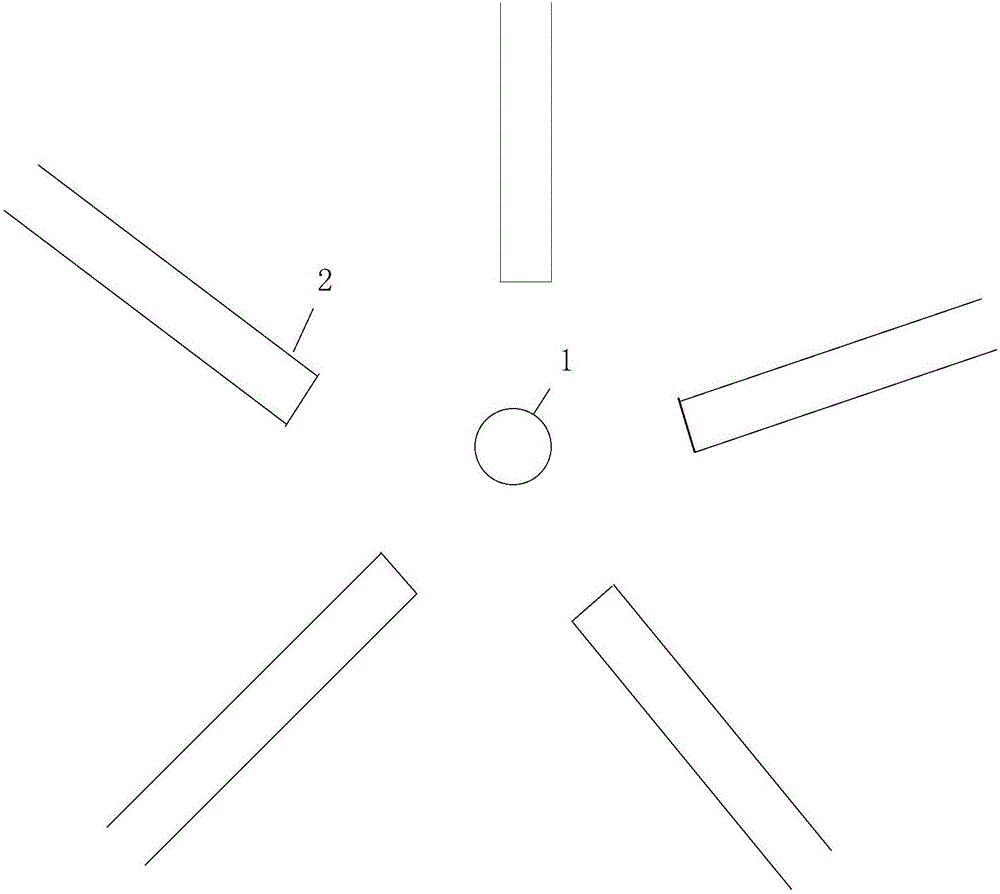

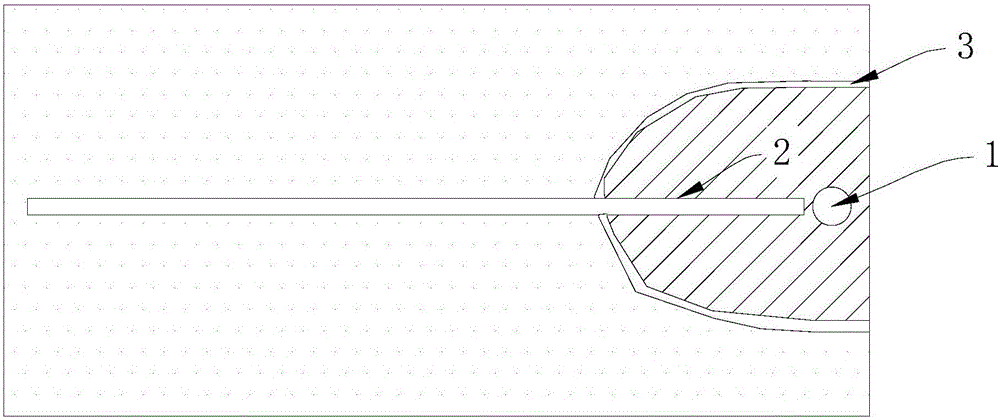

Oil production method and well pattern

ActiveCN106761631AExpand the affected volumeReduced chance of flameoutConstructionsFluid removalCombustionFlue gas

The invention discloses an oil production method and a well pattern. The oil production method includes the following steps that a steam injection well is deployed on an oil pool; the bottom of the steam injection well serves as a center of a circle, and a plurality of horizontal producing wells are deployed in a radial pattern; after deploying the plurality of producing wells, steam is injected in the oil pool through the steam injection wall; after the steam injection, oil layers in the oil pool are ignited by an igniter; after the oil layers are ignited, combustion-supporting gases are continuously injected into the oil pool through the steam injection well. According to the method, the development of a fire chamber is no longer in the direction of a single horizontal producing well, and the fire chamber is uniformly developed in the directions of the various horizontal producing wells arranged in a radial pattern, so that the firing range in the whole oil pool is gradually expanded and the probability of flame out is reduced. Meanwhile, flue gases, movable oil, firing lines and the like can move along the plurality of horizontal producing well, and therefore the firing lines uniformly advance towards multiple directions, the swept volume of combustion is enlarged, the exploiting effect is improved, and the oil production efficiency is improved.

Owner:PETROCHINA CO LTD

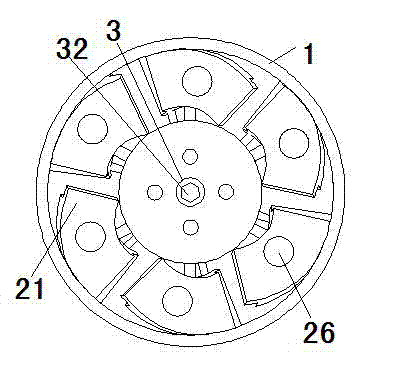

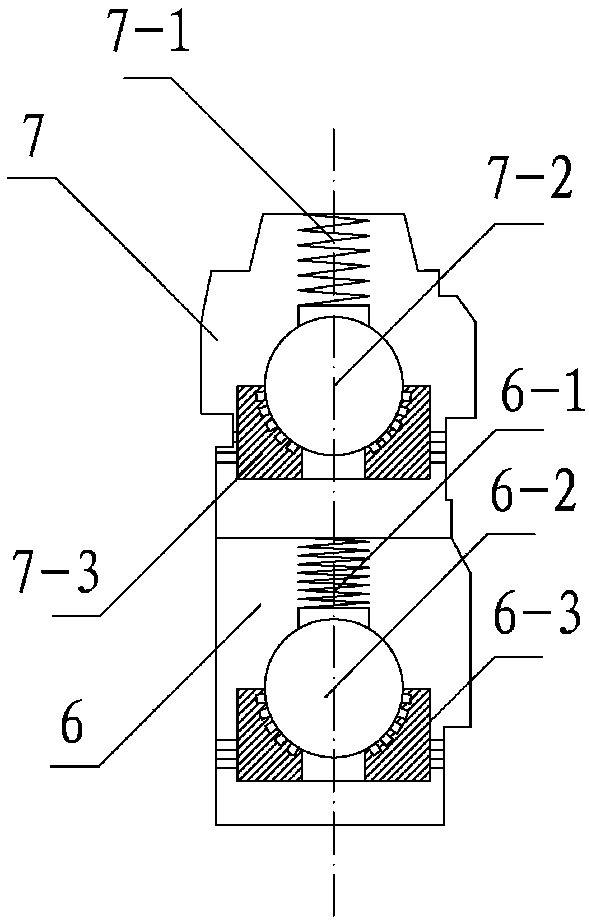

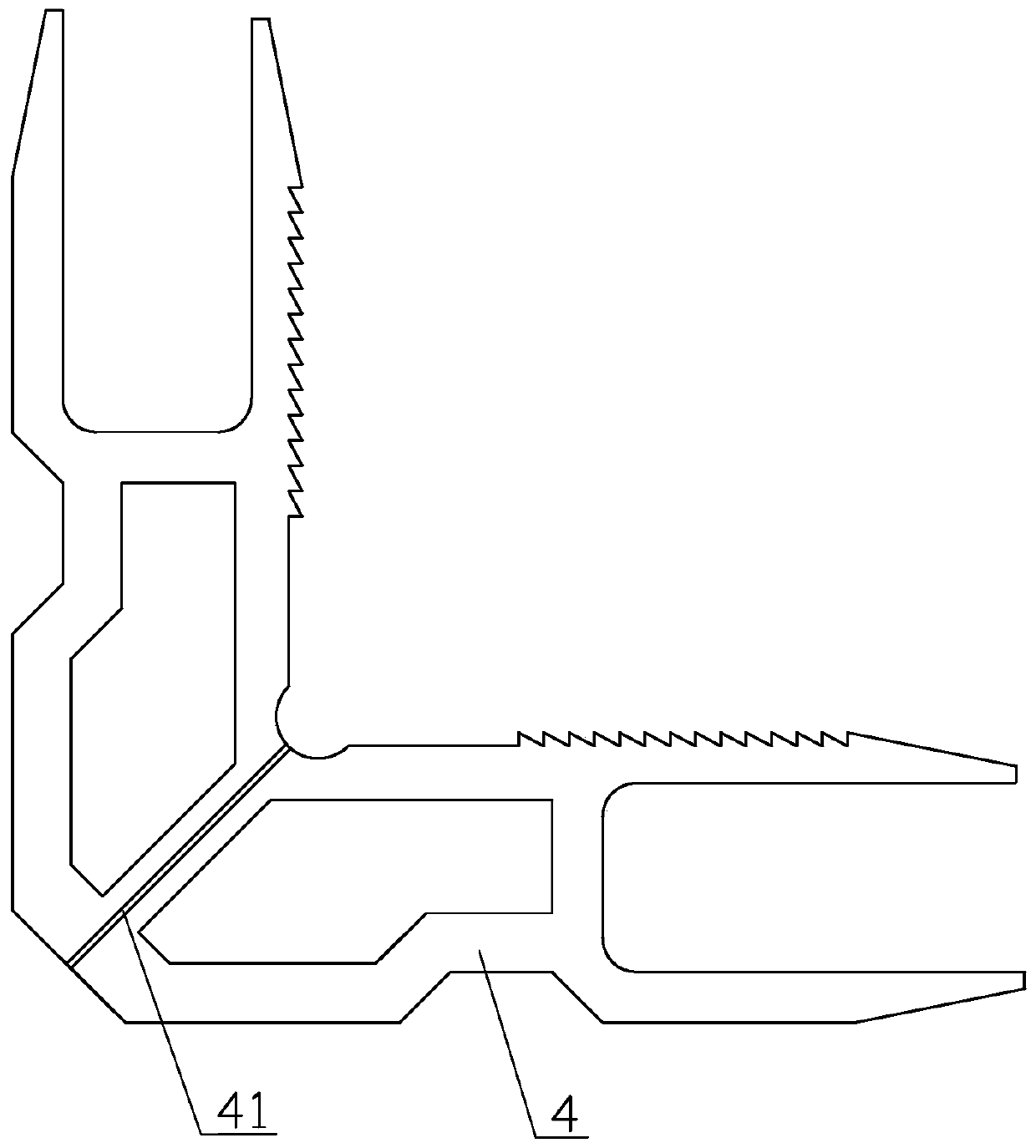

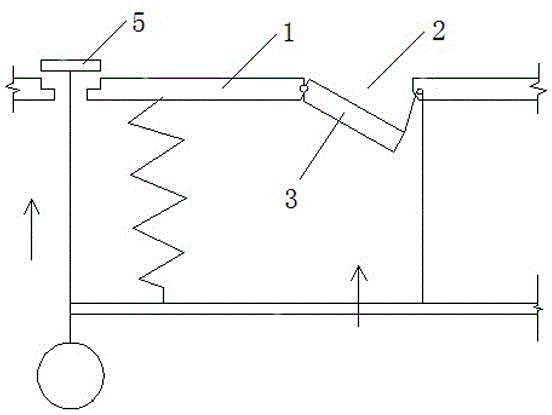

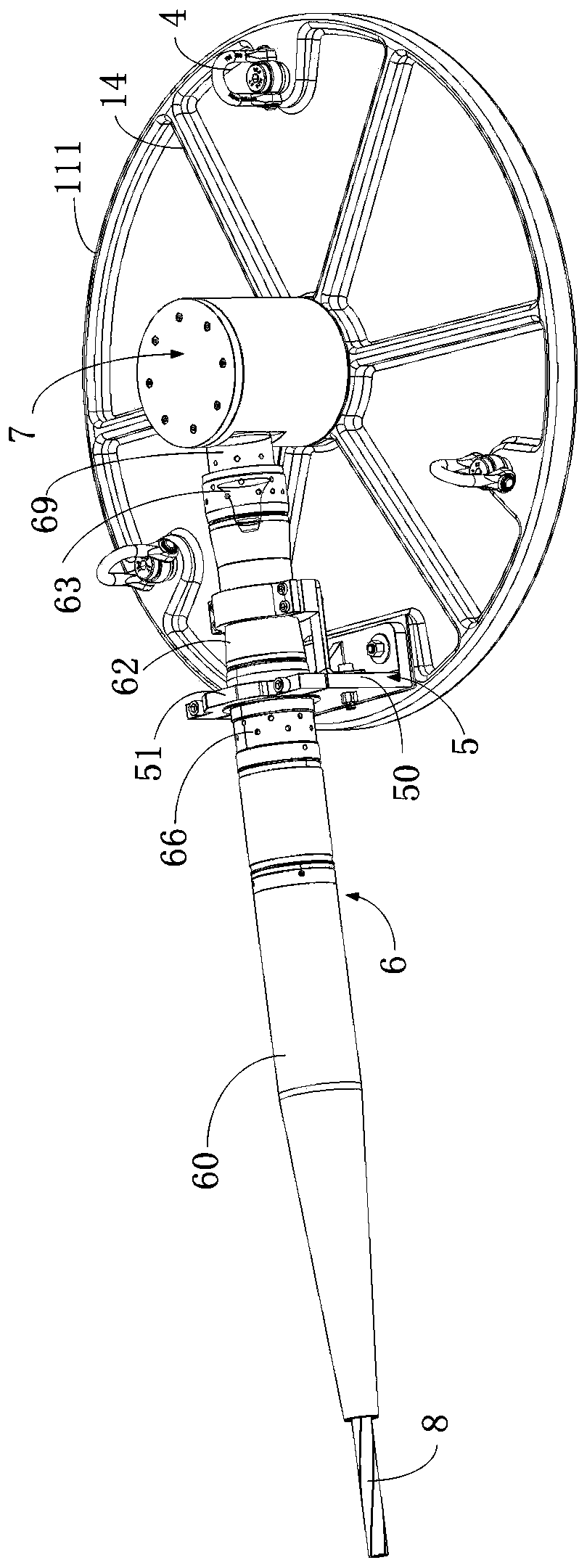

In-section multi-cluster fracturing slide sleeve

ActiveCN104912535AIncrease drainage areaImprove development efficiencyFluid removalMulti clusterSpray nozzle

The invention discloses an in-section multi-cluster fracturing slide sleeve, which comprises an outer tube, a spray nozzle, a slide sleeve, a throttle tube, a ball seat, a clamp spring, a lower joint and the like, wherein the spray nozzle is bonded and arranged on the outer tube; the slide sleeve is arranged in the outer tube, is connected with the outer tube through a shearing pin, and is sealed through a slide sleeve sealing ring; the ball seat is arranged in a position of a ball seat hole formed in the middle part of the slide sleeve; the clamp spring is arranged at the tail of the slide sleeve; the throttle tube is arranged in the slide sleeve and is fixed with the slide sleeve through a connecting pin; and the lower joint and the outer tube are connected through screw threads, are fixed through anti-falling pins and are sealed through a lower joint sealing ring. The in-section multi-cluster fracturing slide sleeve has the advantages that the slide sleeve opening and ball passing actions are realized through diameter reduction and expansion of the ball seat; a plurality of fractures can be opened through one ball; the in-section multi-cluster fracturing in an open-hole horizontal well can be realized; the oil drainage area of the horizontal well can be effectively increased; the initial output and the final recovery ratio are improved; meanwhile, through the design of throttle fracture holes in the outer tube, fixed-point crack positioning can be realized; the influence of near-well zone stress (due to drilling) is reduced; the pressure division probability is increased; and the fracturing effect is further improved.

Owner:PETROCHINA CO LTD

Well lid buoyancy type self open-close system and operation method thereof

ActiveCN106592745ASolve the problem of stagnant waterIncrease drainage areaSewerage structuresEconomic benefitsEngineering

The invention relates to a well lid buoyancy type self open-close system and an operation method thereof. The system comprises a lid body. The lid body is provided with water outlets. The water outlet is internally provided with a turnover panel which controls on-off of the water outlet through rotation. The turnover panel is provided with a weep hole. The lid body is also provided with a buoyancy block. A cross rod hung on the buoyancy block is arranged below the lid body. The cross rod is provided with a stay cord used to pull and control the turnover panel to rotate. The well lid buoyancy type self open-close system drains away water through the weep holes when little rainwater exists, and can automatically open the water outlets when much rainwater exists, so as to expand drainage area to accelerate drainage, and the system is not easy to block and solves a problem of surface gathered water. The system is reliable and stable, and is long in service life, convenient in changing, and good in economic benefit.

Owner:FUJIAN JIANGXIA UNIV

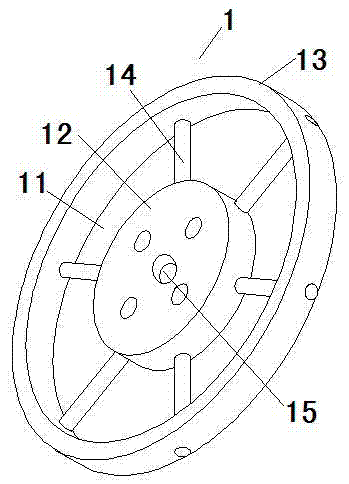

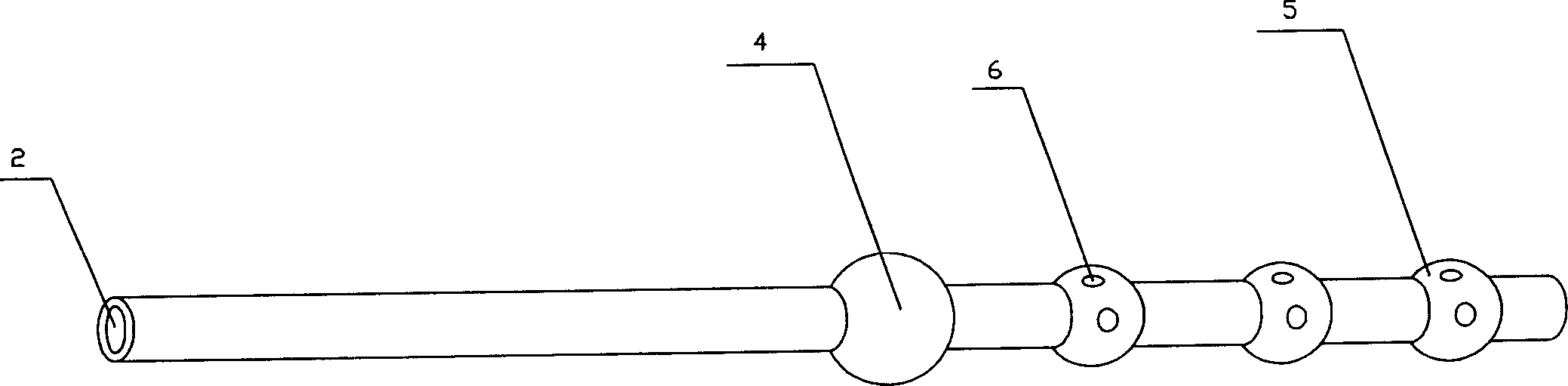

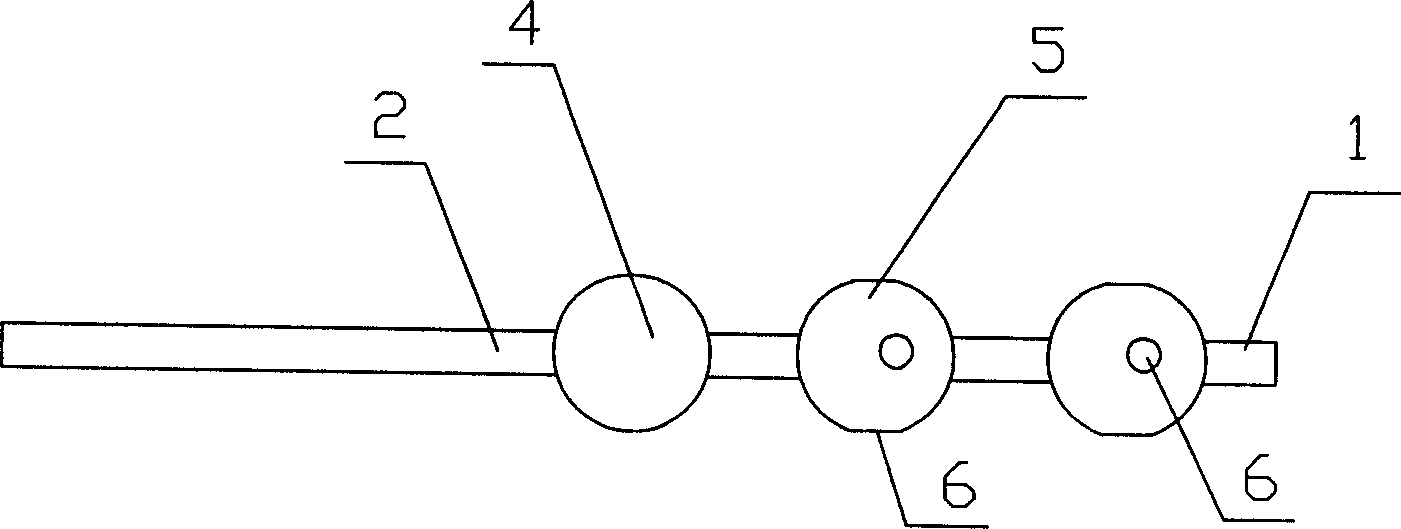

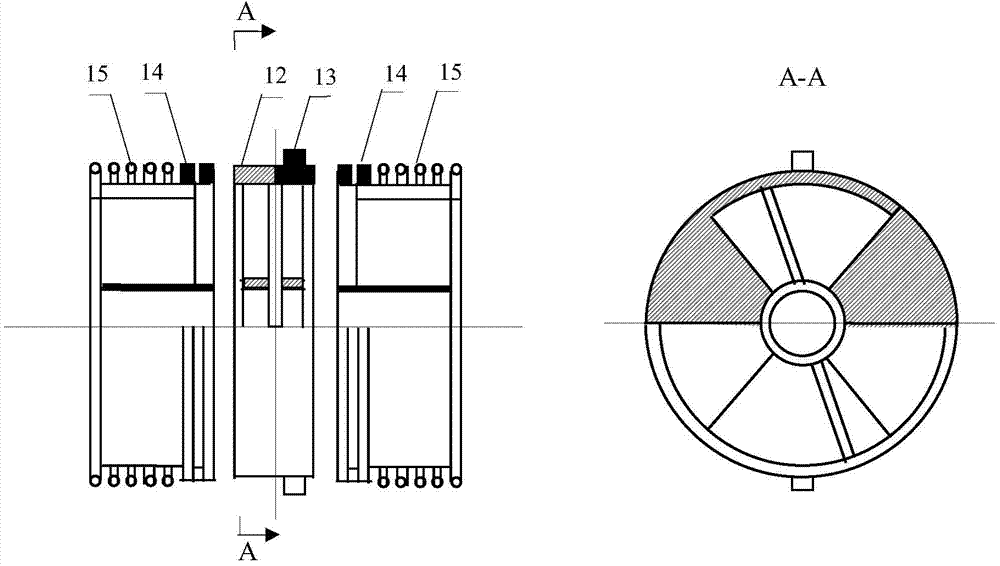

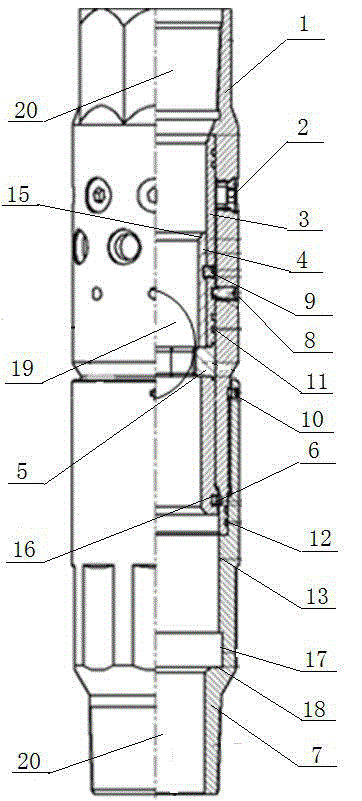

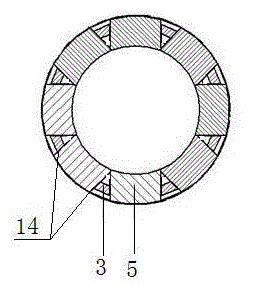

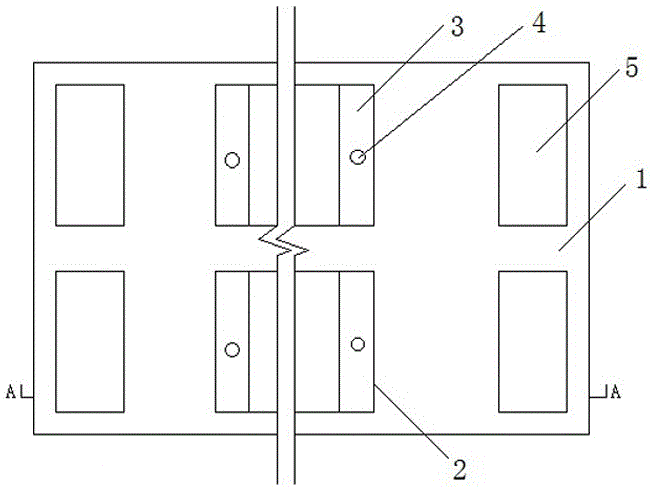

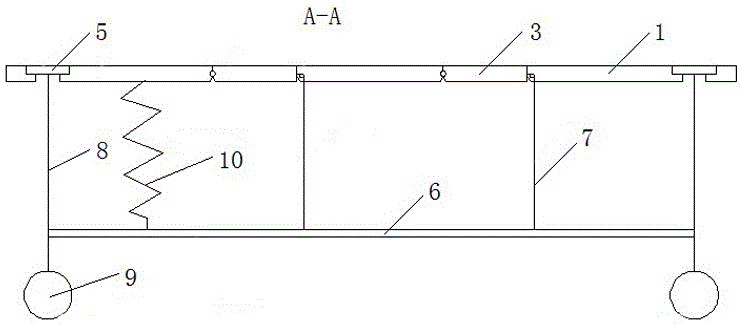

Selective well cementing device

The invention discloses a selective well cementing device and belongs to the technical field of well cementing and completion tools in oil field oil-gas well engineering. The selective well cementingdevice comprises a casing inner pipe 3 and a casing outer pipe 4. An upper isolator 2 and an upper diverter valve 1 are mounted at the upper ends of the casing inner pipe 3 and the casing outer pipe 4. A lower isolator 5 and a lower diverter valve 6 are mounted at the lower ends of the casing inner pipe 3 and the casing outer pipe 4. A double-layer casing structure is adopted, well-cementing cement paste can bypass a production layer through the interlayer of a casing, well cementing is not conducted on the production layer and selectively conducted on the upper portion and the lower portion of the production layer, thus the oil drainage area of the production layer is increased, damage of the cement paste to the production layer is avoided, and the yield of an oil-gas well can be increased easily; and the selective well cementing device is simple in process, low in workload and free of construction risks and breaks through the implement bottleneck of an existing selective well cementing technology.

Owner:SHENGLI OILFIELD SHENGJI PETROLEUM EQUIP

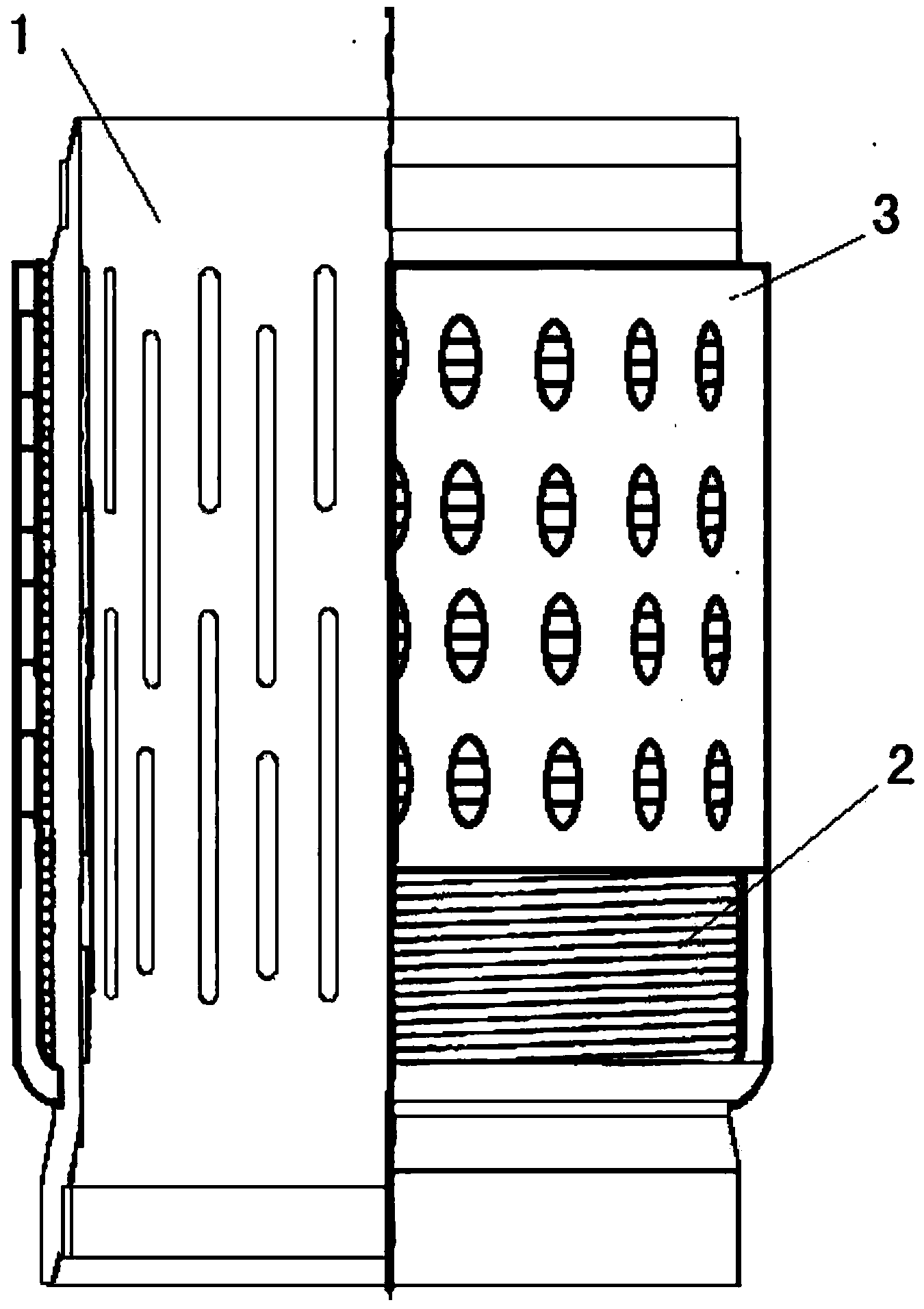

Expansion screen pipe

InactiveCN103967456APrecise control of particle sizeReduce resistanceFluid removalEngineeringCrude oil

The invention provides an expansion screen pipe which comprises an inner layer pipe, a middle layer pipe and an outer layer pipe, wherein the inner layer pipe, the middle layer pipe and the outer layer pipe are fixed and mounted in a sleeved mode in sequence from inside to outside. Multiple kerfs are distributed in the pipe wall of the inner layer pipe, the middle layer pipe is formed by coiling filaments spirally, and multiple holes are also distributed in the pipe wall of the outer layer pipe. The expansion screen pipe has the advantages that the granulometric class of filtered gravel can be controlled accurately, an oil drainage area is enlarged through expansion hole enlargement, oil flow resistance is reduced at the same time, and crude oil produced by a single well daily can be improved by 30-50 percent.

Owner:TIANJIN TOP CLOUD EAST ENERGY TECH

High-silicon cast iron electrode and end station ocean ground

ActiveCN110931994AIncrease drainage areaChange current pathConnection contact member materialElectrically conductiveCast iron

The invention discloses a high-silicon cast iron electrode and an end station ocean ground. The electrode comprises a body and a conductive part, and the body is in a plate shape and comprises a firstpart and an annular second part which are arranged and are connected from inside to outside. One wall surface of the second part is a conical surface, and the conical surface is gradually inclined from the inner side of the second part to the outer edge of the second part, so that the thickness of the second part is gradually reduced from the inner side of the second part to the outer edge of thesecond part. The conductive part comprises a conductive column and a conductive plate, the conductive plate is buried in the first part, one end of the conductive column is vertically connected to the conductive plate, and the other end penetrates out the first part towards the side where the conical surface is located along the axial direction of the body and is used for connecting a cable. According to the invention, by adopting the plate-shaped structure, the drainage area can be increased, a current path can be changed, the drainage uniformity can be improved, a necking effect can be eliminated, the problem that the rod-shaped electrode is easy to break can be solved, and the working life specified by the design can be achieved.

Owner:FIBERHOME MARINE NETWORK EQUIP CO LTD +1

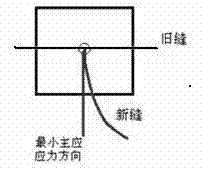

All-directional three-dimensional fracturing method for vertical well of reservoir with ultra low permeability

ActiveCN107956463AAvoid high drilling costsIncrease drainage areaFluid removalPrincipal stressOil well

The invention provides an all-dimensional three-dimensional fracturing method for a vertical well of a reservoir with ultra low permeability. The method comprises the following steps that firstly, a shaft of the target reservoir is subjected to first volume fracturing to form a main crack extending in the direction of the maximum principal stress and secondary net-shaped cracks around the main crack, and the main crack is temporarily blocked; secondly, the shaft of the target reservoir is subjected to second volume fracturing, since the maximum principal stress field within a certain range around the shaft turns over at almost 90 degrees after first volume fracturing, a secondary main crack perpendicularly intersecting with the main crack generally can be constructed through second volumefracturing, and net-shaped cracks are formed around the secondary main crack. By means of the method, the all-dimensional three-dimensional net-shaped cracks can be constructed in the vertical well through fracturing, the transformation volume of an oil well is greatly increased, and the productivity of the oil well is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

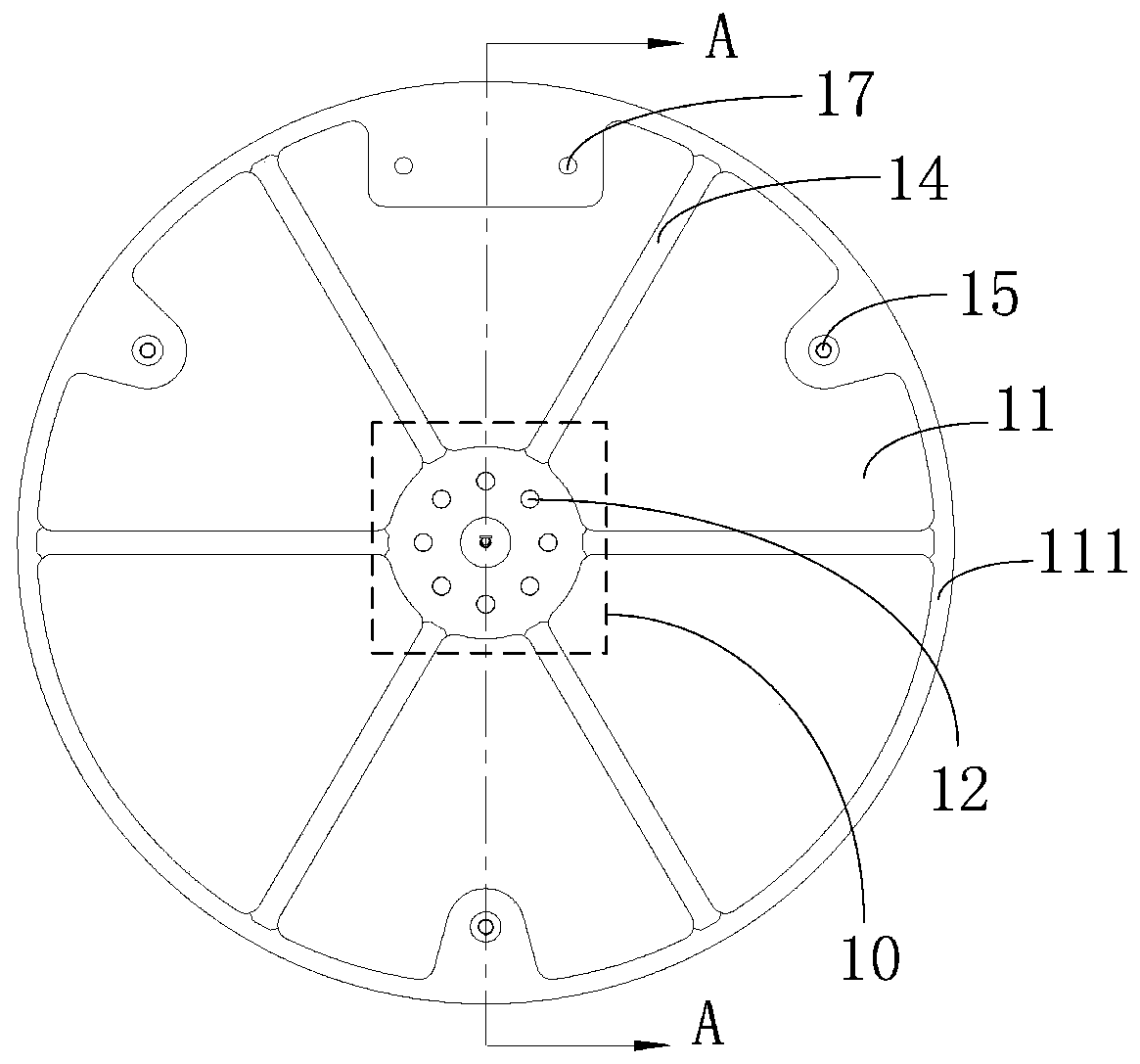

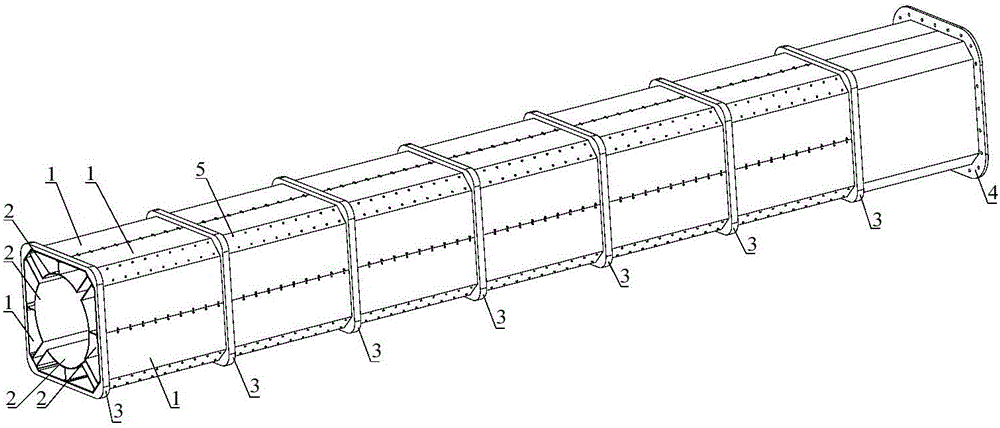

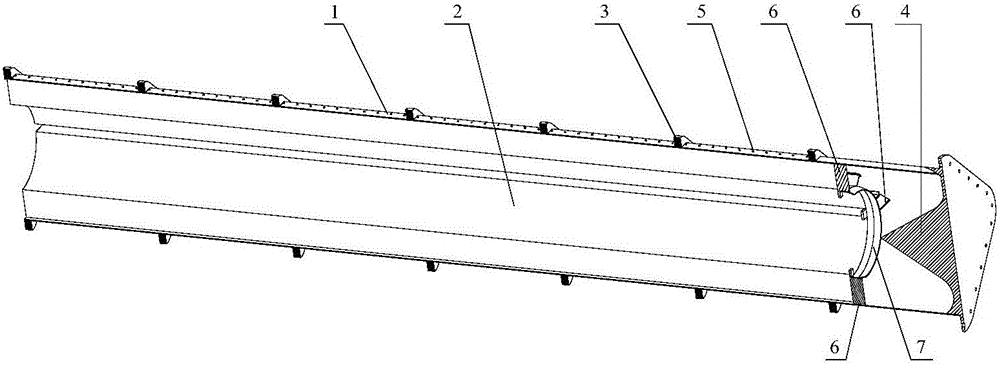

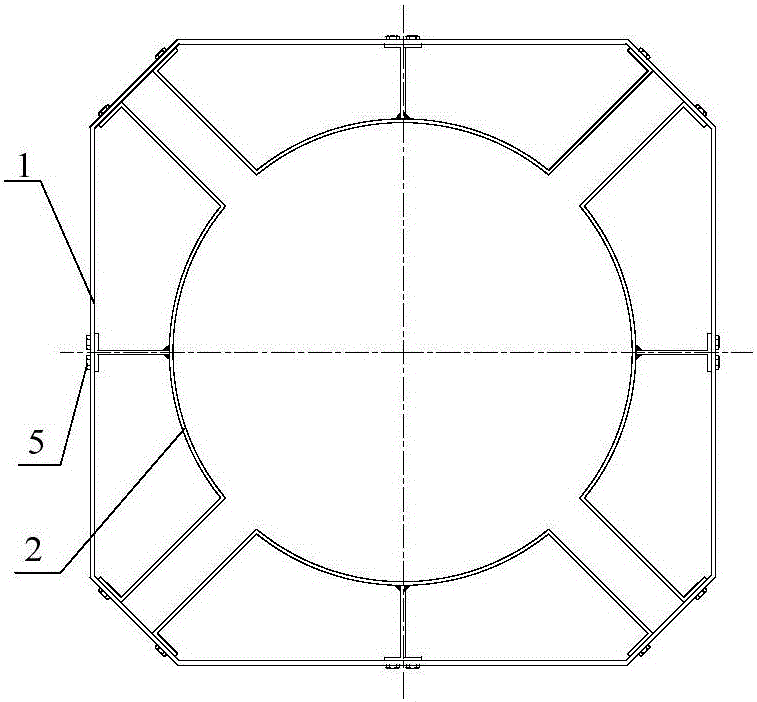

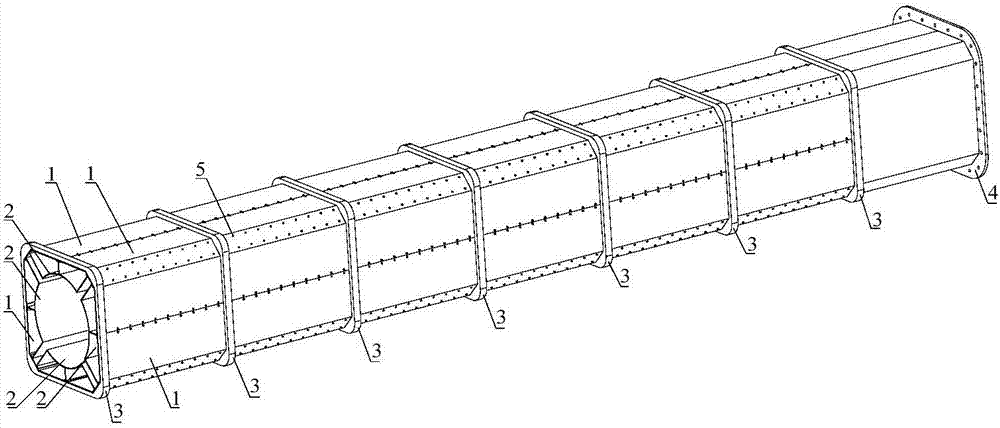

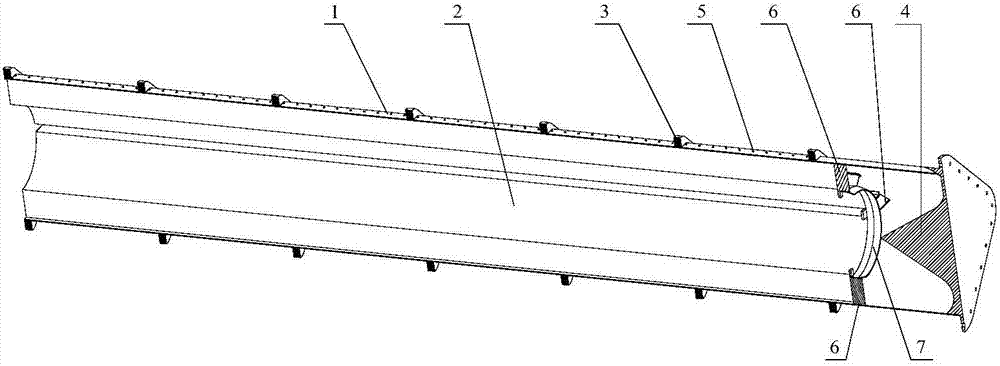

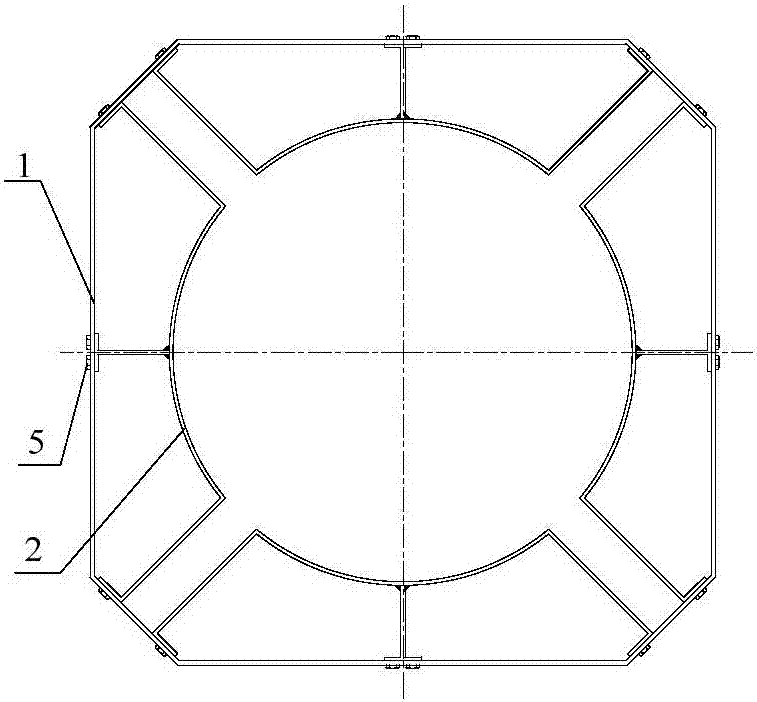

Winged missile vertical thermal emission inner-round outer-square concentric cylinder structure

ActiveCN105910492ARaise the drain clearanceIncrease drainage areaLaunching weaponsConcentric cylinderConoid

The invention discloses a winged missile vertical thermal emission inner-round outer-square concentric cylinder structure comprising an outer barrel, an inner barrel, reinforcing ribs, a diversion cone, stop piece support plates and a diversion plate; the inner barrel is a non-sealing barrel formed by four arc panels, wherein the non-sealing zone of the inner barrel forms a motion channel for the missile and missile wings; the outer barrel is a square barrel formed by splicing four square panels, wherein the outer barrel inner wall is fixed with the inner barrel, and a gas flow exhaust gap is arranged between the outer barrel and the inner barrel; the diversion cone is arranged on the inner side of the bottom of the outer barrel, and is a conical symmetry structure; a missile engine ejects the gas flow applied on the diversion cone, and the ejected gas flow is backflowed by the diversion cone so as to enter the gap between the outer barrel and the inner barrel, thus exhausting the gas flow. The outer barrel is designed into a square shape, thus improving the gas flow exhaust gap between the outer barrel and the inner barrel; compared with a concentric cylinder with an inner round barrel and an outer round barrel, the winged missile vertical thermal emission inner-round outer-square concentric cylinder structure can maximumly effectively improve gas flow exhaust space area, thus better adapting to large missile diameter missile concentric cylinder emission.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

A vertical thermal launch of winged missile with inner circle and outer square concentric cylinder structure

ActiveCN105910492BRaise the drain clearanceIncrease drainage areaLaunching weaponsConcentric cylinderConoid

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com