Selective well cementing device

A selective and cementing technology, which is applied in wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve problems such as failure to guarantee success rate and completion quality, increased construction risk, and many uncertain factors , to achieve the effect of breaking through the implementation bottleneck, no construction risk, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

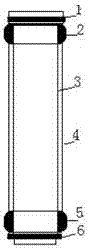

[0007] The present invention is described in detail below in conjunction with accompanying drawing: the present invention comprises sleeve pipe inner pipe 3, sleeve pipe outer pipe 4, upper spacer 2 and upper diversion valve 1 are housed in its sleeve pipe inner pipe 3, sleeve pipe outer pipe 4 upper ends, A lower isolation body 5 and a lower diversion valve 6 are installed at the lower ends of the sleeve inner tube 3 and the sleeve outer tube 4 . The working principle of the present invention: the present invention is connected in series on the cementing casing string and lowered to the position of the production layer, firstly, the internal pressure of the casing is suppressed, the upper isolation body 2 and the lower isolation body 5 of the present invention expand, and the upper isolation body 5 of the production layer is expanded. The lower wellbore is isolated. During cementing, the cement slurry flows from the lower wellbore through the lower diversion valve 6 into the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com