Winged missile vertical thermal emission inner-round outer-square concentric cylinder structure

A thermal launch, outer square technology, applied in the direction of the launch device, can solve the problem of difficult to realize the concentric cylinder launch of a large diameter winged missile, and achieve the effect of increasing the space area of the gas discharge and guiding, reducing the cost, and reducing the difficulty of production and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

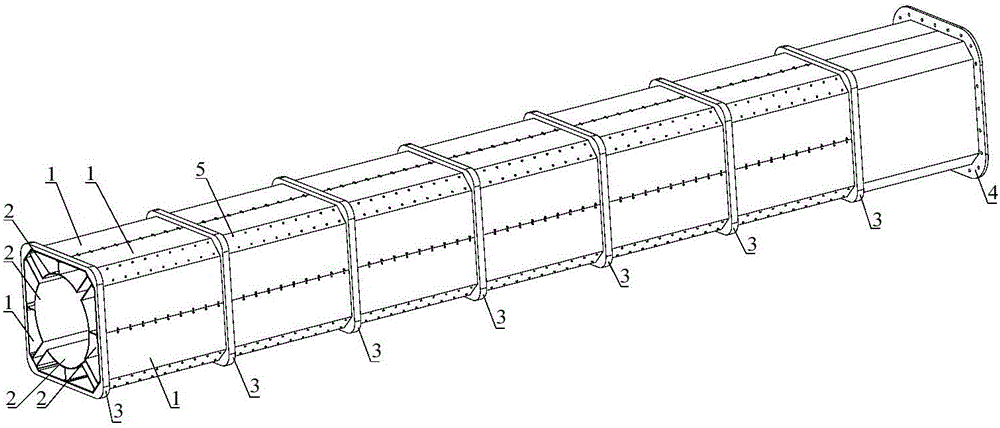

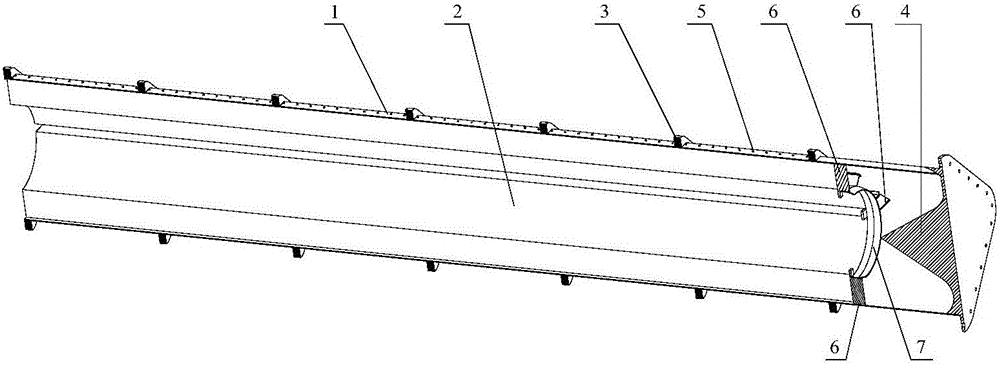

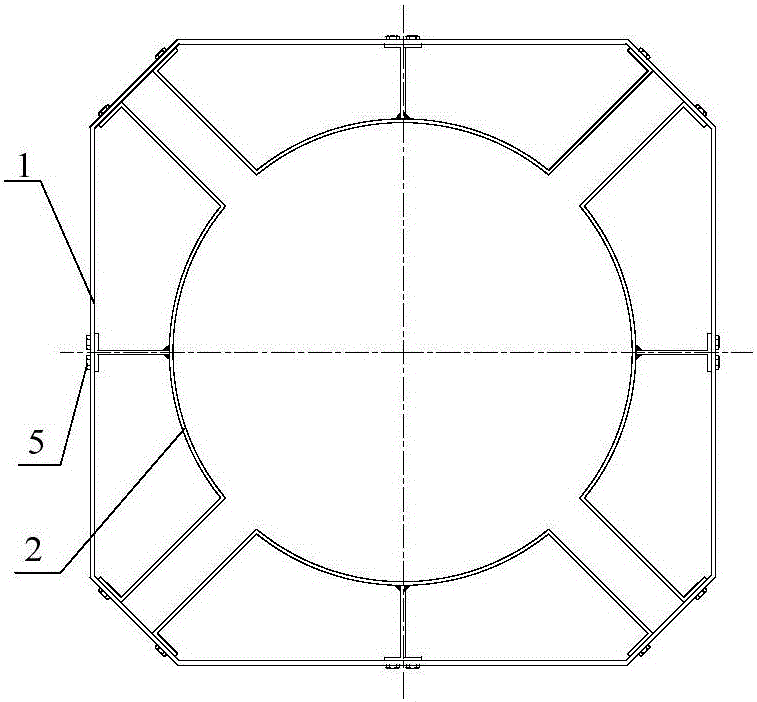

[0026] Compared with the existing concentric cylinder structure, this invention proposes a concentric cylinder structure in which the outer cylinder is a square cylinder and the inner cylinder is a non-closed cylinder. Projectile diameter (diameter greater than Φ500mm) winged non-folding missile concentric tube vertical thermal launch, and the self-guiding of engine gas during launch, so that the surface of the missile is protected from high-temperature gas erosion during missile launch.

[0027] The specific structure is as Figure 1~2 As shown, it includes an outer cylinder 1, an inner cylinder 2, a reinforcing rib 3, a diversion cone 4, a bolt 5, a block support plate 6, and a deflector 7, wherein the inner cylinder 2 is composed of four arc-shaped plates to form a non-closed circle cylinder, the middle part of the outer surface of each arc-shaped plate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com