High-silicon cast iron electrode and end station ocean ground

A high-silicon cast iron and electrode technology, which is used in the field of high-silicon cast iron electrodes and terminal stations in the ocean, can solve the problems of rod electrode failure, reduced working life, and high construction costs, and achieves elimination of necking effect, shortened installation period, and reduced The effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

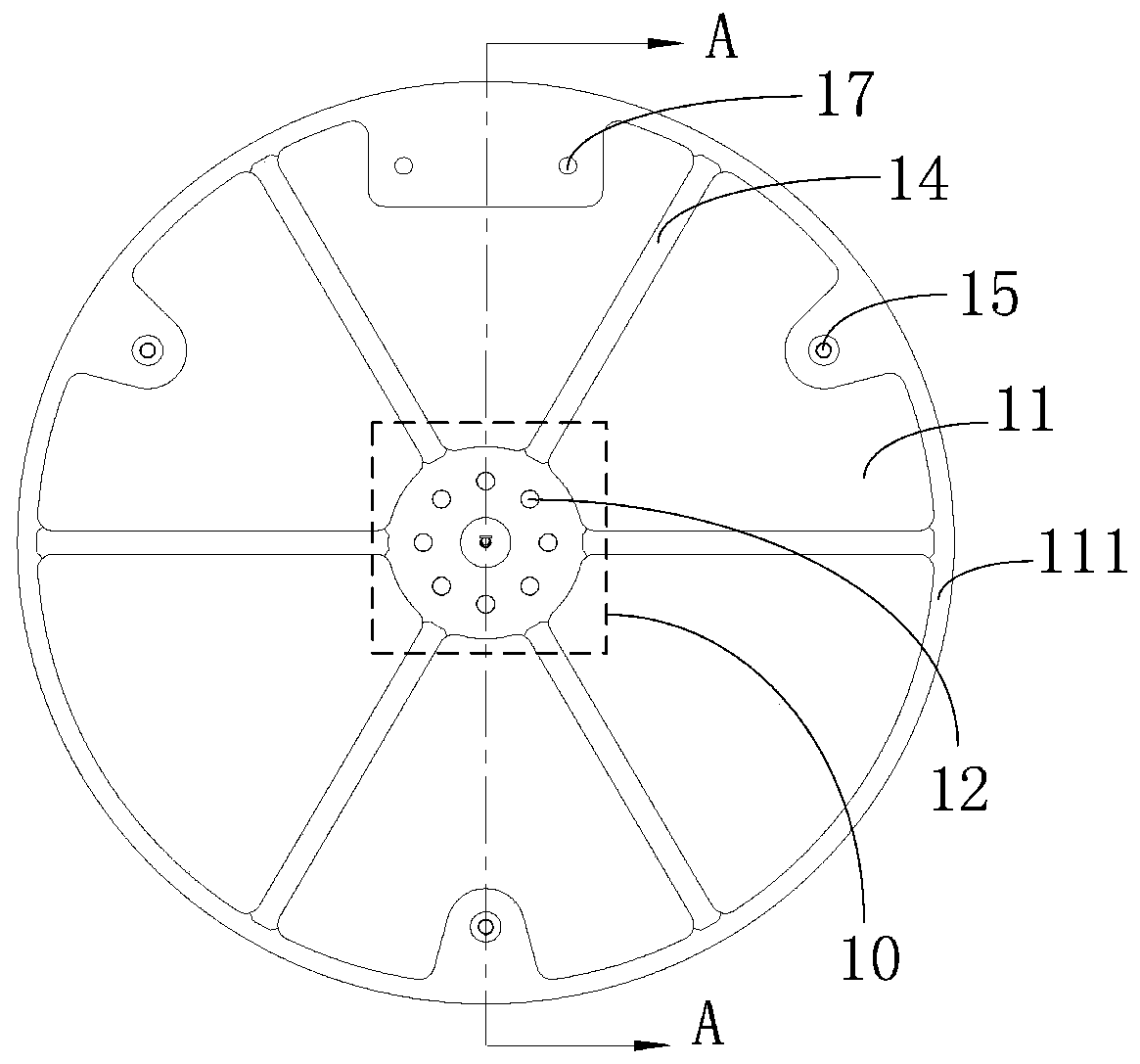

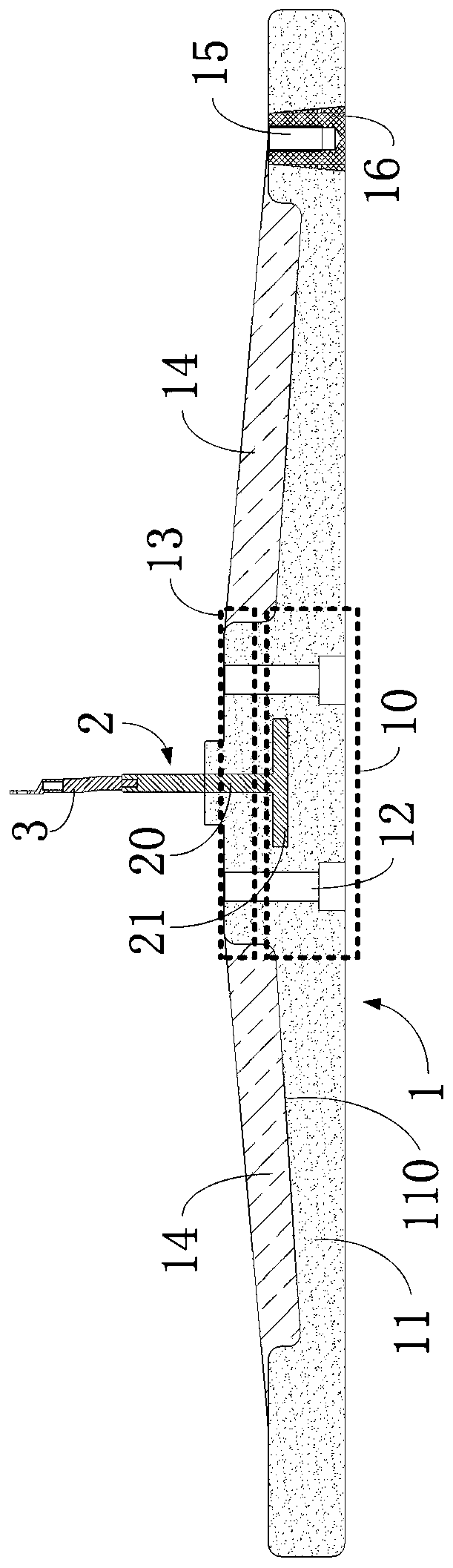

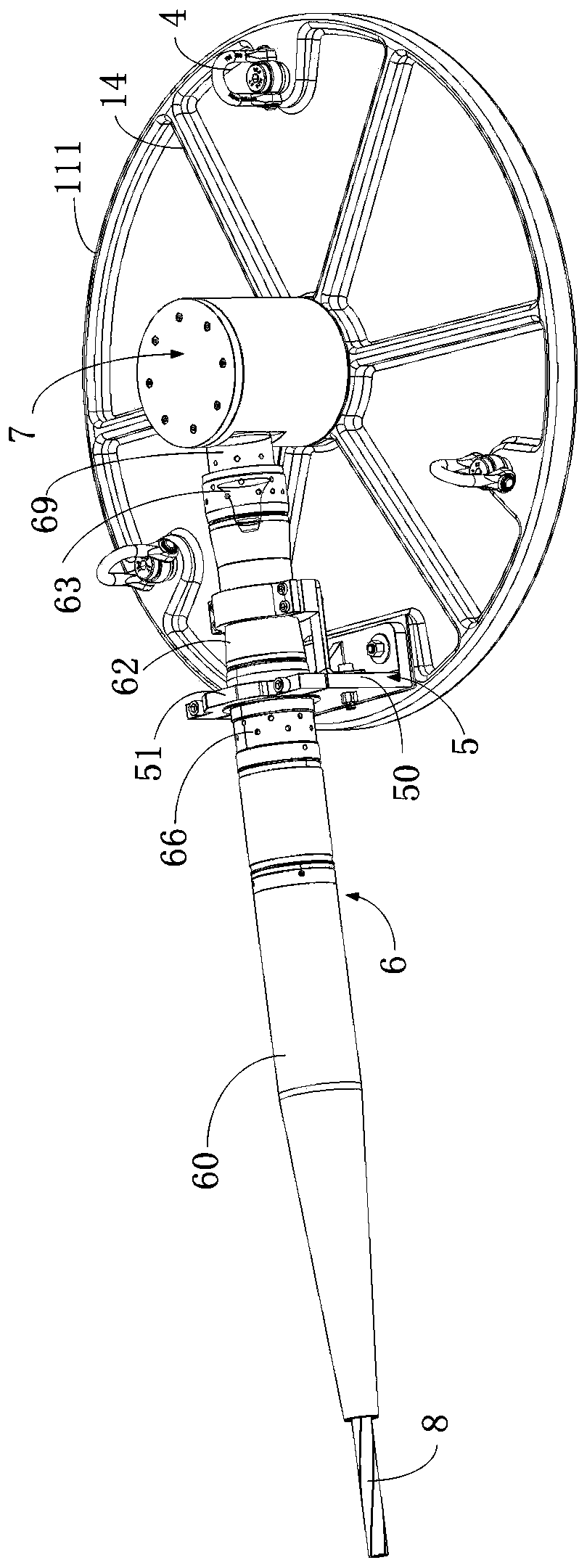

[0043] see figure 1 with figure 2 As shown, the first embodiment of the present invention provides a high-silicon cast iron electrode, the electrode includes a body 1 and a conductive member 2, the body 1 is plate-shaped, and the body 1 includes from the inside to the outside (the inner refers to the first part 10 located at the second The inner side of the second part 11, the outer refers to the second part 11 surrounding the first part 10 (outside of the first part 10) arranged and connected first part 10 and the ring-shaped second part 11, see figure 1 As shown, the first part 10 has a circular structure, and one wall surface of the second part 11 is a conical surface 110. In this embodiment, the other wall surface of the second part 11 is a plane, and of course it can also be a conical surface. The conical surface 110 From the inner sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com