Coiled tubing steel shot jet flow perforating device

A technology of steel pellets and tubing, applied in the direction of wellbore/well valve device, production fluid, wellbore/well components, etc., can solve the problems of small perforation diameter, shallow perforation depth, long construction time, etc., and achieve increased The effect of perforation depth and diameter, increasing oil drainage area and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

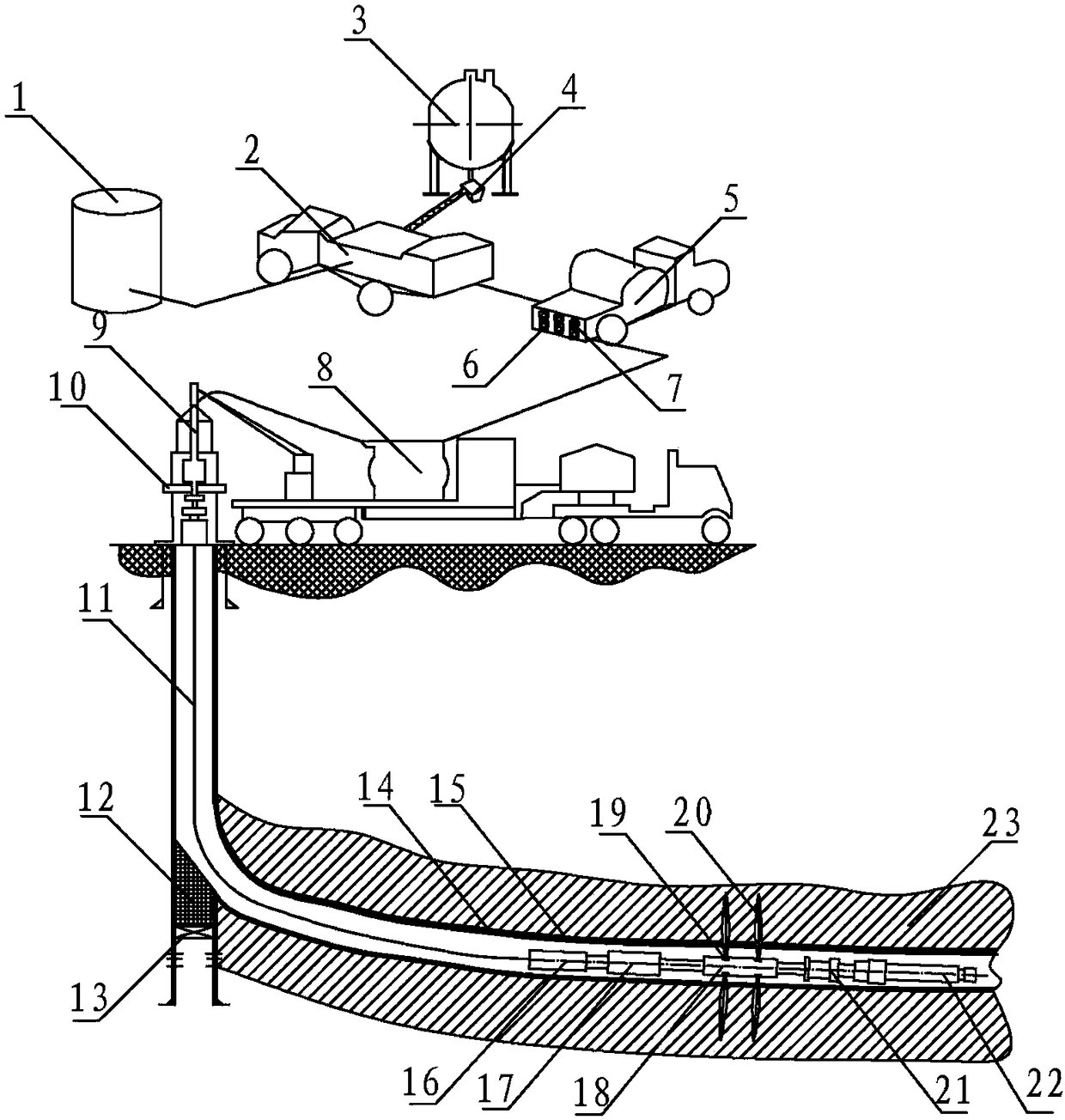

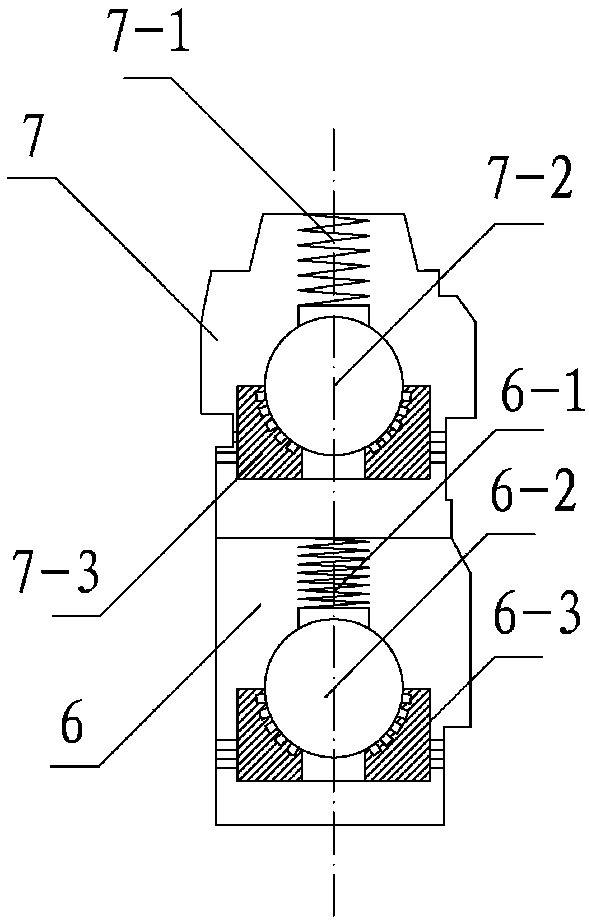

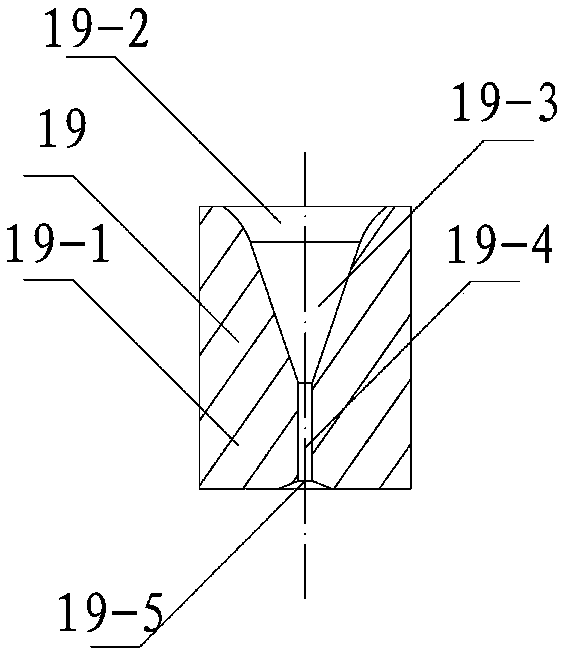

[0022] Such as figure 1As shown, the coiled tubing steel particle jet perforating device of the present invention includes a perforating fluid storage tank 1, a sand mixing pump 2, a steel particle storage tank 3, a screw conveyor 4, a fracturing pump 5, and a liquid inlet valve body 6. Liquid discharge valve body 7, cable car 8, injector 9, blowout preventer 10, coiled tubing 11, inclined device 12, anchoring device 13, cement ring 14, casing 15, connecting nipple 16, centralizing device 17 , Perforation device 18, nozzle 19, perforation hole 20, packer 21, positioning device 22, formation 23. The perforating fluid storage tank 1 is cylindrical and can store the perforating fluid. The perforating fluid in the perforating fluid storage tank 1 is transported to the sand mixing pump 2 through the pipeline. The steel particle storage tank 3 has a structure of upper and lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com